Anisotropic conductive sheet, its manufacturing method, and inspection device for circuit board

An anisotropic, conductive sheet technology, applied in the field of circuit board inspection equipment, can solve the problems of increased inspection costs, low inspection efficiency, and high frequency of anisotropic conductive sheets, so as to reduce inspection costs, improve inspection efficiency, and reduce frequency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

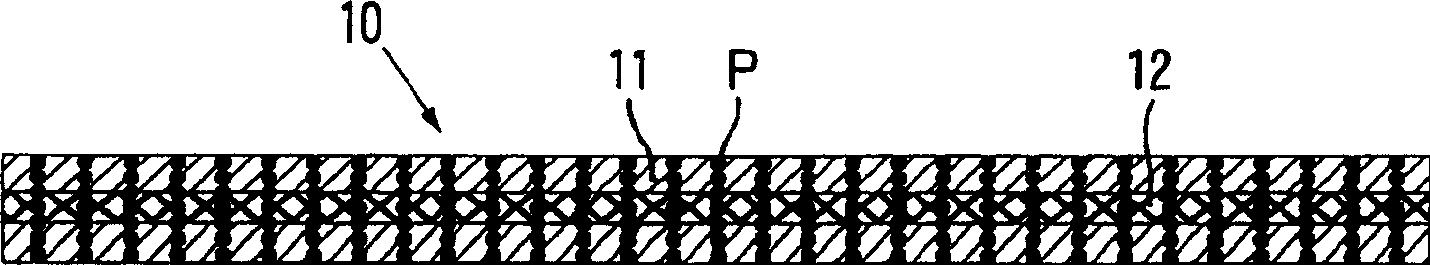

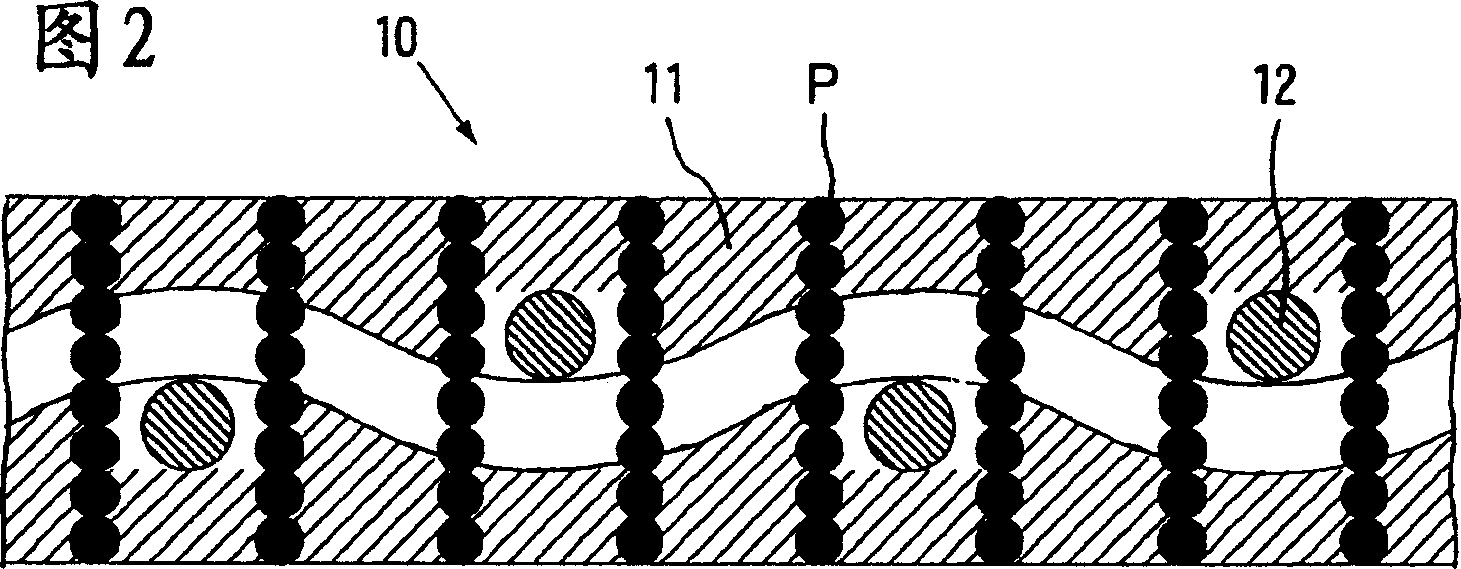

[0266] [Preparation of molding material]

[0267] The solution A and the solution B of two types of additive type liquid silicone rubber are mixed according to the proportion of equal amounts. 18 physiological parts of conductive particles having an average particle diameter of 15 μm were added to and mixed with 100 parts by weight of the above mixture, and the resulting mixture was subjected to defoaming treatment by reducing pressure, thereby preparing a molding material. In the above-mentioned process, as the additive type silicone rubber, a silicone rubber in which solution A and solution B have a viscosity of 2,500P and whose cured product has a compression set of 6% at 150°C (according to JIS K 6249 method of measurement) and a tear strength of 30 kN / m at 23°C (method of measurement according to KIS K6249).

[0268] Further, particles obtained by using nickel particles as core particles and subjecting the core particles to electroless plating treatment with gold (averag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com