Drive unit for a wiper system

A drive unit and wiper technology, which is applied in the direction of electrical components, electric components, vehicle cleaning, etc., can solve the problems of high cost and high cost of drive units, and achieve improved durability and robustness, reliable force transmission, and accurate speed Adjustment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

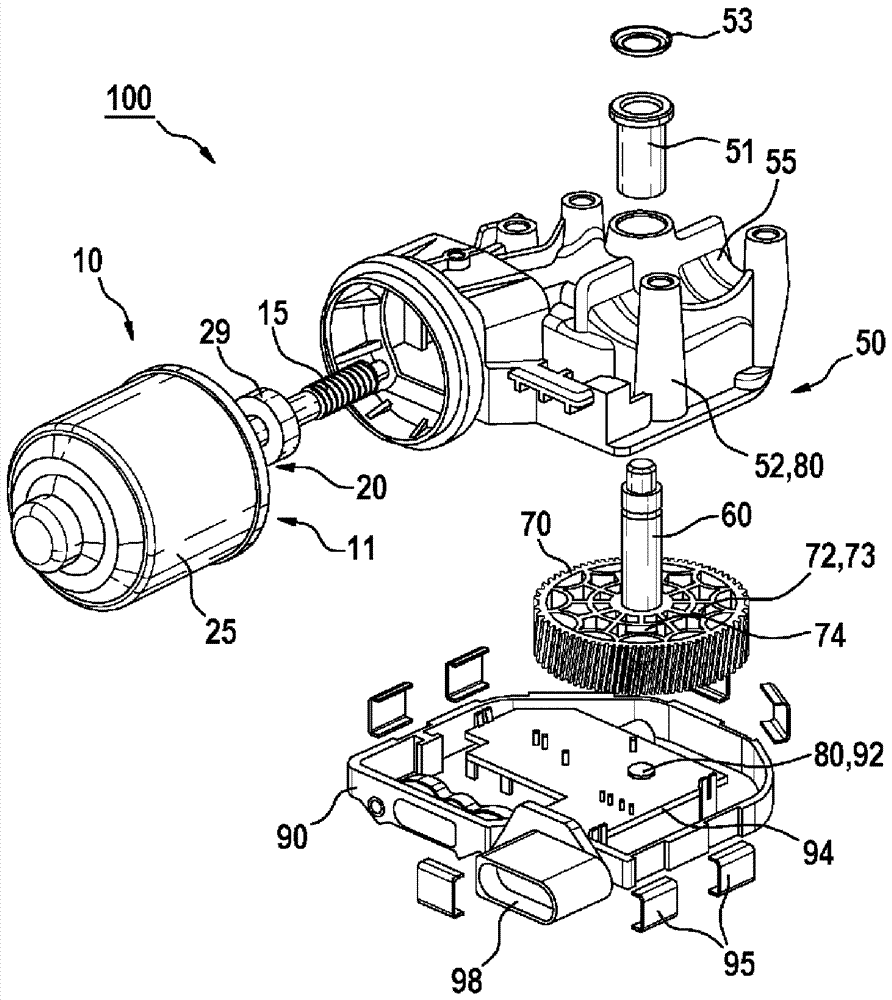

[0040] figure 1 An exemplary embodiment of a drive unit 100 according to the invention for a wiper system is shown. The drive unit 100 preferably has an electronically commutated drive motor 10 which, in the exemplary embodiment shown and for the purposes of the invention, is preferably embodied as a brushless DC motor 11 . The drive motor 10 schematically has a rotor 20 which is connected in a rotationally fixed manner to the drive shaft 15 and which drives the drive shaft 15 . Furthermore, the drive motor 10 has a housing 25 and at least one bearing 29 , wherein the drive shaft 15 of the drive motor 10 or the rotor 20 is mounted in the housing 25 in a rotationally movable manner, preferably via the bearing 29 . Furthermore, the drive unit 100 has a transmission 50 with an output shaft 60 drivable by the drive shaft 15 . The drive shaft 15 of the drive motor 10 and the output shaft 60 of the transmission 50 are preferably arranged at a predetermined angle to one another, pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com