Negative pressure type range hood

A range hood, negative pressure technology, applied in the field of household range hoods, can solve the problems of unstable wind wheel motion, increased grease particles, increased motor operating load, etc., to achieve good smoke exhaust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

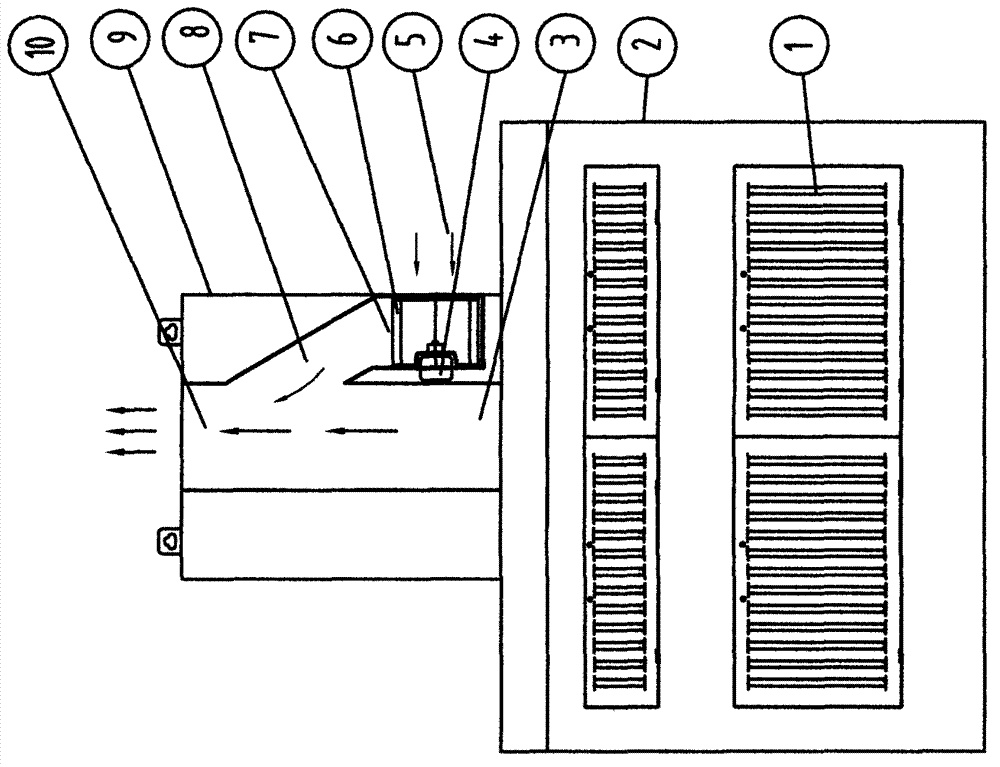

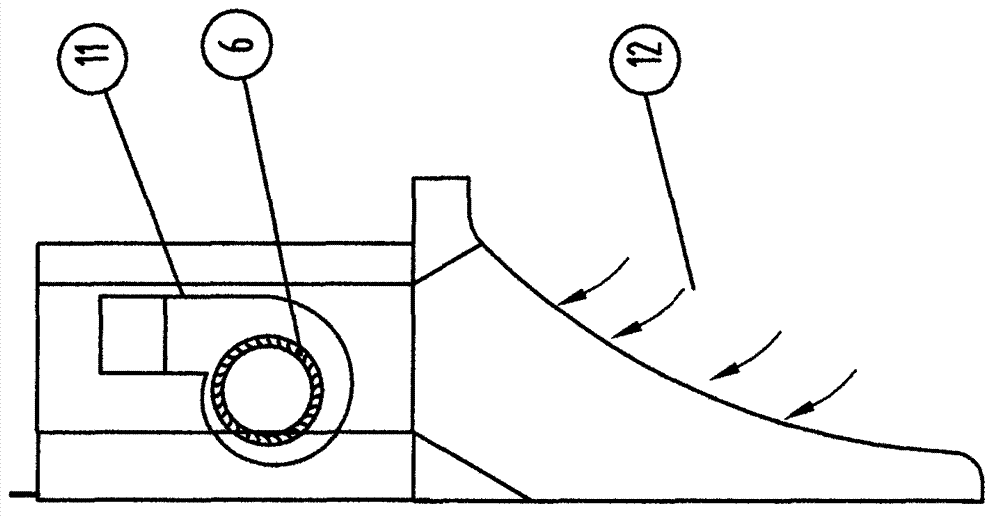

[0015] see figure 1 and figure 2 The negative pressure range hood of the present invention adopts the technical scheme: the volute fan 7 is installed outside the smoke exhaust negative pressure air duct 3, and the positive pressure air outlet 8 connected with the volute fan 7 is upwardly formed at a certain oblique angle to the smoke exhaust The upper end of the negative pressure air duct 3 is connected to form an oil fume outlet air duct 10 in which the positive pressure air outlet 8 is connected to the smoke exhaust negative pressure air duct 3 .

[0016] refer to figure 1 Its technical feature of the present invention is also that the air inlet 5 of the volute fan 7 is outside the upper casing 9 and is not communicated with the negative pressure air duct 3 of the range hood, and is an independent air inlet 5 .

[0017] In addition, in the technical scheme implemented in the present invention: the positive pressure air outlet 8 is connected with the smoke exhaust negative...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com