Vibration compensator apparatus

A vibration compensation and equipment technology, applied in mechanical equipment, inertia force compensation, vibration suppression adjustment, etc., can solve problems such as system efficiency reduction, achieve simple and precise control, and reduce size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

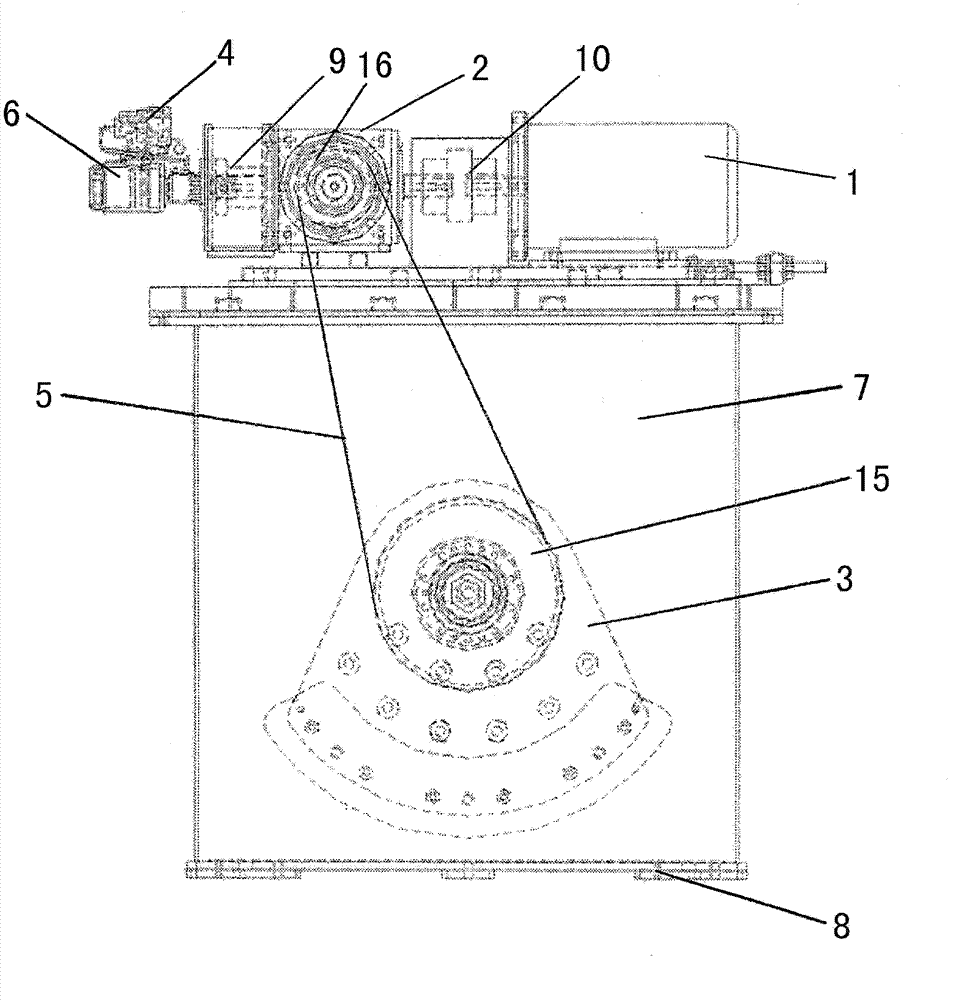

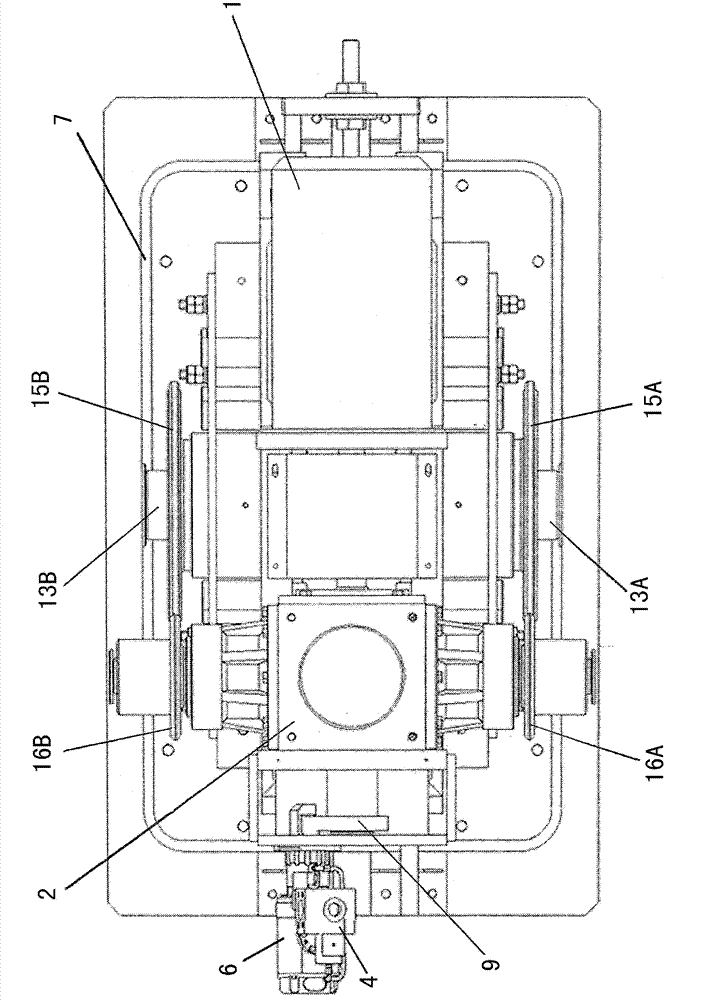

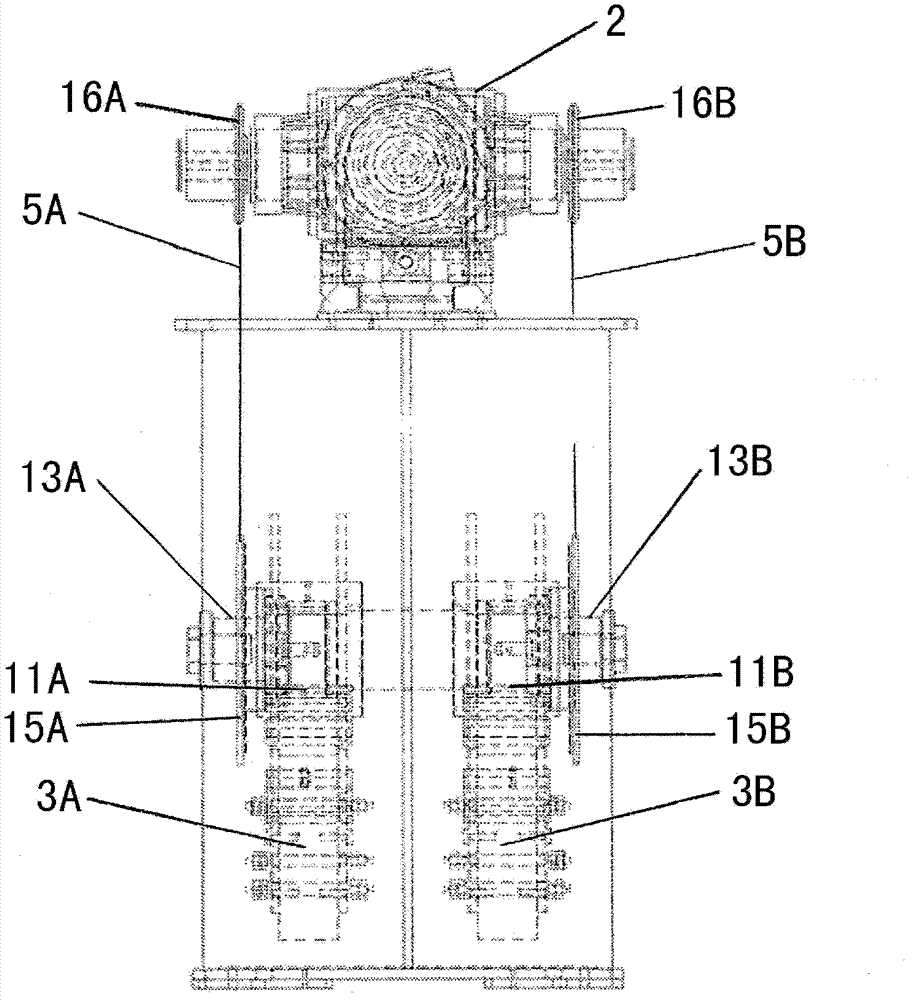

[0042] An embodiment of the vibration compensation device according to the present invention will be explained below. The vibration compensation device according to this embodiment can be implemented so as to cancel vibrations originating from an internal combustion engine installed on the hull of a ship.

[0043] First, the overall configuration of the vibration compensation device is explained based on the drawings. Such as figure 1 As shown, the vibration compensation device includes a housing 7 with a support 8 disposed at the bottom of the housing 7. The support 8 is formed so that the housing 7 can be mounted to the structure requiring vibration compensation via the support 8. The housing 7 with the support 8 is mounted to the aforementioned structure so that the inertial force generated during the operation of the equipment can be between the equipment and the structure (for example, the hull of a ship with an internal combustion engine as a driving source) transfer.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com