Method and device for drying monofilaments

A brown silk and drying technology, applied in the direction of drying solid materials, progressive dryer, heating to dry solid materials, etc., can solve the problems of insufficient technology, large amount of hot air, long drying time, etc., saving manpower and material resources , the effect of convenient maintenance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but not as a limitation to the present invention.

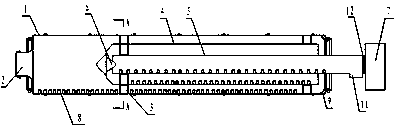

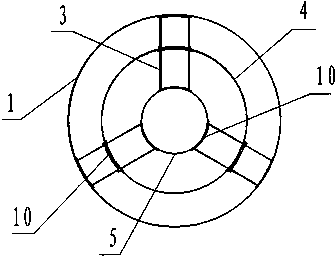

[0015] Embodiments of the present invention: when implementing a method for drying brown silk of the present invention, the hot air used for drying can be directly provided by the hot air device in the prior art. During implementation, the inside of the outer drying cylinder is provided with a In the middle drying cylinder, the inner drying cylinder is installed in the middle drying cylinder, steel nails are respectively set on the inner cylinder walls of the outer drying cylinder, the middle drying cylinder and the inner drying cylinder, and an exhaust fan is installed at one end of the inner drying cylinder, so that In the process of drying the brown silk, the brown silk to be dried is sucked and moved forward by the exhaust fan, and when the brown silk to be dried is sent into the outer dryin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com