A rolling metal mesh welding machine

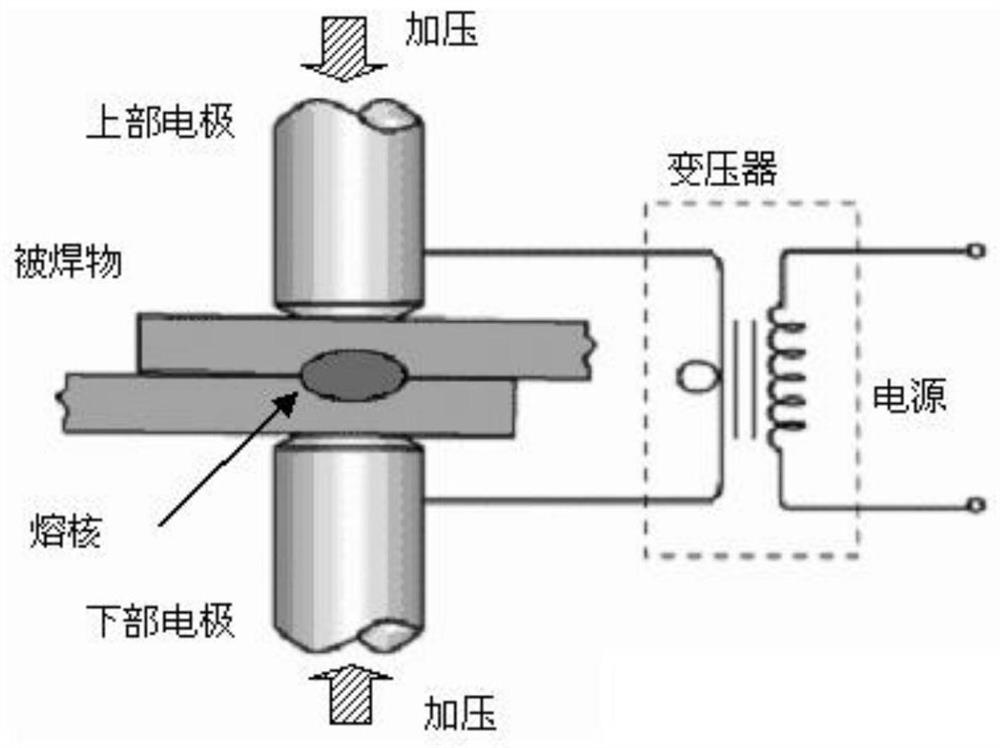

A technology of metal mesh and electric welding machine, applied in roller electrode welding, roller electrode, metal processing, etc., can solve the problems of low efficiency of metal mesh, achieve the effects of ensuring continuity, preventing electric shock, and reducing accidental omissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

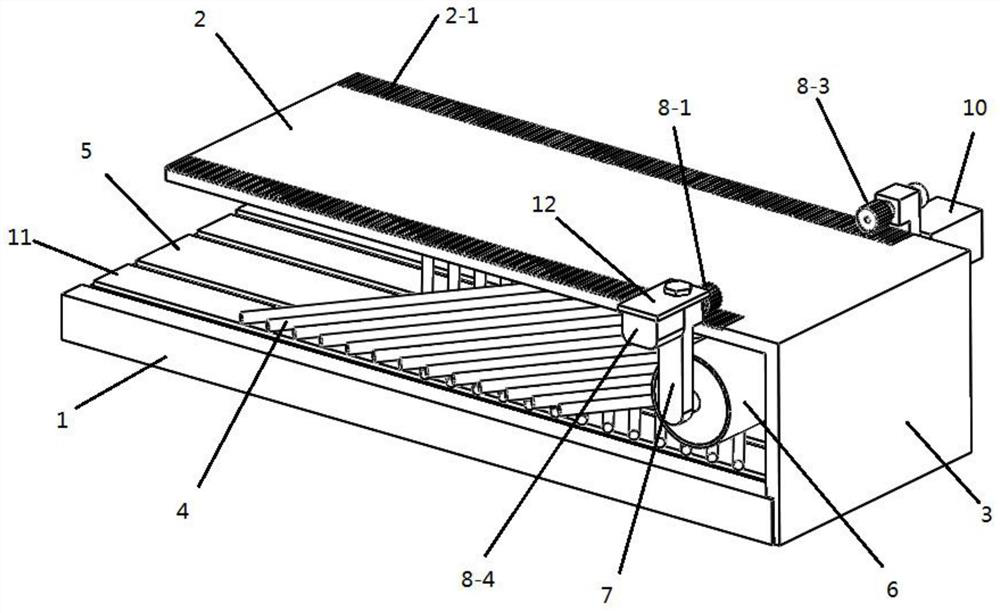

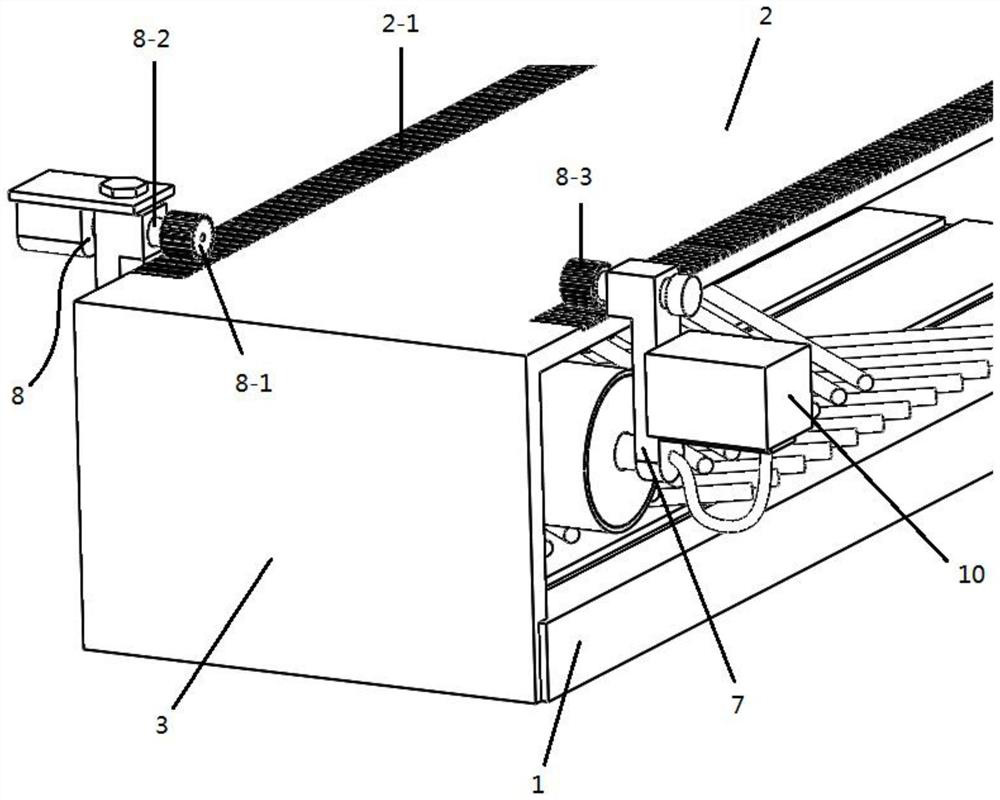

[0030] Such as Figure 2-5 It is a rolling metal mesh welding machine, which includes an operating platform 1, a supporting top plate 2 and a connecting side plate 3. The supporting top plate 2 is arranged above the operating platform 1 and its two ends are connected to it through the connecting side plate 3. The welded metal mesh arranged by wires 4 also includes an electrode plate 5, an electrode roller 6, a connecting arm 7 and a transmission structure 8. The electrode plate 5 is embedded on the surface of the operation platform 1, and the metal mesh is placed on the electrode plate 5. The two ends of the electrode roller 6 are rotatably connected to the bottom end of the connecting arm 7, the transmission structure 8 is arranged on the top of the connecting arm 7 and connected thereto, the two sides of the supporting top plate 2 are provided with tooth rows 2-1, and the top of the connecting arm 7 passes through the transmission structure 8 The built-in gears hang on both ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com