Snow making machine with adjustable quantity of nozzles of nucleon device

A nuclear device and nozzle technology, which is applied in the field of snow making machines, can solve the problems that the number of nuclear device nozzles is not adjustable, inconvenient to use, and cannot be adapted, and achieves the effects of reducing the cost of snow making, increasing the amount of snow making, and having a wide range of adaptation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

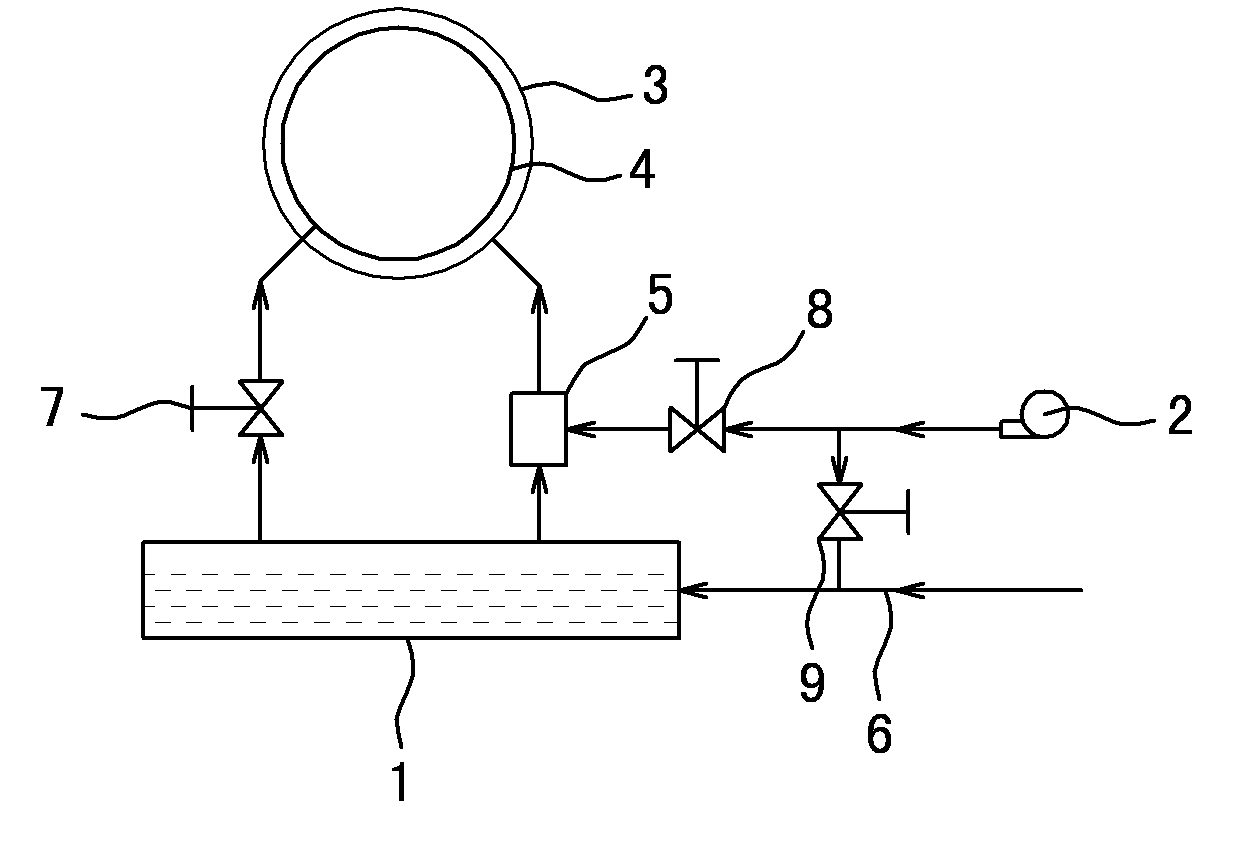

[0008] Embodiment one, such as figure 1 As shown, it includes a water separator 1, an air compressor 2, an outer annular nozzle 3, an inner annular nozzle 4 and an air-water mixer 5, the water separator 1 is connected with a high-pressure water inlet pipe 6, and the inner annular nozzle 4 The valve one 7 is connected with the water separator 1, the water inlet of the air-water mixer 5 is connected with the water separator 1, the water gas outlet is connected with the outer annular nozzle 3, and the air inlet is compressed with the air through the valve two 8 The air outlet of the machine 2 is connected, and the air outlet of the air compressor 2 is connected with the water distributor 1 or the high-pressure water inlet pipe 6 through the valve three 9.

[0009] The outer annular nozzle 3 and the inner annular nozzle 4 are respectively provided with a plurality of atomizing nozzles. It also includes frame and spray head, spray head, air compressor 2 and air-water mixer 5 are i...

Embodiment 2

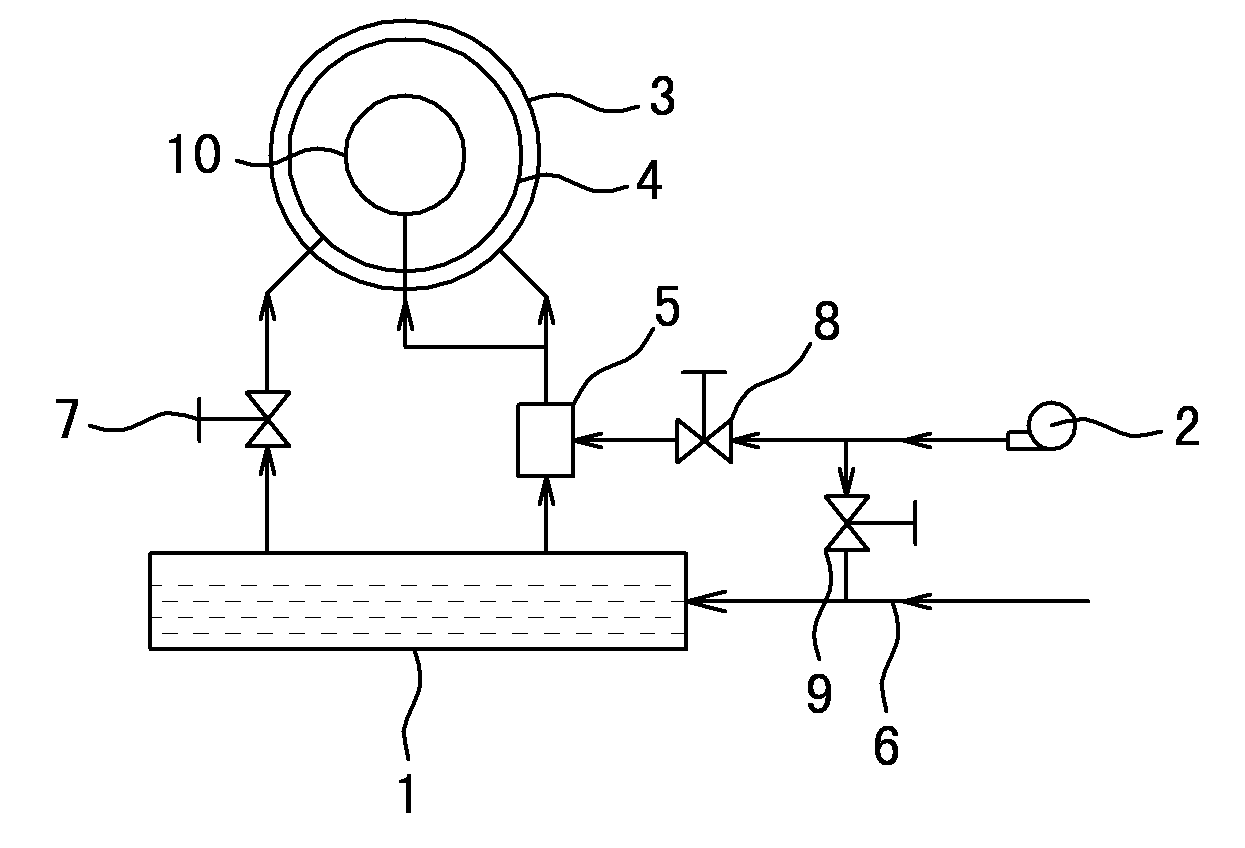

[0010] Embodiment two, such as figure 2 As shown, the difference from Embodiment 1 is that it also includes an annular heat dissipation nozzle 10, and the annular heat dissipation nozzle 10 communicates with the water and air outlet of the gas-water mixer 5. The annular cooling nozzle 10 is suspended between the inner annular nozzle 4 and the blower motor and installed in the spray head. The annular cooling nozzle 10 is provided with a plurality of atomizing nozzles.

[0011] Partial nucleator nozzle status: When the high-pressure water enters the water distributor 1 through the high-pressure water inlet pipe 6, the high-pressure water enters the air-water mixer 5 from the water distributor 1 through the pipeline, and enters the inner annular nozzle through the valve 7 and the pipeline. Pipe 4, the high-pressure water that enters the inner annular nozzle 4 sprays water mist that does not contain compressed air through the atomizing nozzle, and the nozzle on the inner annular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com