Feed applicable for tilapias intensively cultured in pond and preparation method thereof

A tilapia, intensive farming technology, applied in animal feed, animal feed, application, etc., can solve the problems of easy turbidity and incomplete application of ordinary feed, and achieve the effects of low cost, simple and reliable production method, and improved growth performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

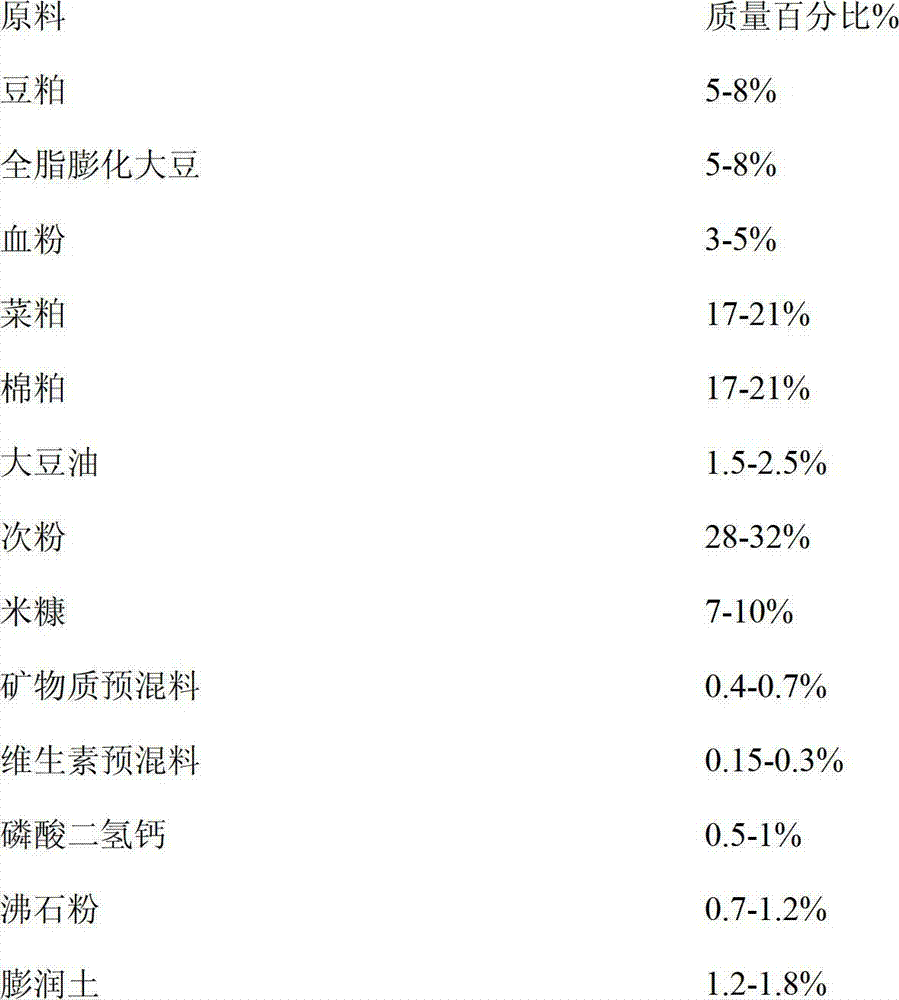

[0026] Example 1 (preparation of feed for intensively cultured tilapia in ponds):

[0027] A compound feed suitable for intensive cultivation of tilapia in ponds, which consists of the following raw materials by mass percentage:

[0028]

[0029]

[0030] In this example, the protein content of the feed was 28.9%, and the fat content was 6.1%.

[0031] A kind of preparation method of feed suitable for intensive cultivation of tilapia in ponds, its steps are:

[0032] A first weigh soybean meal, full-fat puffed soybean, rapeseed meal, cottonseed meal, rice bran and secondary powder according to a certain mass percentage;

[0033] B is evenly mixed and then pulverized by a pulverizer, so that all components pass through a 20 or 25 or 30 or 35 or 40 mesh sieve;

[0034] C. Weigh the remaining raw materials according to a certain mass percentage, and mix them with the raw materials of step B, and mix them thoroughly with a mixer (CV≦5%);

[0035] D. Move the mixed materia...

Embodiment 2

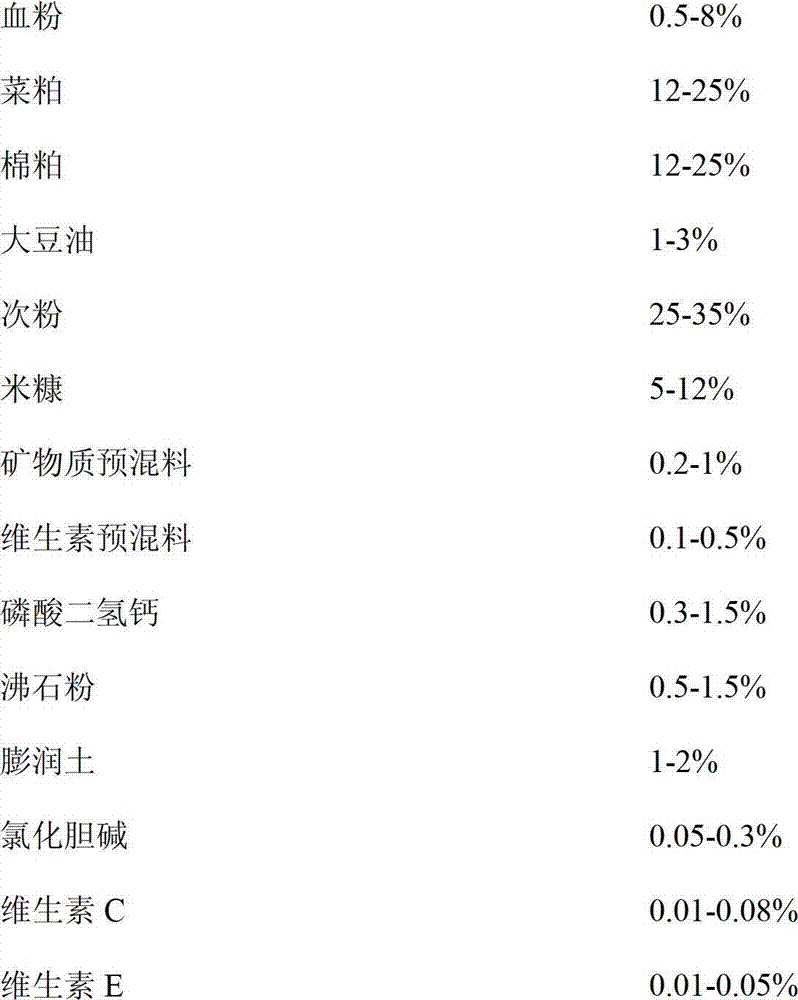

[0038] A compound feed suitable for intensive cultivation of tilapia in ponds, which consists of the following raw materials by mass percentage:

[0039]

[0040]

[0041] In this example, the protein content of the feed was 29.9%, and the fat content was 5.3%.

[0042] The preparation steps are the same as those in Example 1.

Embodiment 3

[0044] A compound feed suitable for intensive cultivation of tilapia in ponds, which consists of the following raw materials by mass percentage:

[0045]

[0046]

[0047] In this example, the crude protein content of the feed was 29.4%, and the fat content was 5.4%.

[0048] The preparation steps are the same as those in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap