Comprehensive inventory management method for production materials

A technology of inventory management and materials, applied in the field of management, can solve problems such as shutdown and slowdown, management security loopholes, and loss of historical records, so as to achieve the effect of not easy loss and avoiding management security loopholes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

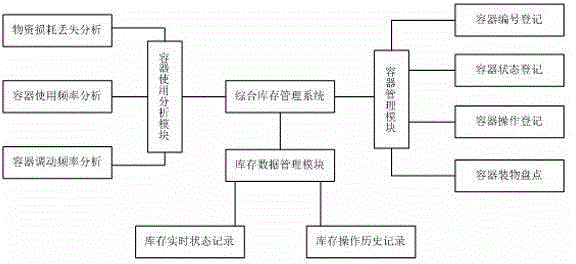

[0021] like figure 1 As shown, the production material comprehensive inventory management method of the present invention is mainly divided into the following three modules:

[0022] Container management module: mainly responsible for registering and updating the state of the container and other related attributes. Among them, container number registration is responsible for registering new containers and canceling scrapped containers; container status registration is responsible for registering container location, full status, goods and containers, and the nesting relationship between containers and other contents; container operation The registration is responsible for recording the operation content of the relevant operators on the container during the production and transportation process, and at the same time registering the change of the container state before and after the operation; the container loading inventory is responsible for recording the inspection results of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com