electric screw driver

An electric screwdriver and motor technology, applied in power tools, manufacturing tools, etc., can solve problems such as difficult maintenance, unadjusted screw torque, and high assembly strength, achieving easy assembly and maintenance, accurate torque adjustment, and easy portability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

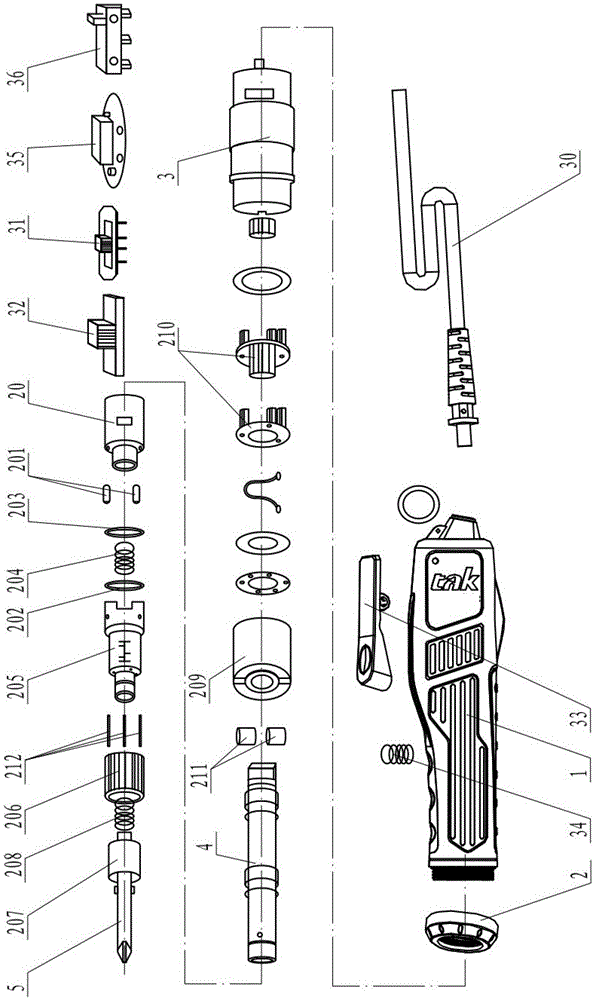

[0010] Such as figure 1 As shown, the electric screwdriver of the present invention includes a handle shell 1, a handle cap 2, a motor 3 and a control circuit, a deceleration transformer box, a main shaft 4, and a screwdriver nozzle 5.

[0011] Motor 3 and control circuit, deceleration variable torque box, main shaft 4 are all arranged in the handle shell 1, and main shaft 4 passes handle cap 2 and is connected with screwdriver mouth 5. The handle shell 1 is made of two-color handle, which is beautiful and elegant; the main shaft 4 adopts steel cold heading technology, which has leading advantages such as high concentricity, smooth inner wall, accurate size, and no broken wall of the main shaft at the nozzle insertion port.

[0012] The deceleration variable torque box includes a box body 20, a push rod 201, a top ring 202, a pressure ring 203, a tors...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com