Thickness detection stability detection method for wafer edge metrology and inspection tools

A technology for edge thickness and detection tools, applied in the field of microelectronics, which can solve the problem of inability to determine the stability of wafer edge thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in combination with principle diagrams and specific operation examples.

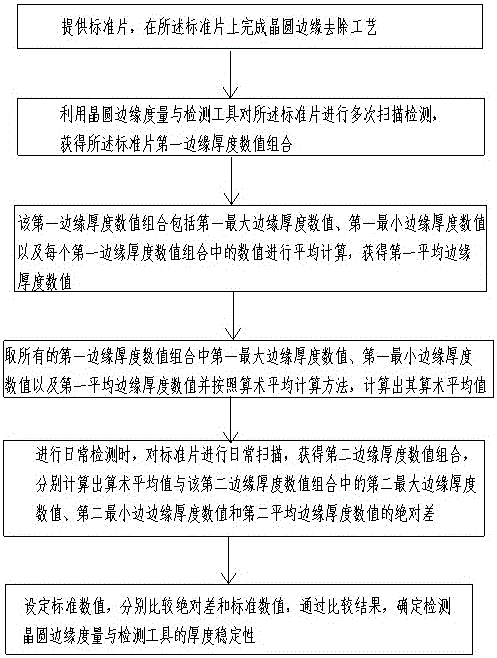

[0029] A method for detecting stability of thickness detection of a wafer edge measurement and detection tool, comprising the following steps:

[0030] S1: Provide a standard sheet and complete the wafer edge removal process on the standard sheet. Specifically, this step can be decomposed into the following steps:

[0031] providing a wafer as a substrate;

[0032] A layer of metal copper film is grown on the wafer;

[0033] Perform a wafer edge removal process on the edge of the exposed wafer to remove the photoresist on the edge of the wafer. Specifically, remove the redundant copper metal on the edge of the wafer with a copper metal film. Specifically, a metal edge washing process or Metal edge etch process removal.

[0034] S2: Use the wafer edge measurement and detection tool to perform multiple scans on the standard wafer to obtain the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com