Electric screwdriver special for electric energy meter verification

A technology for the verification of electric screwdrivers and electric energy meters, which is applied in the direction of motor tools and manufacturing tools, can solve the problems of inconsistent tightening degree of screws in the same row of electric energy meters and low efficiency of single-batch head screwdrivers, and achieves simple structure, consistent torque, and reduced The effect of low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

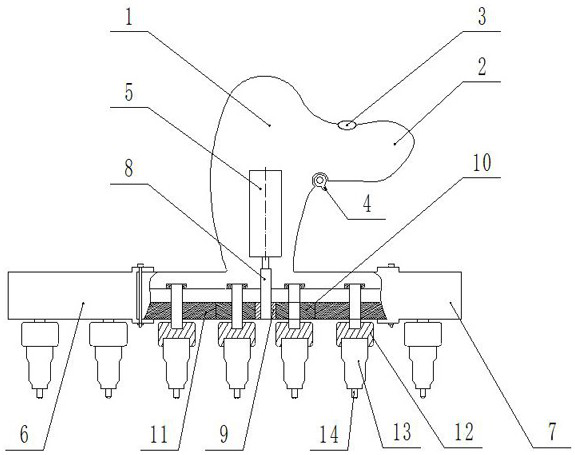

[0012] Example 1, such as figure 1 As shown, it is a special electric screwdriver for electric energy meter verification of the present invention, including a housing 1, a motor 5, an electric switch 4, a reversing switch 3, and a rotating rod 8. The lower part of the shaft of the motor 5 is fixedly connected with the rotating rod 8, and the electric switch 4 It is electrically connected with the motor 5 and is used to control the rotation or stop of the electric screwdriver. The reversing switch 3 is electrically connected with the motor 5 and is used to control the forward or reverse rotation of the electric screwdriver. The handle 2 is provided on the housing 1 for operation When convenient to hold, the lower end of the rotating rod 8 is connected with a driving gear 9 by a key, and the left and right sides of the driving gear 9 are symmetrically provided with the first gear 10 meshed with it, and the first gear 10 is set away from the side of the driving gear 9 The second ...

Embodiment 2

[0016] In embodiment 2, the second housing 6 and the third housing 7 are non-detachably connected to the housing 1, and other settings are the same as in embodiment 1, so that when in use, if only the single-phase meter is checked, the second The batch heads 14 in the second housing 6 and the third housing 7 are removed, and if the three-phase meter is to be checked, then the batch heads 14 in the second housing 6 and the third housing 7 are installed.

[0017] In the present invention, by setting four batch heads 14 or seven batch heads 14, a row of screws can be tightened or disassembled at the same time, and an electric screwdriver can be carried to complete the quick inspection of single-phase meters and three-phase meters, which improves work efficiency , by setting the idle screwdriver 13, the torque of the same row of screws can be guaranteed to be consistent; the operation is simple, and the staff can be familiar with and skillfully use it within a few minutes, reducing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com