Power tool torque overload clutch

An overload clutch and clutch technology, which is applied in the field of power tools and torque overload clutches, can solve the problems of drive chain gearbox displacement, wear, damage height, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

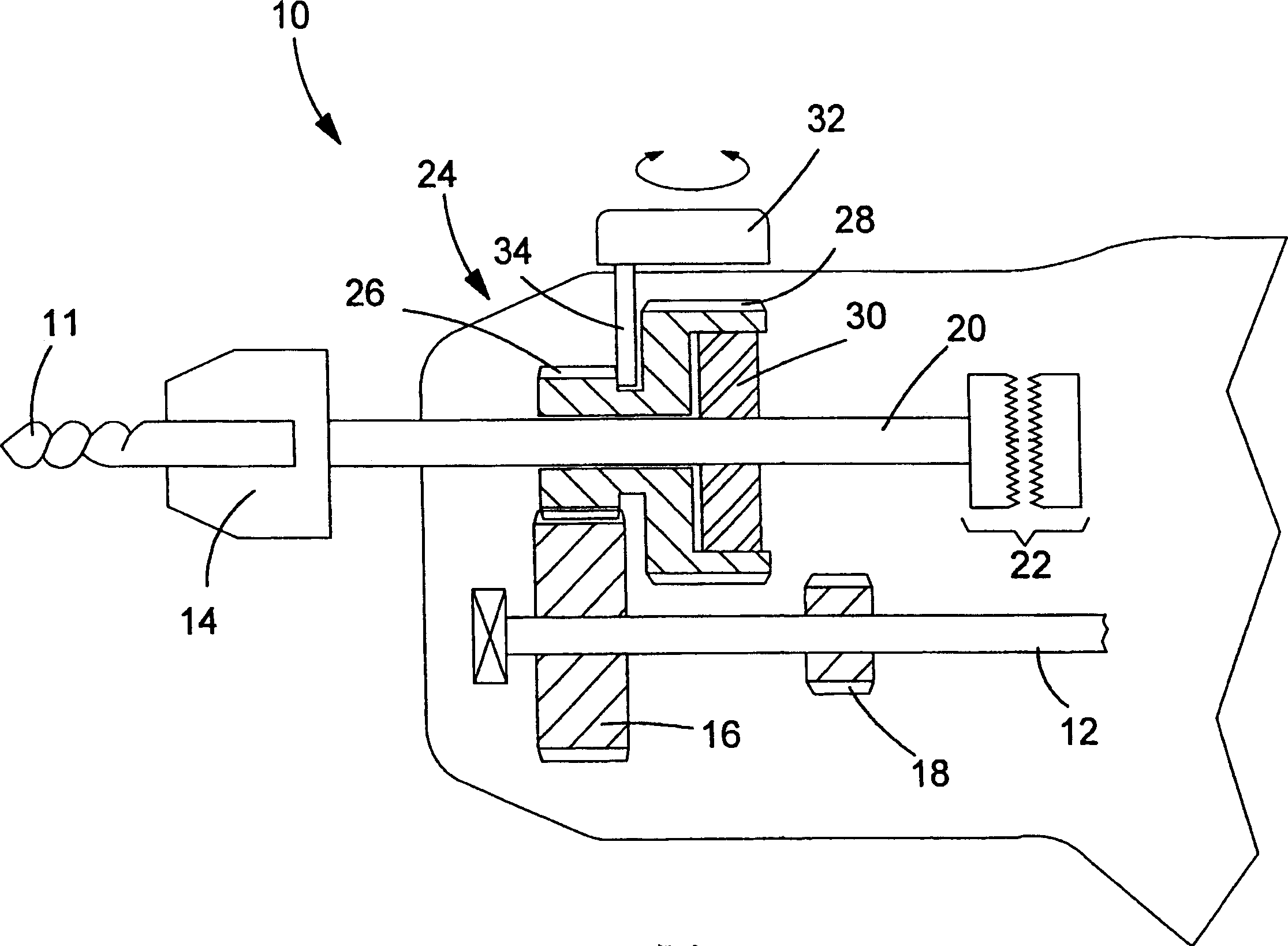

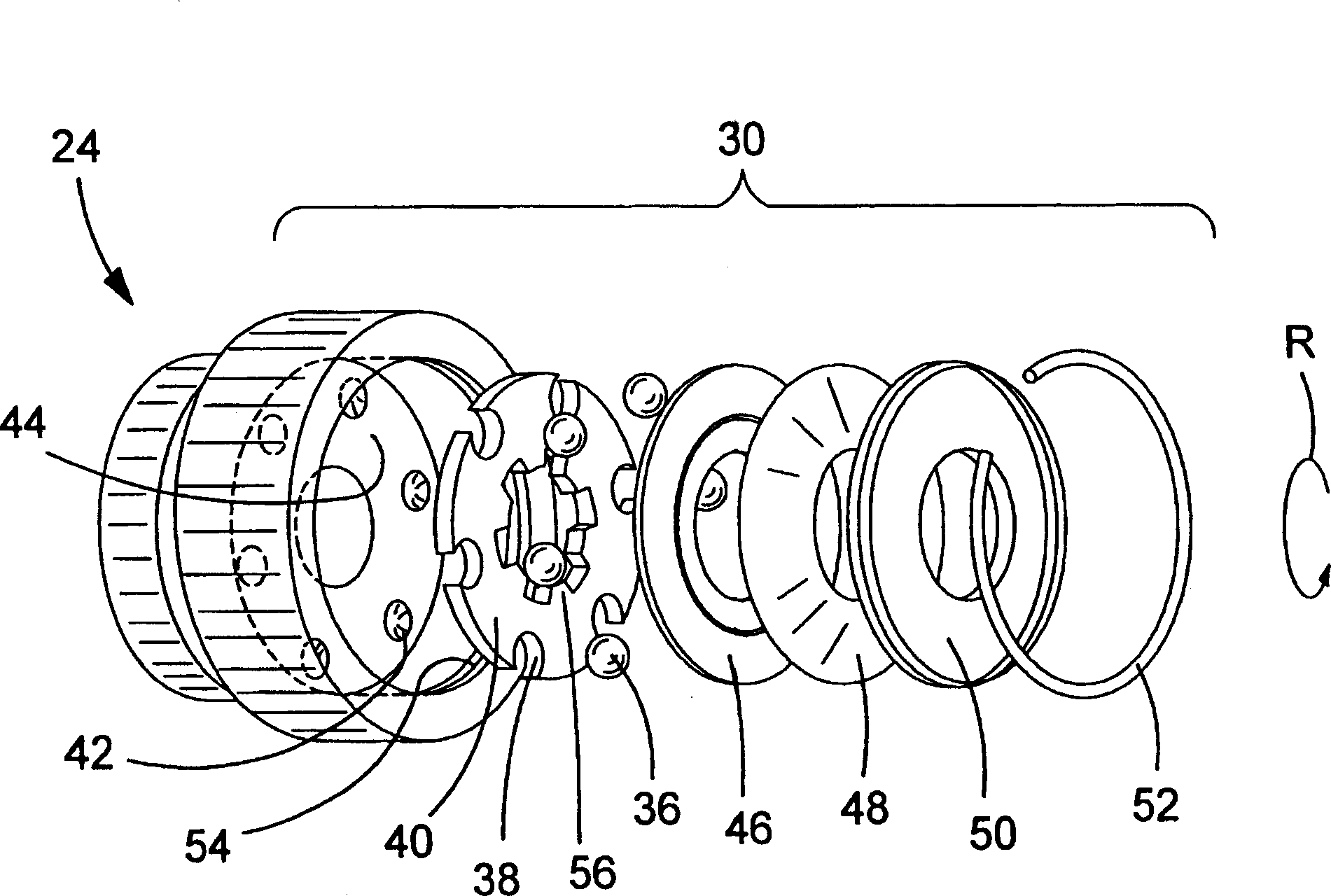

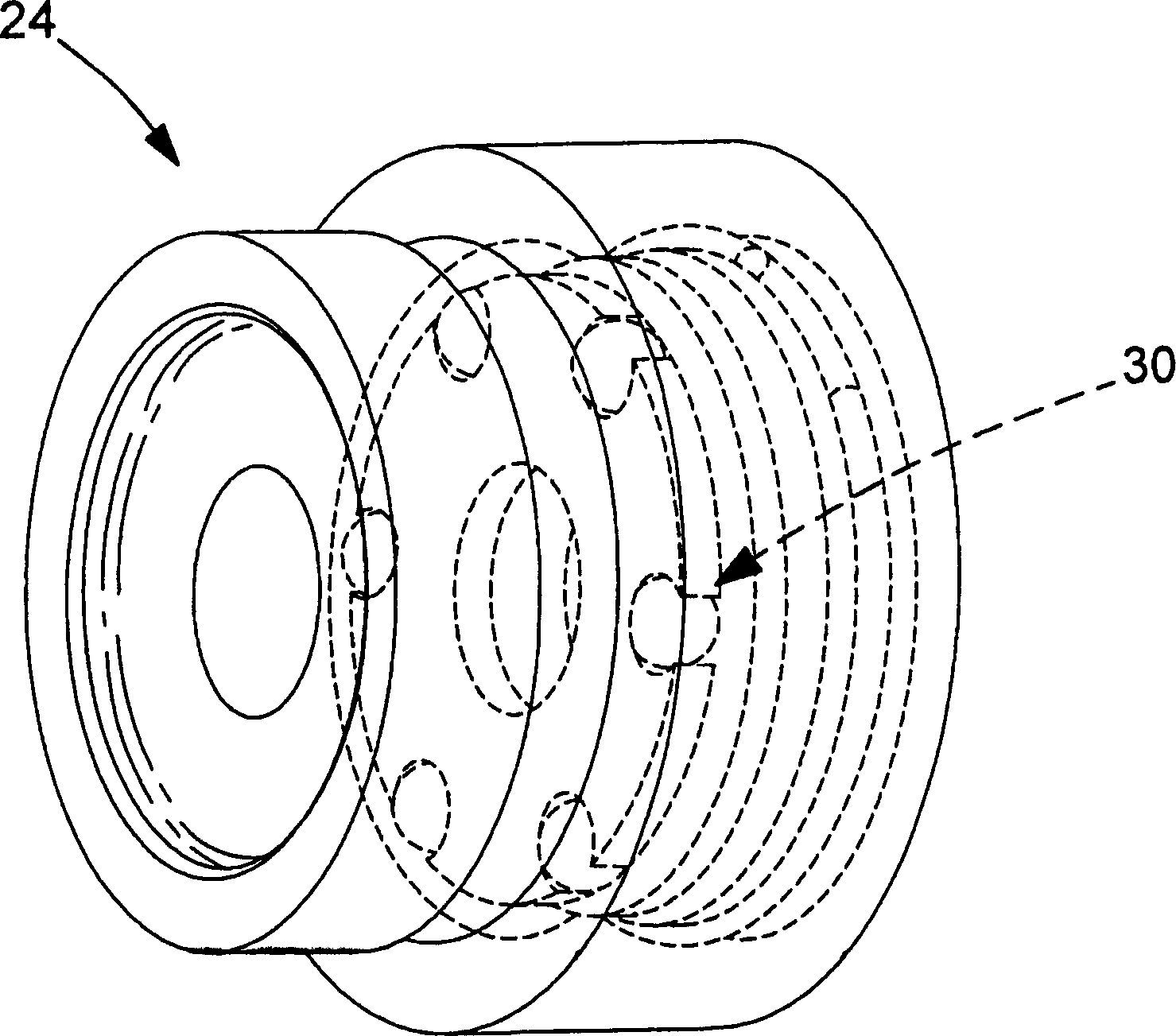

[0026] Hammer drills often have a gearbox with a transmission mechanism in it. According to the requirements of the user and / or the needs of the work in progress, the power tool can be set to output at two or more rotation speeds. Generally speaking, the clutch can be arranged on an intermediate shaft in the gearbox, which is arranged between the motor shaft and the output shaft. However, gear reduction usually affects the torque when the clutch mechanism is working. In other words, the predetermined torque when the clutch cuts in to interrupt the drive from the motor will depend on whether the drill is working at a higher or lower speed; this depends on the gear ratio used by the tool. It seems that this problem can be overcome by placing a clutch between the gearbox and the output shaft, so that the power from the motor is interrupted on the output shaft. However, the provision of a clutch mechanism on the output shaft of the hammer drill is known to cause problems, especially b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com