Hf housing coupler and method for producing the same

A coupling device and housing technology, applied in the direction of coupling devices, two-part connection devices, parts of connection devices, etc., can solve problems such as inability to guarantee connection reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

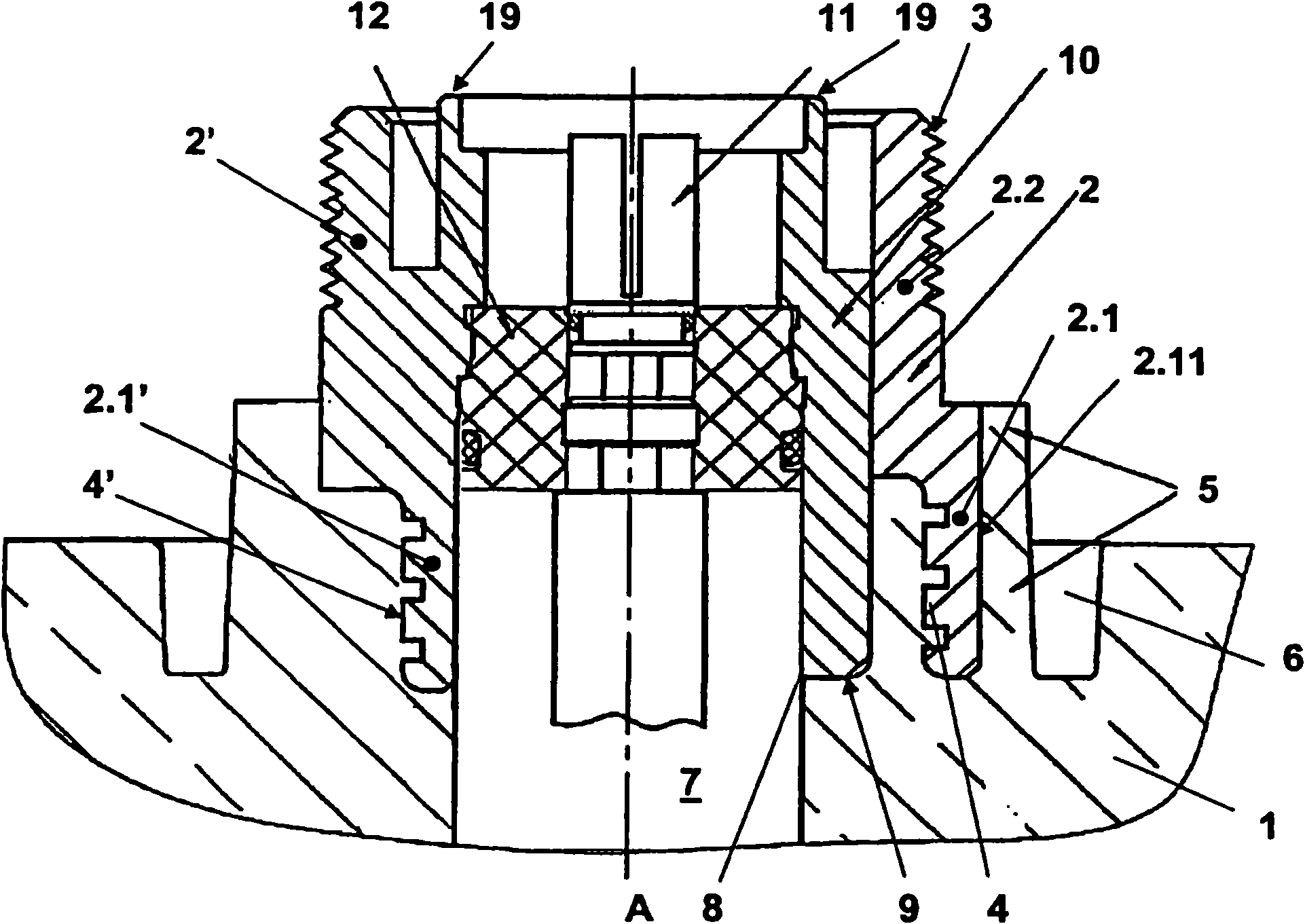

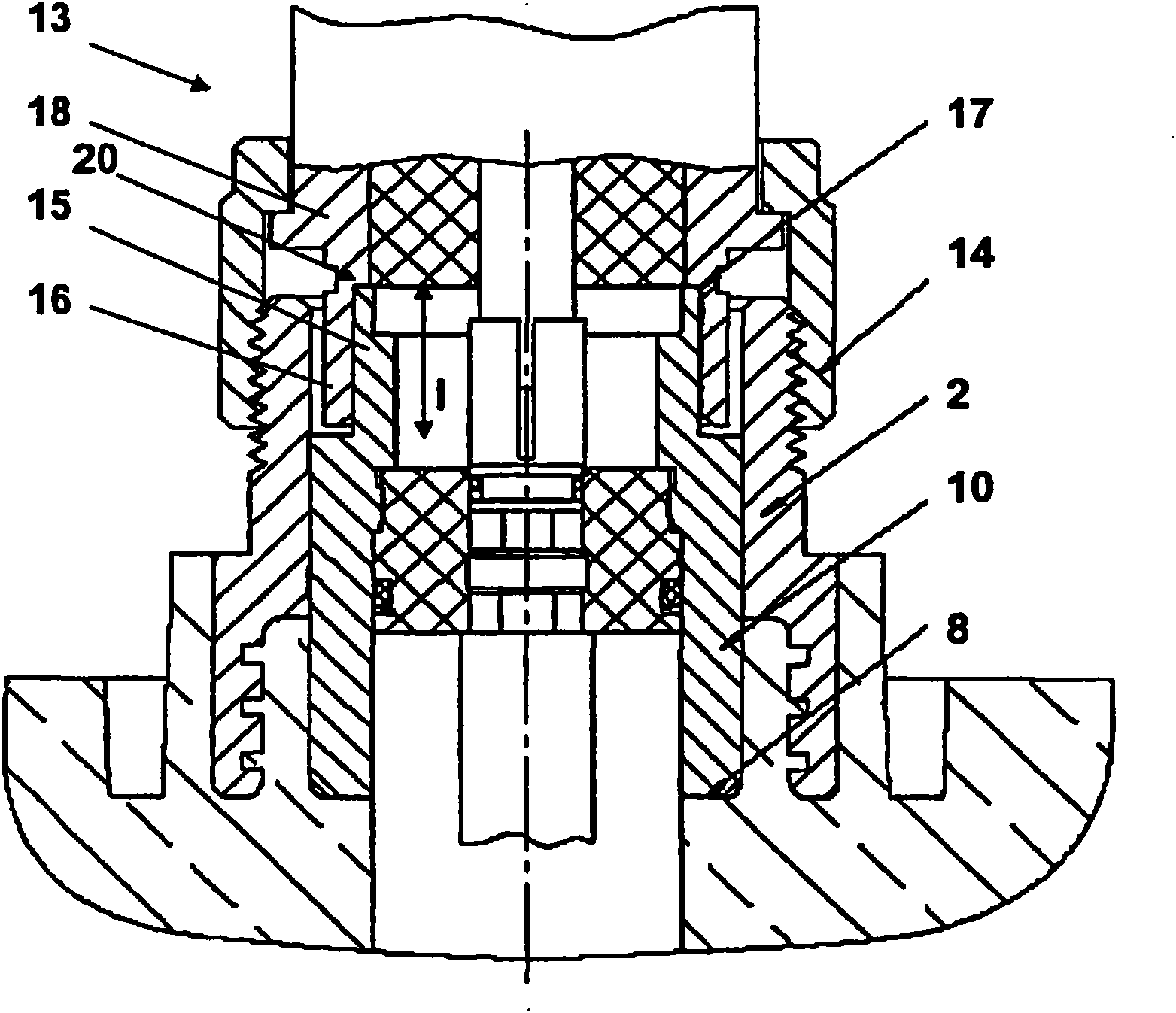

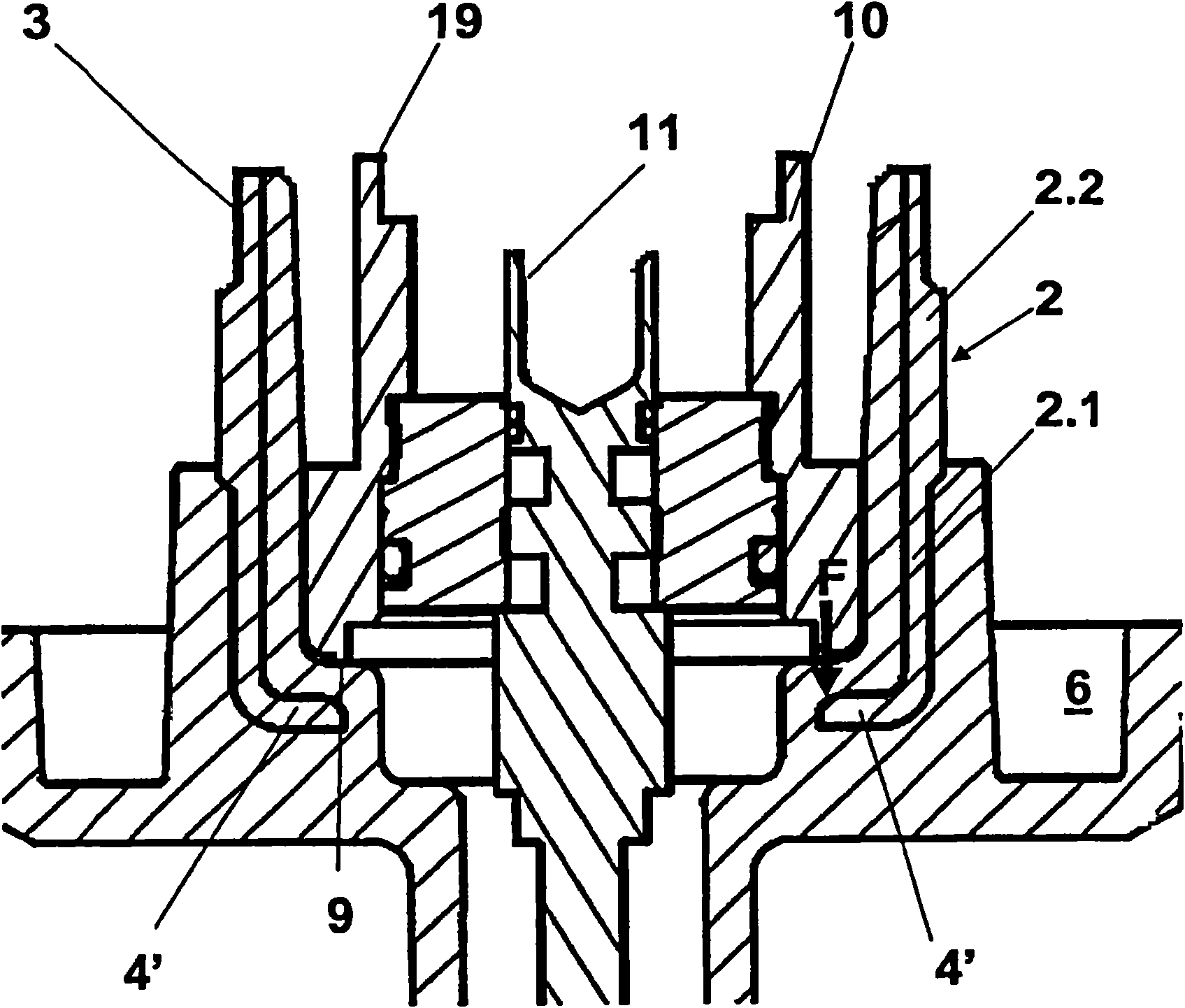

[0023] exist figure 1 shows a longitudinal section through the combination of two high-frequency housing couplings designed according to the solution, wherein the housing coupling halves shown in each case with respect to the shown longitudinal axis A show two alternative embodiments Way.

[0024] First elaborate on the figure 1 The embodiment shown in the right half of , which shows a high-frequency-housing coupling device, the high-frequency-housing coupling device is provided with a plastic housing 1 produced by plastic injection molding and a partly The joint part 2 is cast together with the plastic housing. The sleeve-shaped connecting part 2 made of metal has two sleeve sections 2.1 and 2.2 which are integrally connected to one another, wherein the sleeve section 2.1 is almost completely covered by the shell when forming a form-locking connection. The body 1 is surrounded by plastic material. The other sleeve section 2.2 protrudes beyond the wall of the housing 1 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com