Method and apparatus for recovering heat and converting it into mechanical power

A technology for recovering heat and mechanical power, which is applied to steam engine devices, mechanical equipment, power plants, etc., and can solve problems such as unstable operation of internal combustion engines and reduced heat recovery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

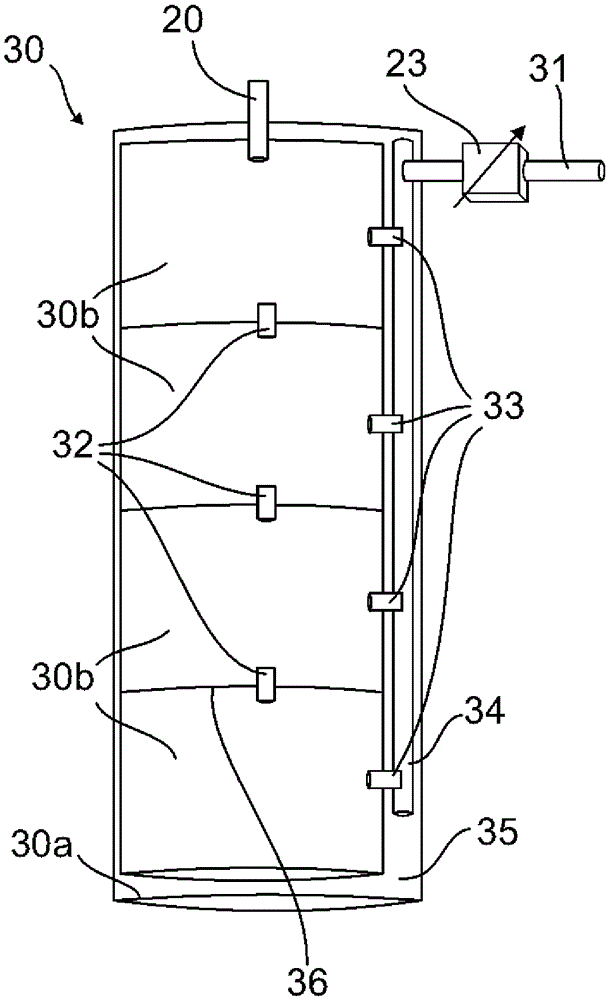

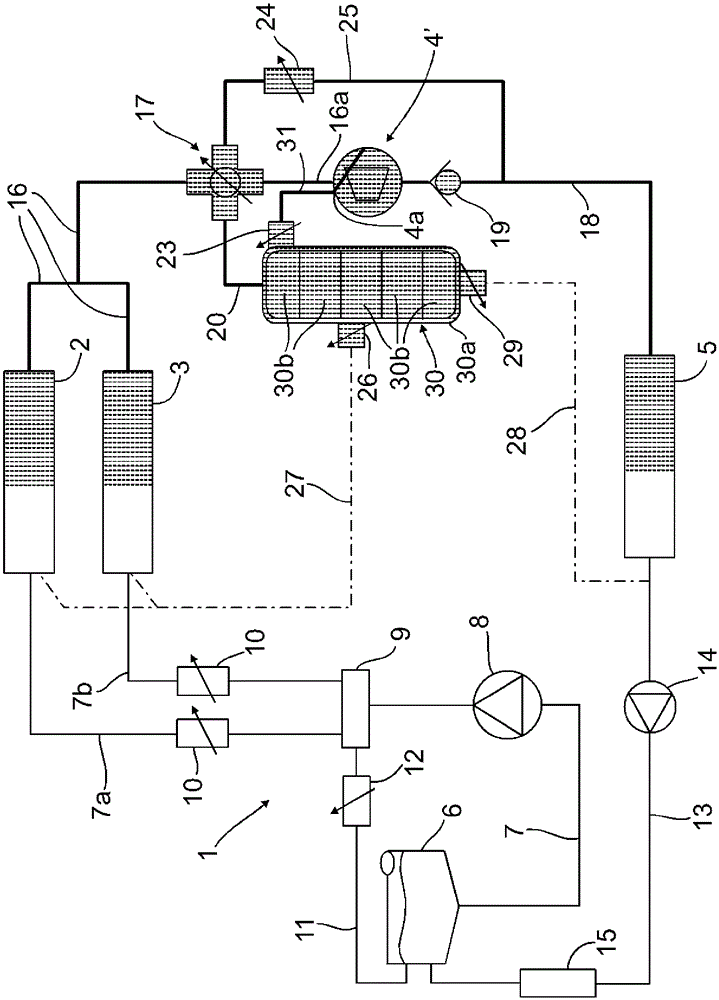

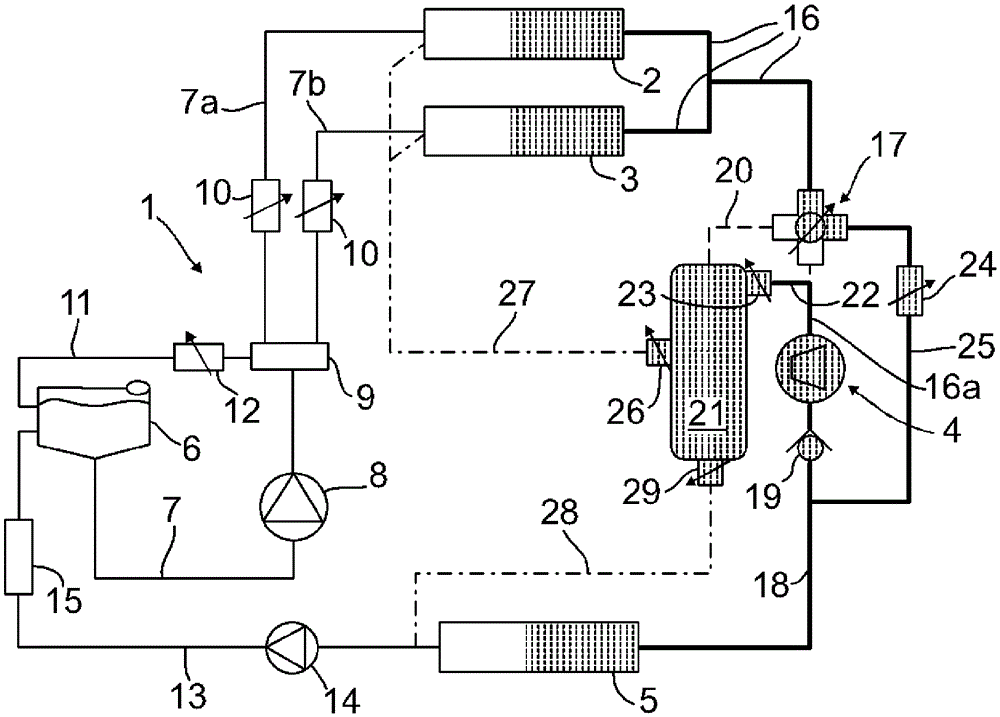

[0077] exist figure 1 shows as a block diagram a method for recovering heat and converting it into a drive for a motor vehicle, in particular a commercial vehicle (such as a truck or bus) with an internal combustion engine (not shown) as drive source An arrangement of the mechanical power of the system with a working medium circuit 1 into which, for example, the two evaporators 2 , 3 , the expander 4 and the condenser 5 are also integrated here.

[0078] For example, deionized water is used as the working medium, which is filled into a storage container 6 at the underside of which a delivery line 7 branches off. A supply pump 8 is arranged in the delivery line 7 , which supplies here two separate delivery lines 7 a , 7 b (which are connected on the inlet side to the evaporators 2 , 3 ) via a distributor. Furthermore, for example electrical proportional flow control valves 10 are installed in each delivery line 7 a , 7 b , by means of which the working medium mass flow and thu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com