Patents

Literature

40results about How to "Achieve electrical contact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

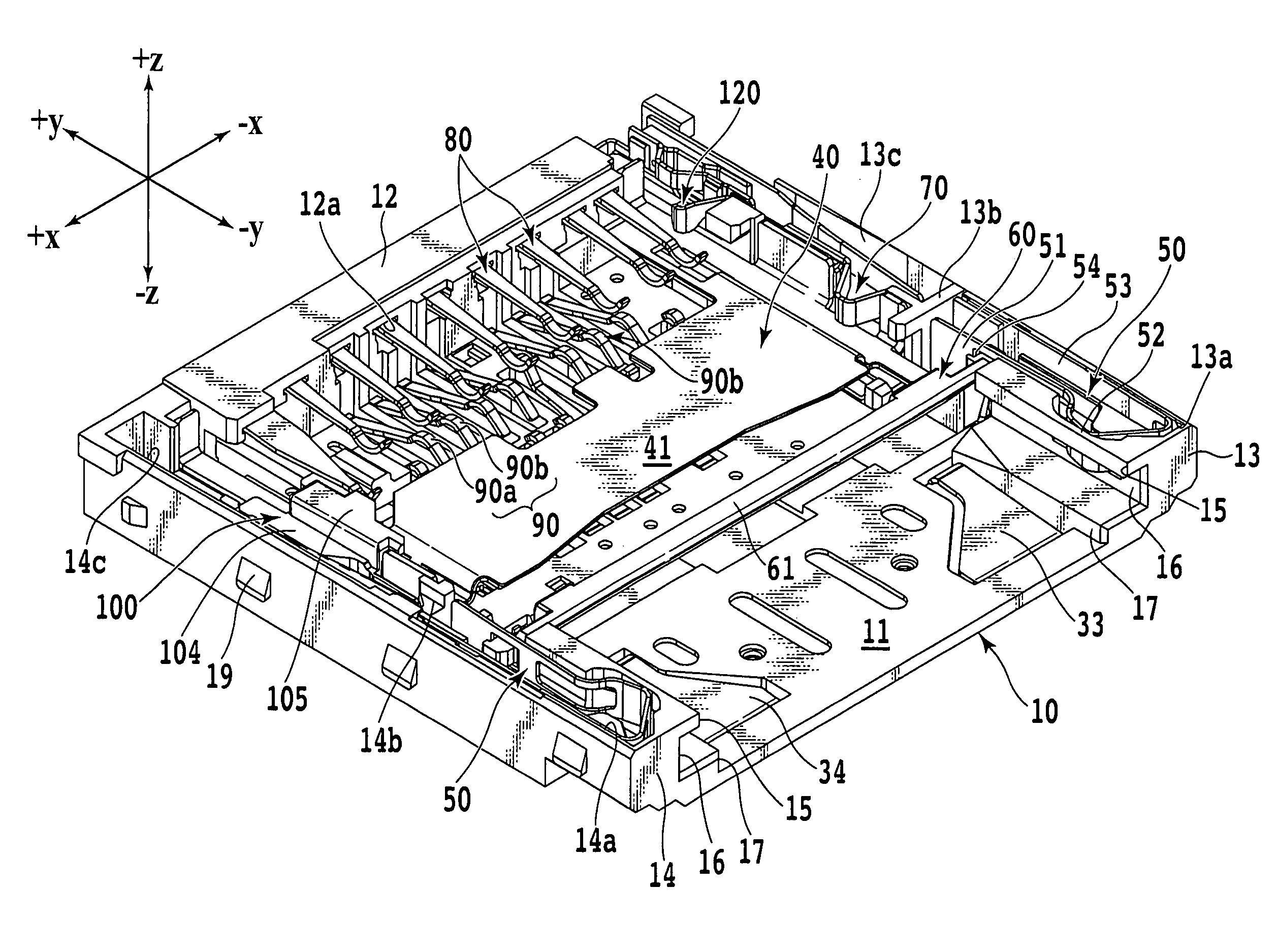

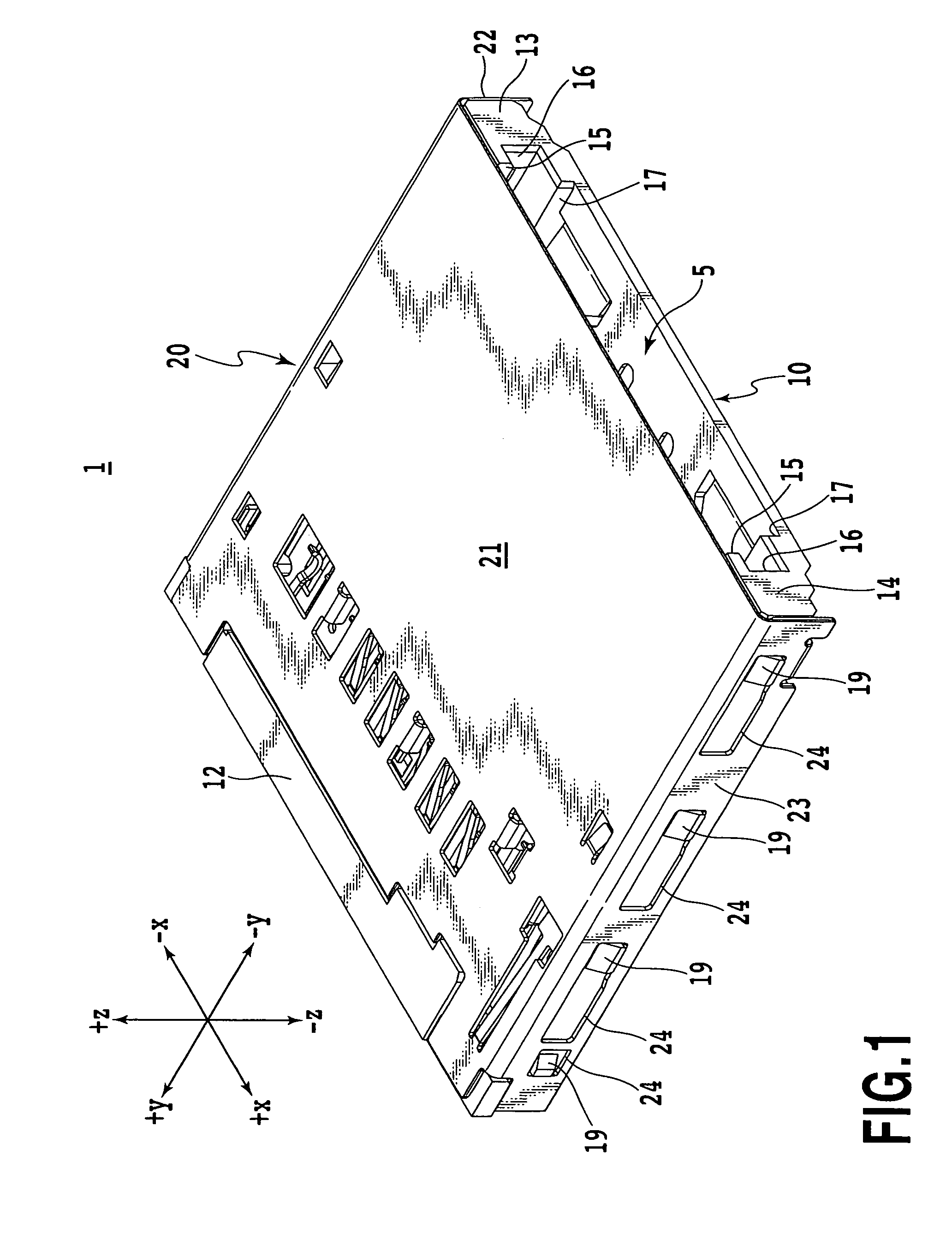

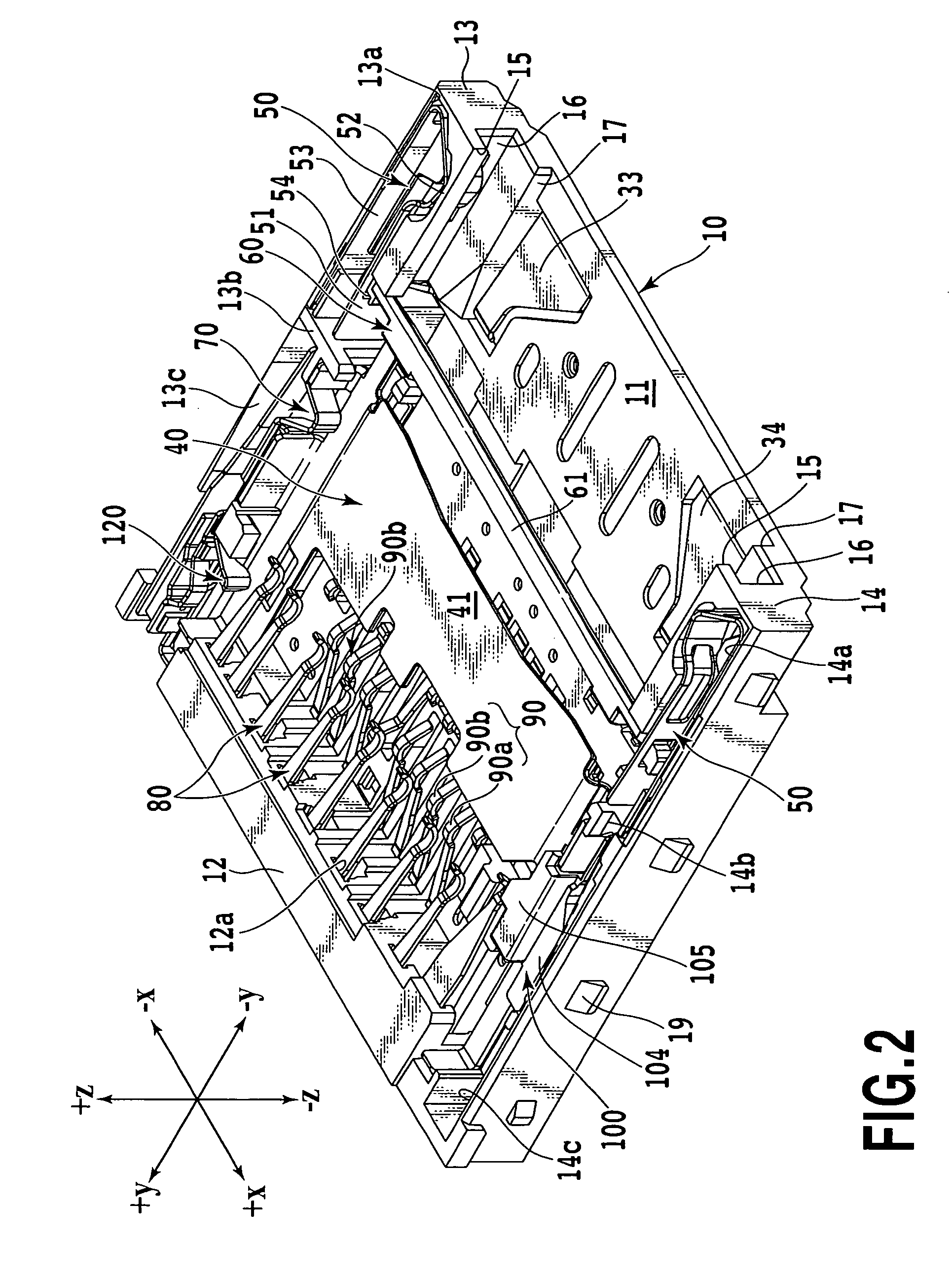

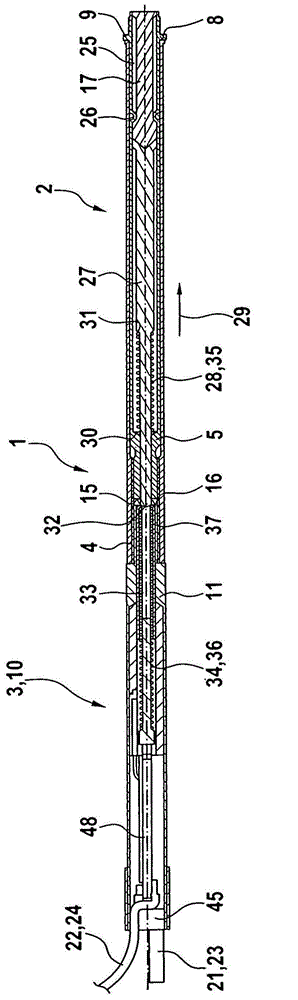

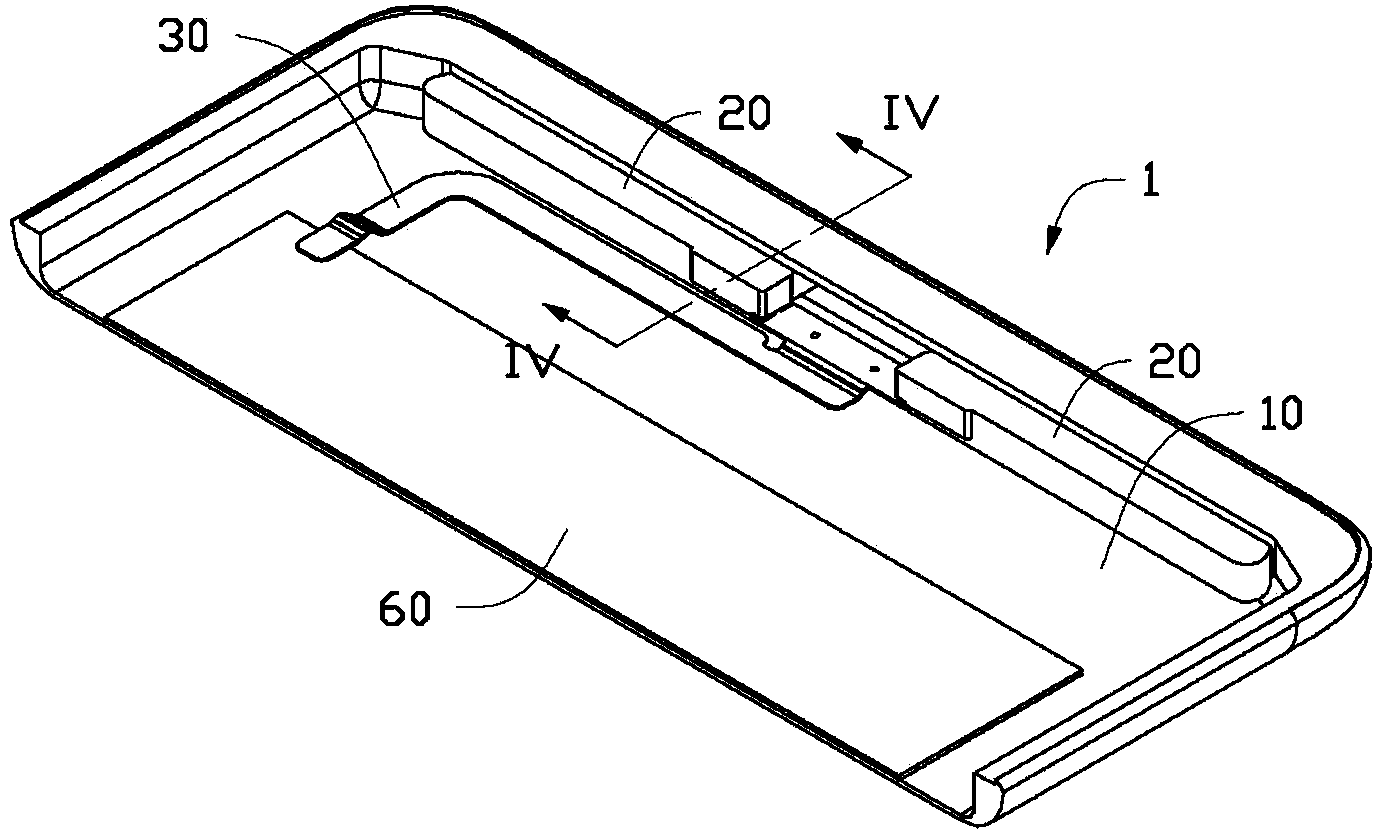

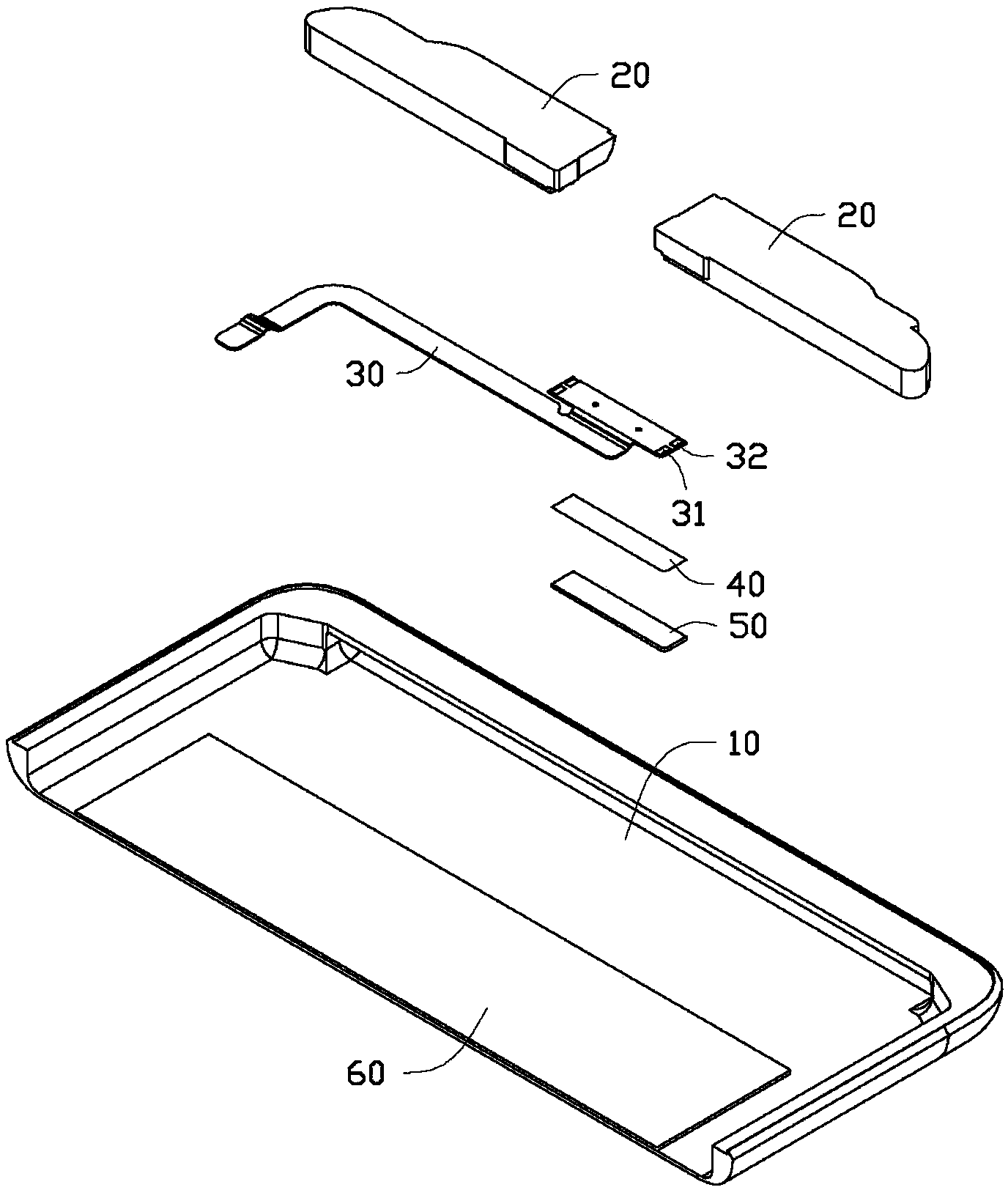

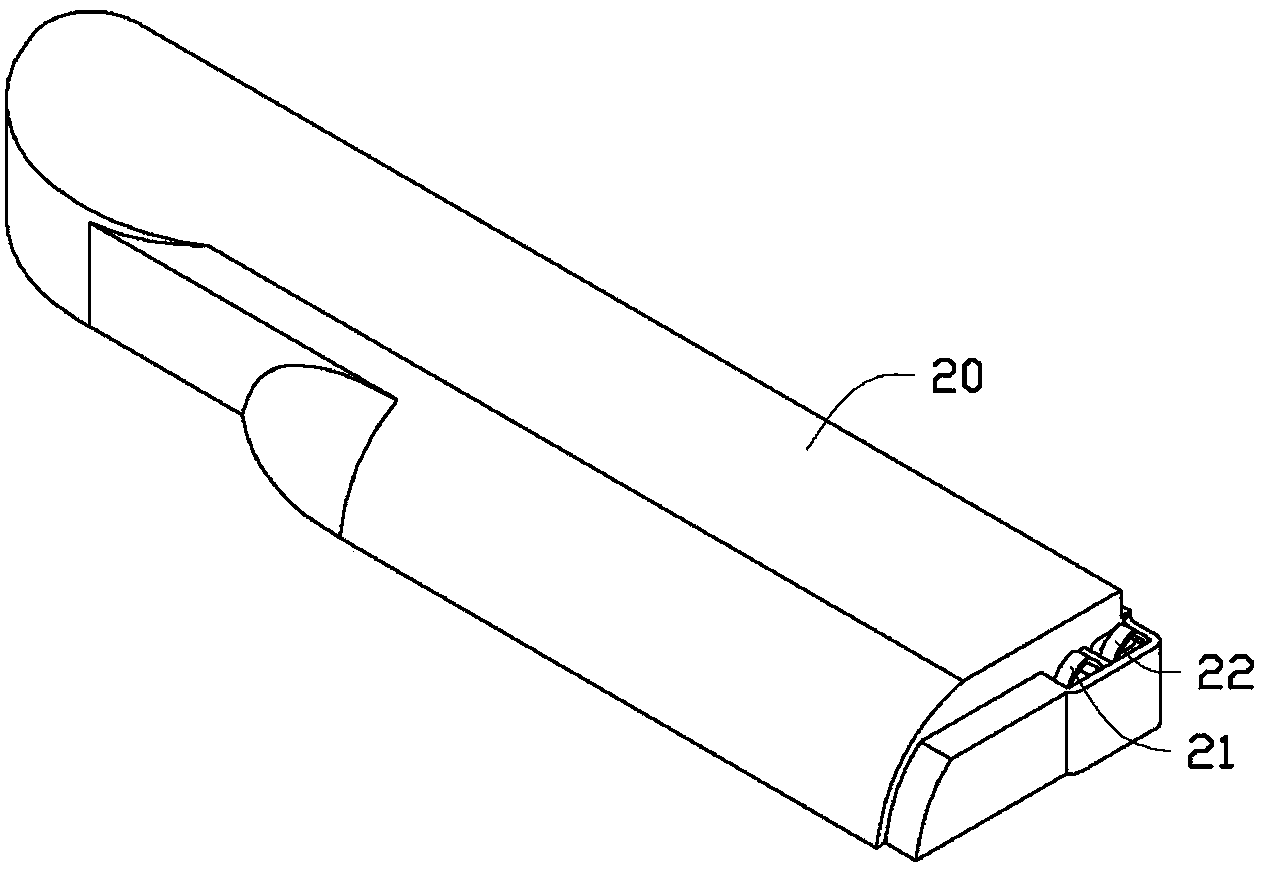

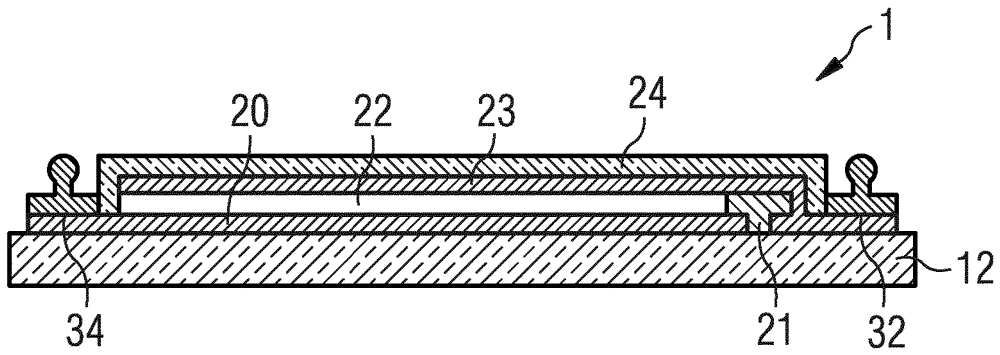

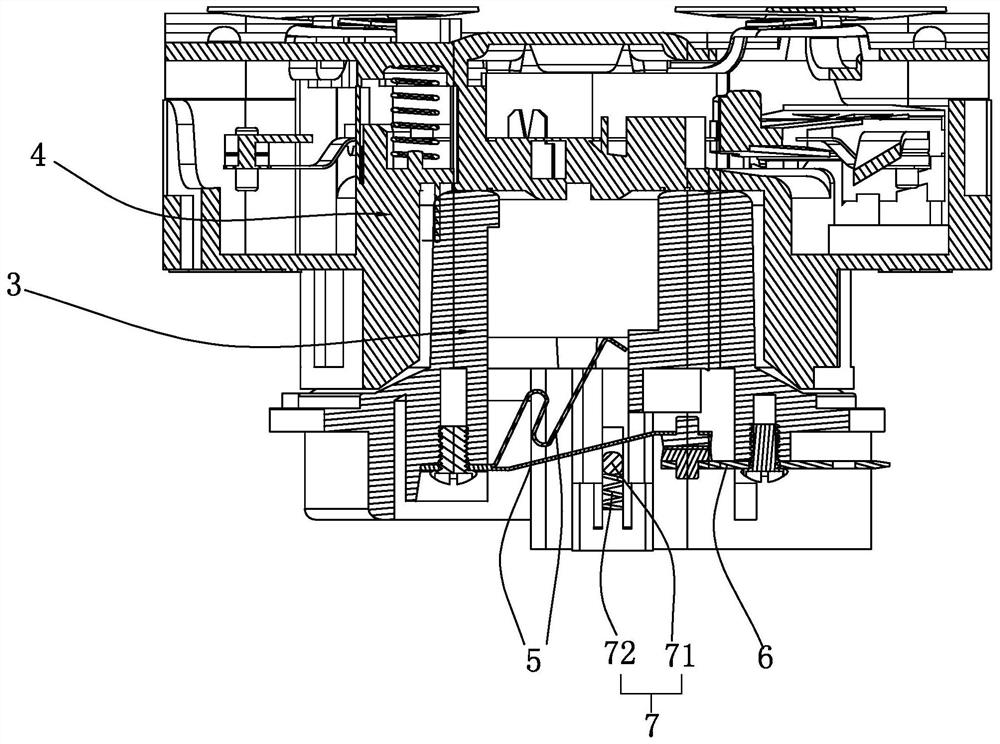

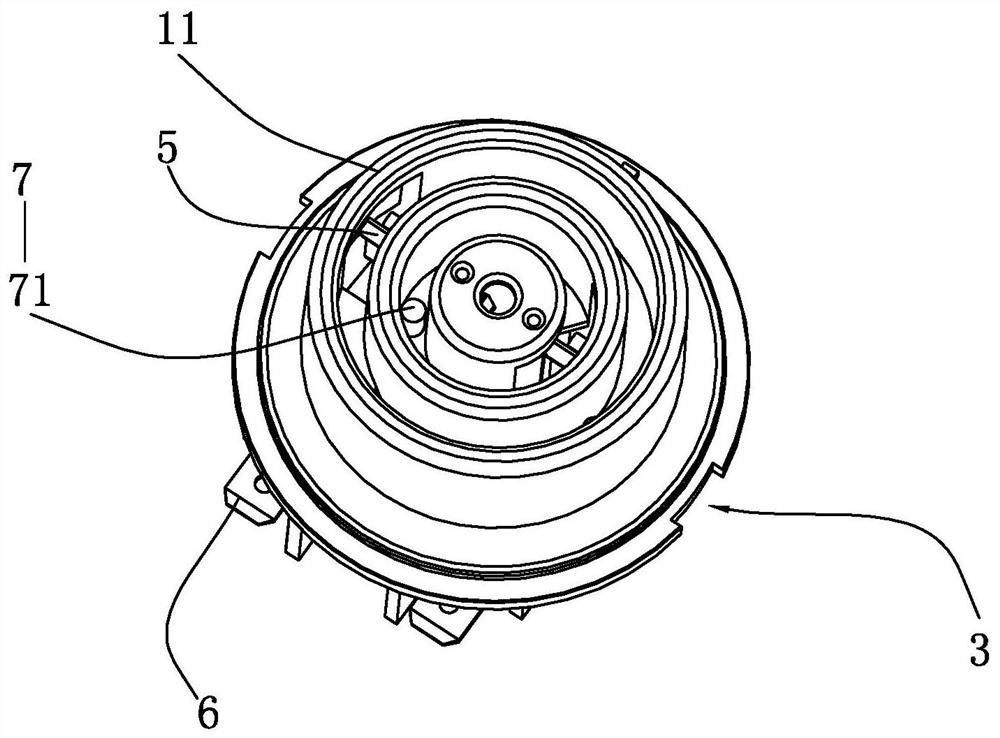

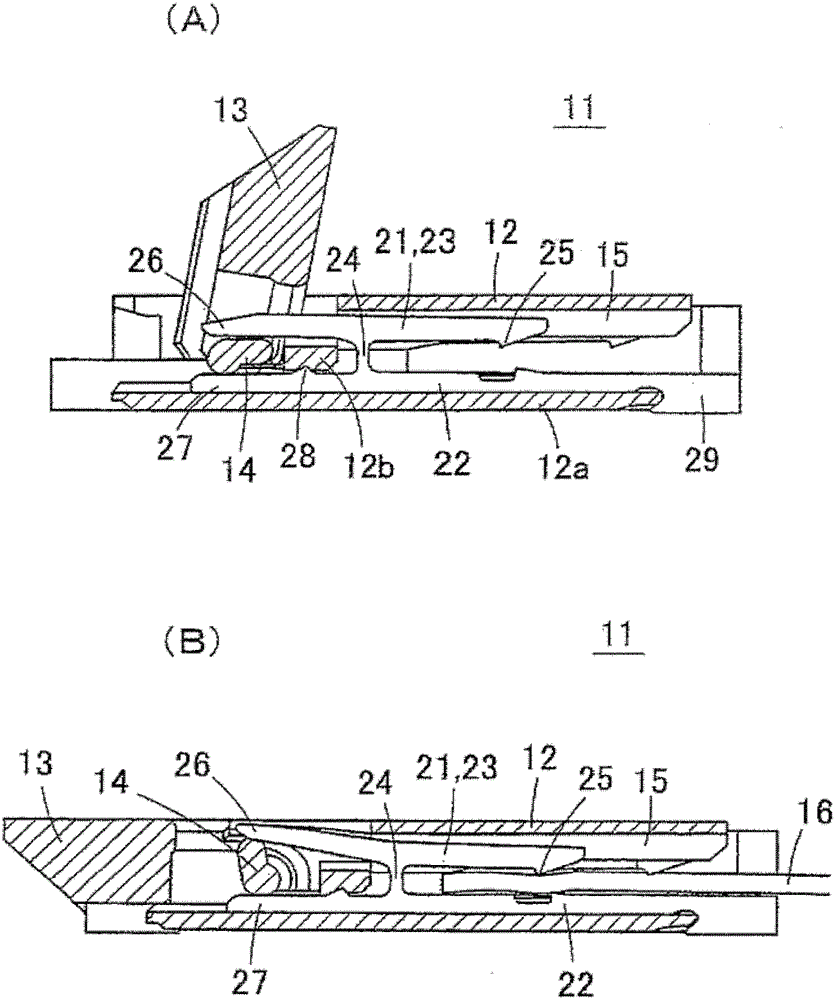

Card connector

ActiveUS7867034B1Reduce the overall heightReduce in quantityEngagement/disengagement of coupling partsTwo-part coupling devicesEngineeringSmart card

A card insertion slot in the card connector through which two types of cards, large and small cards, can be selectively installed in a card accommodation space include first and second guideways in corresponding to the sizes of the cards. The card connector includes first and second contacts, a lock bracket configured to detect the width of the large card, an actuator configured to be rotatable, and a partition member including a partition plate configured to be movable. When the large card is inserted into the card connector, the lock bracket is moved from the first position to the second position. When the large card is further fed into the card connector, the actuator is rotated from the first position to the second position, and the partition plate is moved from the first position to the second position.

Owner:YAMAICHI ELECTRONICS +1

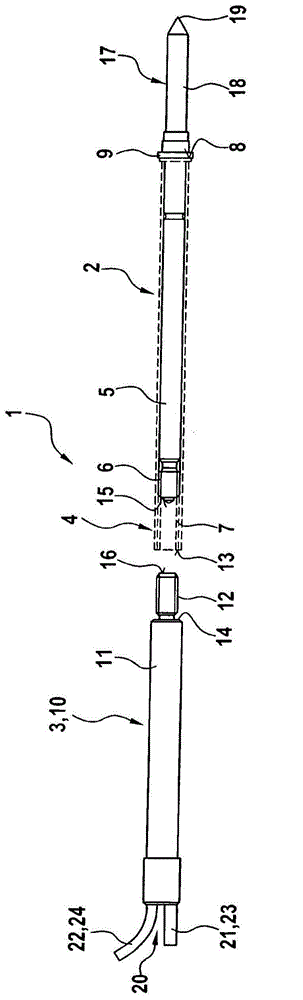

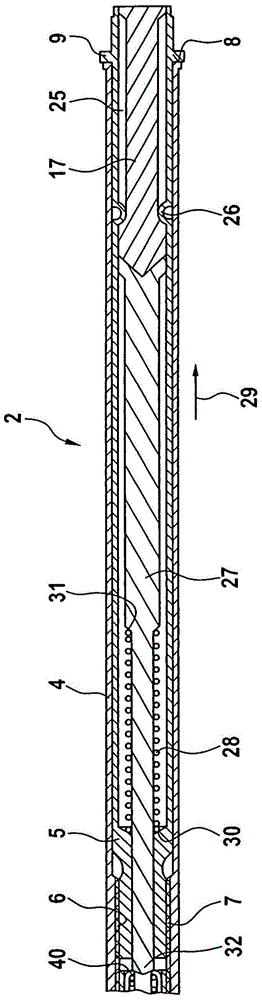

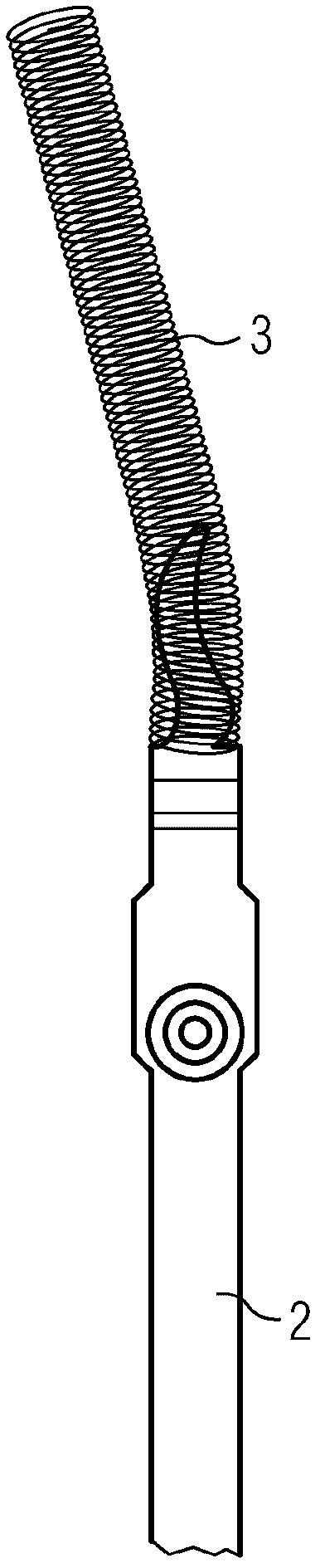

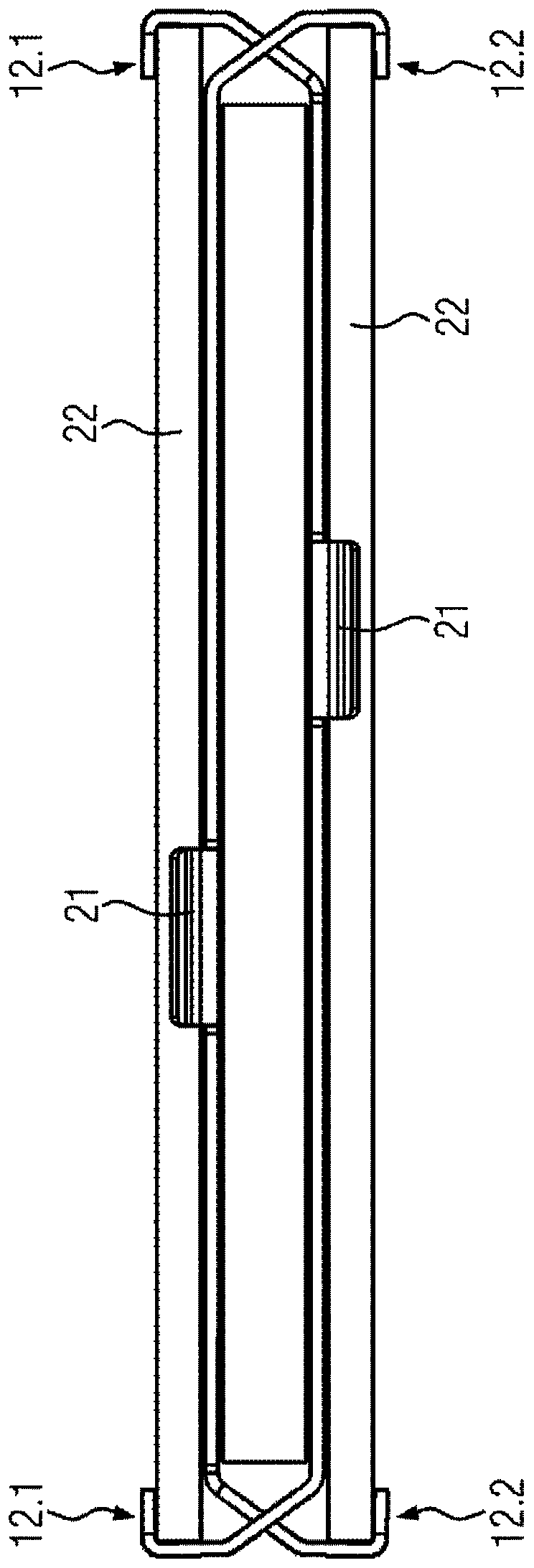

Spring contact pin arrangement

InactiveCN103562733AReduced flexibilityRealize measurementElectrical measurement instrument detailsElectrical testingEngineeringContact element

The invention relates to a spring contact pin arrangement having a spring contact pin that comprises a pin housing in which a contact element is mounted so as to be longitudinally displaceable and is loaded by a spring device acting opposite to a displacement direction, wherein the contact element is connected to at least one first interface of the spring contact pin arrangement and protrudes from the pin housing with a contact region for electrical contacting of an electric test item. According to the invention the spring contact pin arrangement comprises a position sensor, wherein the contact element, in order to transfer the stroke thereof, is connected to a displaceable sensor element of the position sensor detecting the stroke position of the contact element.

Owner:FEINMETALL

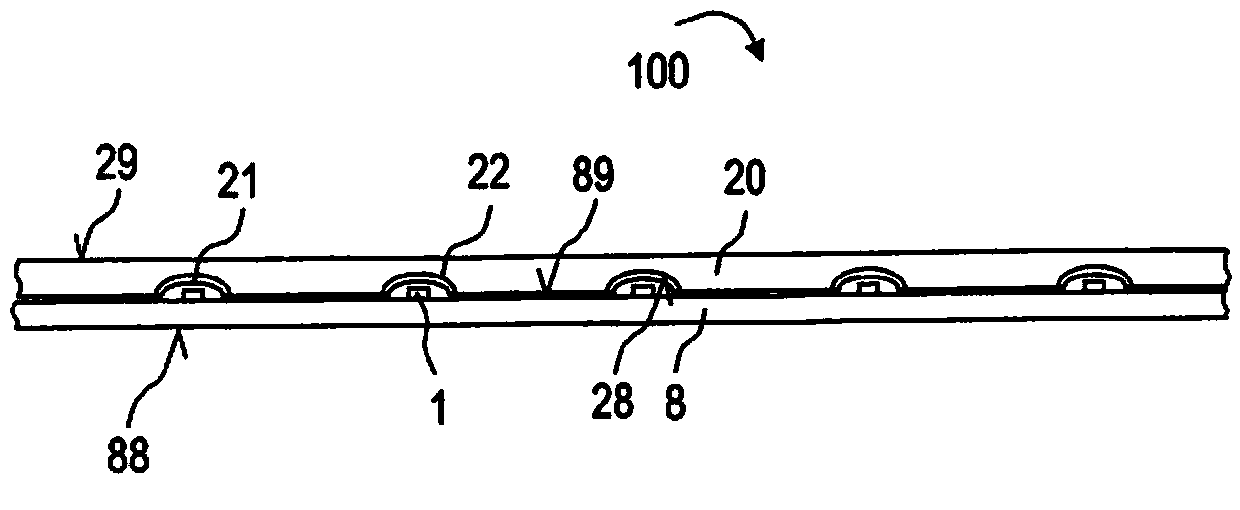

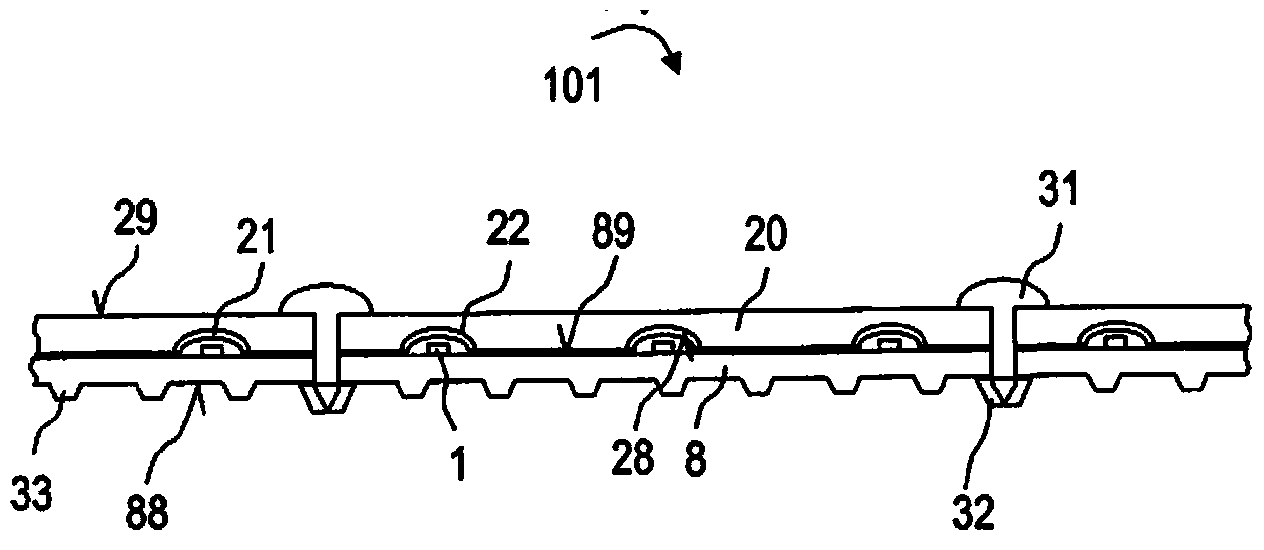

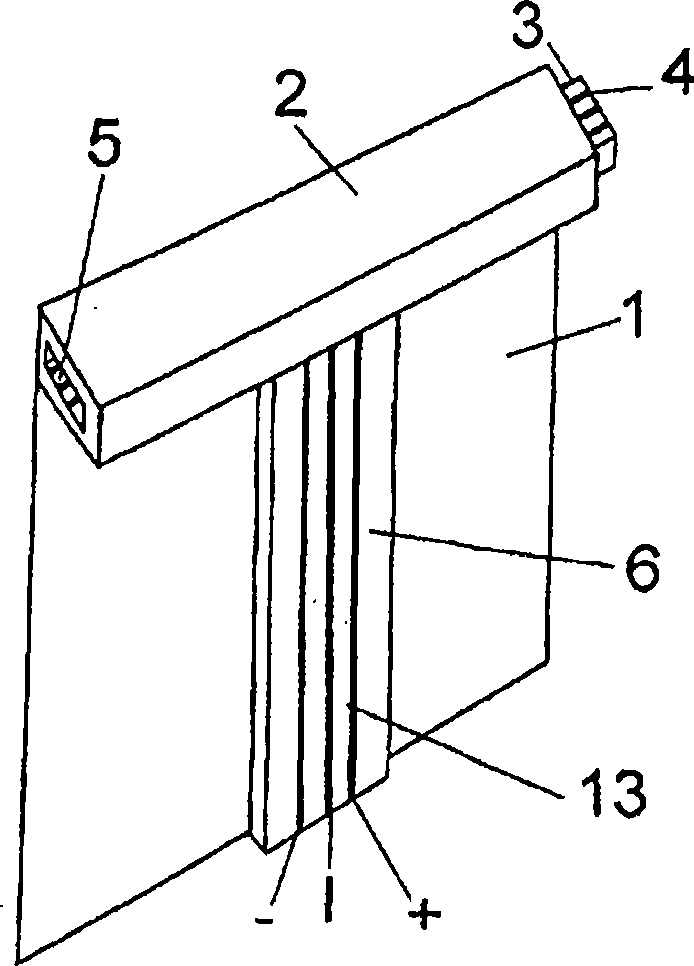

Lighting device

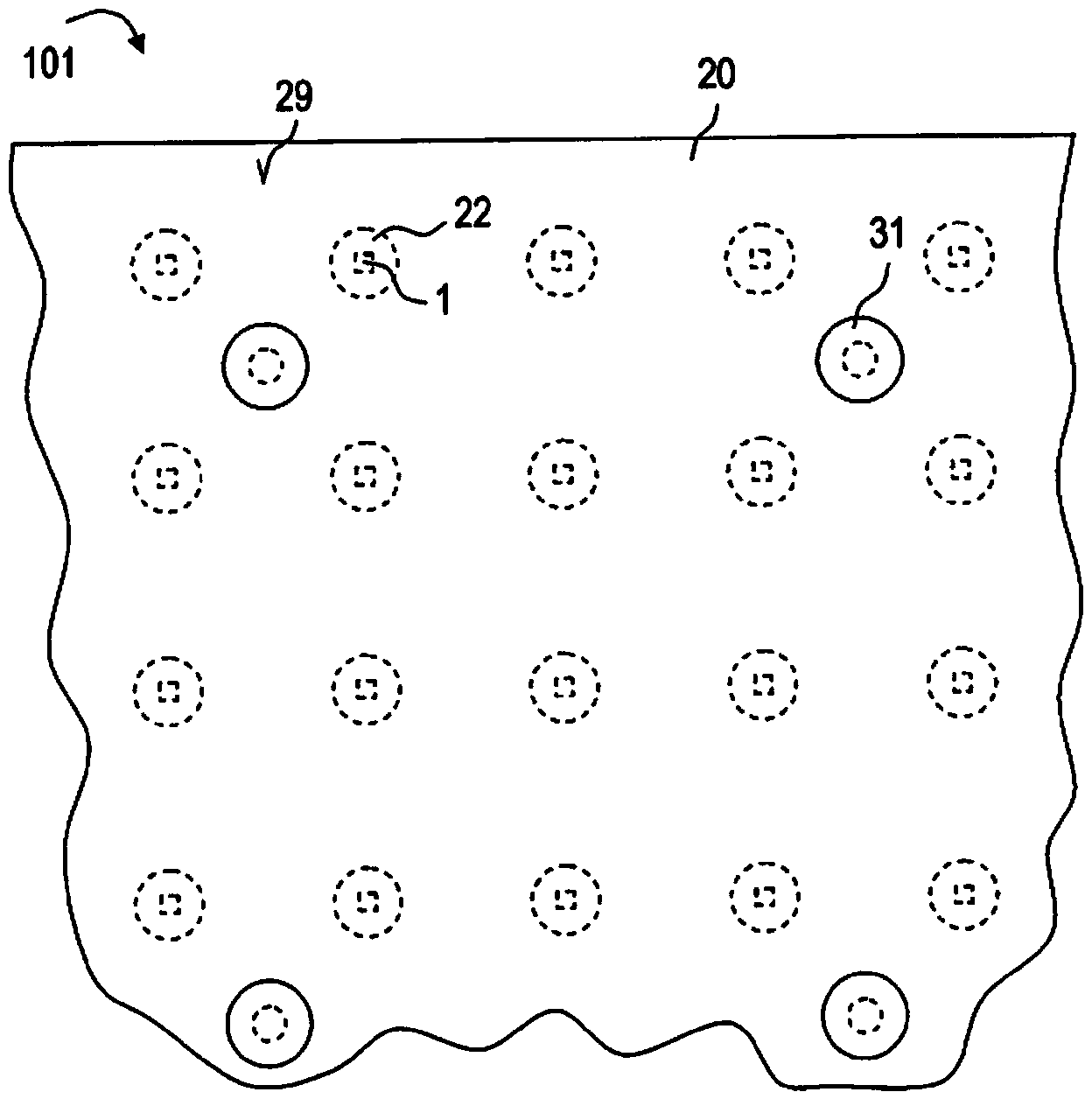

InactiveCN103917819ASimple mechanical installationAchieve electrical contactPlanar light sourcesGlobesLight equipmentSemiconductor chip

The invention relates to a lighting device for room lighting which has a carrier plate (8) having a reflective assembly surface (89) on which a plurality of light emitting semiconductor chips (1) spaced apart from each other is arranged, and furthermore a translucent or transparent emission plate (20) arranged downstream of the light emitting semiconductor chips (1) in the emission direction and having a light decoupling surface (29) facing away from the light emitting semiconductor chips (1), wherein the emission plate (20) has a plurality of recesses (22) which are each arranged after at least one semiconductor chip (1), and wherein each of the recesses (22) has a diffusor material and / or a wavelength conversion material (21) on the inner surface (28) facing the semiconductor chips (1), and spaced apart from the light emitting semiconductor chips (1).

Owner:OSRAM GMBH

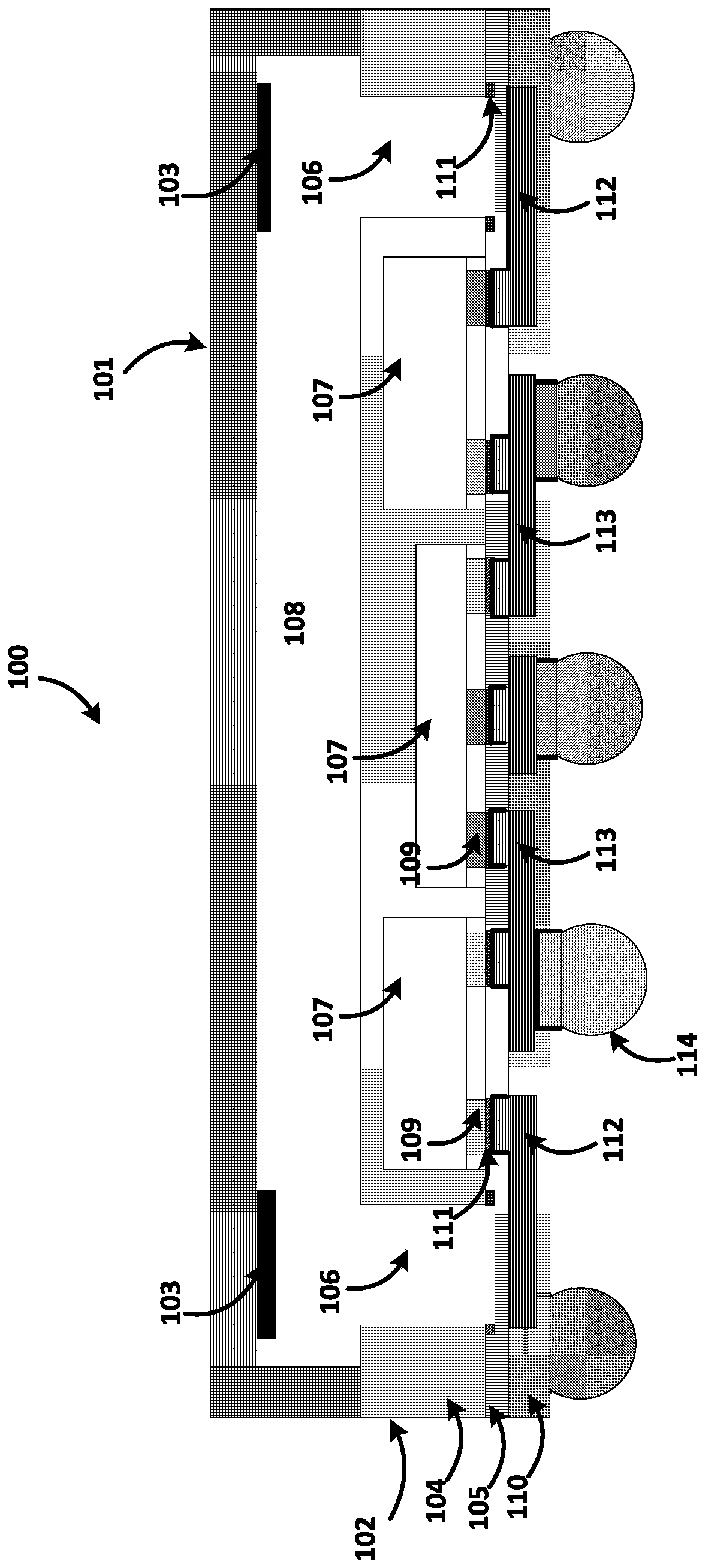

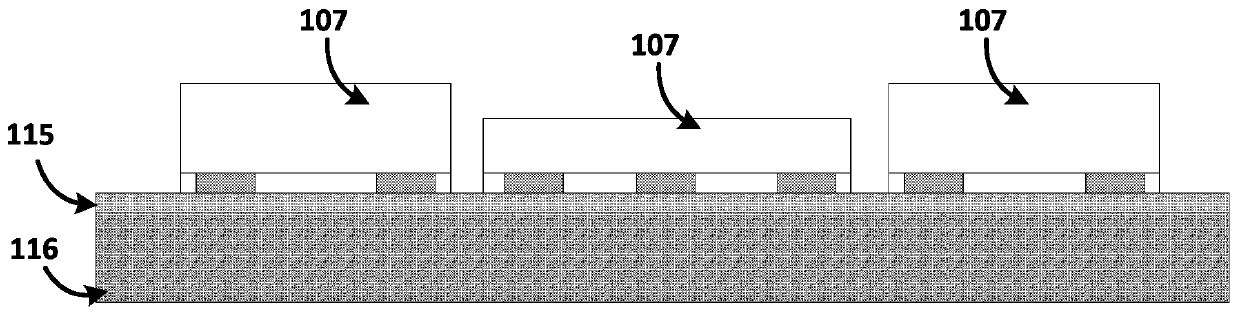

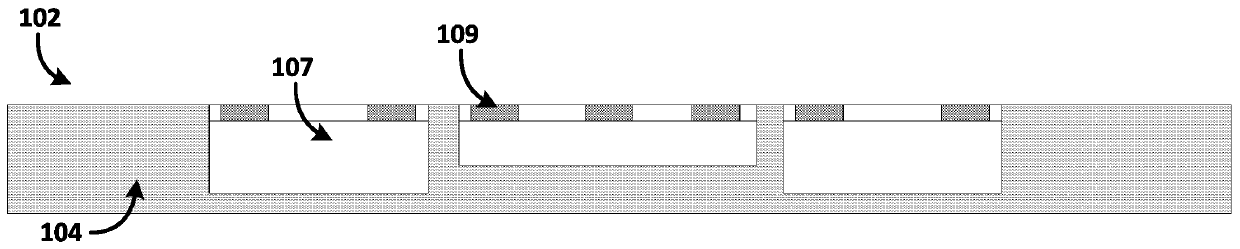

Radar module packaging body and manufacturing method thereof

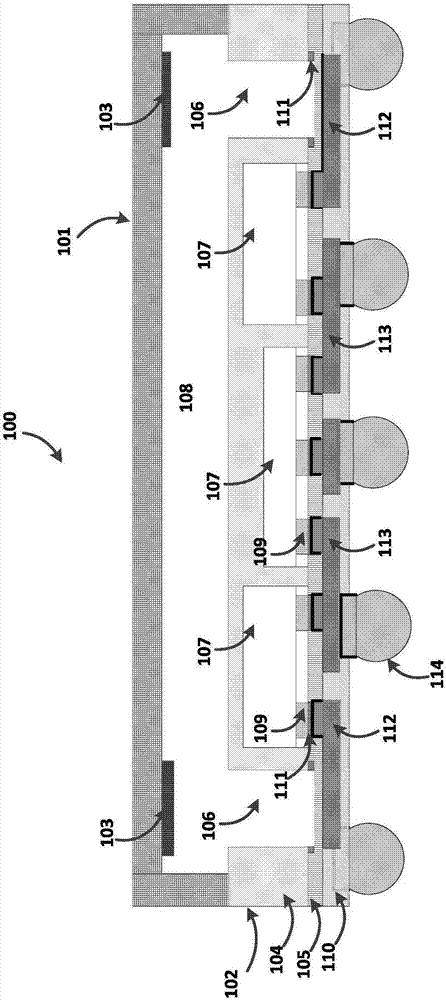

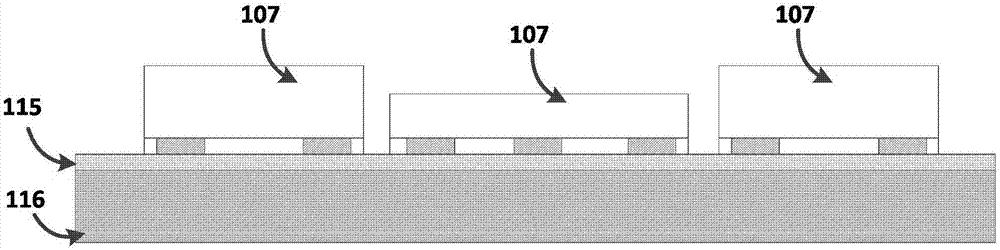

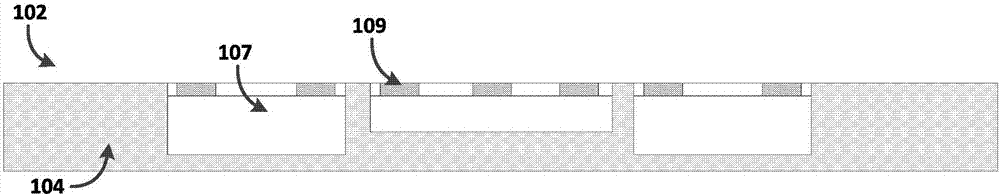

ActiveCN107479034AReduce thicknessShorten the lengthWave based measurement systemsSemiconductor/solid-state device detailsRadarElectric contact

The present invention relates to a radar module packaging body. The radar module packaging body comprises: a box cover having a metal layer arranged at the inner surface of the box cover, wherein a cavity is formed between the box cover and a box body; the box body, wherein the box body comprises a first insulation body connected with the box cover, the first insulation body is internally provided with a hole channel, one end of the hole channel corresponds to the position of an antenna, and the other end of the hole channel is communicate with the cavity, and the box body also comprises one or more than one chips which are arranged on a second insulation body in an inversion mode and are covered with the first insulation body, the second insulation body and a third insulation body; and the antenna and a conduction circuit which are arranged in the third insulation body and pass through the second insulation to connect with the bonding pads of the one or more than one chips, wherein the metal barrier layers are arranged between the antenna and the bonding pads and between the conduction circuit and the bonding pads, and the conduction circuit is exposed from the third insulation body for electric contact. The present invention further relates to the manufacturing method of the packaging body.

Owner:NAT CENT FOR ADVANCED PACKAGING

Loudspeaker and electronic device with loudspeaker

InactiveCN103905934AAchieve electrical connectionAchieve electrical contactCircuit lead arrangements/reliefTransducer casings/cabinets/supportsElectrical connectionEngineering

Owner:FU TAI HUA IND SHENZHEN +1

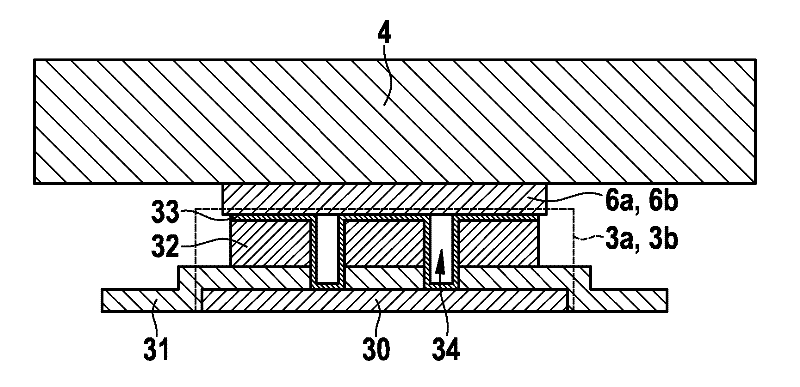

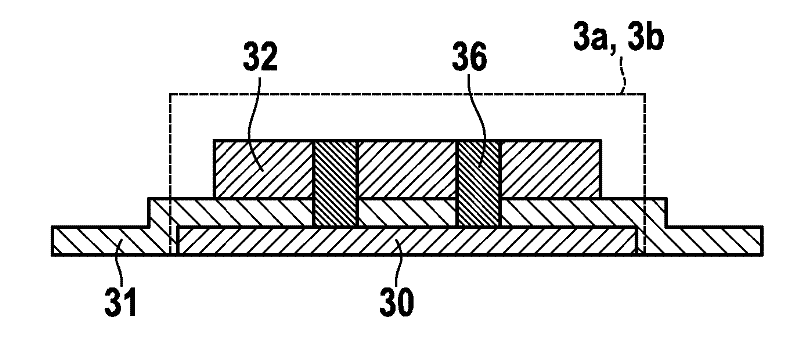

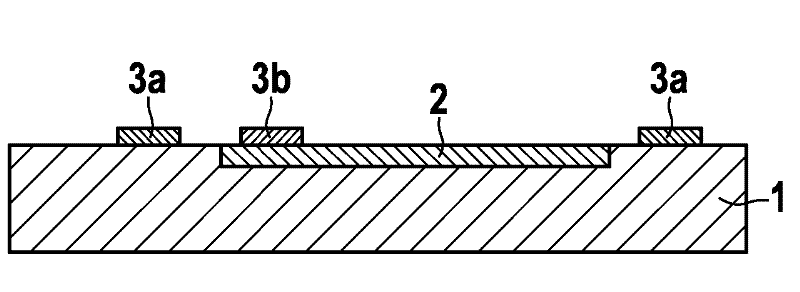

Contact arrangement for establishing a spaced, electrically conducting connection between microstructured components

InactiveCN102164847AAchieve electrical contactDecorative surface effectsSolid-state devicesElectrical connectionEngineering

The present invention relates to a contact arrangement (3a, 3b) for establishing a spaced, electrically conducting, and preferably hermetic connection between a first wafer (1) and a second wafer (4), wherein the contact arrangement (3a, 3b) comprises an electrical connection contact (30), a passivation layer (31) on the connection contact (30), and a dielectric spacer layer (32) disposed on the passivation layer (31), and wherein the contact arrangement (3a, 3b) is disposed at least on one of the wafers (1, 4). The invention is characterized in that the contact arrangement (3a, 3b) having a first material (33, 36) capable of forming a metal-metal connection comprises at least partially filled trenches (34), wherein the trenches (34) are continuous trenches from the spacer layer (32) through the passivation layer (31) to the connection contact (30), and wherein the first material (33, 36) is disposed in the trenches (34) from the connection contact (30) to the top edge of the trenches.

Owner:ROBERT BOSCH GMBH

Hf housing coupler and method for producing the same

InactiveCN101682151AAchieve electrical contactTwo pole connectionsContact member cases/bases manufactureEngineeringElectrical and Electronics engineering

Owner:斯宾纳机床制造有限公司

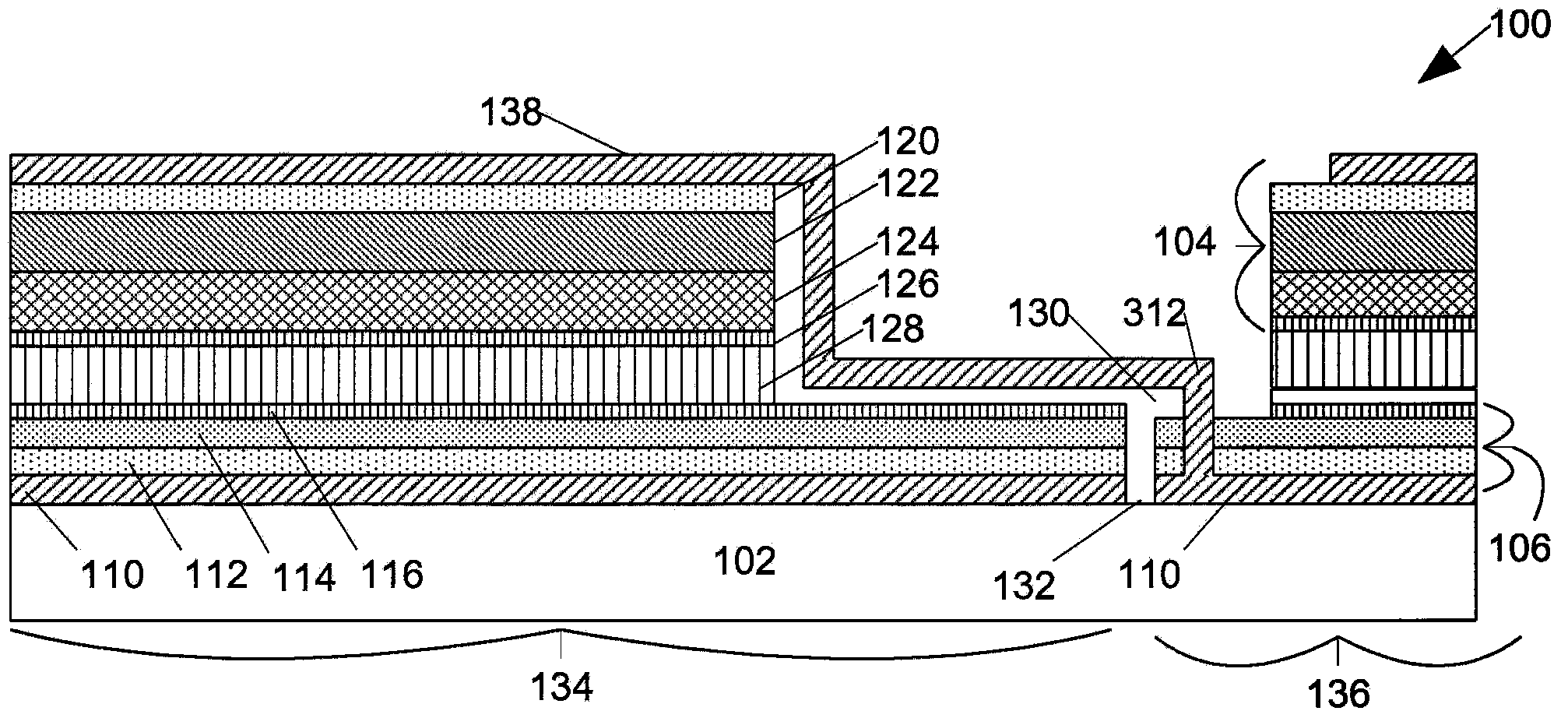

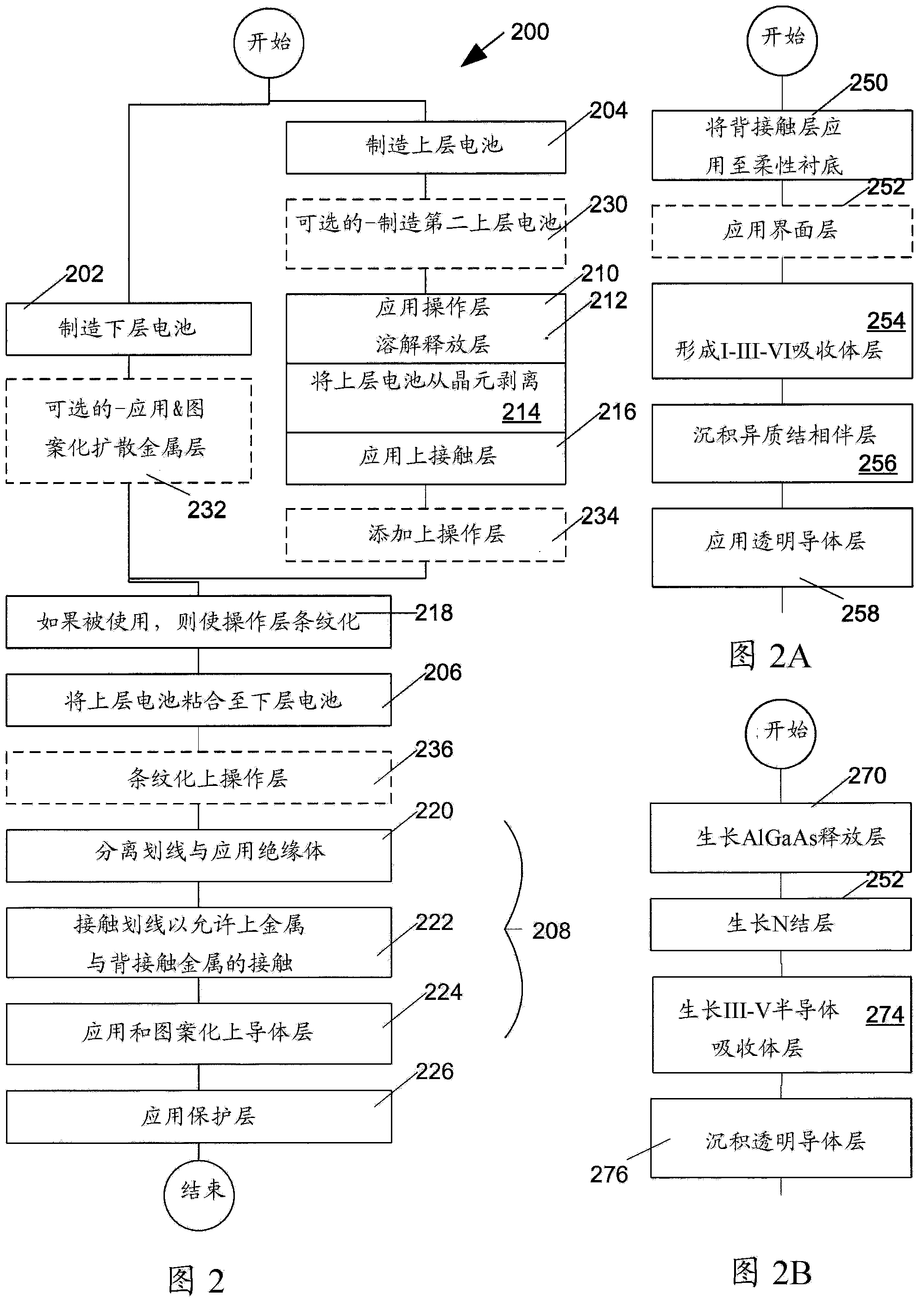

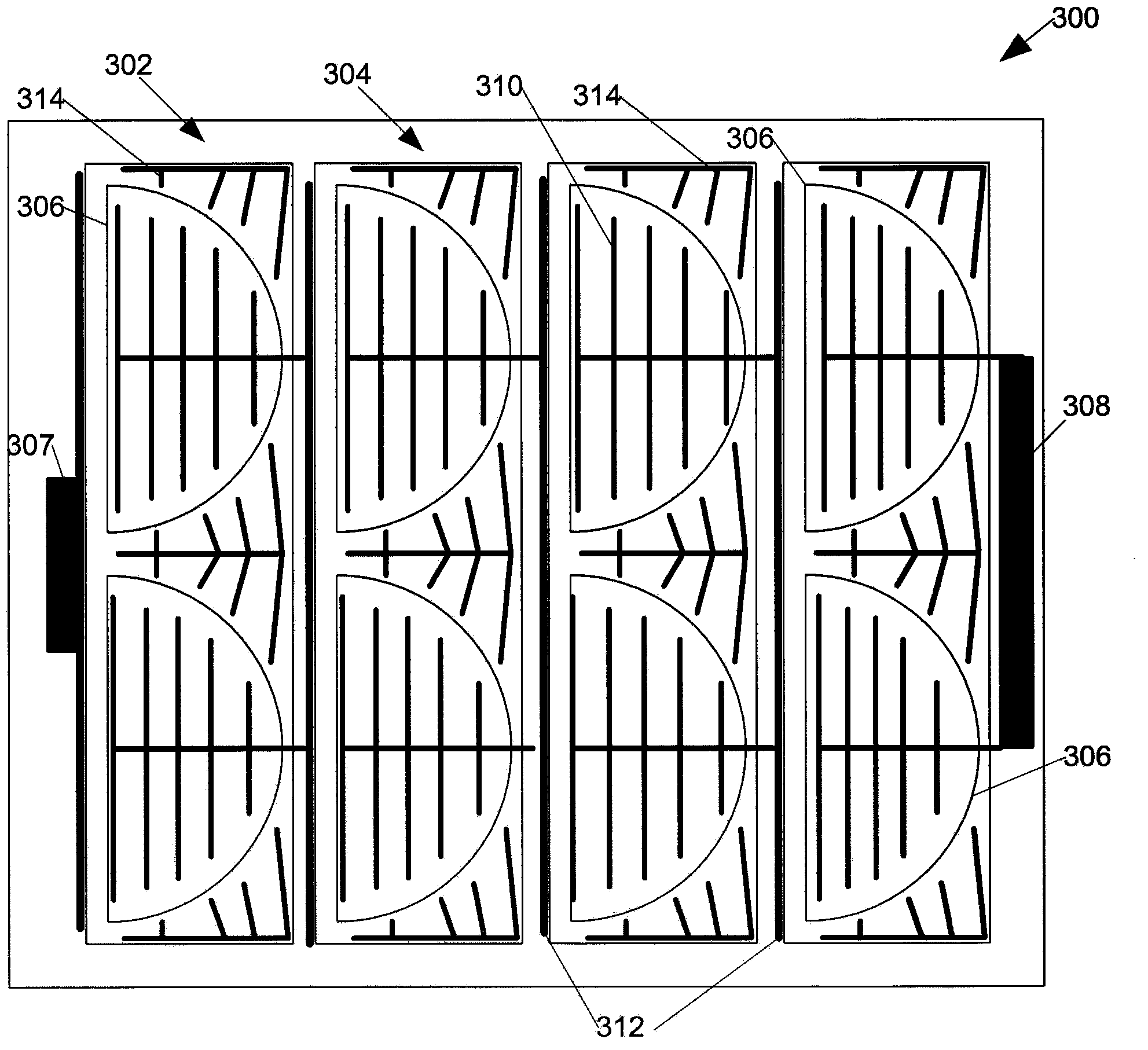

Apparatus and method for hybrid photovoltaic device having multiple, stacked, heterogeneous, semiconductor junctions

InactiveCN103534804AAchieve electrical contactFinal product manufactureSolid-state devicesElectrical conductorAdhesive

A photovoltaic (PV) device has at least one lower PV cell on a substrate, the cell having a metallic back contact, and a I-III-VI absorber, and a transparent conductor layer. An upper PV cell is adhered to the lower PV cell, electrically in series to form a stack. The upper PV cell has III- V absorber and junction layers, the cells are adhered by transparent conductive adhesive having filler of conductive nanostructures or low temperature solder. The upper PV cell has no substrate. An embodiment has at least one shape of patterned conductor making contact to both a top of the upper and a back contact of the lower cells to couple them together in series.; In an embodiment, a shape of patterned conductor draws current from excess area of the lower cell to the upper cell, in an alternative embodiment shapes of patterned conductor couples I-III-VI cells not underlying upper cells in series strings, a string being in parallel with at least one stack. In an embodiment, the bonding agent is a polymeric adhesive containing conductive nanostructures. In an embodiment the III-V absorber is grown on single crystal, substrate. A method for forming the device is described.

Owner:ASCENT SOLAR TECH

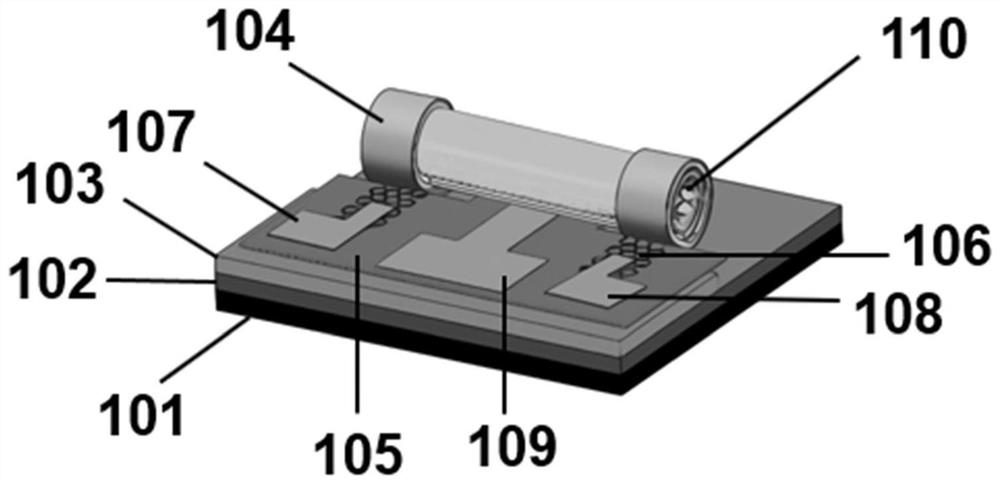

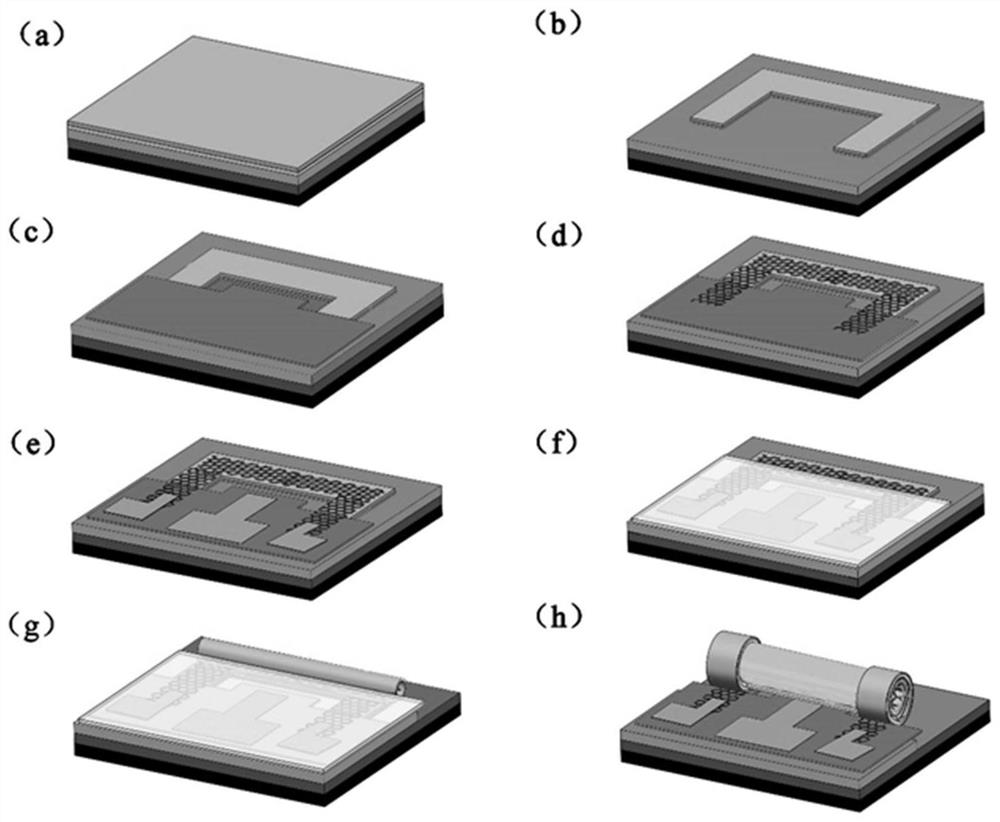

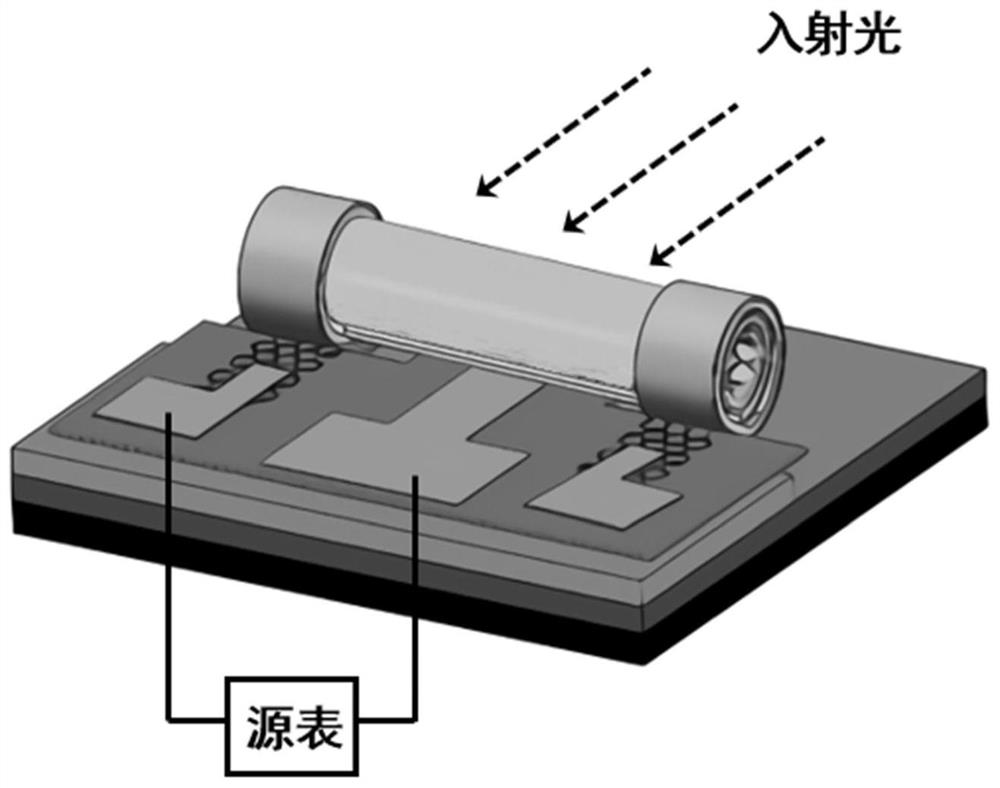

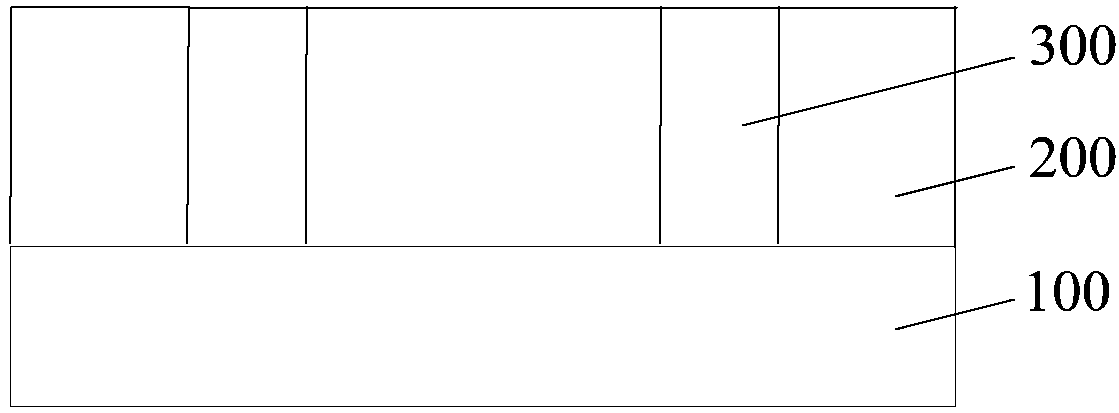

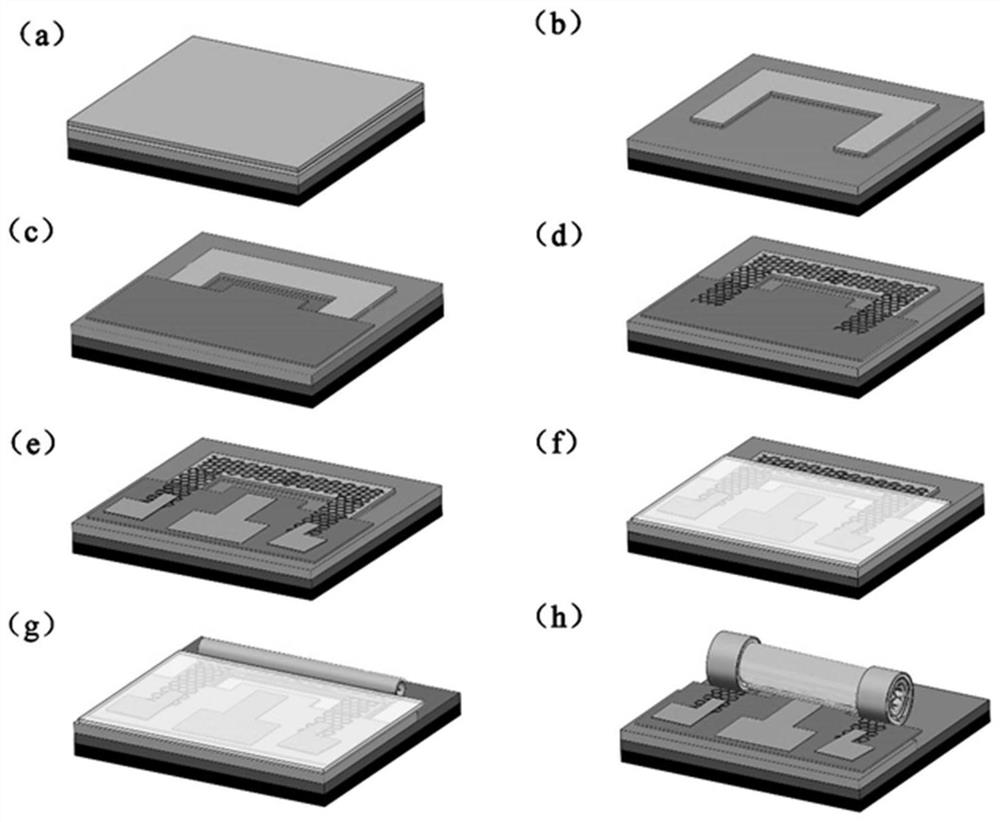

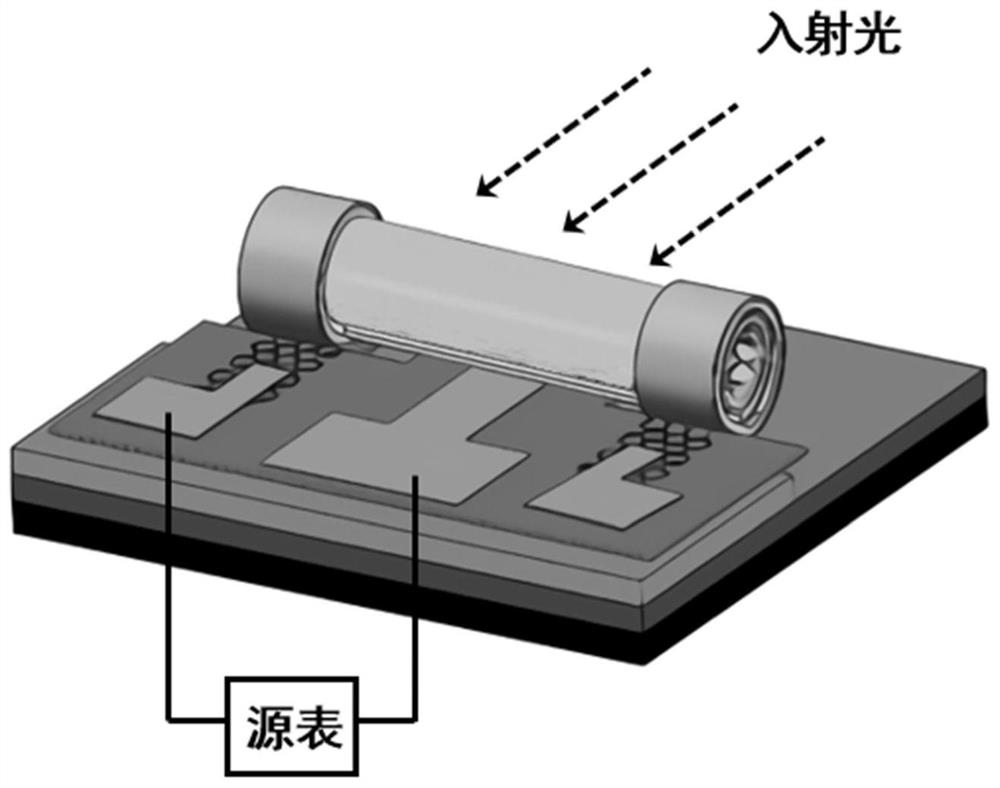

Micro-tube type three-dimensional heterojunction device structure and preparation method and application thereof

ActiveCN112151629ASolve the problem of unpreparableAchieve electrical contactFinal product manufacturePhotovoltaic energy generationHeterojunctionElectronic component

The invention relates to a micro-tube type three-dimensional heterojunction device structure and a preparation method and application thereof. The micro-tube type three-dimensional heterojunction device structure comprises a micro-tube type semiconductor two-dimensional material three-dimensional heterojunction, an inner wall electrode, an outer wall electrode and a substrate, the inner wall electrode is only in electric contact with the inner wall material of the micro-tube type three-dimensional heterojunction; the outer wall electrode is only in electric contact with the outer wall materialof the micro-tube type three-dimensional heterojunction; the inner wall electrode and the outer wall electrode are insulated from the substrate; the micro-tube type semiconductor two-dimensional material three-dimensional heterojunction is a tubular three-dimensional heterojunction formed by self-curling of a semiconductor two-dimensional material planar heterojunction located on the substrate. The problem that a tubular three-dimensional heterojunction device cannot be prepared is solved, the process is simple, the preparation of the micro-tube three-dimensional heterojunction and electric contact between the outer wall material and the outer wall electrode can be achieved at the same time, it is guaranteed that current only passes through the micro-tube three-dimensional heterojunctionin the radial direction instead of a planar heterojunction, and the structure can be widely applied to the fields of photoelectric detection, photovoltaics, gas sensing, electronic components and thelike.

Owner:BEIJING UNIV OF POSTS & TELECOMM

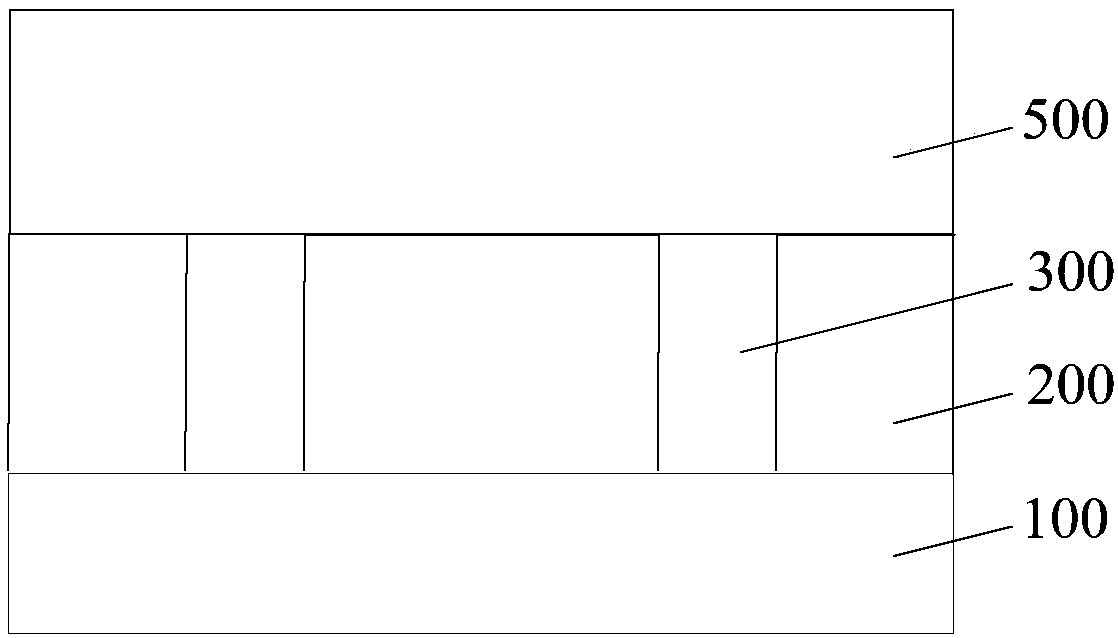

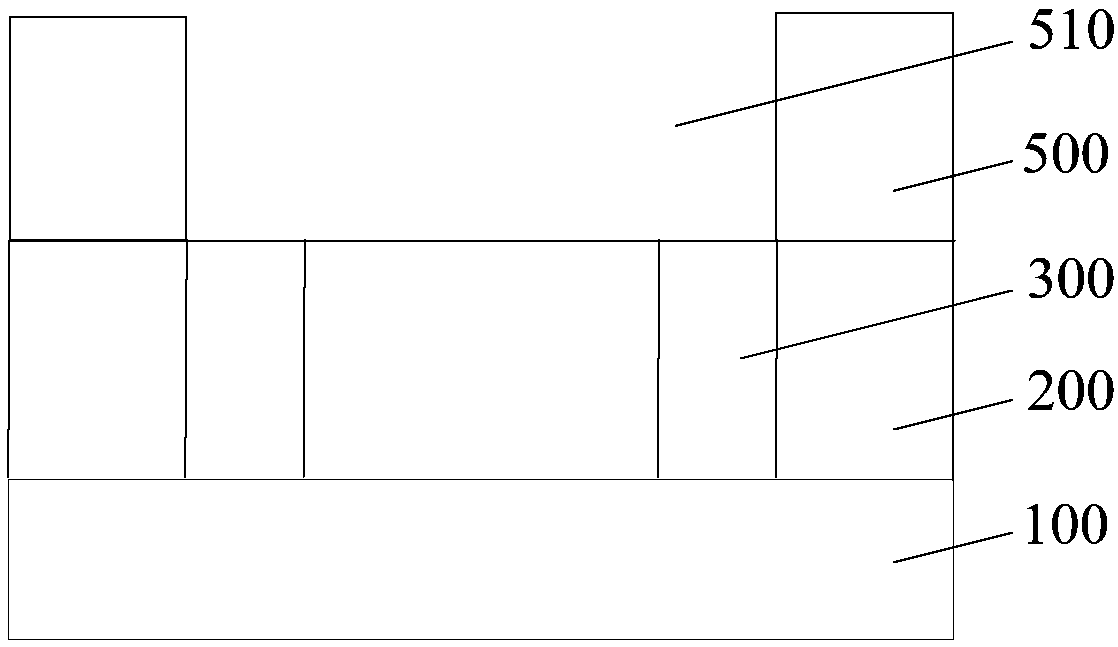

Phase change memory and preparation method thereof

PendingCN109755384AImprove pass ratePrecise alignmentElectrical apparatusPhase-change memoryDielectric layer

The invention relates to a phase change memory and a preparation method thereof. The preparation method comprises the steps that a substrate is provided, wherein a dielectric layer is arranged on thesubstrate, and a groove penetrating through the thickness of the dielectric layer is formed in the dielectric layer; the groove is filled with a conductive layer, and the top of the conductive layer is lower than the top of the dielectric layer; and a heating electrode layer is formed on the top of the conductive layer and on the side wall of the groove exposed by the conductive layer. The preparation method can realize accurate alignment of the heating electrode layer and the conductive layer, is small in implementation difficulty, and is beneficial to improving the product qualification rateof the prepared phase change memory.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Multi-contact tactile sensor including variable-size and -impedance spacing means

InactiveCN102144272AProblems that limit false detectionAchieve electrical contactMicroprotrusions contactsMovable contactsInteraction layerComputational physics

Owner:STANTUM

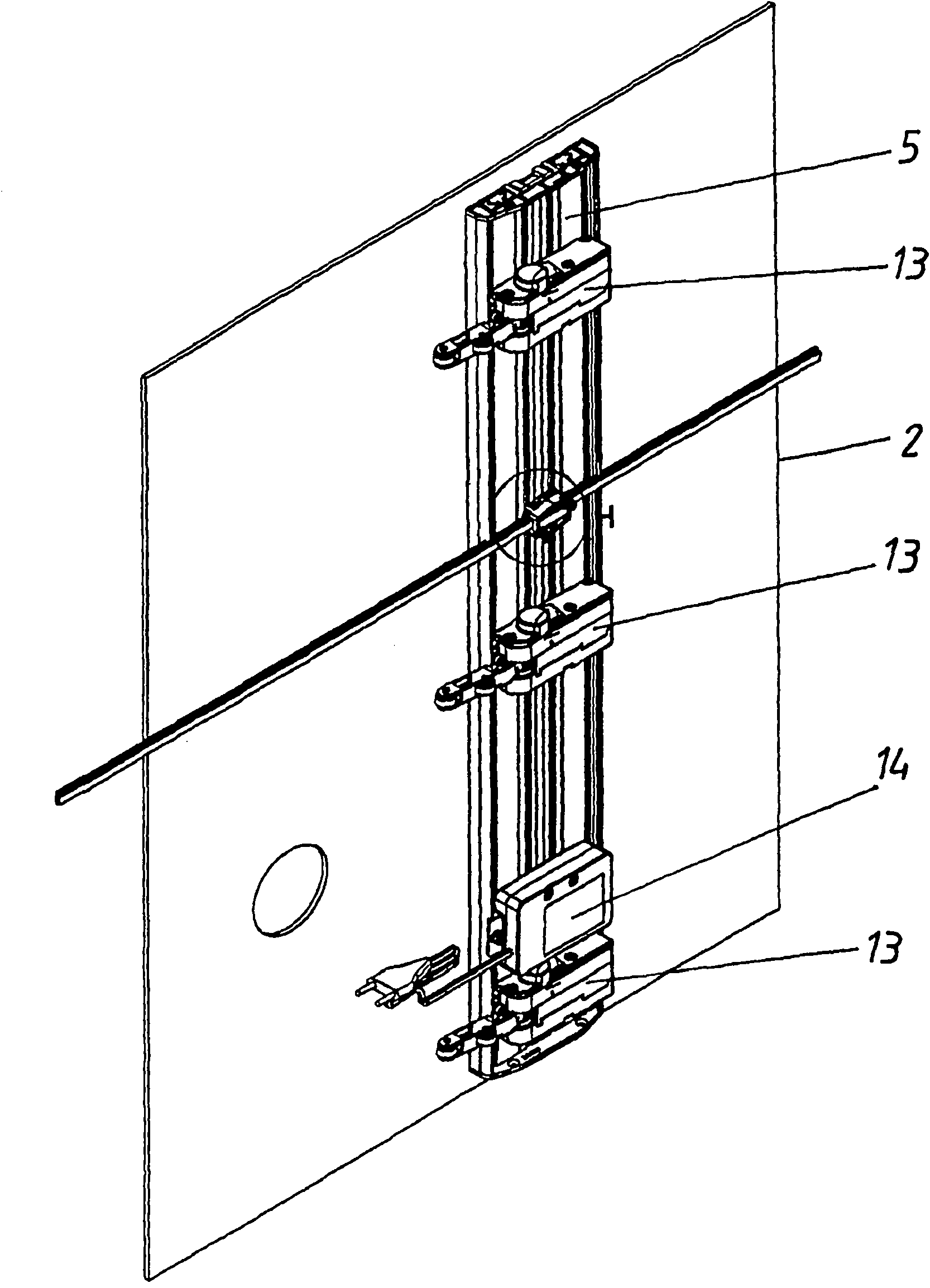

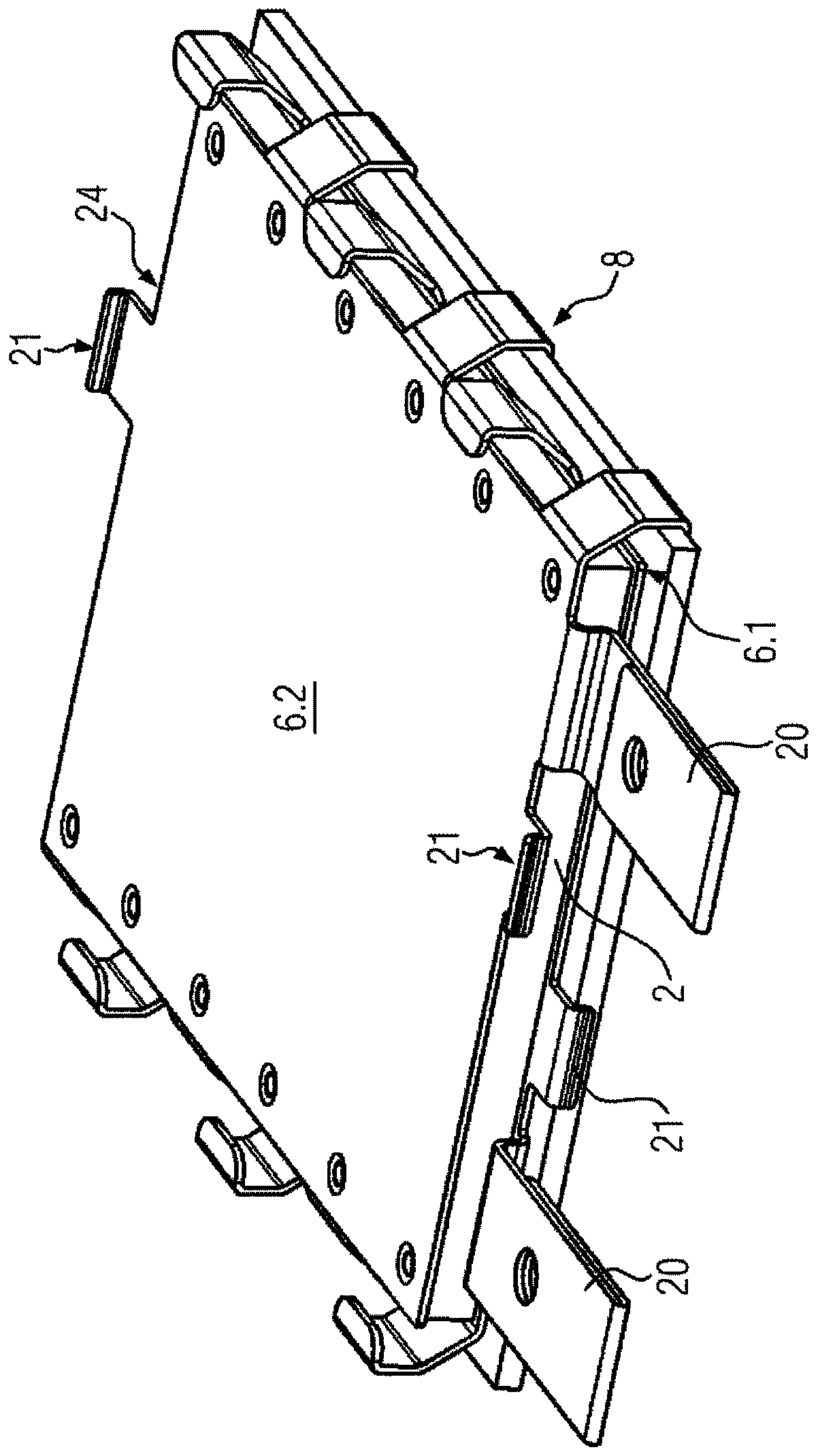

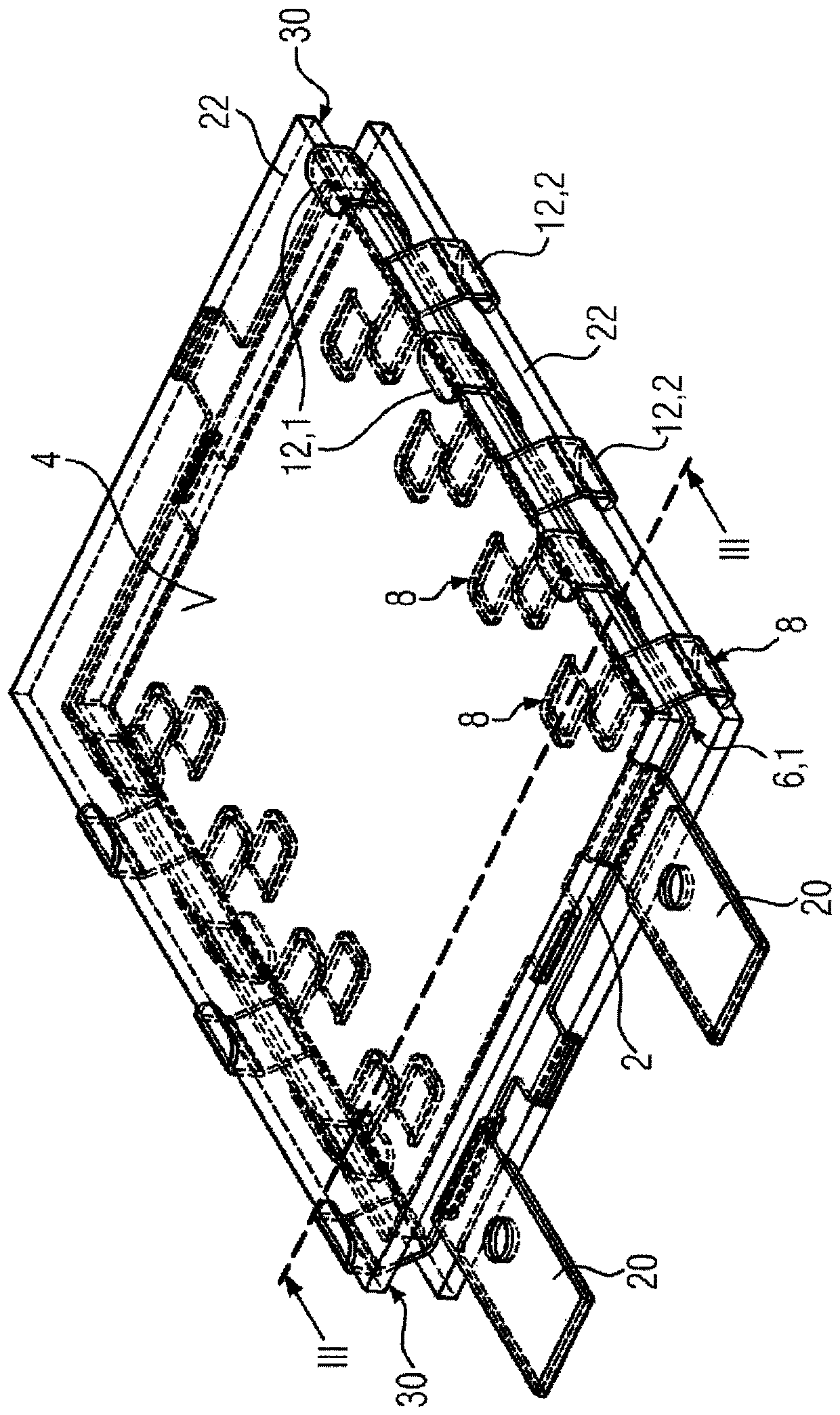

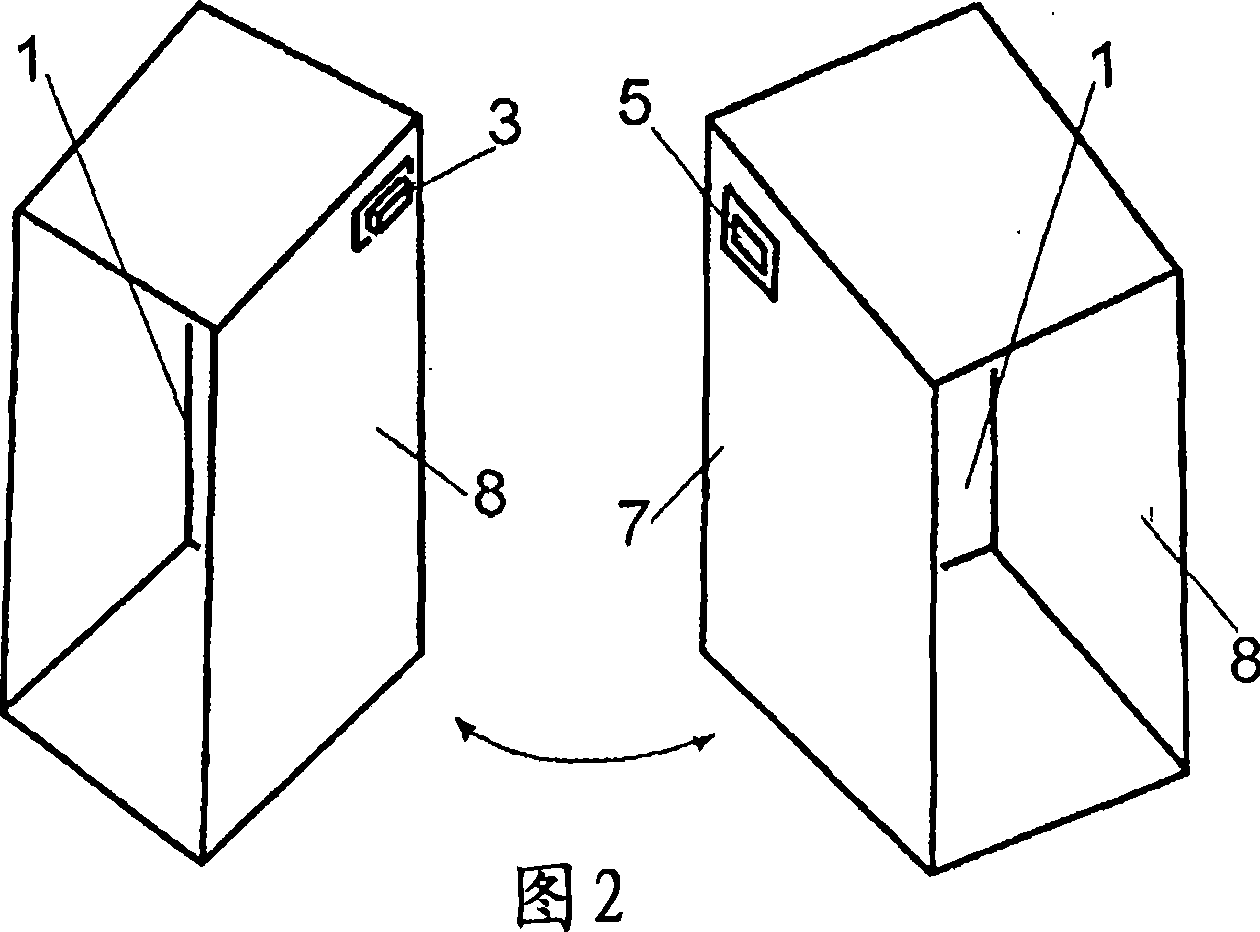

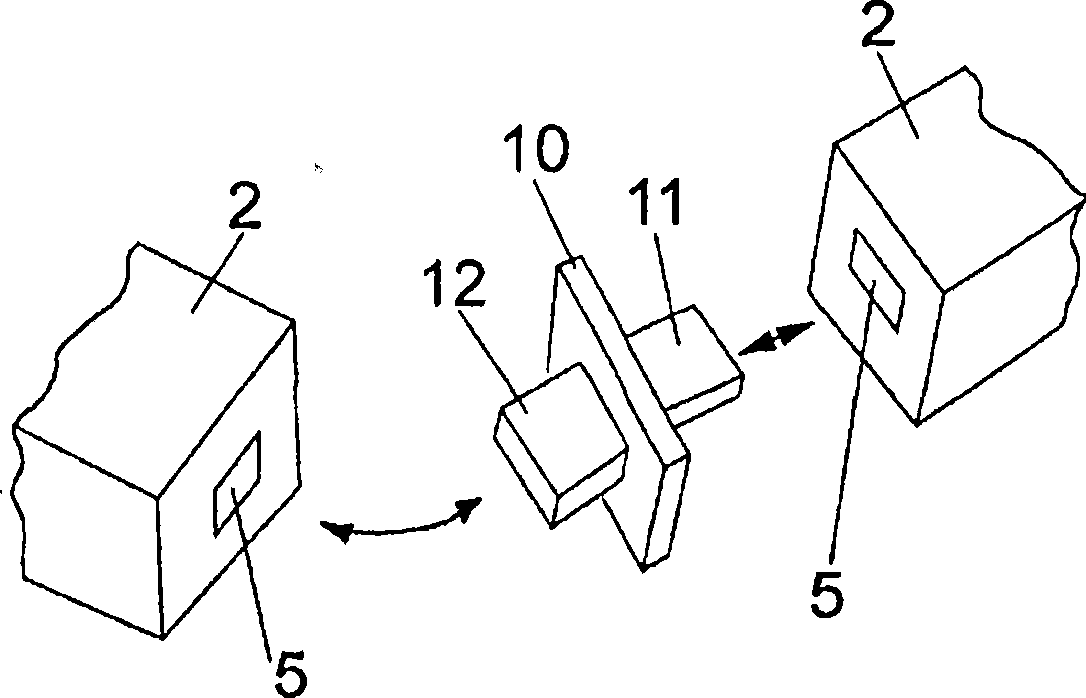

Piece of furniture having a drawer and current consumer

InactiveCN102143699AContact automaticAutomatic electrical contactDrawersElectrical connectionElectrical contacts

A furniture (1) includes a furniture body (2), a carrier element (5) that can be attached to the furniture body (2) of the furniture and a movable furniture portion. A power consumer is arranged on the furniture portion. At least one power supply unit (6) for the power consumer is disposed releaseably on the carrier element. A chargeable current storage means is arranged in or on the movable furniture portion, wherein the power supply unit charges up the current storage means by way of contact locations in the closed position of the movable furniture portion, the electrical connection between the power supply unit and the current storage means is separated when the furniture portion is opened, the current storage means is connected to the current consumer and supplies same with current in the opened position of the furniture portion. An electric line arranged in or on the carrier element is connected to an external power source and which can be connected to the power supply unit. When the power supply unit is mounted to the carrier element electrical contact is automatically effected with the electric line, and the power supply unit can contact the electric line with piercing pins.

Owner:JULIUS BLUM GMBH

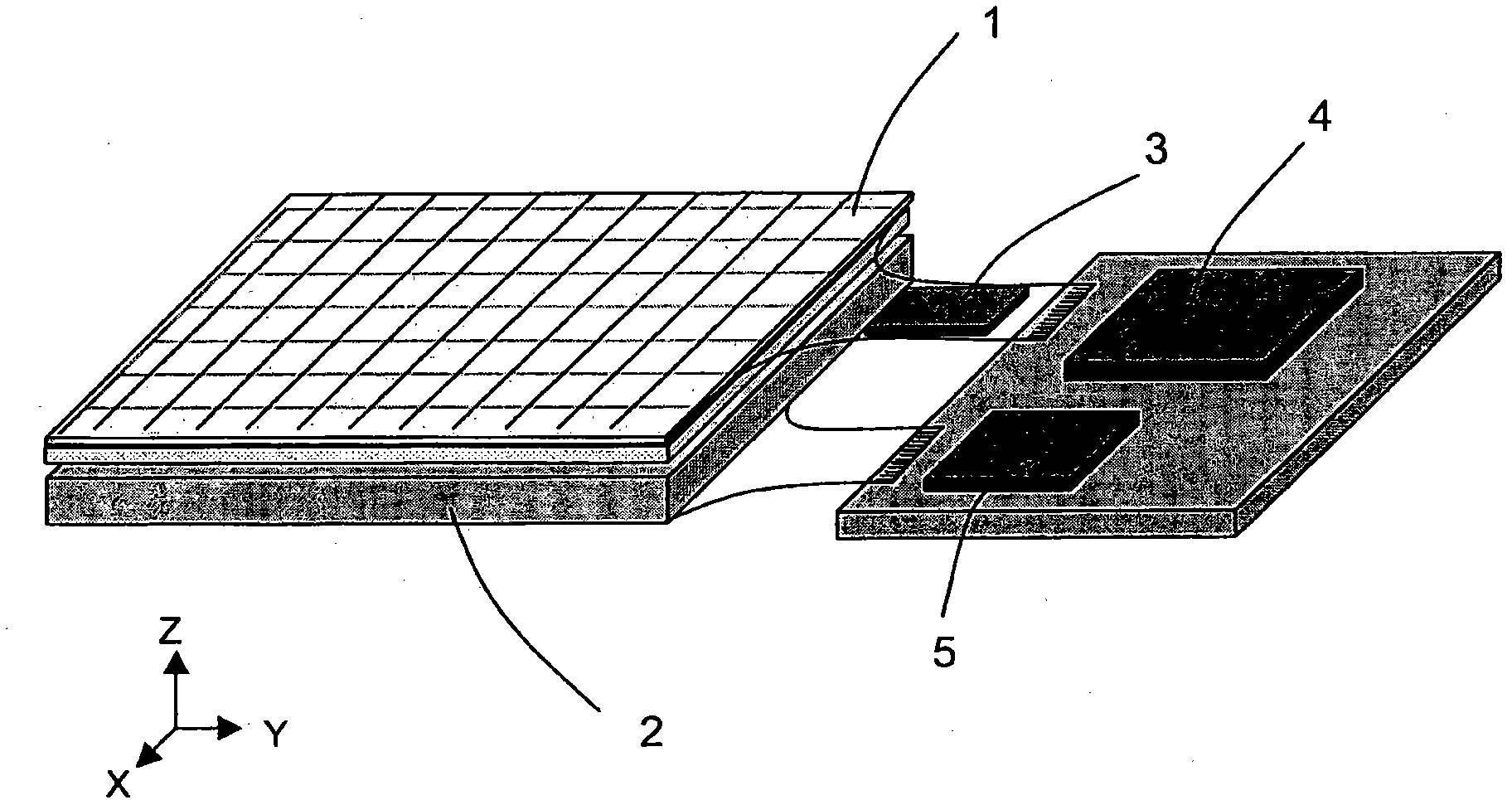

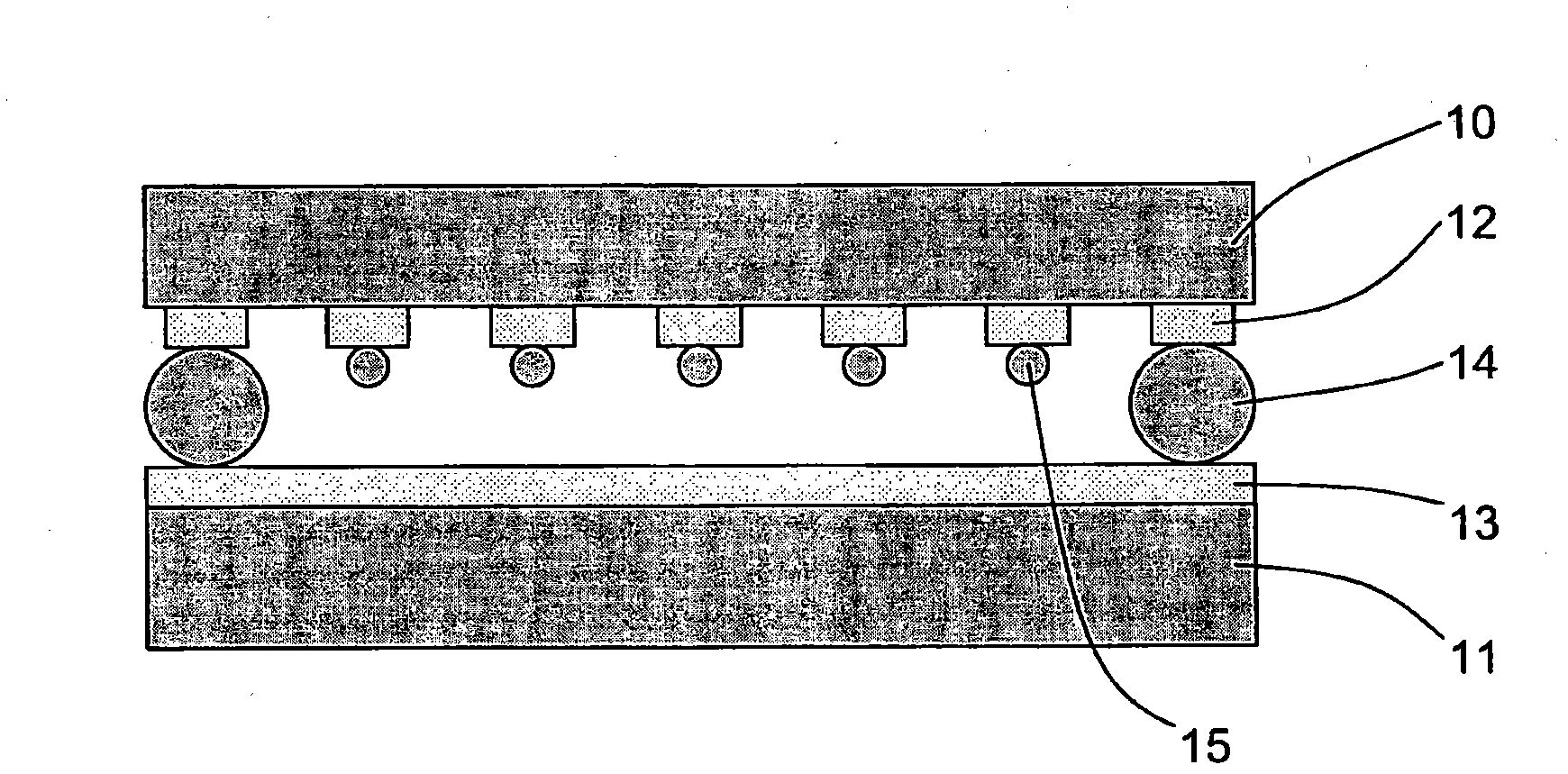

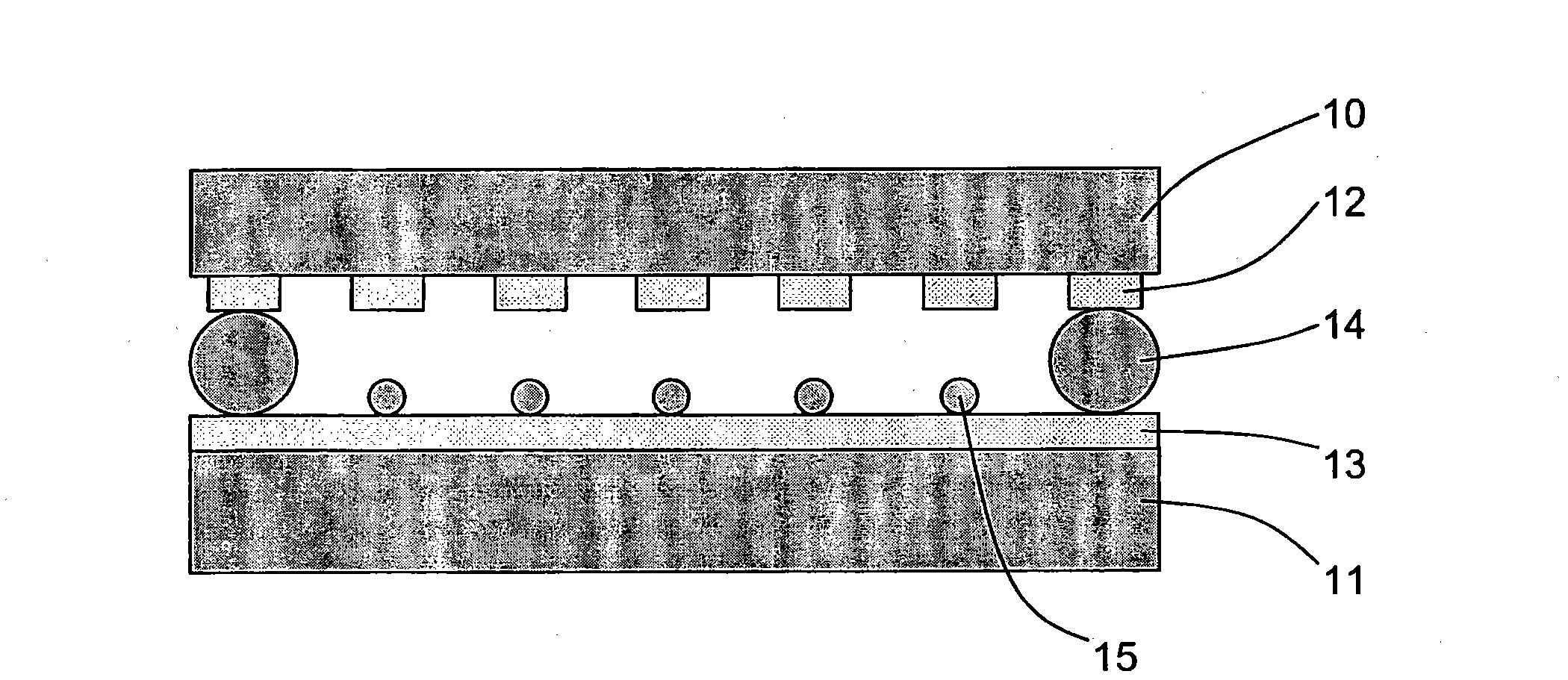

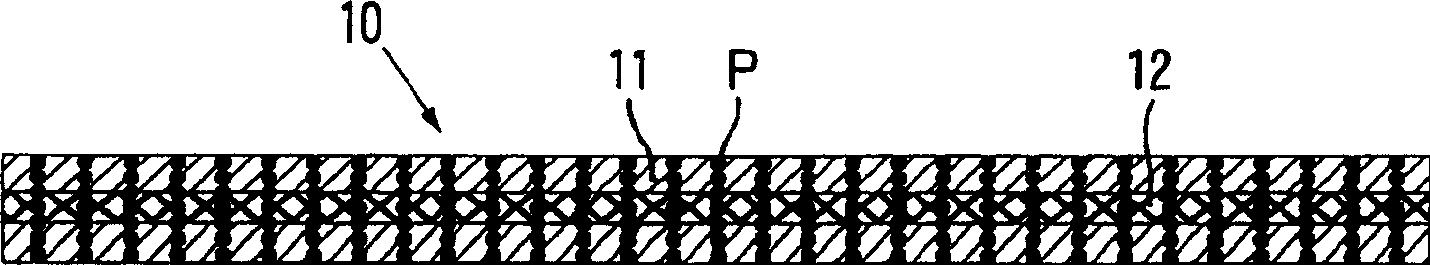

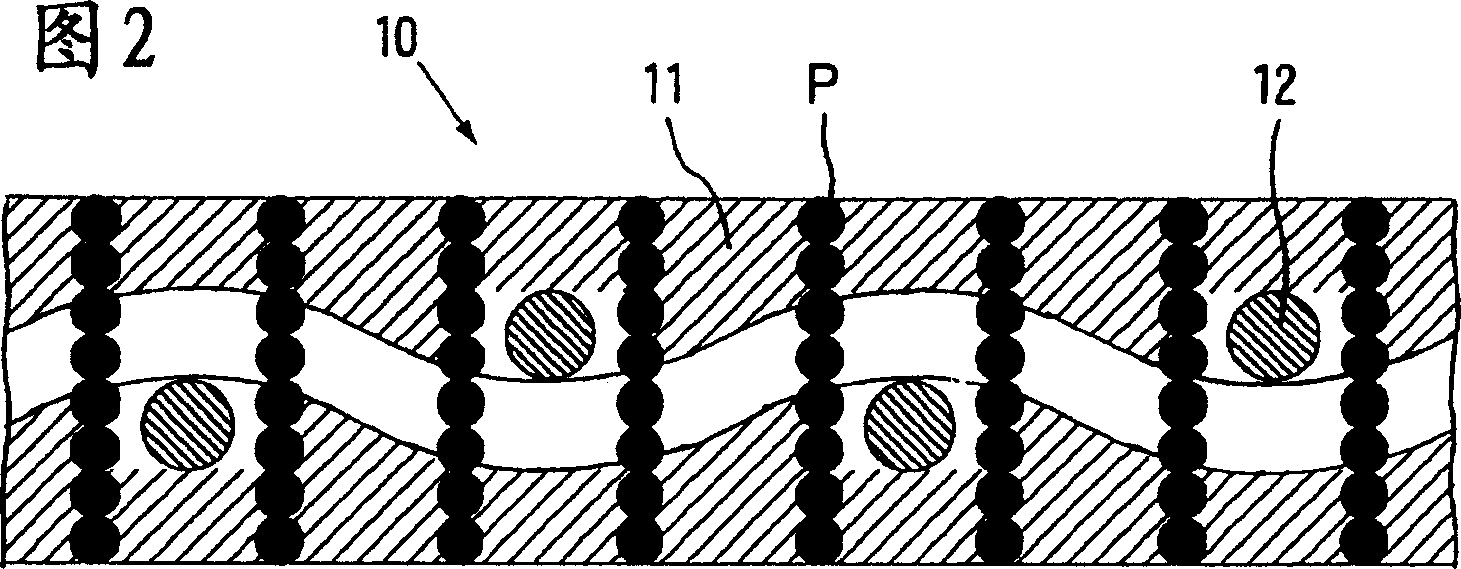

Anisotropic conductive sheet, its manufacturing method, and inspection device for circuit board

InactiveCN1842940AReduce thicknessHigh resolutionNon-insulated conductorsElectronic circuit testingEngineeringPolymer

Disclosed herein are an anisotropically conductive sheet that can retain necessary conductivity over a long period of time upon its repeated use even when its thickness is small, and thus permits achieving high resolving power and long service life, a production process thereof, and an inspection apparatus for circuit boards equipped with this anisotropically conductive sheet. The anisotropically conductive sheet of the invention comprises a base material composed of an insulating elastic polymeric substance and a great number of conductive particles exhibiting magnetism, which are contained in the base material in a state oriented in a thickness-wise direction of the sheet to form chains, wherein an insulating reinforcing material formed of mesh is contained in the base material. The production process of the anisotropically conductive sheet of the invention comprises preparing a molding material with conductive particles exhibiting magnetism contained in a polymeric substance-forming material, which will become an elastic polymeric substance by being cured, forming a molding material layer containing a reinforcing material formed of mesh in a state immersed in the molding material, and subjecting the molding material layer to a curing treatment while applying or after an application of a magnetic field to the molding material layer in a thickness-wise direction thereof.

Owner:JSR CORPORATIOON

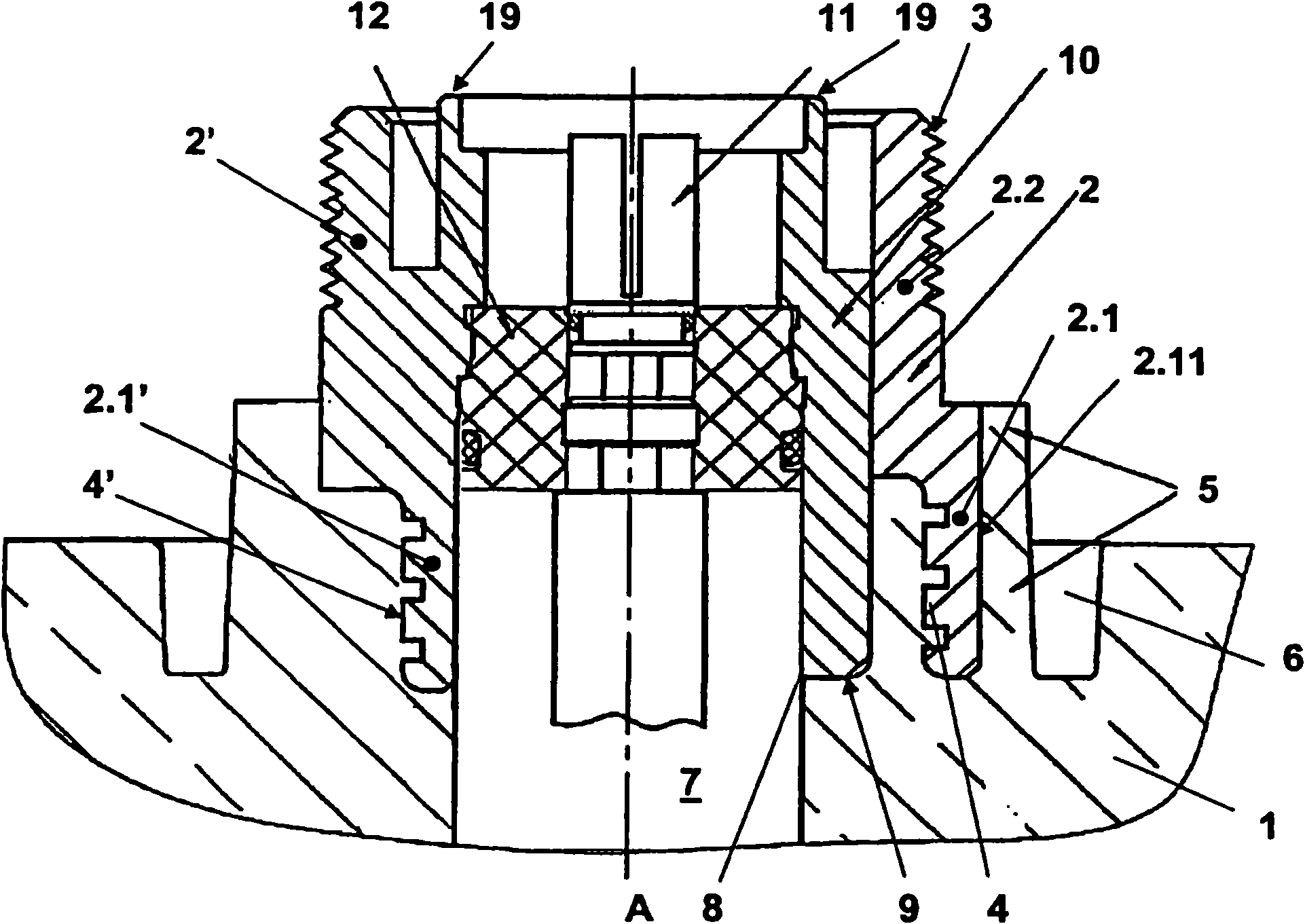

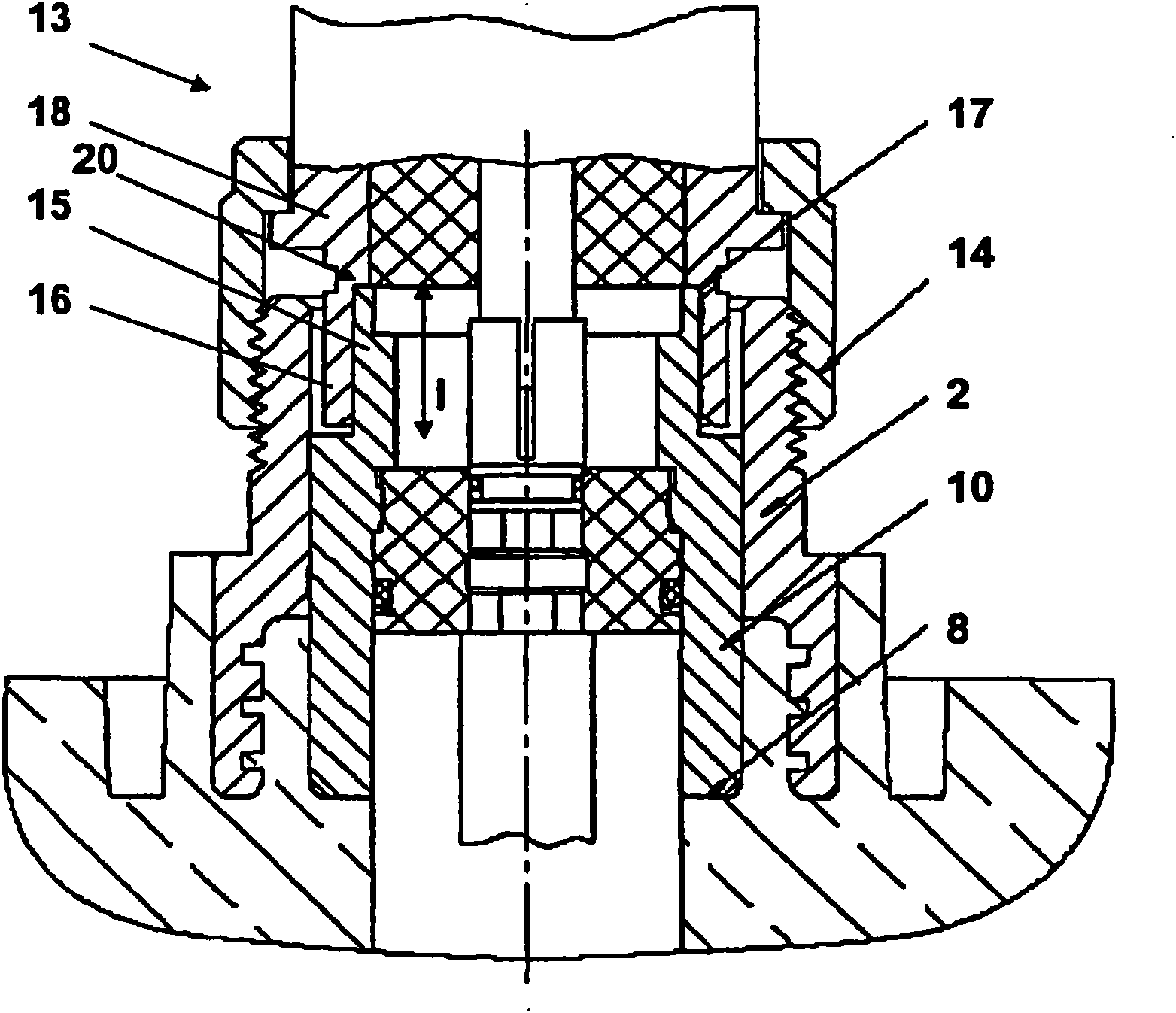

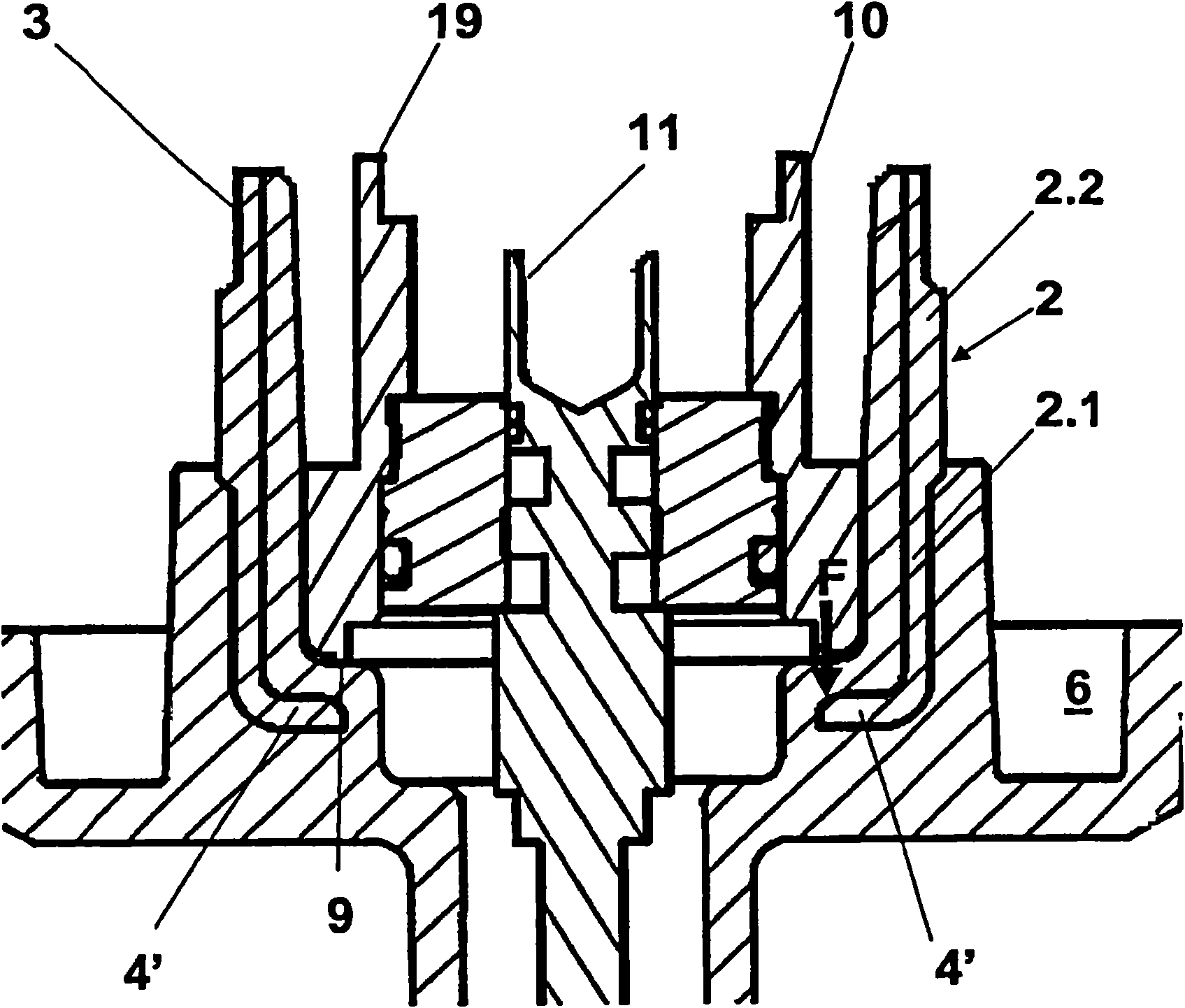

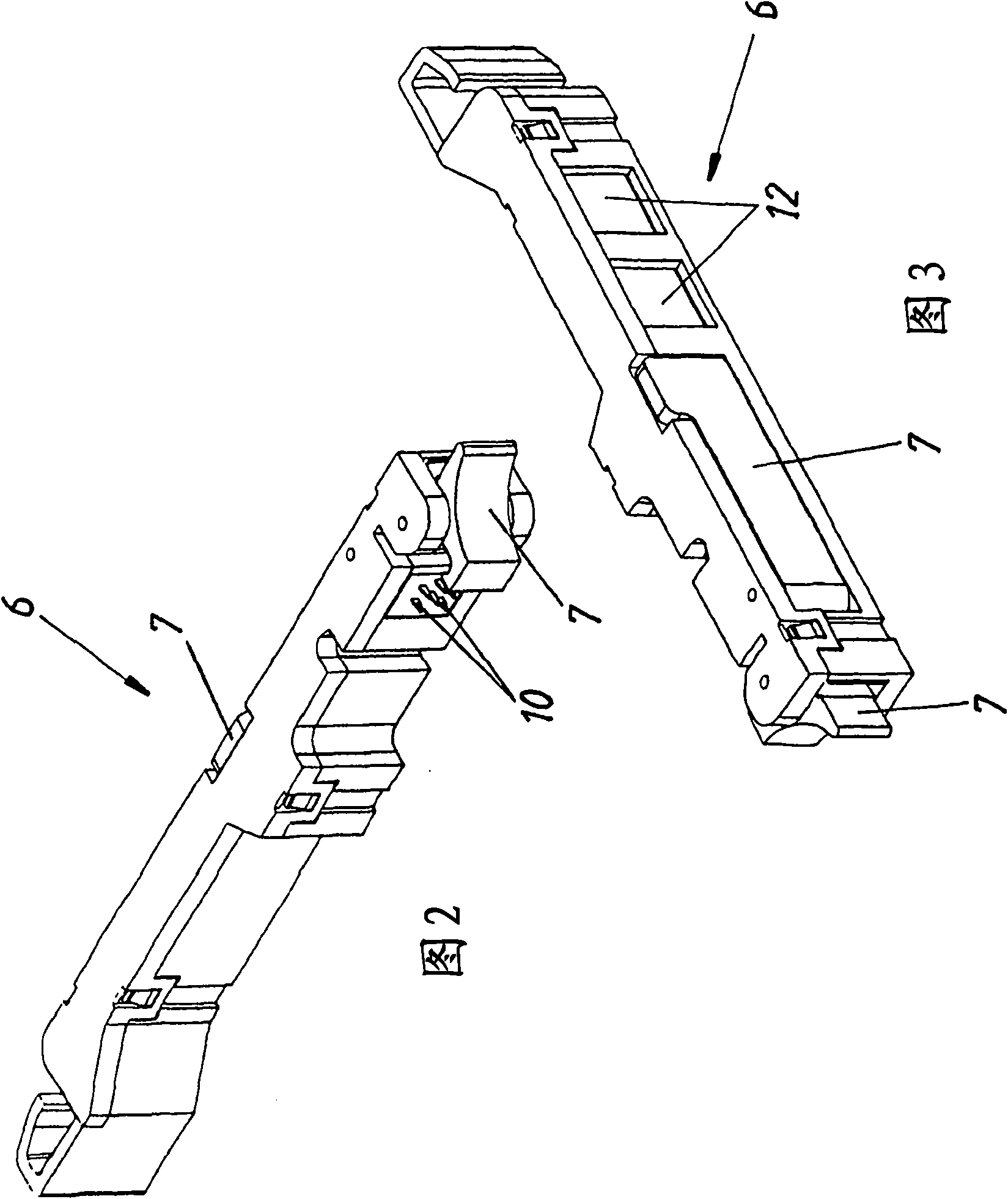

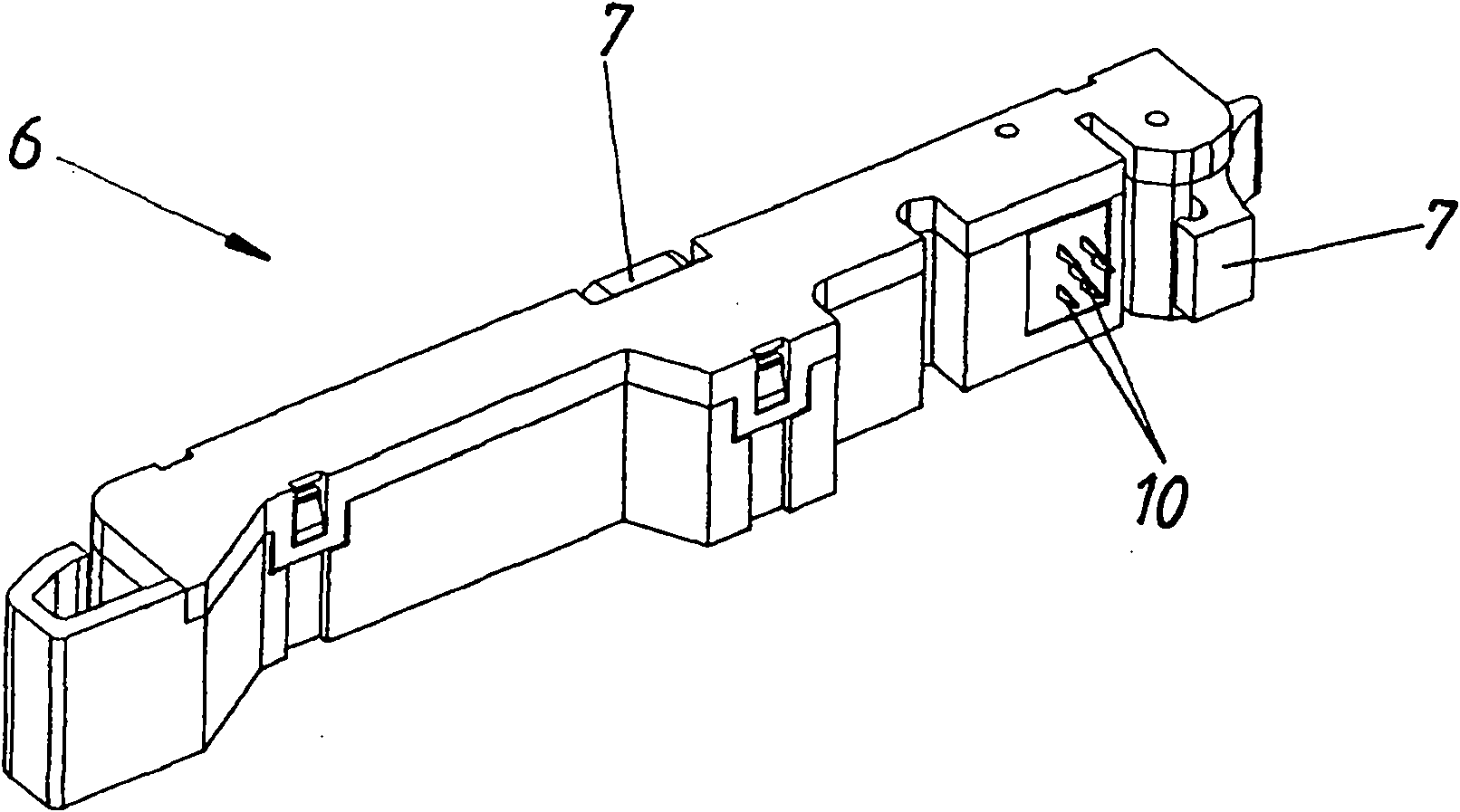

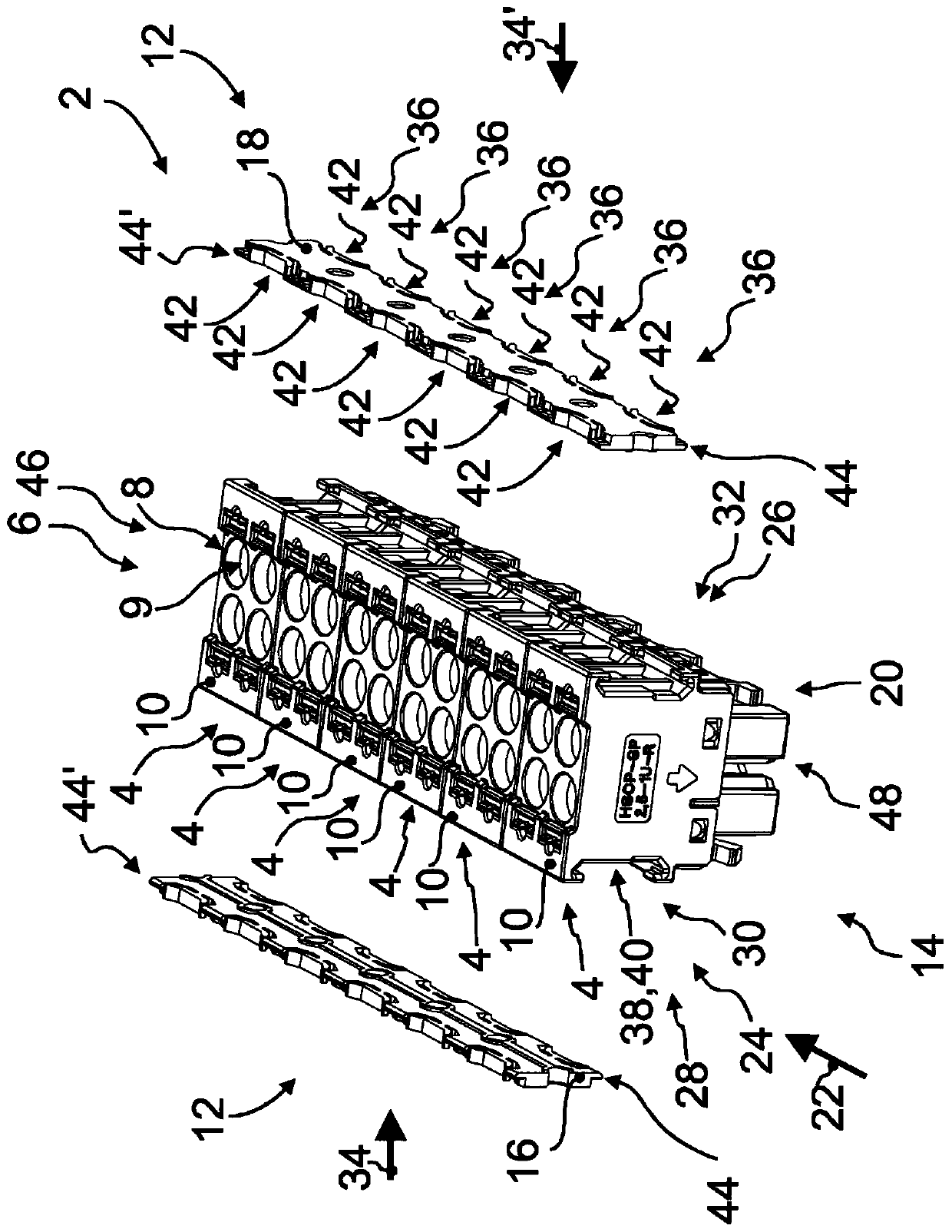

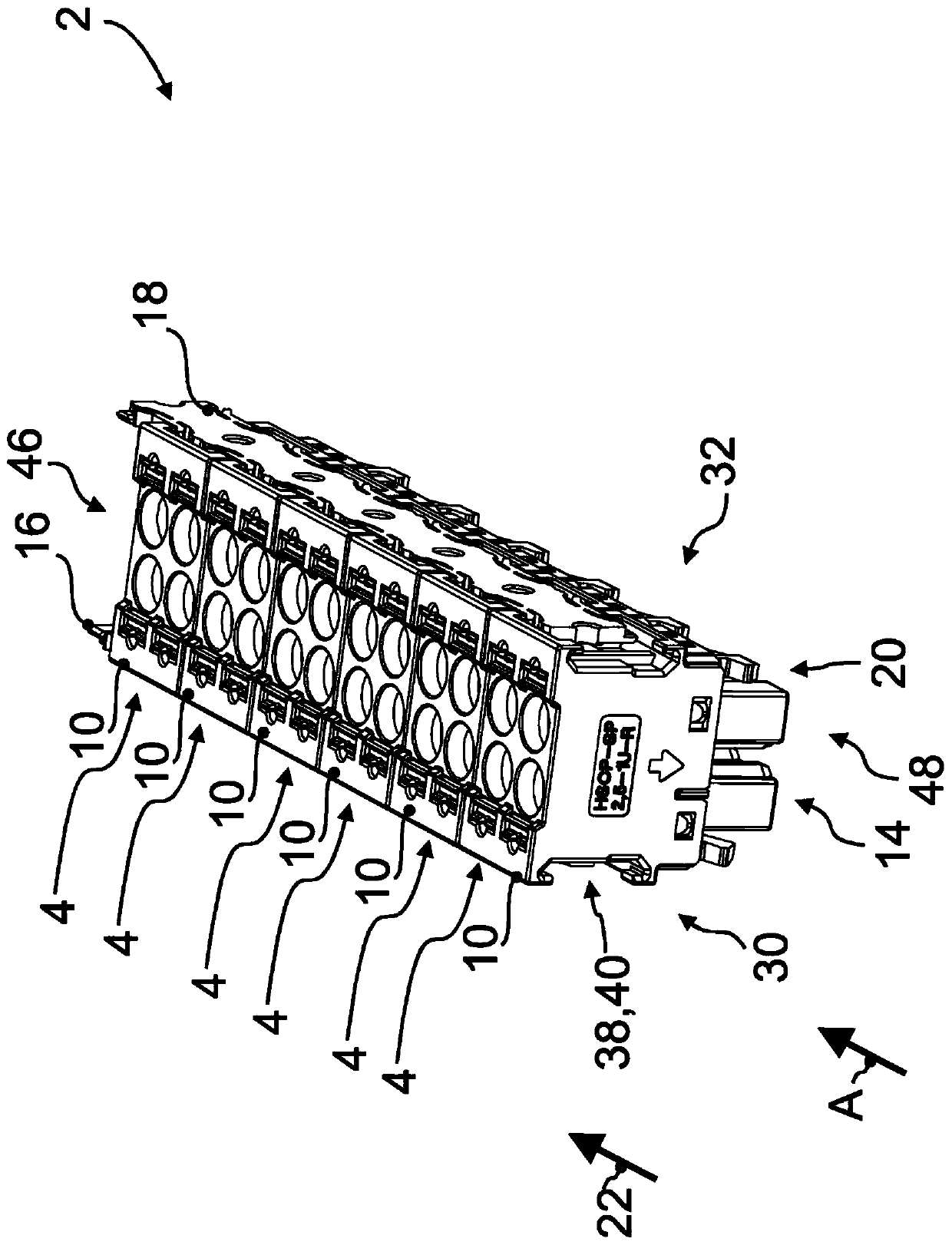

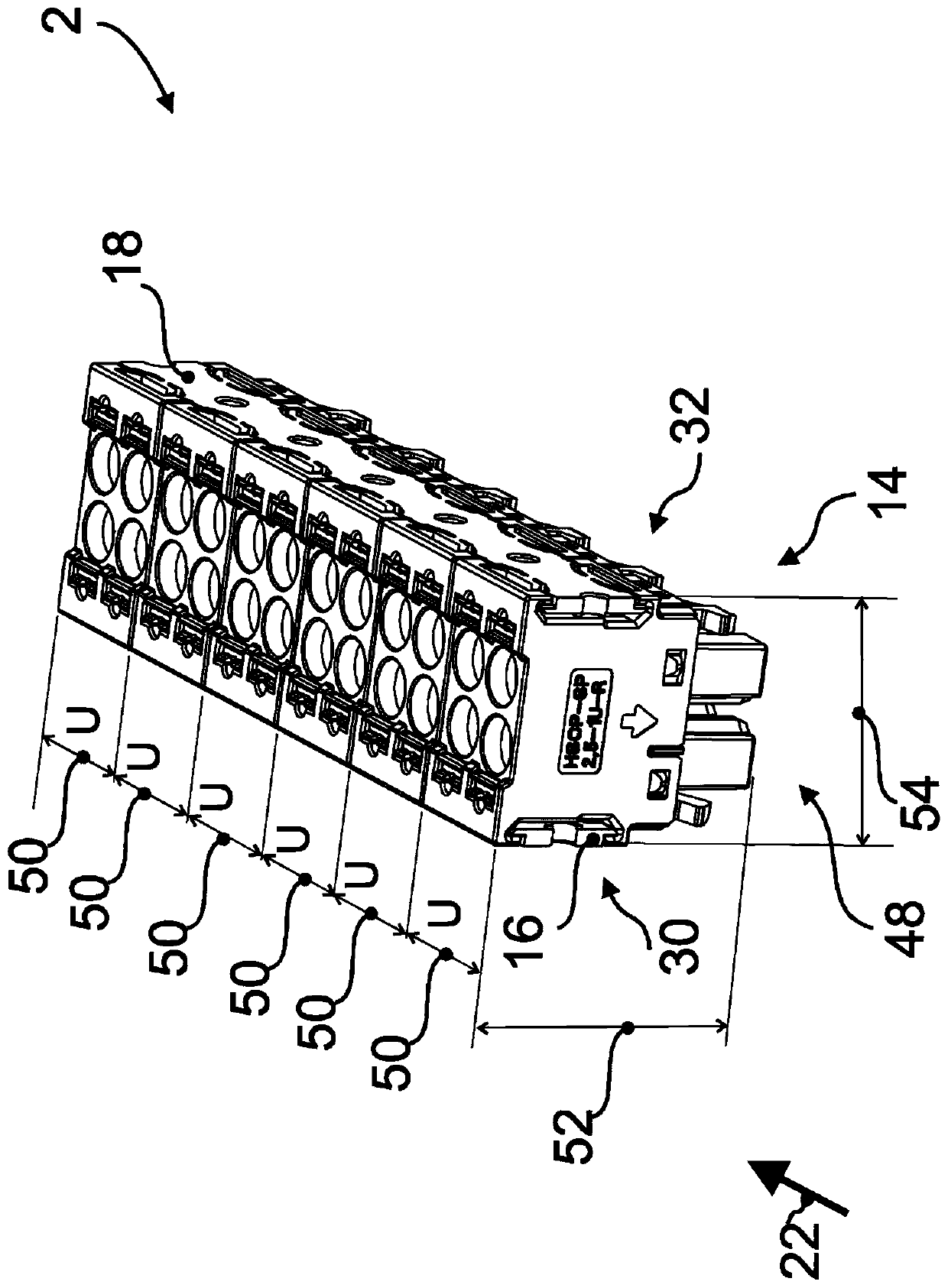

Modular connection block with a plurality of connection modules for an electronic component

ActiveCN111108652AReduce the numberIncrease freedomCoupling device detailsElectrical connectionElectronic component

Abstract The invention relates to a modular connection block (2, 2') with a plurality of electrical connection modules (4) for conductor connection to an electronic component (66), wherein the connection modules (4) each have a 5 connection housing (10) which are held together in a grouping (14) by holding means (12). The holding means (12) have at least one strip-like connecting element (16, 18,56, 58), by means of which the connection housings (10) are connected, wherein the connection housings (10) are arranged next to one another along the strip-like connecting element (16, 18, 56, 58) ina 10 row arrangement (20, 20', 20'').

Owner:PHOENIX CONTACT GMBH & CO KG

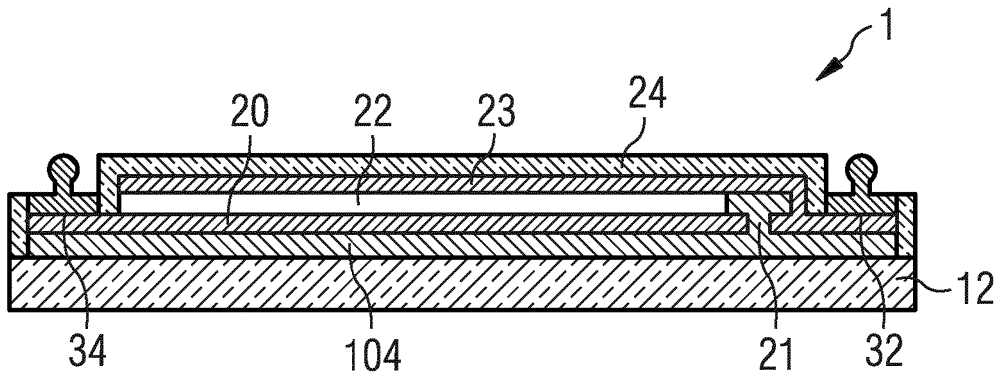

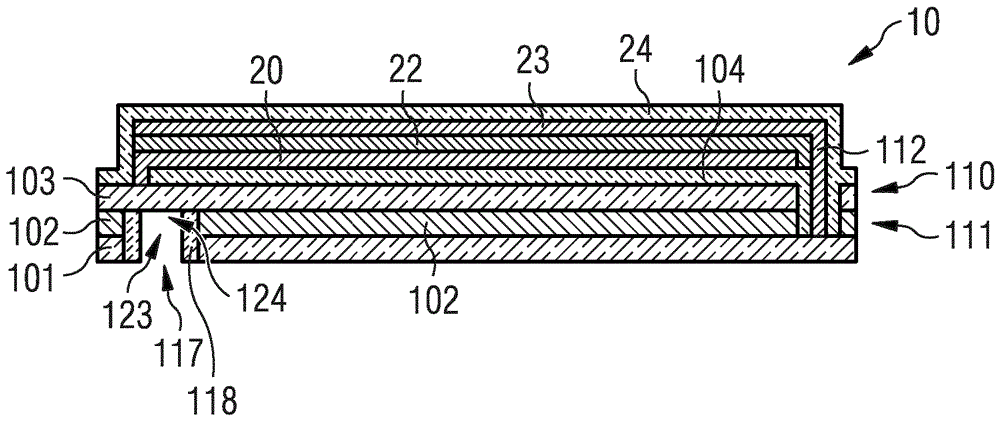

Optoelectronic component and method for producing same

ActiveCN106663744AReduce contact resistanceImprove efficiencySolid-state devicesSemiconductor/solid-state device manufacturingElectronElectrically conductive

An optoelectronic component (10) and a method for producing same are provided in various exemplary embodiments. The optoelectronic component (10) has a first electrically conductive contact layer (101), an electrically insulating layer (102) over the first electrically conductive contact layer (101), a second electrically conductive contact layer (103) over the electrically insulating layer (102), a first electrically conductive electrode layer (20) over the second electrically conductive contact layer (103), at least one optically functional layer structure (22) over the first electrically conductive electrode layer (20) and a second electrically conductive electrode layer (23) over the optically functional layer structure (22). The second electrically conductive contact layer (103) comprises a first recess (110). The electrically insulating layer (102) comprises a second recess (111) which overlaps the first recess (110). An electrically conductive through-contact (112) is arranged in the first recess (110) and in the second recess (111), said through-contact being guided to the first electrically conductive contact layer (101). The electrically conductive through-contact (112) is electrically insulated with respect to the second electrically conductive contact layer (103).

Owner:OSRAM OLED

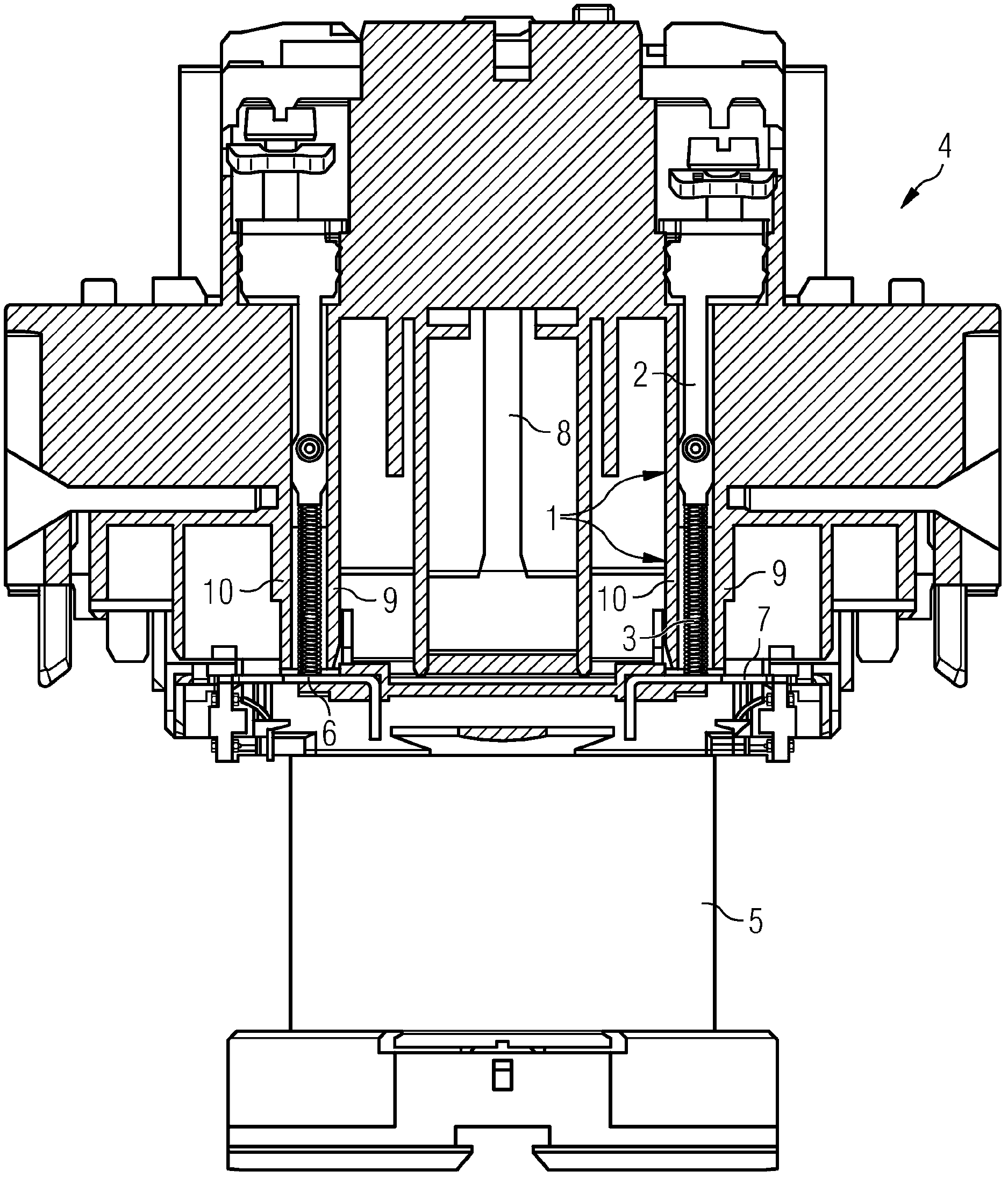

Connection device for a coil of an electromagnetic switching device

ActiveCN102473536AComponent Tolerance EffectsNot affected by toleranceCoupling contact membersElectromagnetic relay detailsElectrical and Electronics engineering

Owner:SIEMENS AG

Multifunctional dielectrophoresis operated micro-electrode on-chip system and its manufacture method

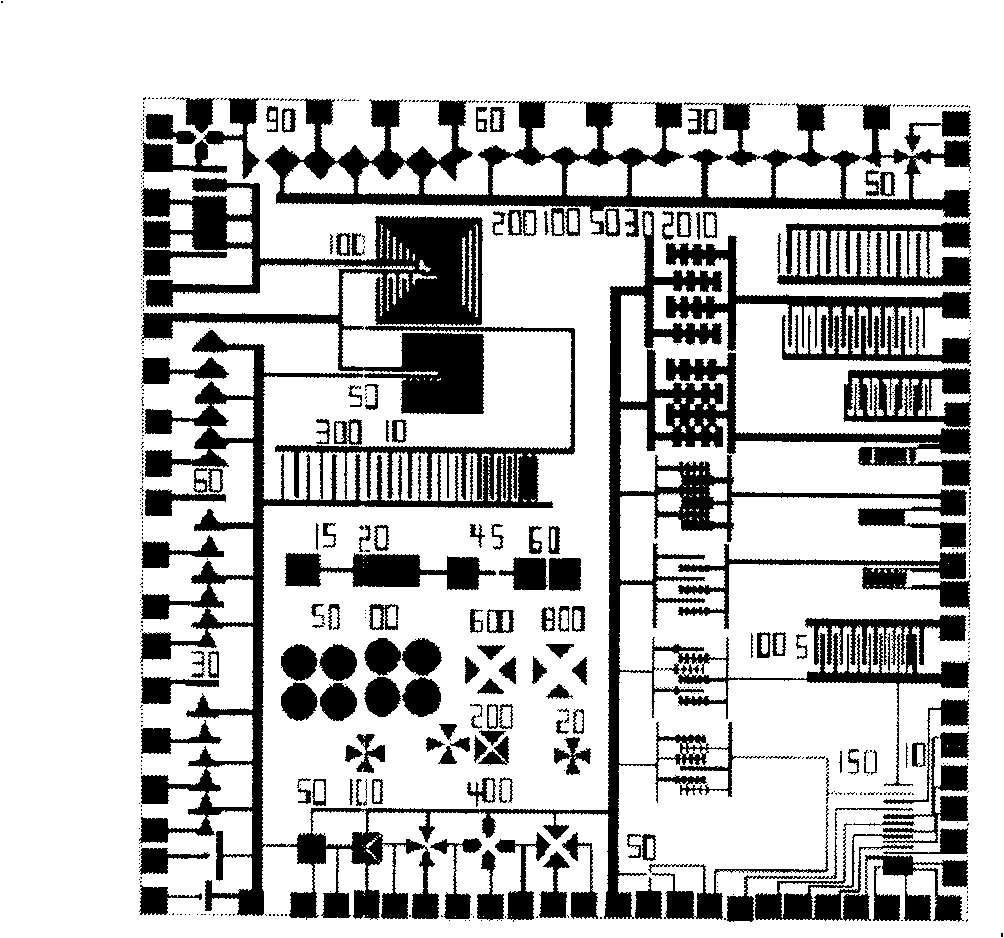

InactiveCN101307481ARealize separation operationAchieve electrical contactTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesHigh volume manufacturingEngineering

The invention discloses a multifunctional dielectrophoresis manipulated microelectrode SOC (system on a chip) and a method for making the same. The invention is characterized in that under the comprehensive consideration of influences of shape, distance, material and proportion of size of the microelectrode on the distribution of manipulating electric field and requirements of the dielectrophoresis manipulation in production study, the SOC is provided inside with a series of electrodes and arrays with different shapes and distances by the micro-processing technique in order to provide designs for microelectrodes and arrays with different shapes and distances needed for different materials waiting for manipulation. The products obtained by the method have the advantages that: 1. the mass production is realized by standard micro-processing technique, so that the cost is quite low; 2. the microelectrode SOC comprises shapes and sizes of usual electrodes needed for production study, so that the microelectrode SOC has wide adaptability.

Owner:EAST CHINA NORMAL UNIV

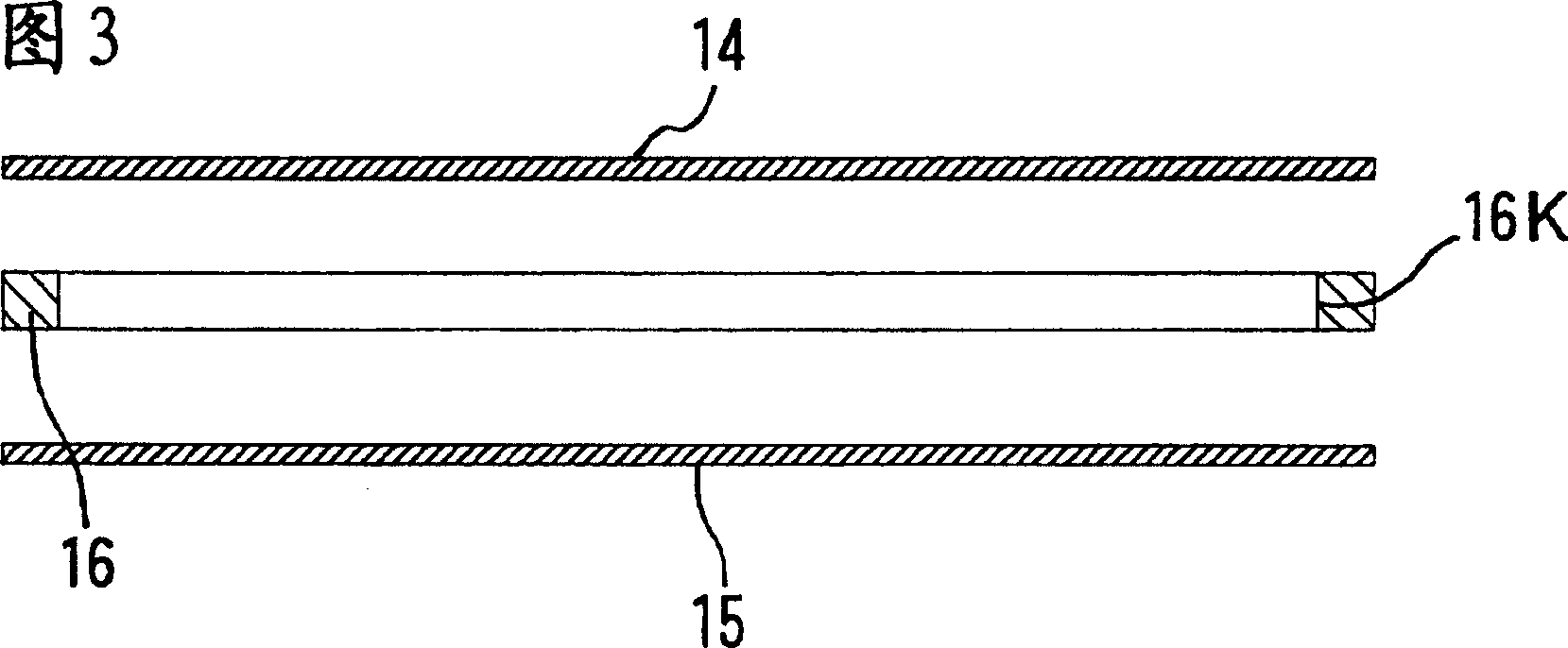

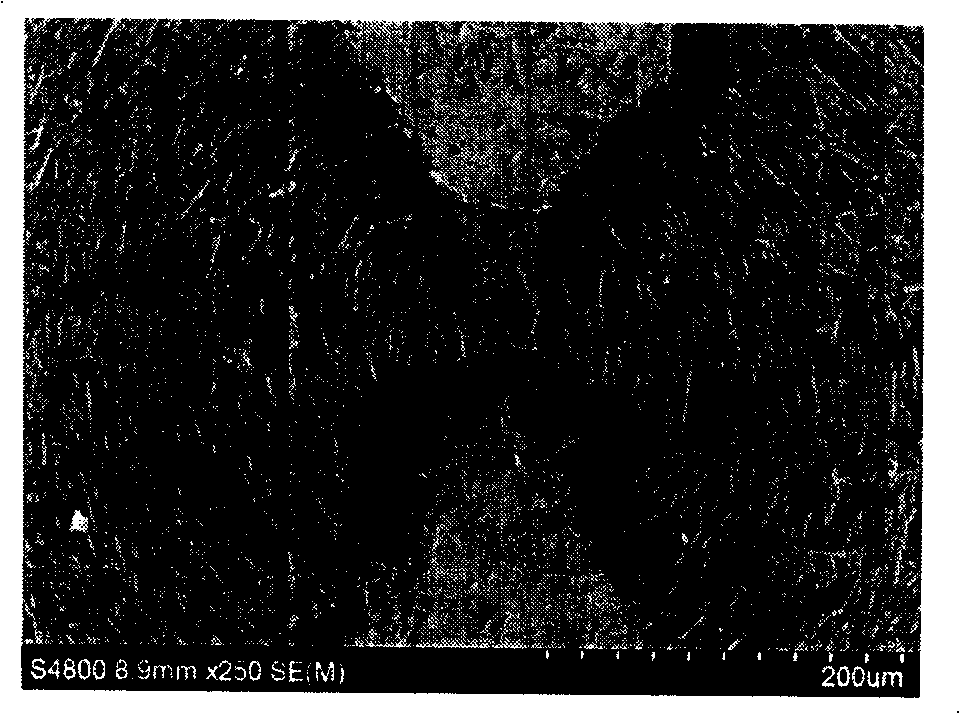

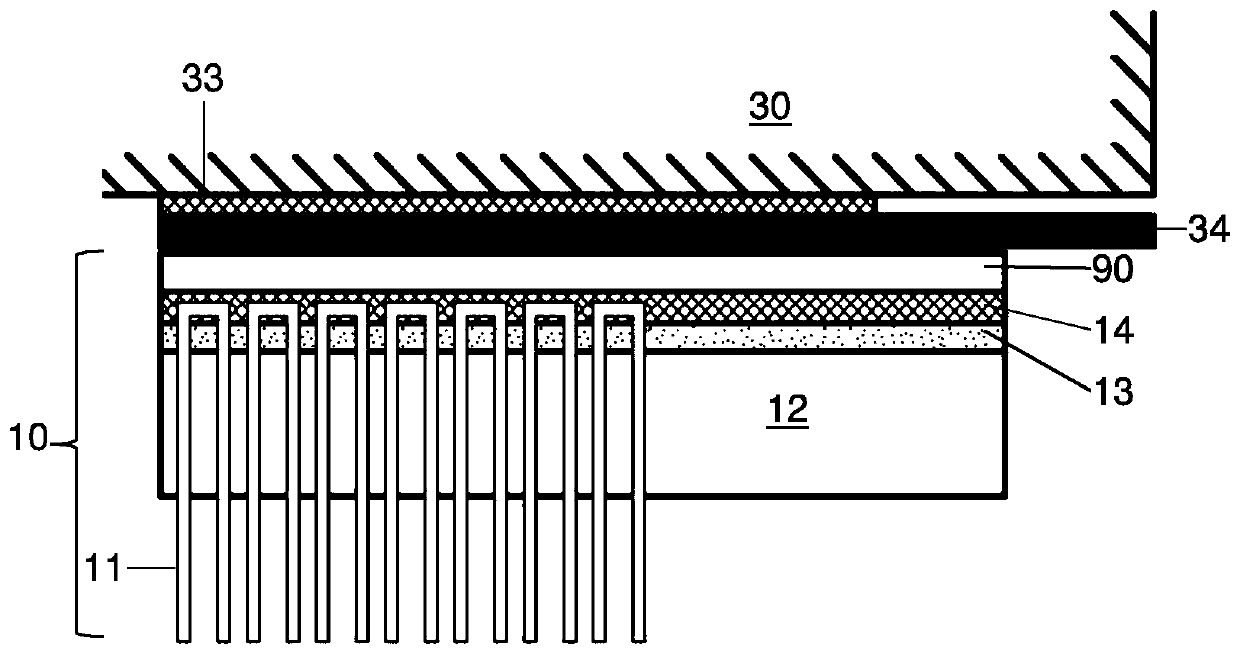

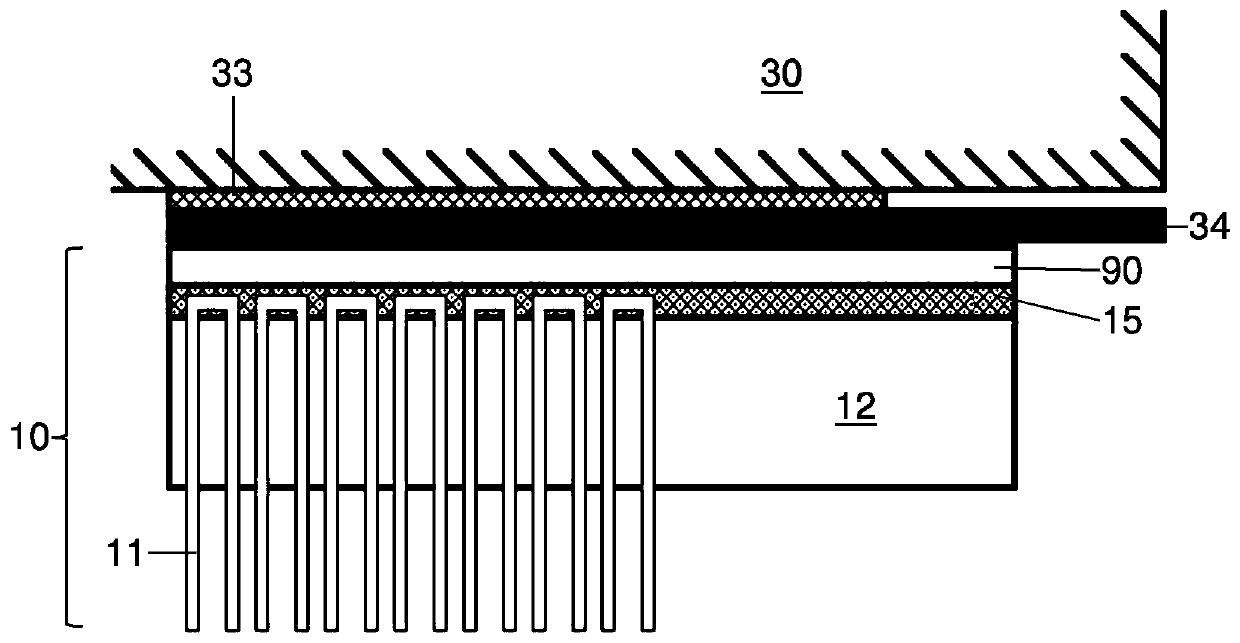

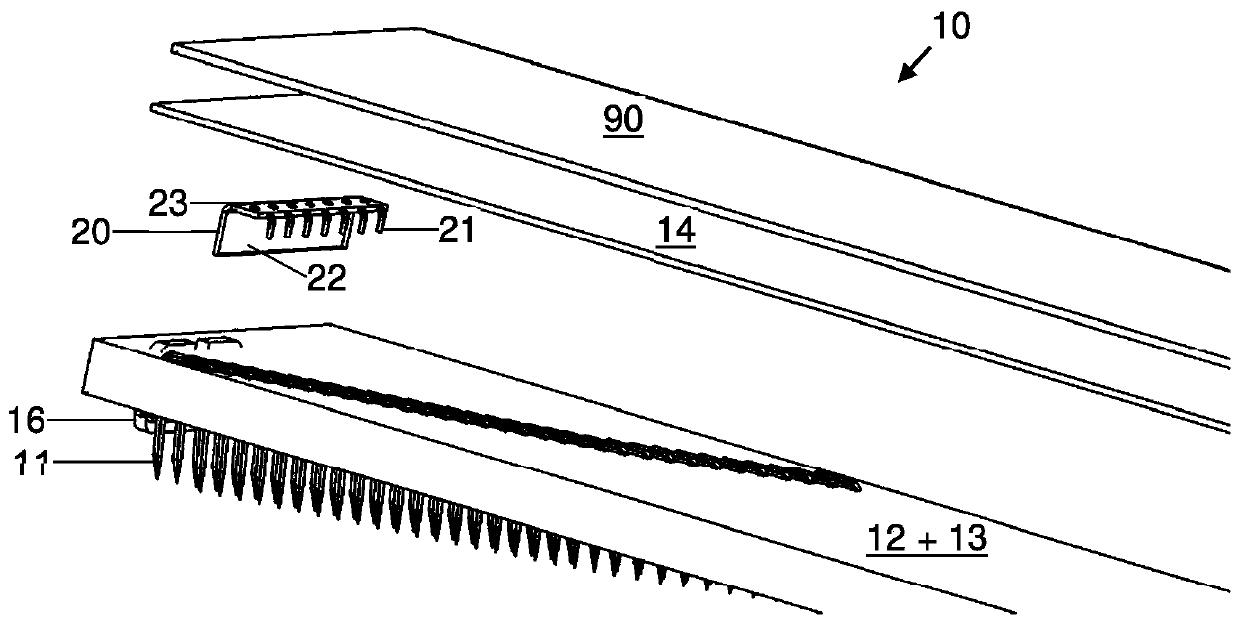

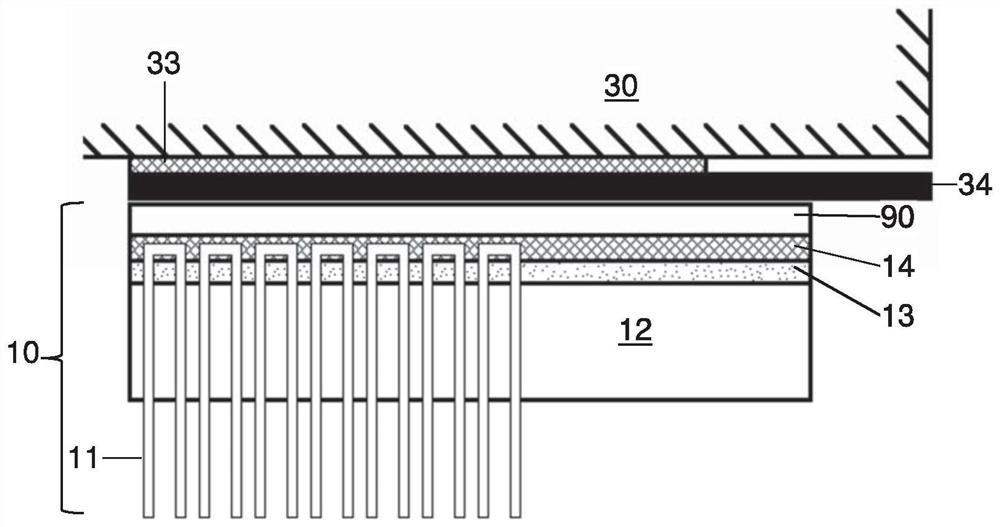

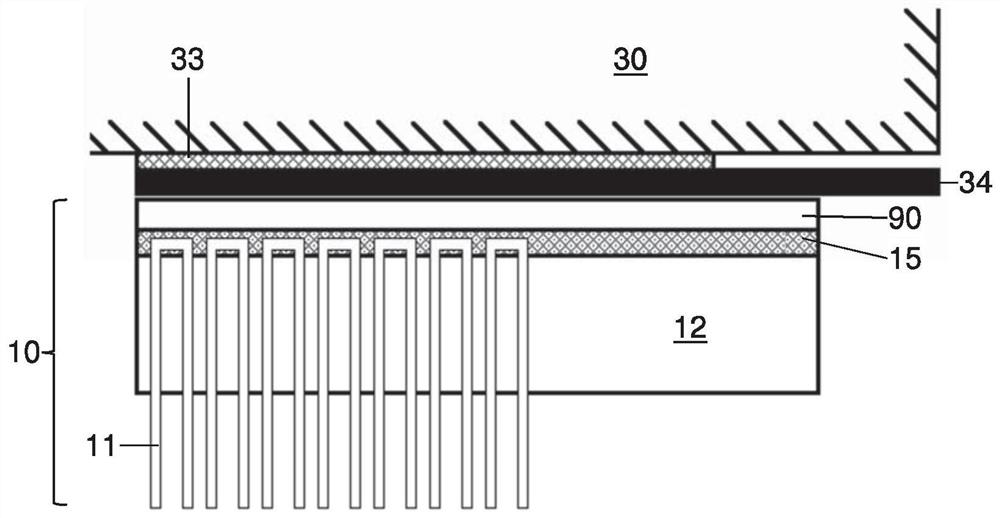

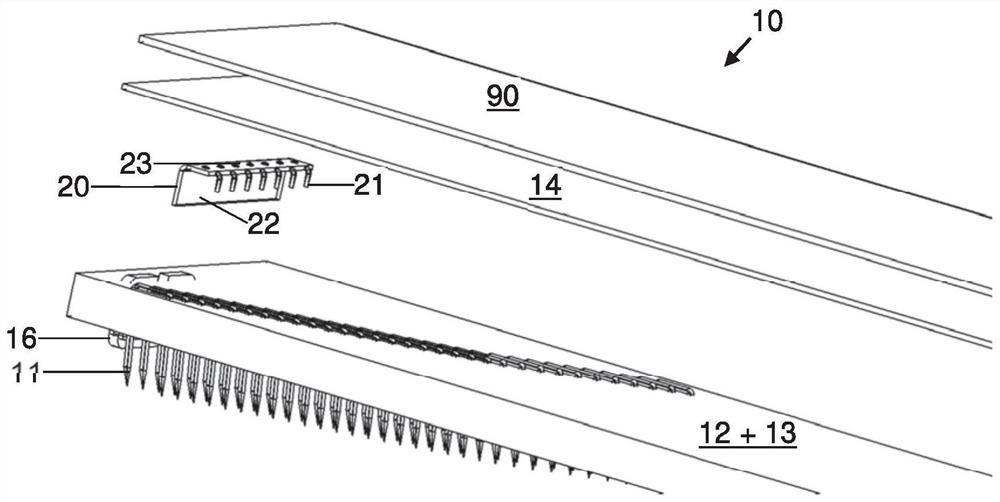

Detection device on a spinning preparation machine and carding bar set intended therefor

ActiveCN110234803ALow conductivityReduce or even avoid conductivityCarding machinesEngineeringContact layer

A carding cloth (10) has a backing (12), carding needles (11) passing through this, held in position thereby and projecting on a first side of the backing (12) and an electrically conductive layer (13, 15) arranged on a second side on the backing (12) facing away from the first side such that it is in electrical contact with the needles (11) on the second side of the backing (12). Or the layer (15) is a component of the backing (12), and the needles (11) contact the layer (15) through said backing. The layer (15) can be a textile fabric (15) with electrically conductive threads which are coupled together electrically directly or indirectly via the carding cloth needles (11), which threads can extend longitudinally or transversely to the cloth (10), which has an electrically conductive contact element (20) such that it contacts the layer (13, 15) electrically in such a manner that the contact section is electrically coupled to all the threads. The contact element (20) has a connection section (16) designed to electrically contact an external element (50). A carding bar (10, 20, 30) comprises a cloth holder (30) having a holding section and an electrically conductive cloth connectionsection (20) forming the external element (50) and the cloth (10) held stationary in the cloth holder (30). A spinning preparation machine has a carding bar (10, 20, 30) of this type, a carding bar holder (70) to hold the carding bar (10, 20, 30) and a carding bar contact section (3) designed to be electrically coupled to the cloth connection section (20) when the carding bar (10, 20, 30) is mounted on the carding bar holder (70).

Owner:TRUETZSCHLER GRP SE

Heat-generating element and method for producing the same

ActiveCN110740527AImplementing Entity Pre-BiasingImprove bindingOhmic-resistance electrodesHeater elementsElectrical polarityEngineering

The invention relates to a heat-generating element comprising a PTC element (2) and a contact piece (6) which is electrically conductively attached to a lateral surface (4) of the PTC element (2) andwhich is provided for feeding the PTC element (2) with different polarities. The aim of the invention is to permanently and reliably establish a contact between a contact piece and a PTC element and to easily operate a heat-generating element within the scope of a production scheme. According to the invention, at least one contact piece (6) is provided with a retaining tab (12), which rests against the opposite side (4) of the PTC element (2), on which the other contact piece (6) rests in an electrically conductive manner, with an insulating layer interposed therebetween, and which engages over the PTC element (2) in a form-fitting manner.

Owner:EBERSPACHER CATEM

Furniture

InactiveCN101431922AAchieve electrical contactRealize the assemblyLighting elementsCoupling device detailsEngineeringElectric network

The invention relates to an item of furniture, in particular kitchen furniture, comprising a furniture body (1), at least one electric consumer provided on or in the item of furniture and a strip (2, 22) that is fixed to the furniture body (1). Said strip (2, 22) has at least one electric conductor (4) for forming an electric network and can be connected to a strip (2, 22) of a neighbouring item of furniture. As a result, a networked supply of power can be provided in the items of furniture by the connection of several strips (2, 22).

Owner:PAUL HETTICH

Card clothings, flat strips with clothing and machines with flat strips

ActiveCN110234803BKeep fasteningAchieve electrical contactCarding machinesContact layerMechanical engineering

The card wire (10) has a base (12), a card wire passing through the base, held in place by the base and protruding on a first side of the base (12) The needle (11) and the electrically conductive layer (13, 15) are arranged on the second side of the base (12) facing away from the first side, so that the layer is in contact with the clothing needle (11) in the Electrical contacts are made on the second side of the base (12). Alternatively the layer (15) is an integral part of the base (12) and the needles (11) pass through the layer in contact with the layer (15). The layer (15) has a textile fabric (15) with electrically conductive threads which are electrically coupled to each other directly or indirectly via the clothing needles (11), which extend along or transversely to the clothing (10), said The card clothing has electrically conductive contact elements (20), so that they are in electrical contact with the layers (13, 15), so that the contact sections are electrically coupled to all wires. The contact element (20) has a connection section (16), which is designed for electrical contact with an external element (50). The flat strips (10, 20, 30) have a clothing carrier (30) comprising a holding section and an electrically conductive clothing-connecting section (20) forming the outer element (50) and in said clothing carrier ( 30) Card clothing (10) held in a fixed position. The spinning preparation machine has such a flat strip (10, 20, 30), a flat strip support (70) for holding the flat strip (10, 20, 30) and a flat strip-contact section (3) , which is designed to be electrically coupled to the clothing-connecting section (20) when the flat strips (10, 20, 30) are mounted on the flat strip holder (70).

Owner:TRUETZSCHLER GRP SE

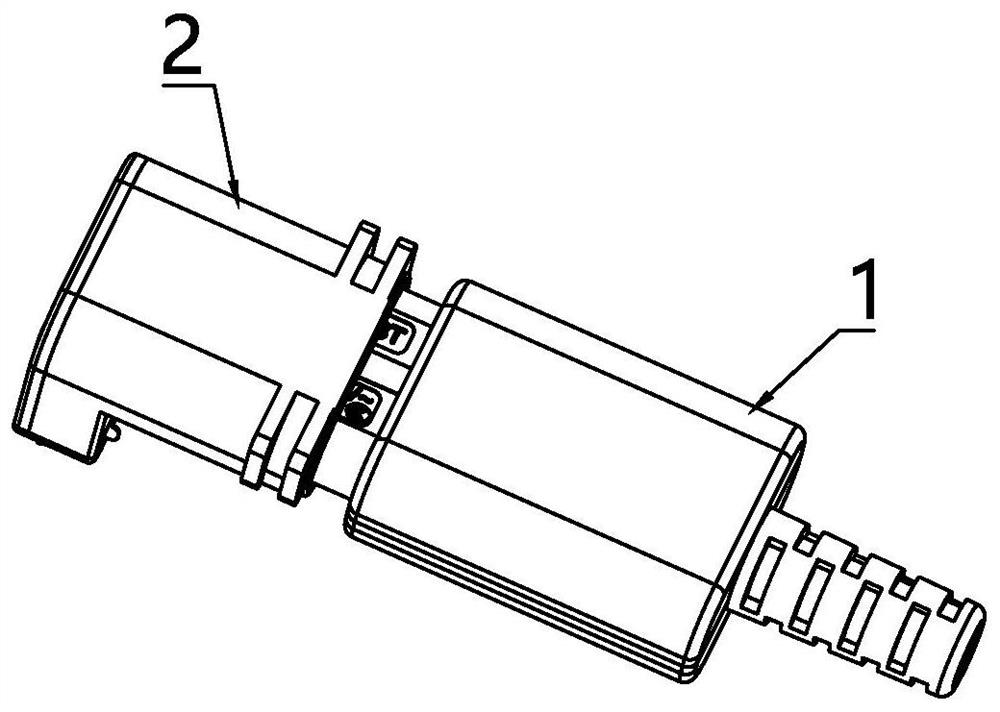

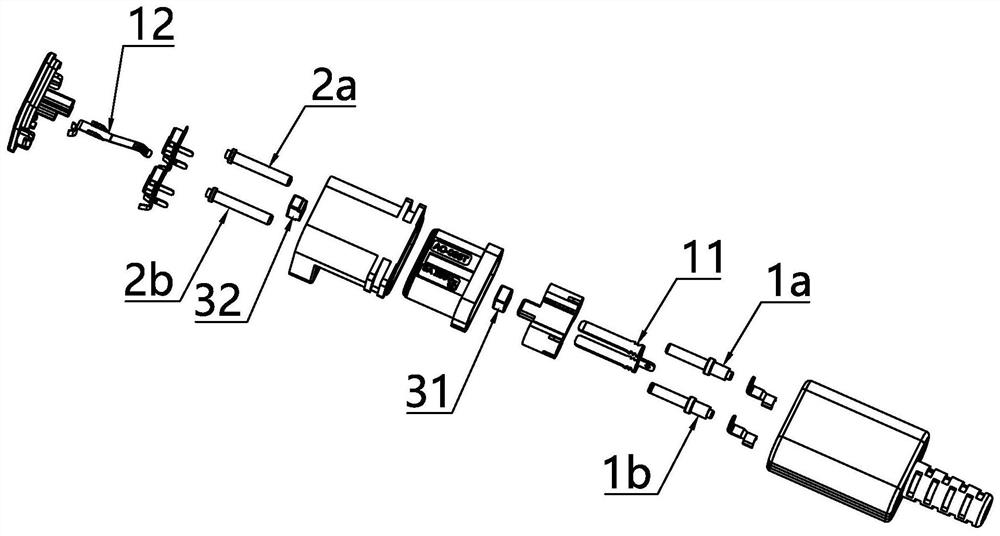

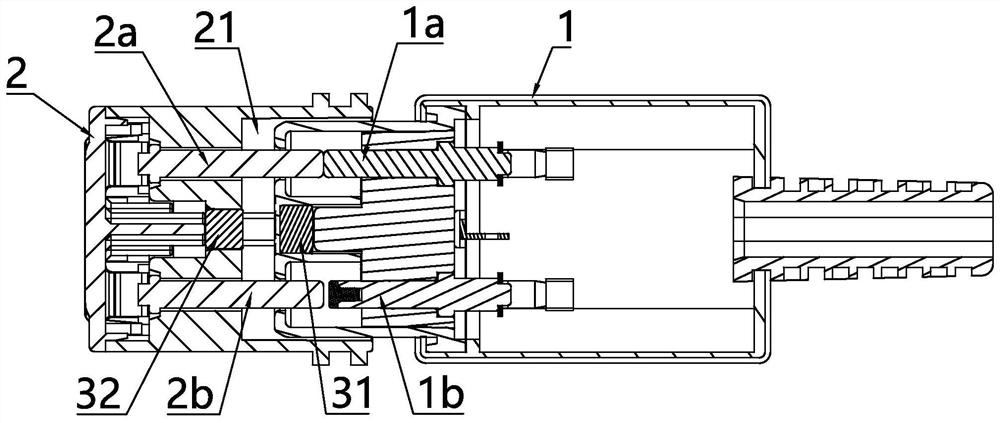

A short circuit proof connector

ActiveCN109638585BAvoid fireReduce sticky water and electrical connectionsElectric discharge tubesCoupling device detailsElectrical connectionStructural engineering

The invention discloses an anti-short circuit connector, which comprises a first part and a second part which cooperate with each other. Components, the wiring elements are in communication with the neutral wire or live wire, the connecting elements are used for electrical connection with the second part, when the first part is matched with the second part, the connecting element is in electrical contact with the wiring element; the first part and the When the second component is separated, the connection element is separated from the wiring element, and the distance between them is greater than 1.5mm. Since the connection element and the wiring element are separated, the distance between the two is greater than 1.5mm, so when the first part is sprayed with water, it can effectively reduce the possibility of the connection element and the wiring element being connected by water and electricity, so as to prevent the connection element and the wiring element from being shocked by high voltage Through and conduction, the connecting element can be stably disconnected from the high-voltage power supply.

Owner:JOYOUNG CO LTD

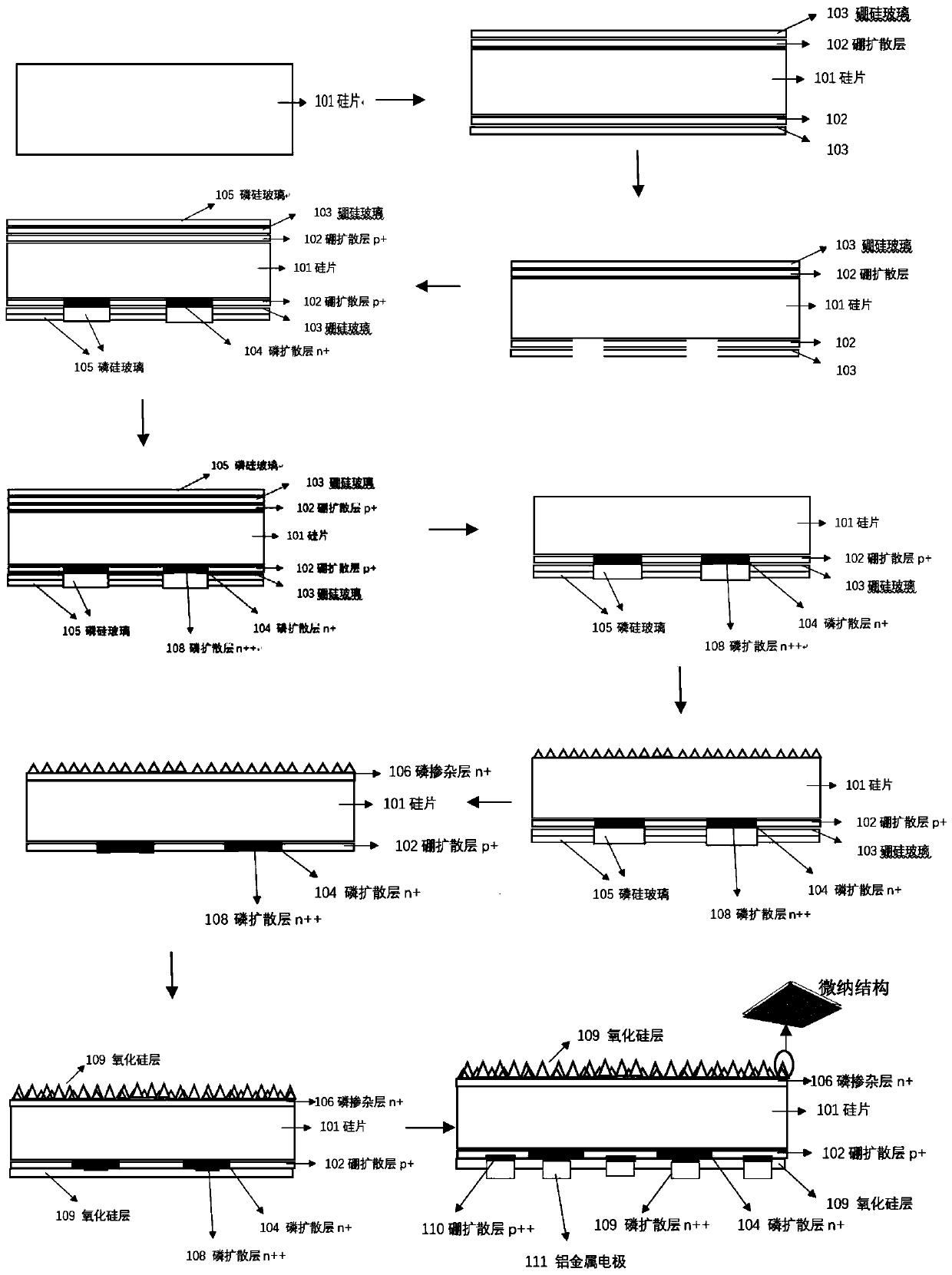

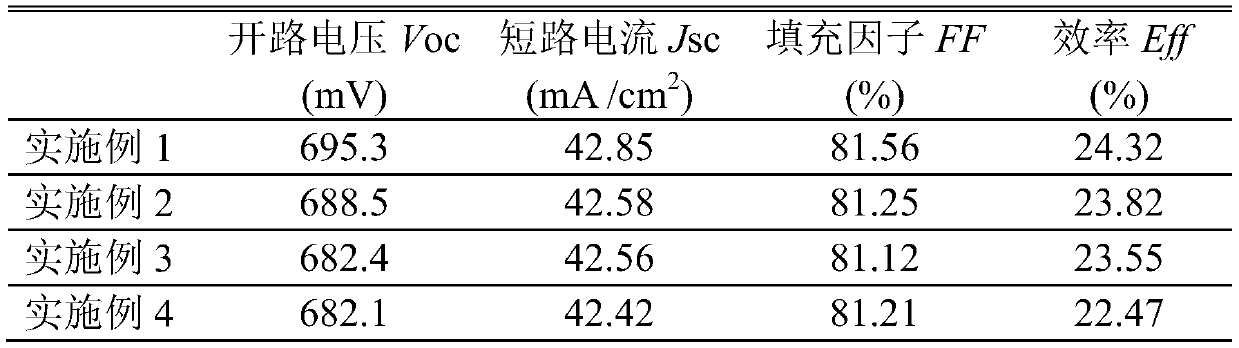

A full back electrode cell and its high-efficiency light trapping and selective doping manufacturing method

ActiveCN109192809BReduce parasitic light absorptionGuaranteed surface passivationFinal product manufacturePhotovoltaic energy generationPicosecond laserEvaporation (deposition)

The invention belongs to the technical field of solar cell manufacturing, in particular to a high-efficiency trapping and selective doping manufacturing method of a full-back electrode battery. Ultra-thin silicon oxide passivation film is prepared by micro-nano structure combined with atomic layer deposition technology to reduce the light reflection and parasitic light absorption on the front surface, while ensuring the passivation of the front surface. In order to solve the problem of large metal area recombination on the back, selective doping is adopted and picosecond laser is utilized on aphosphor doping layer to ensure heavy doping on the surface of n + layer, the depth of heavy doping layer is strictly controlled, which ensures good ohmic contact between phosphorus doped layer and metal contact region, and does not cause serious carrier recombination due to heavy doping. Crystalline silicon is further bulk passivated by ultra-thin silicon oxide passivation followed by low temperature annealing in hydrogen atmosphere. Al metal electrode is fabricated by thermal evaporation method. Under laser irradiation, Al forms good ohmic contact with p + and n + + through silicon oxide.

Owner:CHANGZHOU UNIV +2

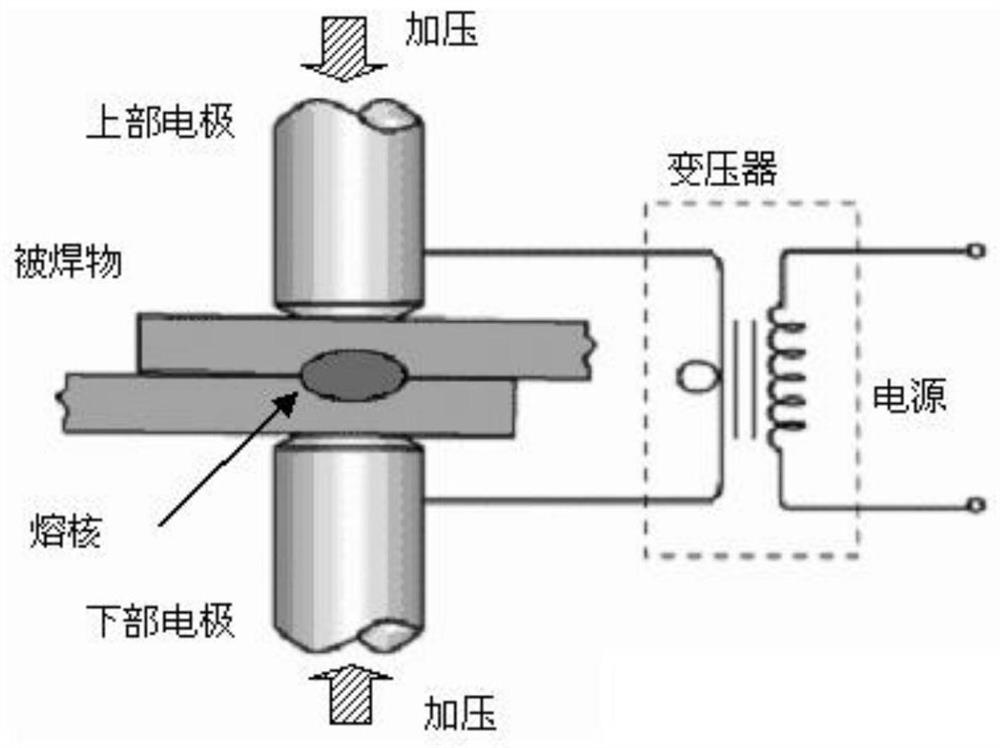

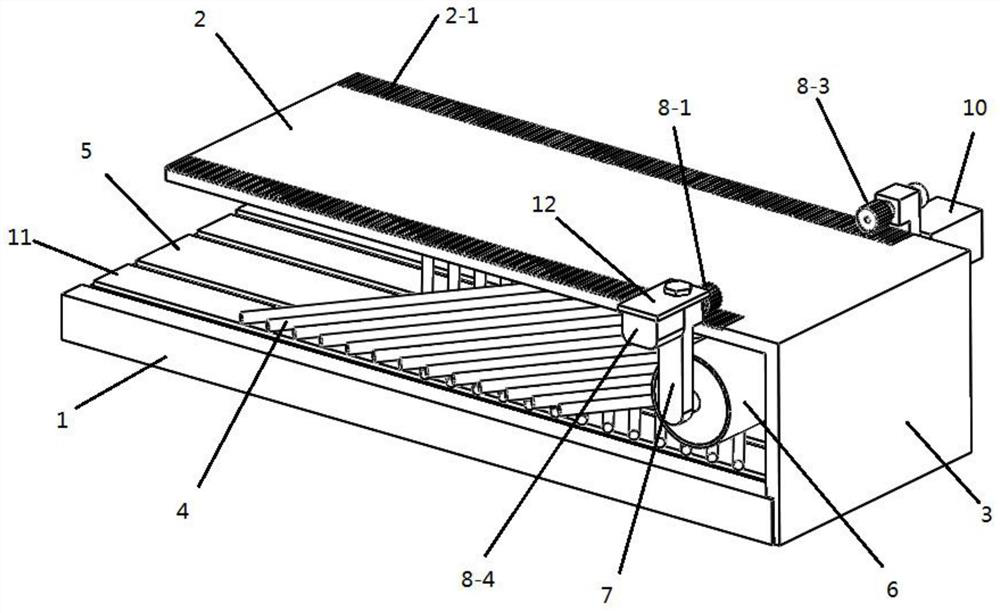

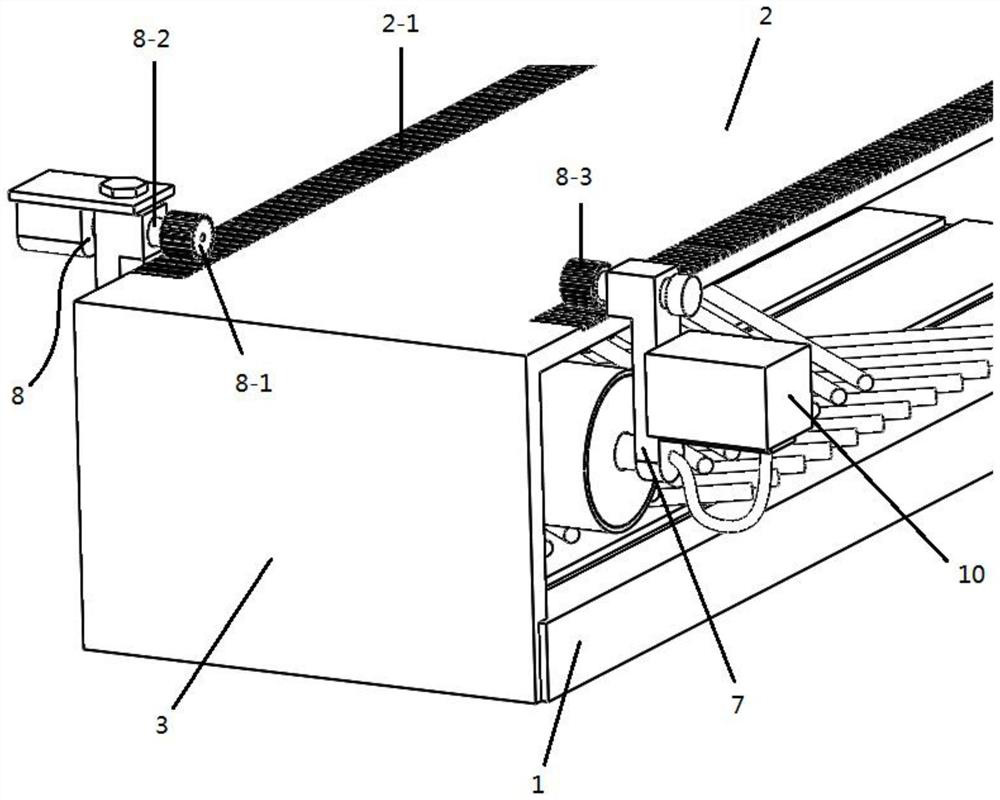

A rolling metal mesh welding machine

ActiveCN108723567BGuaranteed compression effectAchieve electrical contactWelding with roller electrodesWelding/soldering/cutting articlesGear wheelElectric resistance welding

The invention relates to metal mesh electric welding equipment, in particular to a rolling-type metal mesh electric welding machine. The rolling-type metal mesh electric welding machine mainly solvesthe technical problem that the efficiency in large-area welding of metal meshes is low due to the limitation of existing resistance welding structures. The rolling-type metal mesh electric welding machine comprises an operation platform, a supporting top plate, a connecting side plate, an electrode plate, an electrode roller, connecting arms and a transmission structure. According to the rolling-type metal mesh electric welding machine, an electrode structure in conventional resistance welding is improved, and through the utilization of a cylindrical structure, not only can the pressing function be ensured, but also the electric contact during rolling can be achieved; through the arrangement of the transmission structure, it is ensured that the electrode roller can move along the supporting top plate, and therefore the two ends of the electrode roller synchronously move; through the adoption of a driving gear and a driven gear and the cooperation of tooth rows on the supporting top plate, compared with common belt transmission, slipping can be prevented, the limiting function is achieved during rotation at the same time, the welding consistency can be ensured, and the accidental omission of welding points is reduced.

Owner:宁国市吉思知识产权运营有限公司

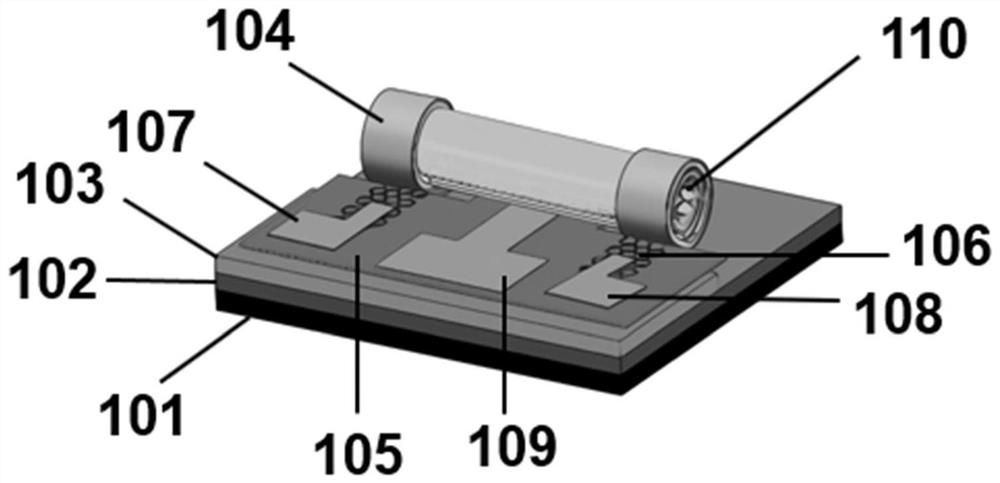

A micropipe three-dimensional heterojunction device structure and its preparation method and application

ActiveCN112151629BSolve the problem of unpreparableAchieve electrical contactFinal product manufacturePhotovoltaic energy generationHeterojunctionEngineering

The present invention relates to a micropipe three-dimensional heterojunction device structure and its preparation method and application. The structure includes: micropipe semiconductor two-dimensional material three-dimensional heterojunction, inner wall electrodes, outer wall electrodes and substrate; The inner wall material of the tubular three-dimensional heterojunction forms electrical contact; the outer wall electrode only forms electrical contact with the outer wall material of the microtubular three-dimensional heterojunction; both the inner wall electrode and the outer wall electrode are insulated from the substrate; the microtubular semiconductor two-dimensional material three-dimensional The heterojunction is a tubular three-dimensional heterojunction formed by the self-curling of the plane heterojunction of the semiconductor two-dimensional material on the substrate. The invention solves the problem that the tubular three-dimensional heterojunction device cannot be prepared, has simple process, can simultaneously realize the preparation of the microtubular three-dimensional heterojunction and the electrical contact between the outer wall material and the outer wall electrode, and also ensures that the current only passes through the microstructure in the radial direction. Tubular three-dimensional heterojunctions can be widely used in photodetection, photovoltaics, gas sensing, electronic components and other fields without passing through planar heterojunctions.

Owner:BEIJING UNIV OF POSTS & TELECOMM

Radar component package and manufacturing method thereof

ActiveCN107479034BReduce thicknessShorten the lengthWave based measurement systemsSemiconductor/solid-state device detailsRadarElectrical contacts

The present invention relates to a radar component packaging body, comprising: a case cover, which has a metal layer arranged on the inner surface of the case cover, wherein a cavity is formed between the case cover and the case body; and a case body, which has: An insulator, which is connected to the box cover, wherein a hole is opened in the first insulator, one end of the hole corresponds to the position of the antenna and the other end communicates with the cavity; one or more chips, the chip is flip-chip arranged on the second insulator and covered by the first insulator; the second insulator; the third insulator; and the antenna and the conductive line, the antenna and the conductive line are arranged in the third insulator and pass through the soldering of the second insulator and the chip A pad connection, wherein a metal barrier layer is arranged between the antenna and the pad and between the conductive line and the pad, respectively, and the conductive line is exposed from the third insulator for electrical contact. The invention also relates to a method of manufacturing the package.

Owner:NAT CENT FOR ADVANCED PACKAGING CO LTD

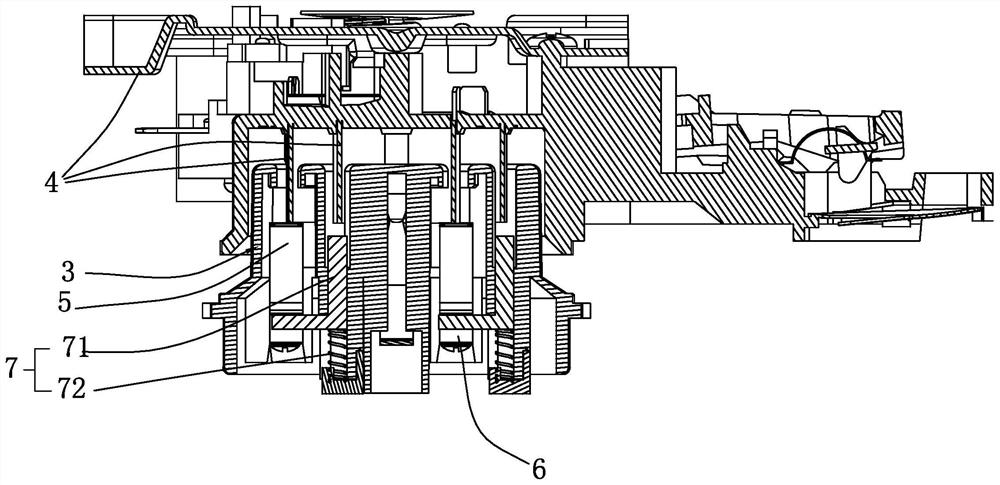

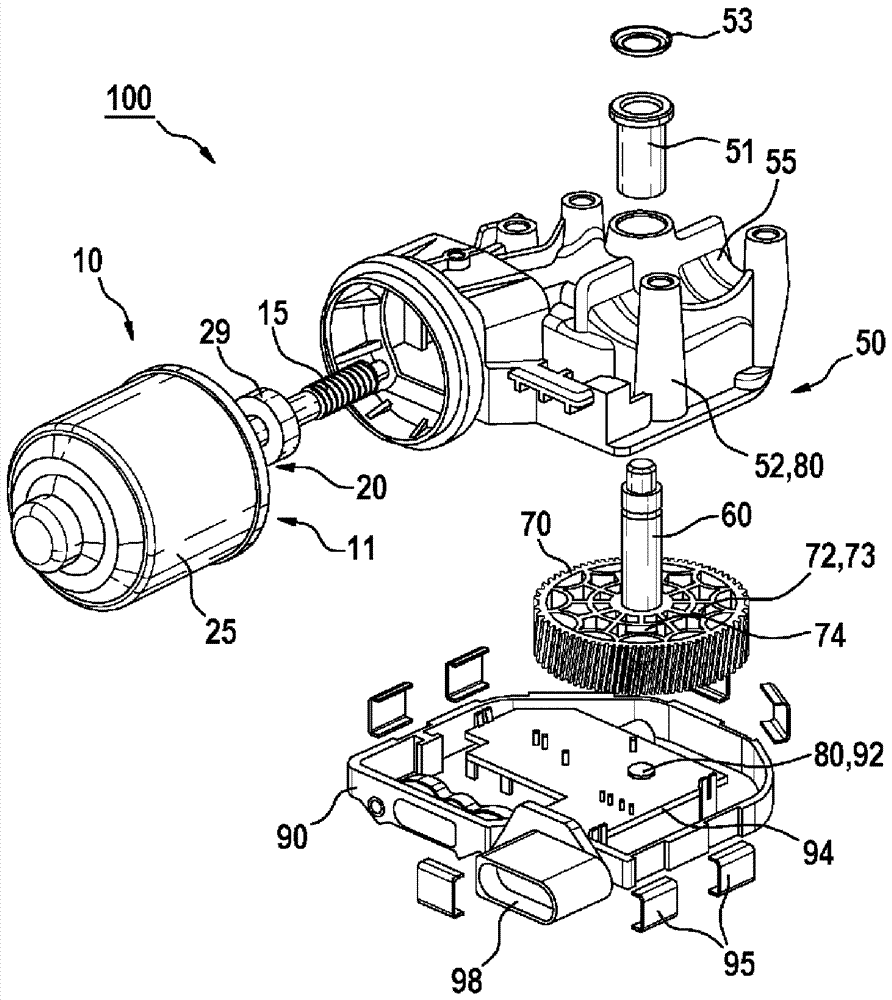

Drive unit for a wiper system

ActiveCN107206969ASimple and precise controlSimple and precise adjustabilityVehicle cleaningMechanical energy handlingDrive shaftEngineering

The invention relates to a drive unit (100) for a wiper system, comprising an electronically commutated drive motor (10) having a drive shaft (15), and a transmission (50) having an output shaft (60) that can be driven by the drive shaft (15). According to the invention, at least one angular position sensor (80) for determining a respective angular position of the output shaft (60) is assigned to the output shaft (60) of the transmission (50).

Owner:ROBERT BOSCH GMBH

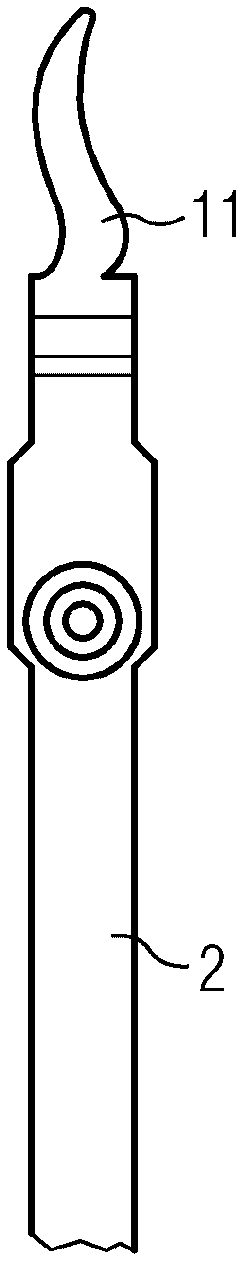

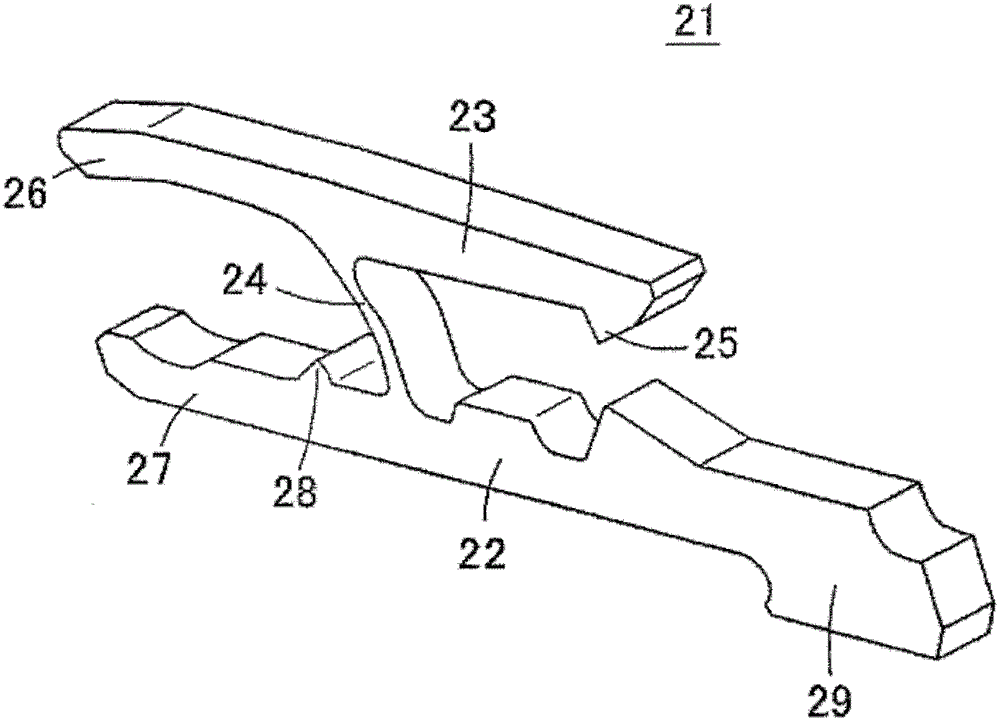

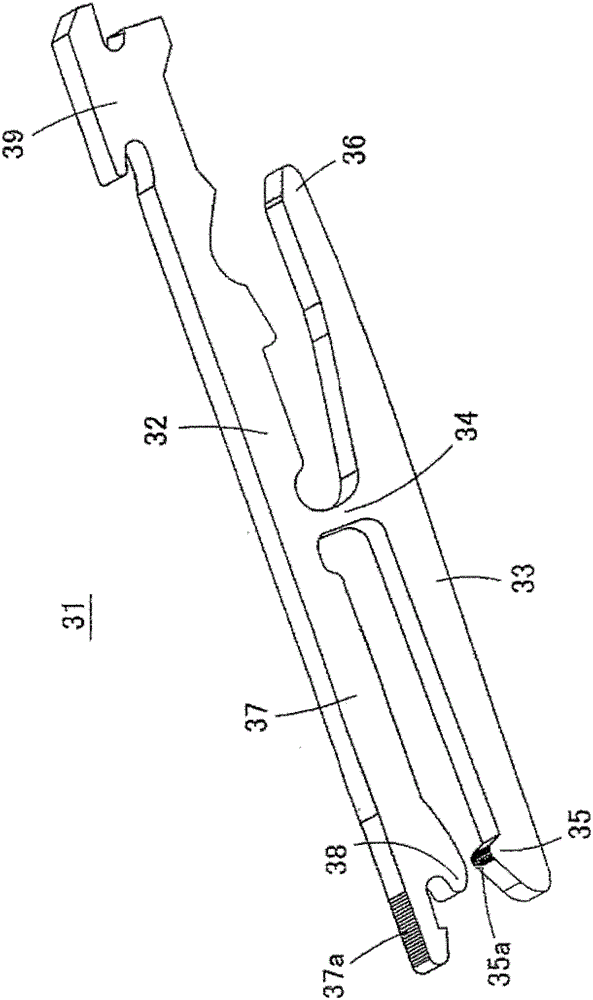

Method for manufacturing contact and metal part

ActiveCN102870283BReliable electrical contactImprove mechanical propertiesContact member manufacturingCoupling contact membersResistPhotomask

A method for manufacturing a contact piece and a metal part, capable of reliably making electrical contact and mechanical contact with other parts. The contact piece (31) connects the fixed piece (32) and the movable piece (33) which are substantially parallel with each other through a connecting portion (34). The lower surface of the front end of the movable piece (33) is provided with a movable contact portion (35) for contacting with a flexible printed circuit board, etc., and a movable contact portion (35) is provided on the rear end of the movable piece (33). The movable piece (33) is inclined to operate the receiving part (36). The front end portion of the fixing piece (32) is a fitting portion (37) for fitting with the housing of the connector. On the contact (31), a contact contact surface (35a) serving as a contact surface of the movable contact portion (35) is provided with concavo-convex shapes extending in the width direction of the contact (31). In addition, the lower surface of the fitting portion (37) is a contact surface with the crimping surface (37a), that is, the bottom surface of the housing, and the crimping surface (37a) is also provided with a of concave-convex shape.

Owner:OMRON CORP

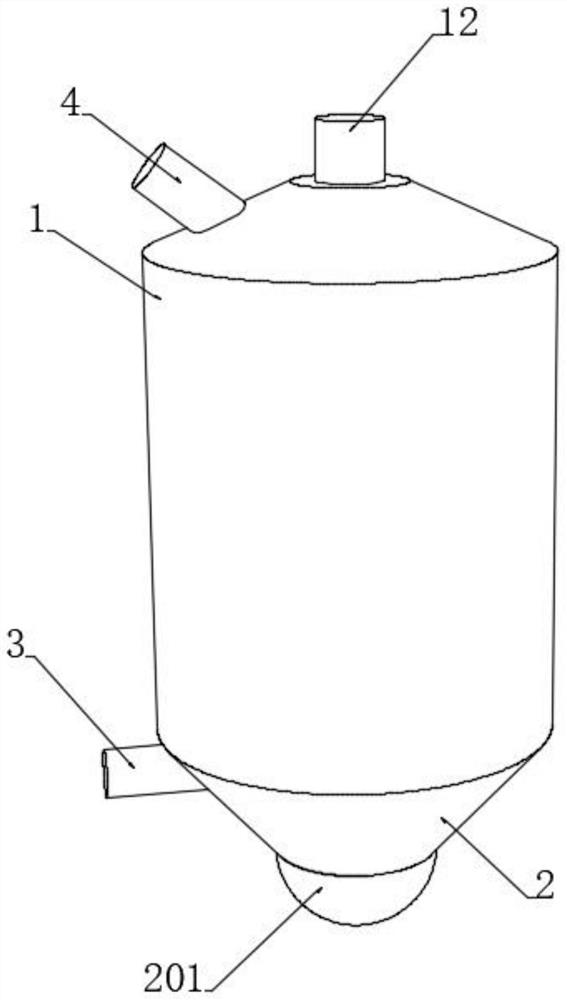

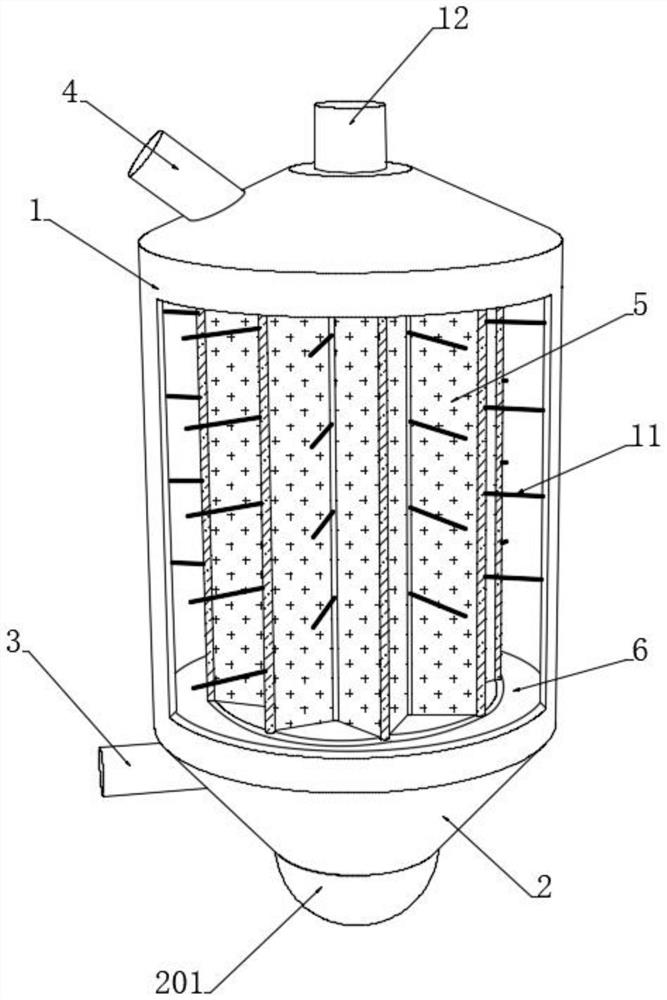

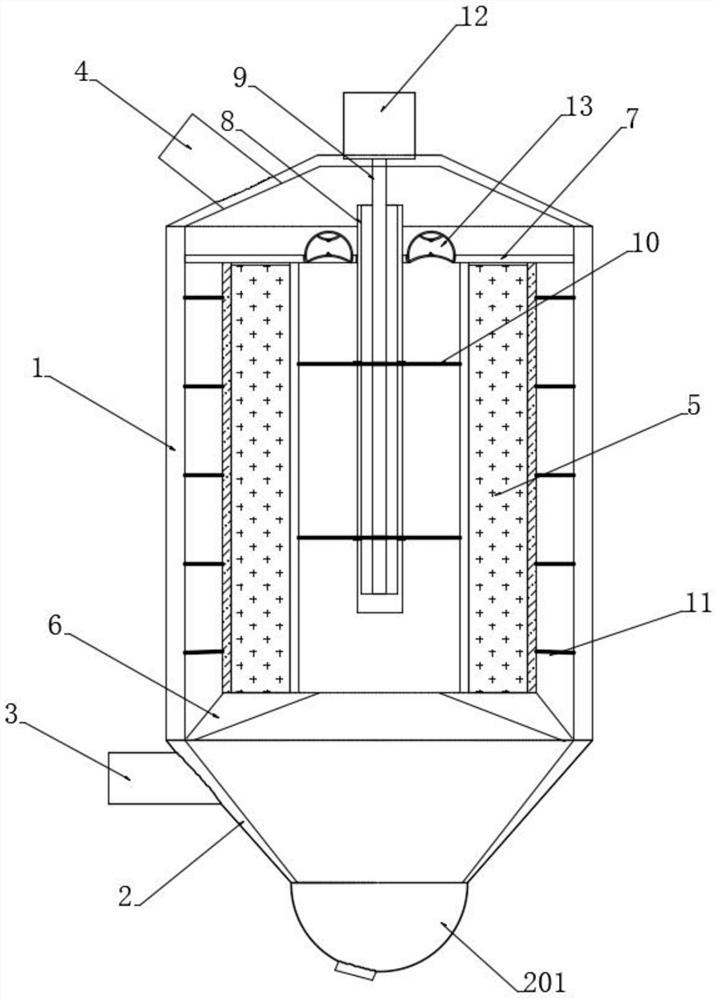

High-efficiency interception type environment-friendly bag-type dust collector

InactiveCN112316605AIncrease the suction areaLarge filter areaDispersed particle filtrationTransportation and packagingFiberDust control

The invention discloses a high-efficiency interception type environment-friendly bag-type dust collector, and belongs to the technical field of bag-type dust collection. A plurality of dust-passing fiber nets are annularly encircled to form a polygonal dust collection bag, the dust-passing fiber nets are connected between an outer positioning rod and an inner moving rod, and the outer positioningrod and the inner moving rod are distributed in an inside-outside staggered manner, multiple groups of dust passing fiber nets are symmetrically arranged at a certain angle, the dust passing area of the multi-angle dust removal cloth bag is increased to a certain extent, when the multi-angle dust removal cloth bag absorbs dust to reach a certain saturation state, the dust blockage triggering module is triggered under the influence of high air pressure, and the high air pressure formed by blockage serves as a triggering condition, the motor is triggered and driven, and then the pulling mechanism is wound to be matched with the multiple inner moving rods, the dust passing fiber net is driven to vibrate back and forth inside and outside, the effect of shaking off dust on the dust passing fiber net is achieved, the continuous dust suction performance of the dust passing fiber nets is recovered to a certain degree, and the high-efficiency interception effect of the dust passing fiber nets is achieved.

Owner:广州凡瑞智能装备科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com