Method for manufacturing contact and metal part

A manufacturing method and technology of metal parts, applied in the direction of contact manufacturing, contact parts, connection, etc., can solve the problem that the contact 21 cannot be eliminated gradually loosening and falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] Hereinafter, preferred embodiments of the present invention will be described with reference to the drawings. However, the present invention is not limited to the following embodiments, and various design changes can be made without departing from the gist of the present invention.

[0070] (Structure of Contacts)

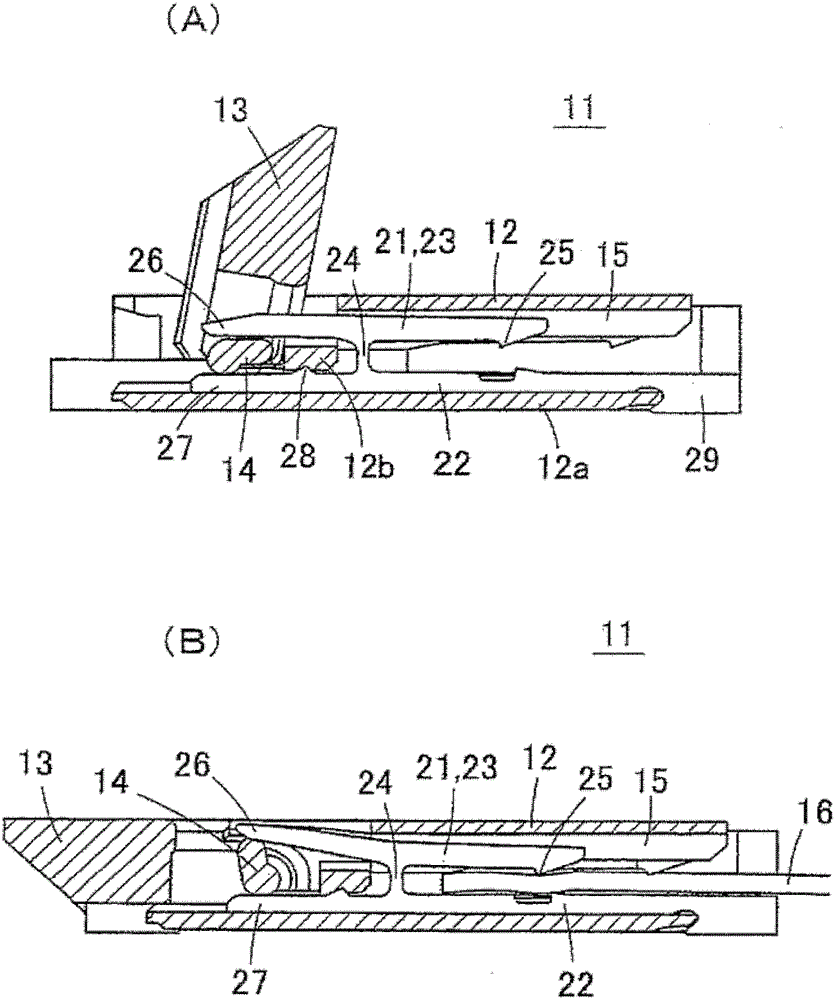

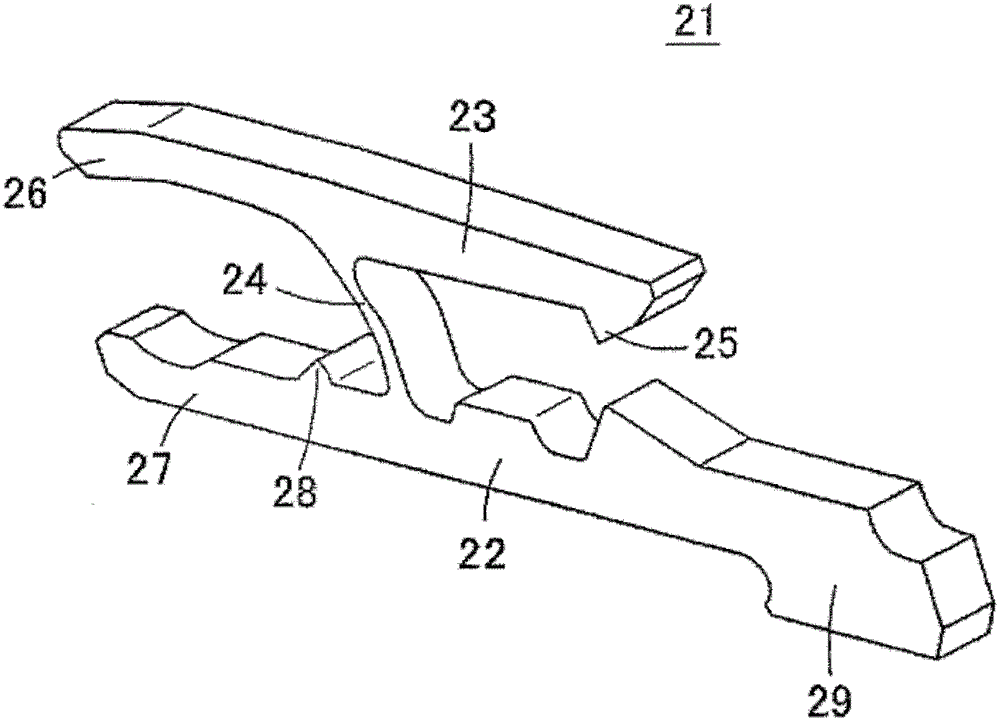

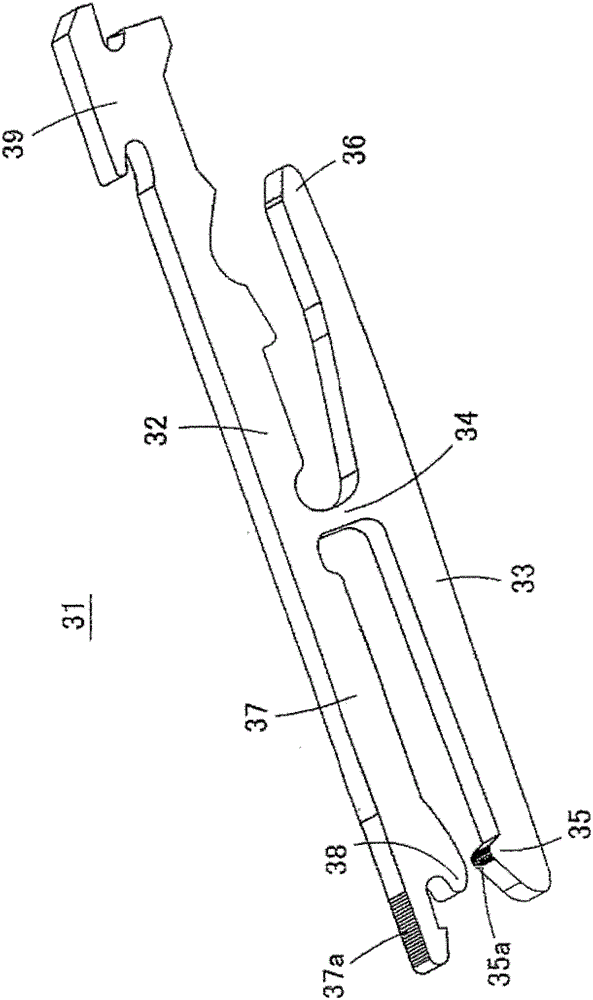

[0071] image 3 It is a perspective view of the contact 31 which concerns on one Embodiment of this invention, and is shown in the state turned upside down. The contacts 31 are minute connection terminals produced by electroforming. Figure 4 (A) and Figure 4 (B) is an enlarged view of a part of the contact 31 . in addition, Figure 5 (A) is a sectional view of the connector 51 assembled into the contact 31, Figure 5 (B) is a sectional view of the connector 51 to which the flexible printed circuit board 46 is connected.

[0072] The fixed piece 32 and the movable piece 33 of the contact piece 31 are substantially parallel, and the fixed piece 32 and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com