A high temperature resistant relay and its production method

A production method and relay technology, applied in relays, electromagnetic relays, detailed information of electromagnetic relays, etc., can solve problems such as substandard sealing performance, and achieve the effects of improving safety in use, improving anti-adhesion ability, and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

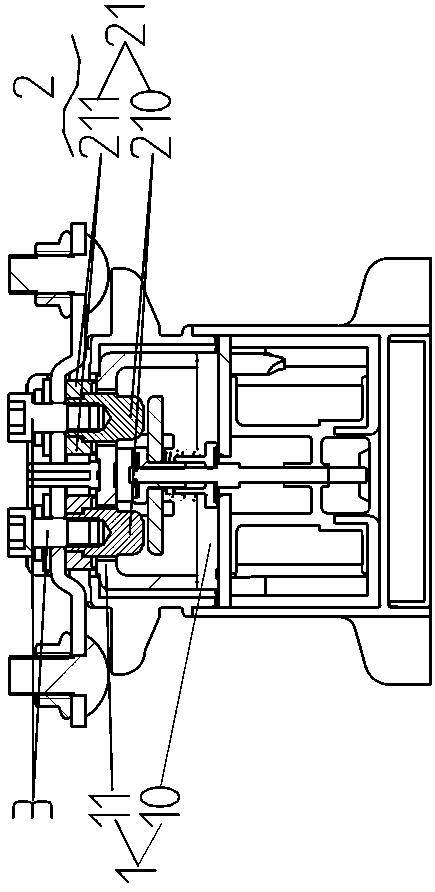

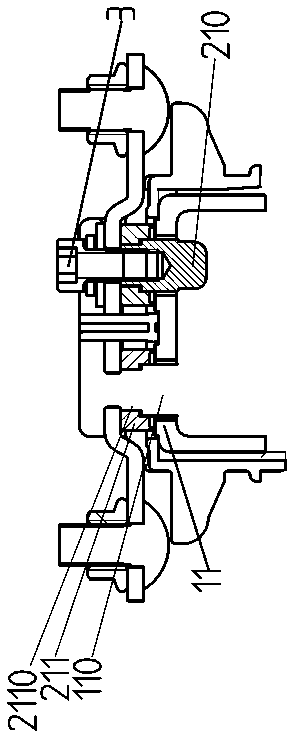

[0038] Such as figure 1 , figure 2 A high temperature resistant relay is shown, which includes a magnetic circuit system (not shown in the figure) and a contact system; the contact system includes a ceramic cover assembly 1 and a contact assembly 2; the ceramic cover assembly 1 includes a frame piece 10 And the ceramic cover 11; the contact assembly 2 includes a moving contact part and a static contact part 21, and the static contact part 21 includes a static contact lead-out end 210 and a transition lead-out end 211.

[0039] The magnetic circuit system can convert electrical energy into mechanical energy to drive the part to move, so that the movable contact in the contact system is in contact with or separated from the static contact lead-out end 210, so as to achieve the function of opening or closing.

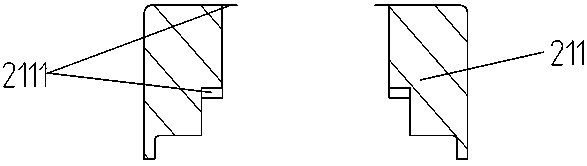

[0040] The transition lead-out 211 is provided with a through hole 2110 in the vertical direction of its mounting surface; one end of the static contact lead-out 210 ma...

Embodiment 2

[0056] A production method of a high temperature resistant relay, which comprises the following steps:

[0057] 1) Use machining or powder metallurgy to press the terminal of the static contact through the mold;

[0058] 2) Using machining or powder metallurgy to press the transition lead-out end through the mold;

[0059] 3) Assemble the static contact lead-out on the transition lead-out, and add solder on the axial contact surface of the transition lead-out and the static contact lead-out;

[0060] 4) Weld the transition lead-out end to the ceramic cover;

[0061] 5) Install a frame on the mouth of the ceramic cover to form a closed space in the ceramic cover;

[0062] 6) Take the static contact lead-out end, transition lead-out end, ceramic cover and frame piece as a whole, and put the whole body into a high-temperature furnace for brazing until the solder completely covers the contact corresponding to the static contact lead-out end and transition lead-out end surface, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com