A snowmaking machine for aircraft testing

A technology for testing and snowmaking machines, applied in aircraft component testing, aircraft parts, applications, etc., can solve problems such as low control accuracy, freezing nozzles and pipelines, affecting the test process, etc., to achieve high control accuracy and integration High, improve the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Next, the plan of the invention will be described in detail with reference to the drawings.

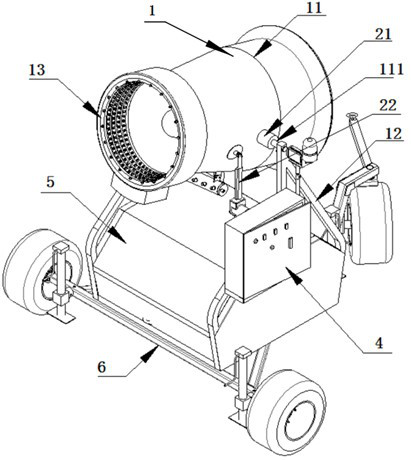

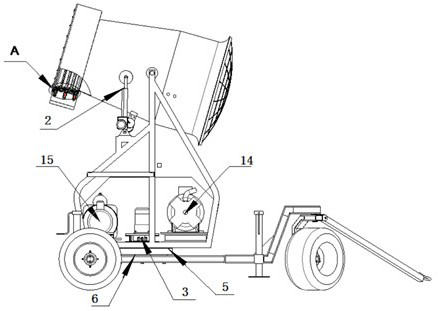

[0042] like figure 1 , 2 As shown, a stencil for aircraft test includes a snowcotting mechanism 1, a homogeneous mechanism 2, a swing mechanism 3, and a control cabinet 4;

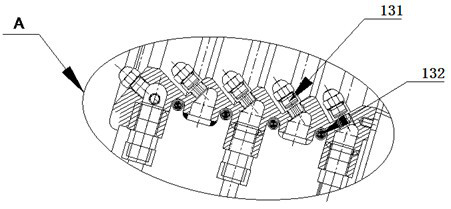

[0043] The snow mechanism 1 includes a wind cylinder 11 with an axial flow fan, located at the lower end of the air cylindrical 11 and the wind cylindrical bracket 12 connected to the side wall of the air cylinder 11, and is provided at the air inlet of the wind tube 11. The jet ring 13 of the five row nozzle 131 is provided along the inner wall circumferential direction of the wind cylindrical 11, respectively, water pump 14 and air compressor 15, respectively, and air compressors 15, such as image 3 As shown, the adjacent two row nozzles 131 are provided with a heating ring 132, preventing the nozzle 131 from freezing, affecting normal use, and controls the wind cylindrical blowing speed by adjusting the axia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com