UBM etching methods for eliminating undercut

A technology of substrate and copper seed layer, applied in the field of UBM etching, can solve the problems of low yield of manufacturing process and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The making and using of various embodiments of the invention are discussed in detail below. It should be appreciated, however, that the present invention provides many applicable concepts that can be implemented in a wide variety of specific contexts. The specific embodiments discussed are illustrative only, and do not limit the scope of the invention.

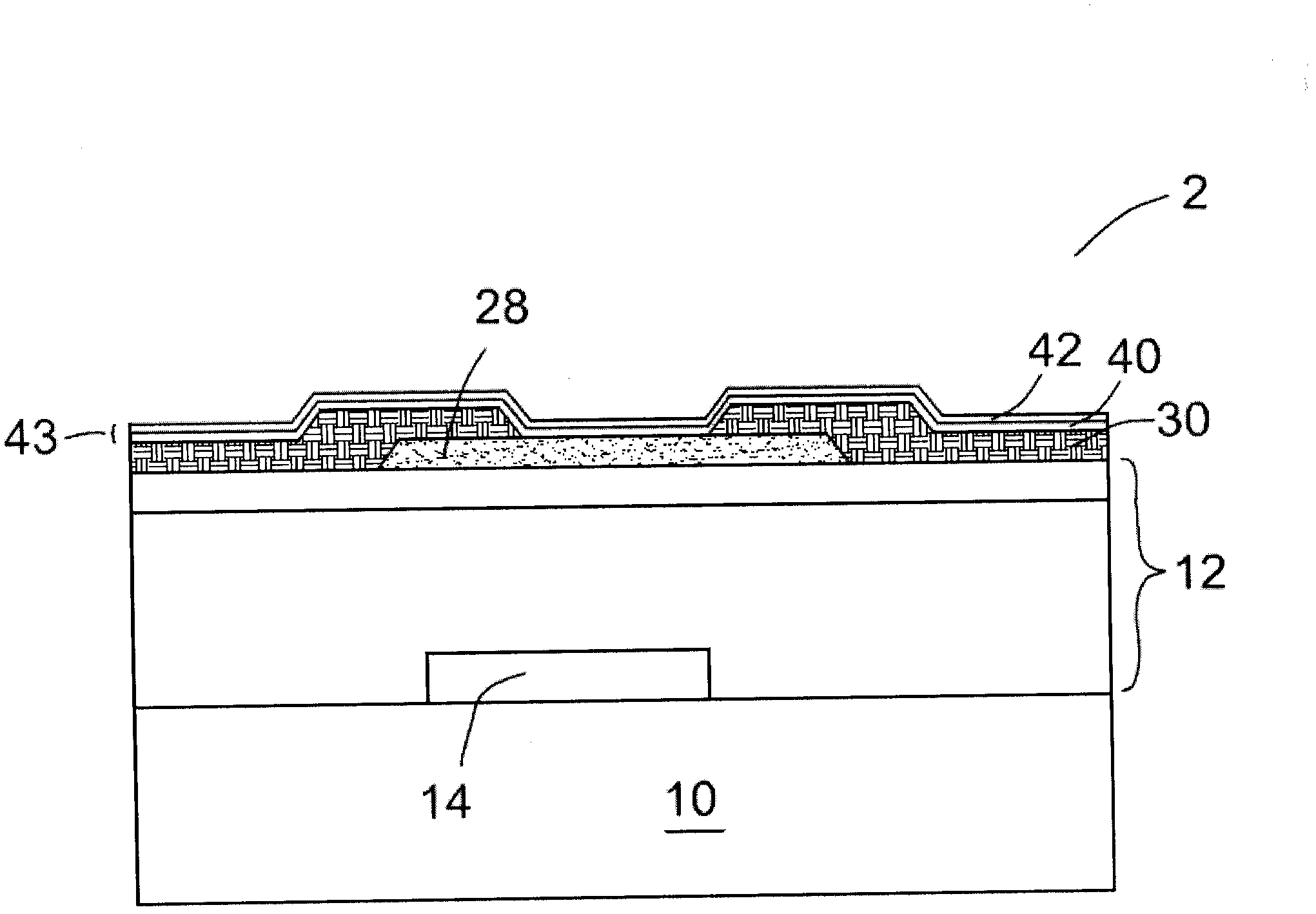

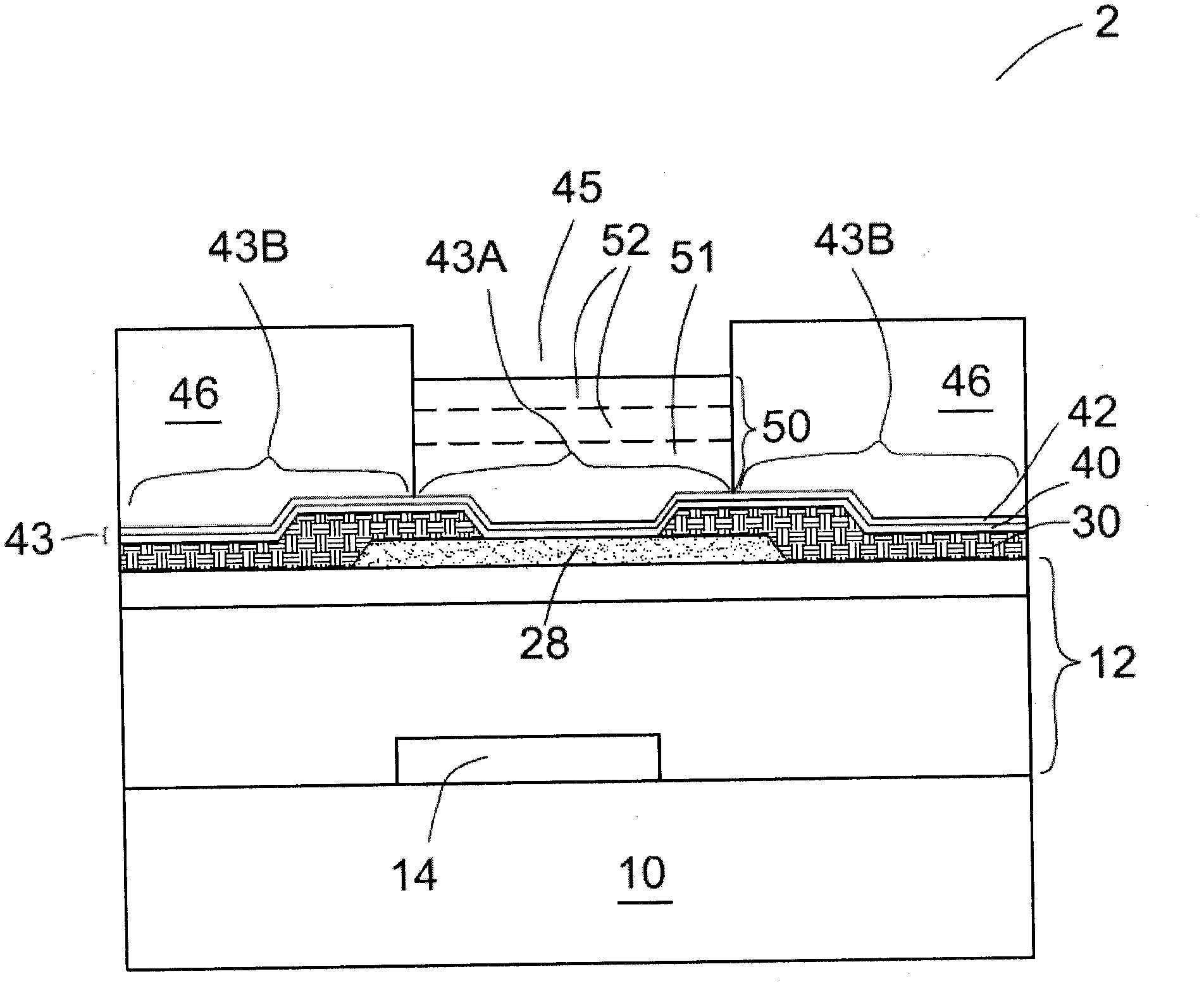

[0019] According to various aspects of the embodiments, methods of forming undercut-free metal bumps in an underlying underbump metallurgy (UBM) are presented. Metal bumps and intermediate fabrication stages of the UBM are shown according to an embodiment. Modifications of the embodiments are discussed. Like reference numerals are used to refer to like elements throughout the various views and illustrative embodiments.

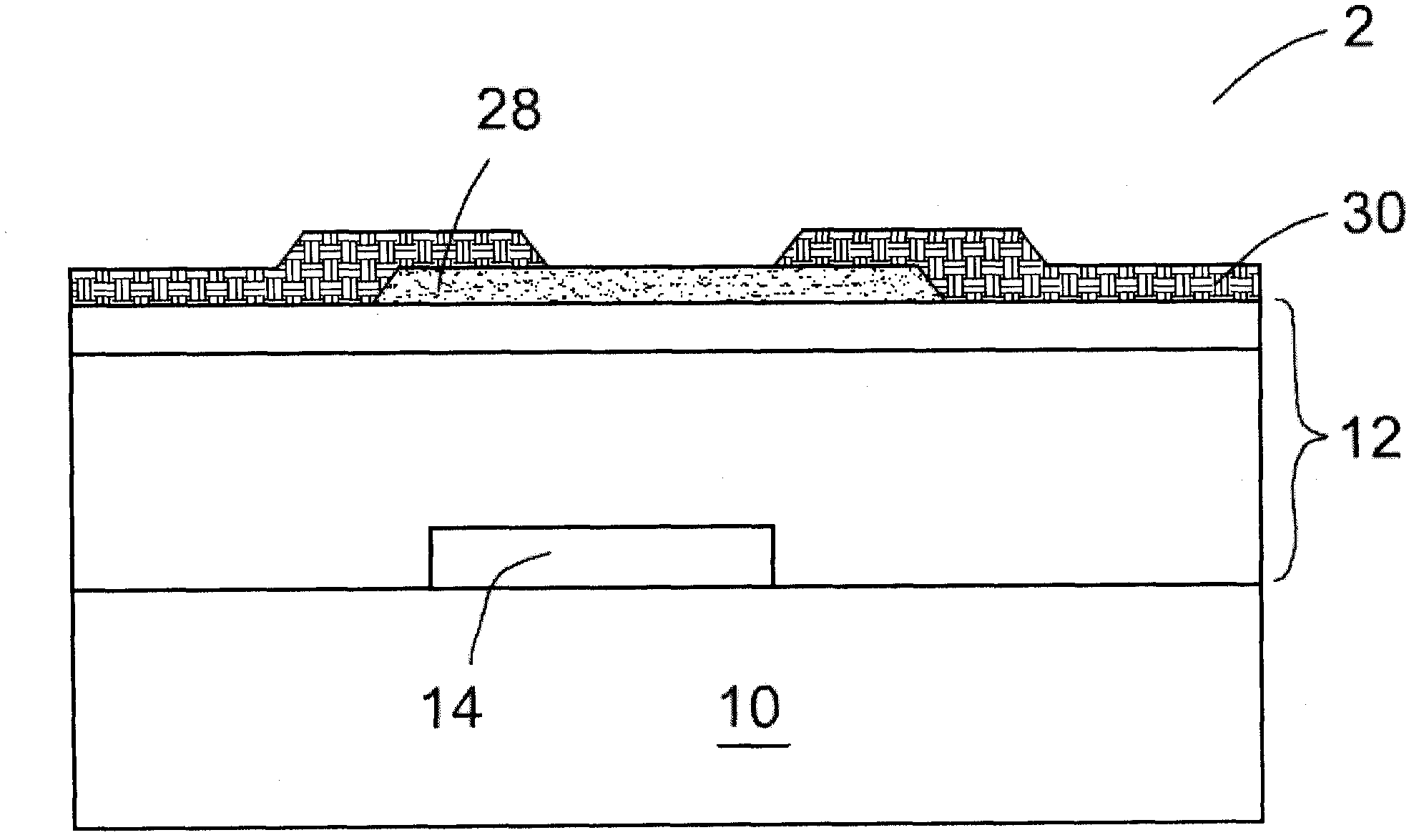

[0020] refer to figure 1 , a wafer 2 comprising a substrate 10 is provided. In an embodiment, the substrate 10 is a semiconductor substrate such as a silicon substrate, however, the substrate may ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com