High-pressure pump

A high-pressure pump and pump piston technology, applied in pump components, pump control, fuel injection pumps, etc., can solve problems such as poor adjustability, mechanical vibration, high noise, etc., and achieve the effect of improving structure, compact structure, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

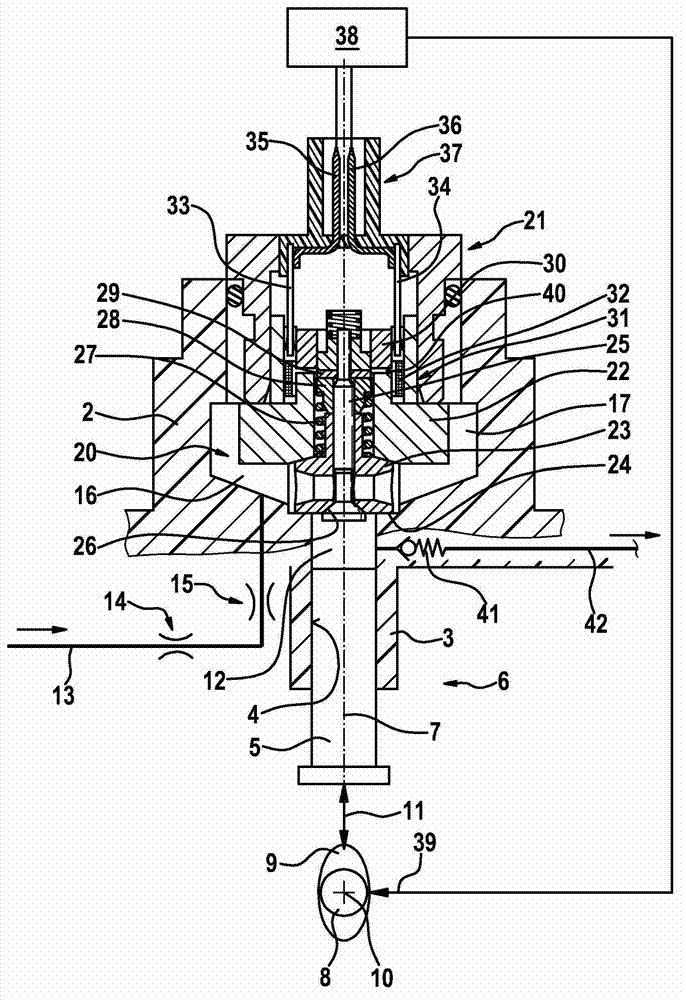

[0017] figure 1 A high-pressure pump 1 according to an embodiment of the invention is shown in a diagrammatic, schematic axial section. In particular, the high-pressure pump 1 can be designed as a radial or in-line piston pump. In particular, the high-pressure pump 1 is suitable as a fuel pump for a fuel injection system of an air-compressed, self-igniting internal combustion engine.

[0018] The high-pressure pump 1 is preferably used in fuel injection systems having a fuel distribution rail for storing high-pressure diesel fuel. However, the high-pressure pump 1 according to the invention is also suitable for other applications. In particular, the high-pressure pump can also be designed as a piston pump in order to deliver suitable liquids, ie also other liquids as fuel.

[0019] The high-pressure pump 1 has a pump housing, to which a cylinder head 2 is mounted. The cylinder head 2 has an attachment 3 which protrudes into a bore of the pump housing. Here, a cylinder bor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com