Adhesion-preventing material

An anti-adhesion, carboxymethyl cellulose technology, applied in the directions of drug combination, surgery, coating, etc., can solve the problems of unpredictable anti-adhesion effect, complicated sealing operation, insufficient effect, etc., and achieve excellent anti-adhesion effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

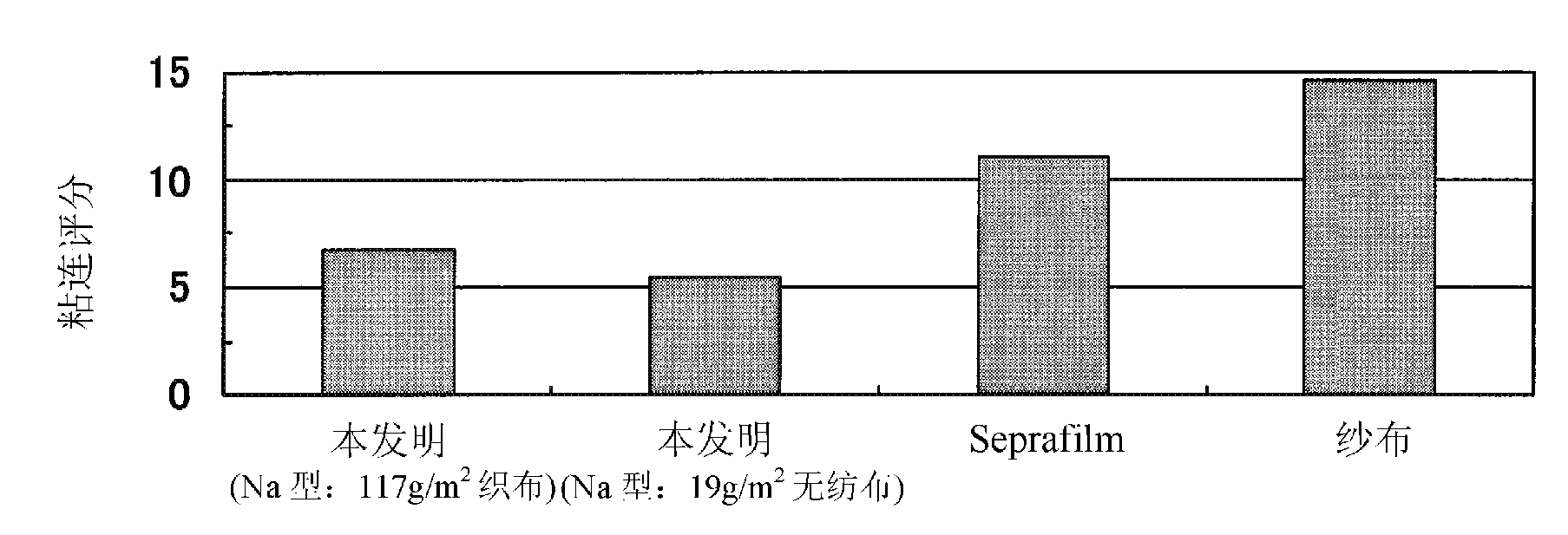

[0054] In the preparation method of the present invention, acid treatment is carried out to the structure formed by alkali metal CMC (preferably Na-type CMC) while maintaining its structure, before the alkali metal CMC is completely converted into acid CMC, such as acid treatment The above-mentioned acid treatment is terminated before reaching the central part or inner part of the above-mentioned structure (hereinafter referred to as the first production method). Or, carry out alkali treatment to the structure body that acid type CMC forms under the state that maintains its structure, before acid type CMC is completely converted into alkali metal type CMC (preferably Na type CMC), for example alkali treatment reaches the center of above-mentioned structure Or finish the above alkali treatment before the inner part (hereinafter referred to as the second production method). The structure formed by the alkali metal type CMC is easy to form an aqueous solution by adding water beca...

Embodiment 1

[0097] (1) Preparation of non-woven anti-adhesion material

[0098] 0.17g of rayon nonwoven fabric (size 10cm×10cm, unit area weight 17g / m 2 , thickness 0.08mm) into the reaction vessel, add 1L of sodium hydroxide-containing ethanol aqueous solution (4.2mol / L sodium hydroxide, 9.3mol / L ethanol), and incubate at room temperature for 17 hours. Further, 615 mL of monochloroacetic acid-containing ethanol aqueous solution (4.9 mol / L monochloroacetic acid, 10.3 mol / L ethanol) was added, and cultured at 50° C. for 4 hours. Wash with 70% aqueous methanol and 80% aqueous methanol in sequence, and then neutralize to pH 6.0~8.0 with aqueous methanol containing hydrochloric acid (1.2mol / L hydrochloric acid, 90% methanol).

[0099] Then, it was washed with 80% methanol aqueous solution and 100% methanol in this order, and then dried to obtain a sheet (1). Most of the CMCs constituting this sheet are Na-type CMCs. In addition, at this time, the degree of etherification was 0.83, and the ...

Embodiment 2

[0116] (1) Preparation of film-like anti-adhesion material

[0117] The sheet (1) composed of Na-type CMC (etherification degree: 0.83, molecular weight: 160,000 Da) obtained as an intermediate product in Example 1 (1) was dissolved in water to make the concentration 50 mg / mL, and prepared Na-type CMC aqueous solution. Of these, 5 mL was added to a slide glass (76 mm×26 mm), and left at room temperature for 2 days and nights to dry. The obtained membranous substance was peeled off from the glass slide, cut into slices (2 cm×1 cm), and 10 slices were put into 50 mL plastic tubes.

[0118] Add 30 mL of methanolic aqueous solution containing hydrochloric acid (1.2 mol / L hydrochloric acid, 90% methanol) to each tube, and incubate at room temperature for 0 hour (ie untreated) and 2 hours. After culturing, wash with 80% methanol aqueous solution and 100% methanol in sequence, and then dry to obtain the anti-adhesion material sample of the present invention.

[0119] (2) Evaluatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com