Method for checking paper-making forming fabrics

A paper-making forming wire and forming wire technology, applied in the field of inspection, can solve the problems of tension control of the forming wire, quality problems cannot be found, and the inspection effect is not good, and the effect of ensuring the service life is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

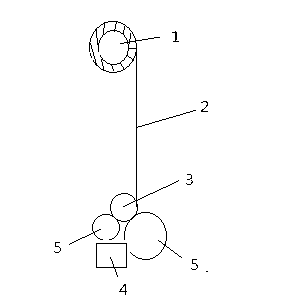

[0012] see figure 1 , a method for inspecting a papermaking forming wire is provided in the present embodiment, comprising the following steps:

[0013] a. Place the forming net 2 to be inspected on the position of the coiled net steel pipe 1, and send the forming net 2 from top to bottom;

[0014] b. The lower coil steel pipe 3 coils the delivered forming net 2 while the upper coil steel tube 1 delivers the forming net 2;

[0015] c. Check the forming net 2 that is sent down with the coiled net steel pipe 1, and use the torque to control the coiled net motor 4 at the same time.

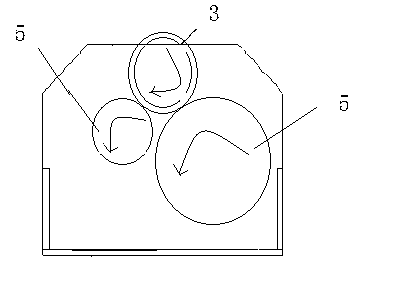

[0016] Among them, the speed at which the upper coil steel pipe 1 feeds the forming net 2 is lower than the speed at which the lower coil steel tube 3 coils the forming net 2, so that the forming net 2 can always maintain a certain tension during the inspection process, and it is easier to find small quality problems. Put the lower rolled mesh steel pipe 3 on the rolling mesh equipment 5, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com