Diesel engine particulate filter regeneration system and methods

A particulate filter, engine system technology, applied in the direction of engine components, combustion engine, engine control, etc., to achieve the effect of improving particulate filter regeneration, generating consistency, and reducing possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

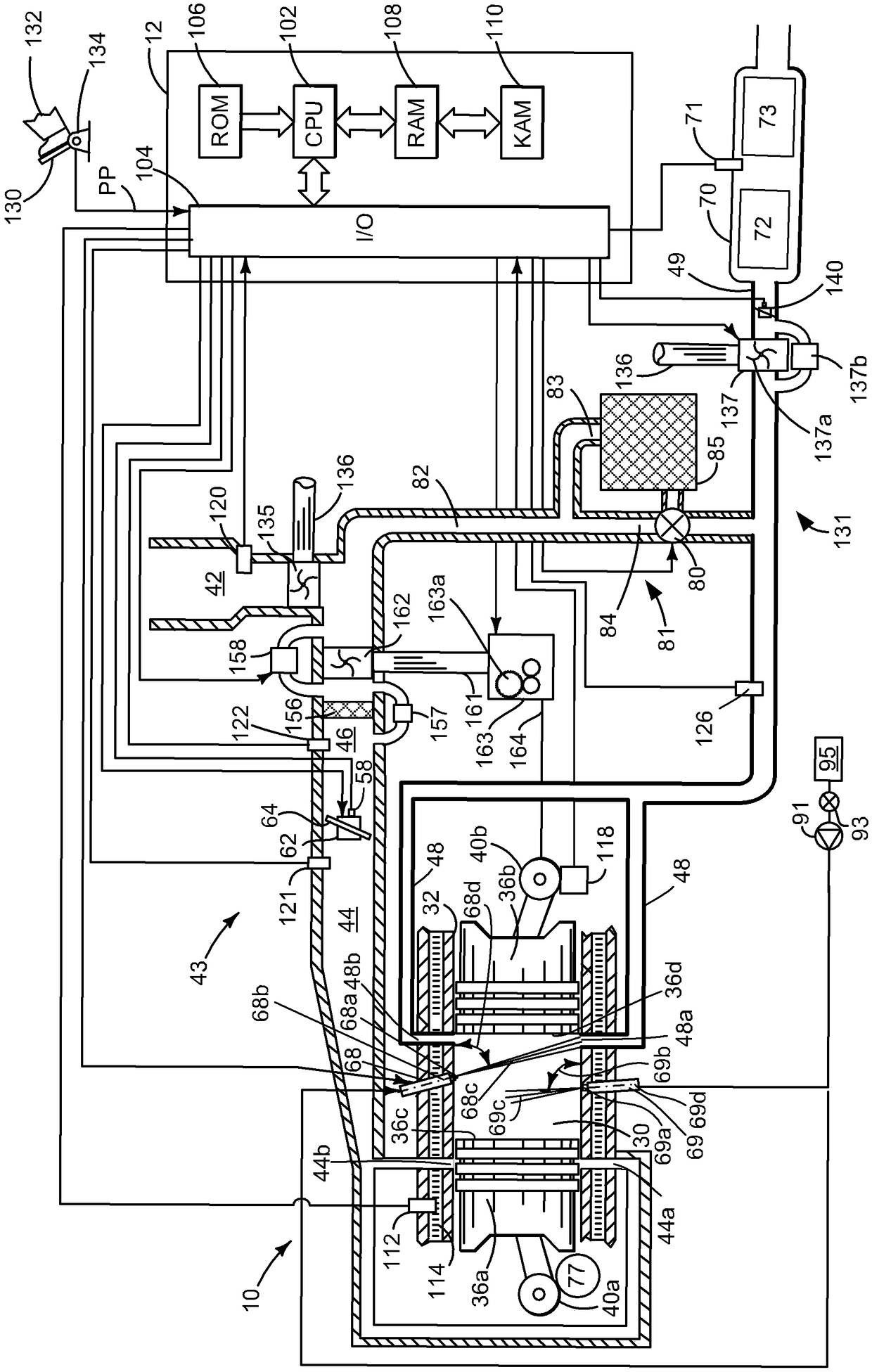

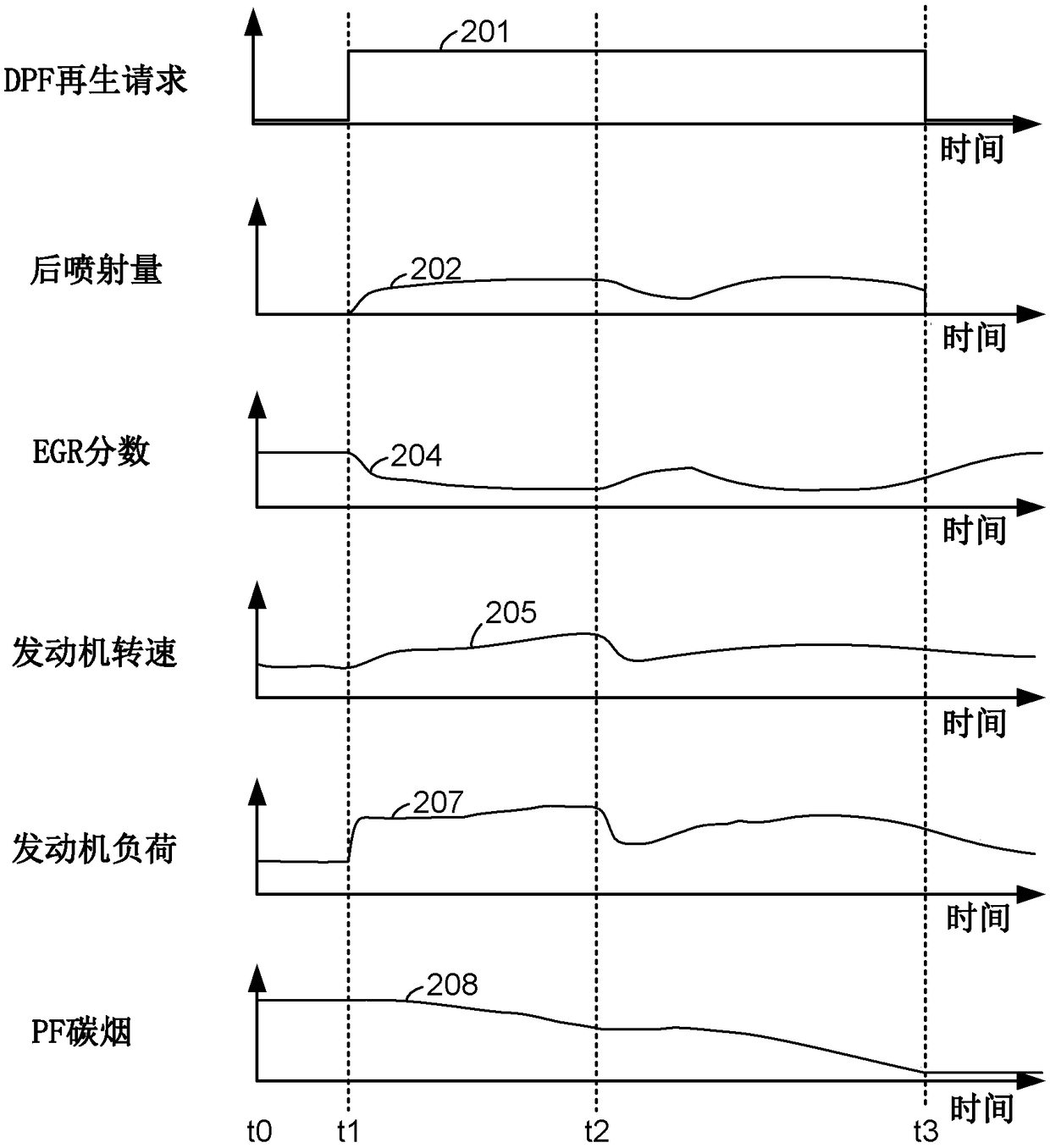

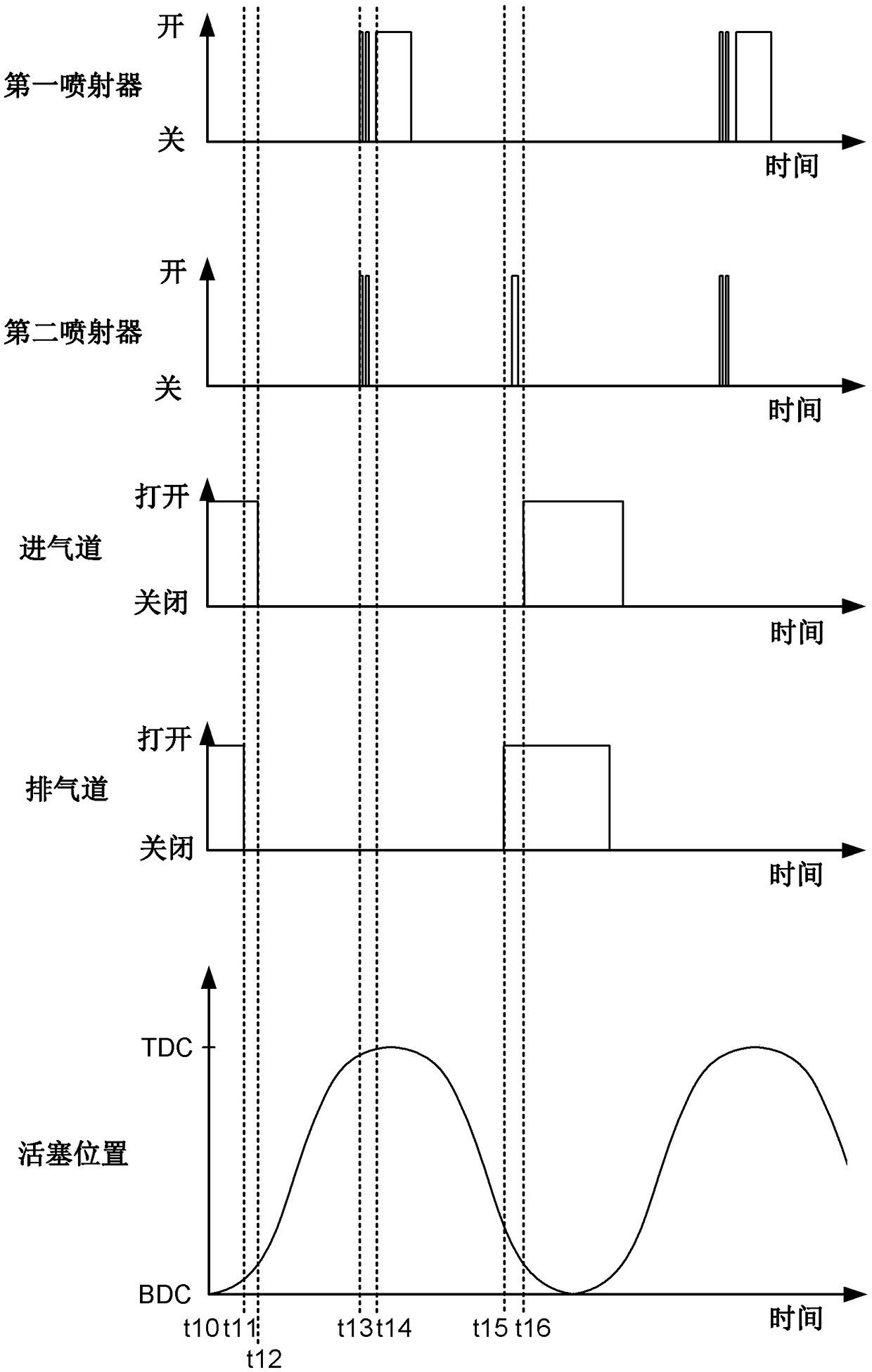

[0012] This specification relates to regenerating particulate filters for two-stroke diesel engines. figure 1 An example of a supercharged two-stroke diesel engine is shown. figure 1 The diesel engine in is an opposed piston engine, but the methods described herein can also be applied to two-stroke engines comprising a single piston in each engine cylinder. figure 2 An example particulate filter regeneration sequence is shown. image 3 The fuel injection timing for a two-stroke diesel engine is shown in . Figure 4 A method for regenerating a particulate filter is shown in .

[0013] refer to figure 1 , an opposed-piston internal combustion engine 10 comprising a plurality of cylinders, one of which is at figure 1 shown in . The controller 12 receives from figure 1 signals of various sensors, and employs figure 1 various actuators to adjust engine operation based on the received signals and instructions stored on the controller's memory.

[0014] Engine 10 includes cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com