Skylight glass mounting pressure stability control method

A voltage stabilization control, glass technology, applied in the direction of manufacturing tools, fluid pressure actuation devices, fluid pressure actuation system testing, etc. Batch output driving torque can not meet the requirements and other problems, to achieve the effect of consistent torque, consistent installation quality, and stable air source pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

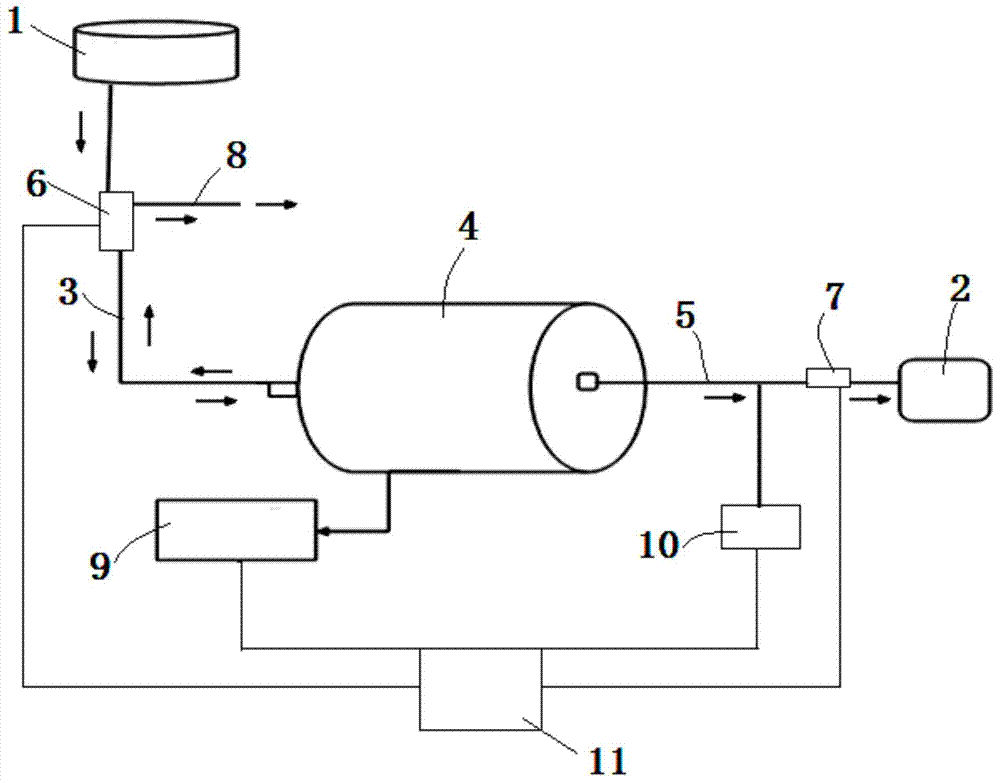

[0027] figure 1 The structure schematic diagram of the control system used for the skylight glass installation and voltage stabilization control method of the present invention, the control system includes a total air source 1 and a wind batch or rivet gun 2, and also includes an air storage tank 4, the air storage tank 4 passes through the air pipe 3 and the main air The source 1 is connected, and the gas storage tank 4 is connected with the wind batch or rivet through the inflation pipe 5; the air pipe 3 is provided with a first control valve 6, and the first control valve 6 is connected with a deflation pipe 8; the inflation pipe 5 is provided with a second control valve 7; the air storage tank 4 is connected with the first pressure gauge 9; the gas charging pipe 5 is connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com