Stripping method applied to full-glass solar cell panel and stripping machine thereof

A solar panel and stripping machine technology, applied in the field of solar photovoltaic power generation, can solve the problems of reducing production costs, inability to repair defective products, and inability to strip full-glass components, etc., to reduce production costs, solve inability to repair, and reduce waste of resources and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045]The core of the present invention is to provide a peeling machine for peeling off the front and back glass of the all-glass solar cell panel, so as to solve the problem that the all-glass solar cell Blank for battery boards without rework equipment

[0046] Without loss of generality, the specific implementation of the stripping machine for stripping the front and back glass of the all-glass solar panel provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

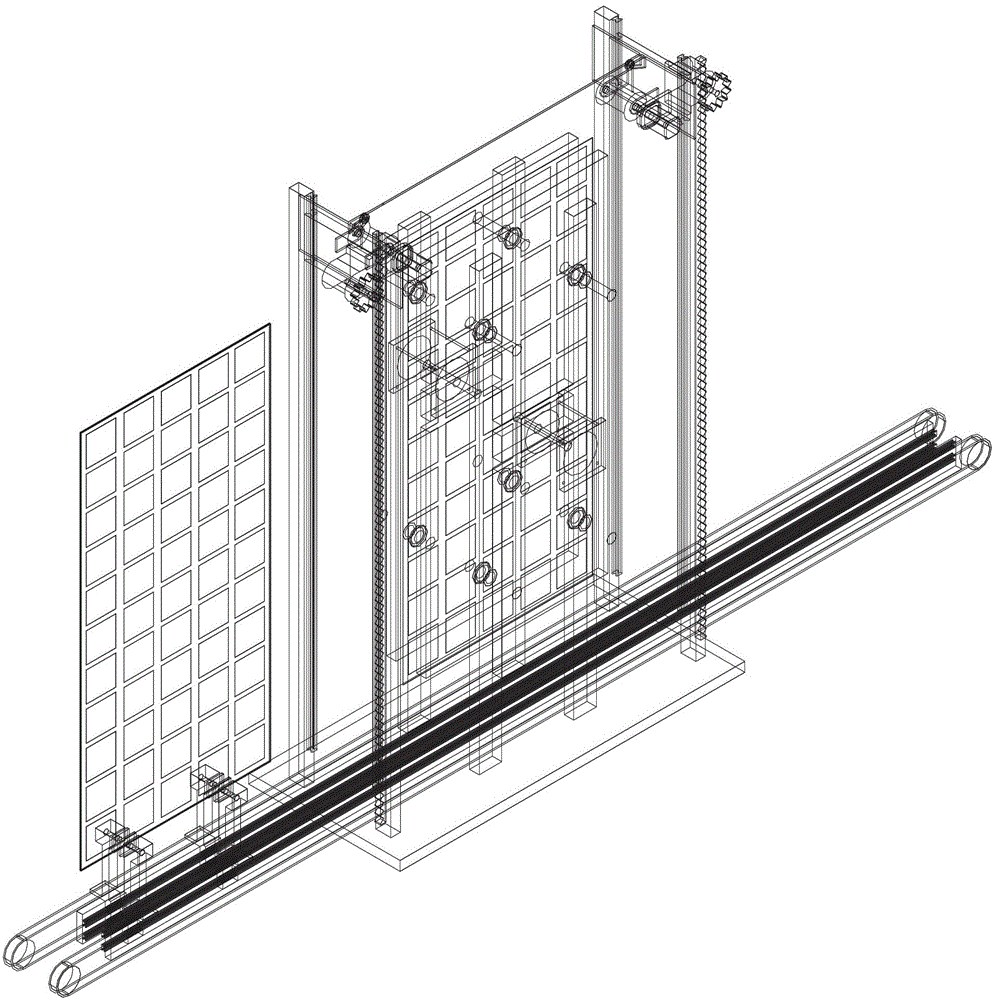

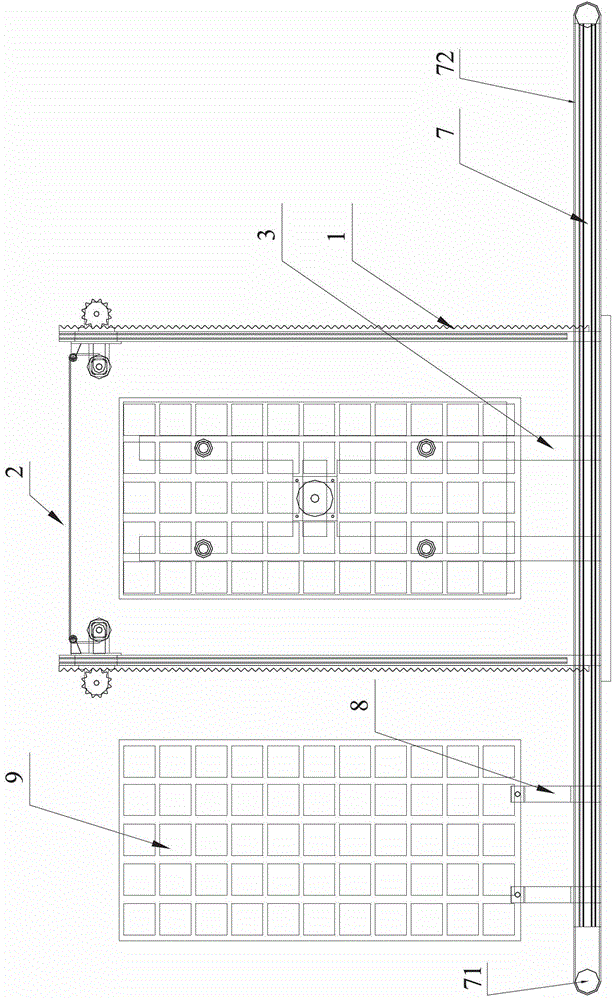

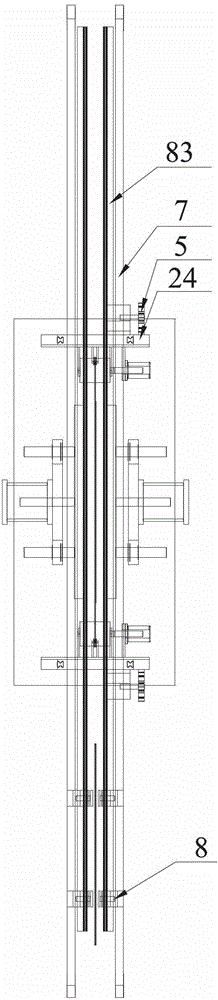

[0047] See figure 1 , figure 2 , image 3 and Figure 4 ,in, figure 1 Shows the three-dimensional perspective schematic view of the peeling machine in the specific embodiment, figure 2 show figure 1 main view of image 3 show figure 1 top view of Figure 4 show figure 1 left view of .

[0048] like figure 1 , figure 2 , image 3 and Figure 4 As shown, a peeling machine provided by the present invention includes two parallel supports 1 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com