Plug-in type connector and liquid heater

A technology of plug-in connectors and plugs, which is applied in the direction of connecting, joining/disconnecting connected parts, two-part connecting devices, etc., which can solve the problems of laborious plug-in and pull-out operations, large inertial forces, and burns to users, and achieve The effect of saving labor, reducing the range of rotation, and reducing the occupied space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

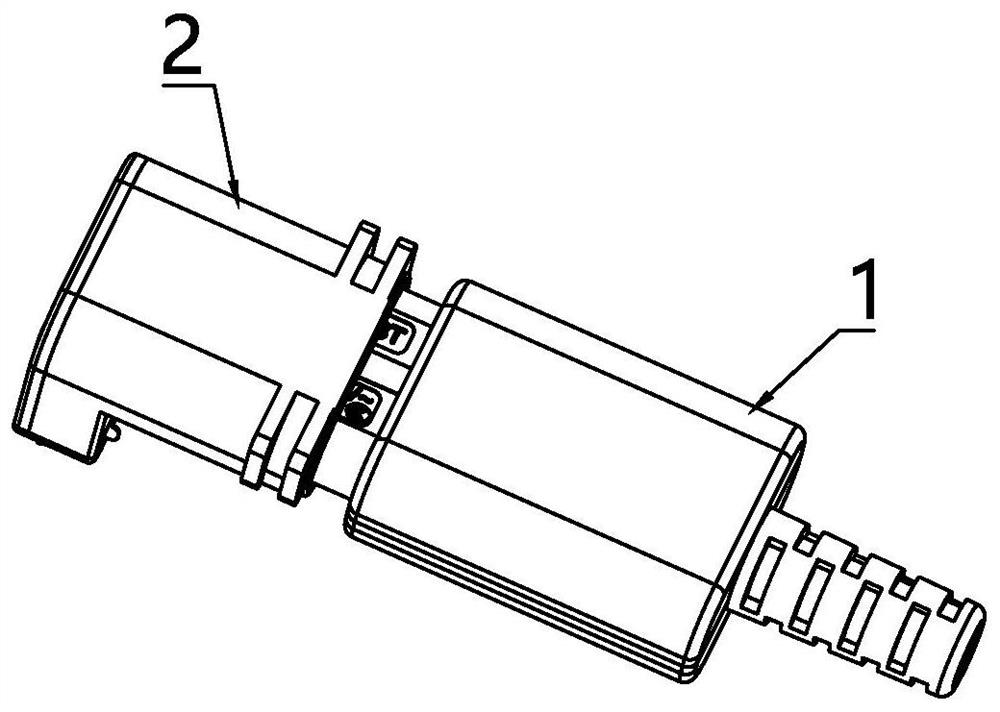

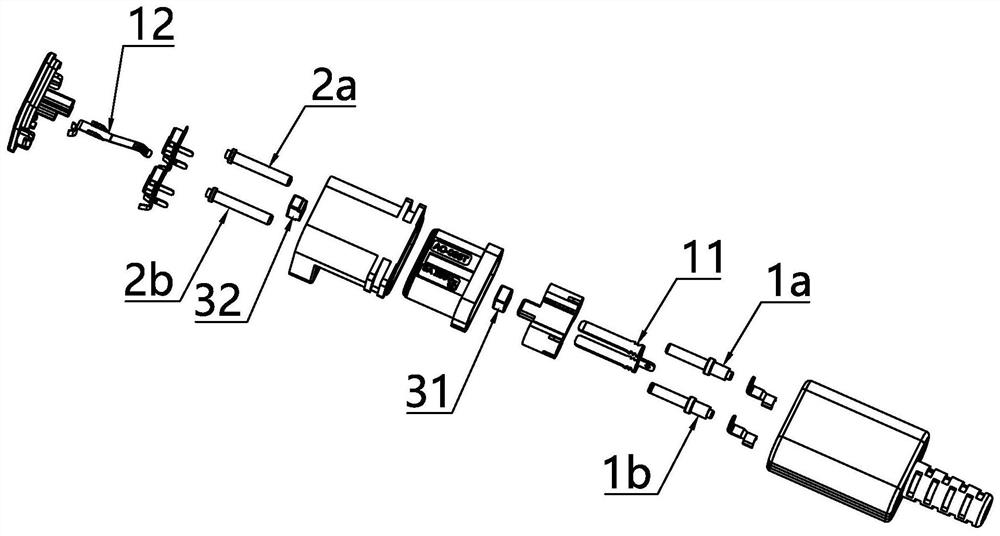

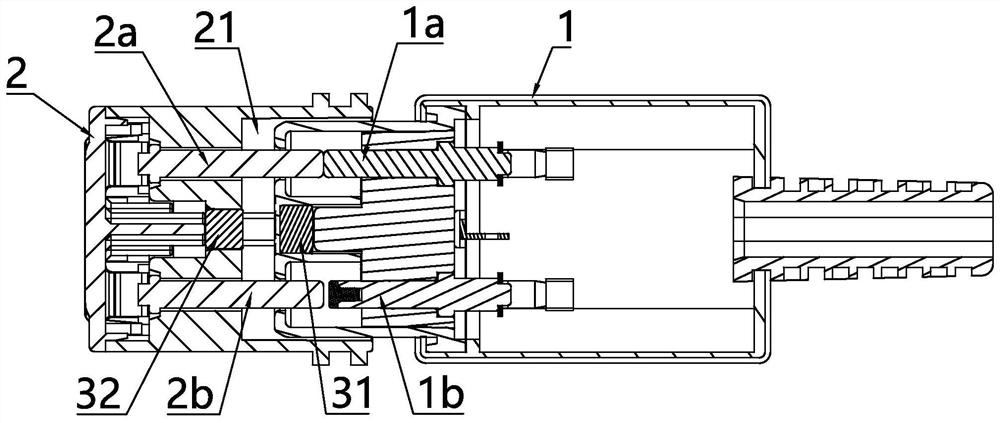

[0037] Such as Figure 1 to Figure 7 As shown, this embodiment provides a plug-in connector, including a plug 1 and a socket 2 with a slot 21, the socket 2 is mated with the plug 1 through the slot 21, and after the plug is inserted into the slot, the plug The relative socket is non-rotatable, and there is an anti-off structure between the socket 2 and the plug 1 to prevent the plug 1 from being loosened from the socket 21. The plug 1 has multiple insertion orientations relative to the socket 21. The plug 1 and the socket 2 One of them is provided with a first ground wire 11 , and the other is provided with a second ground wire 12 , and the first ground wire 11 and the second ground wire 12 can be electrically contacted when the plug 1 is in different insertion orientations.

[0038]First of all, the socket 2 is mated with the plug 1 through the slot 21, which increases the mating area between the plug 1 and the socket 2, facilitates the contact between the neutral wire, live ...

Embodiment 2

[0050] Of course, the first ground piece 11 may no longer be provided with a plurality of independent contact pieces 111 in contact with the conductive piece 121, but the first ground piece 11 has a contact ring sleeved on the outside of the plug 1, and the second ground piece The piece 12 has a conductive piece 121 protruding into the slot 21 , and the contact ring is in electrical contact with the conductive piece 121 when the plug 1 is mated with the slot 21 . Since the contact ring is a continuous closed ring, no matter what direction the plug 1 is plugged in, it can ensure that the conductive piece 121 is in contact with the contact ring, and the user's plugging operation is more convenient. At the same time, the contact ring is sleeved on the plug 1 Not only is the installation more convenient, but also the overall strength and aesthetics are good after the cooperation of the two.

[0051] It can be understood that the first ground piece 11 can also be arranged on the so...

Embodiment 3

[0054] In addition to the magnetic force anti-off in the first embodiment, the plug 1 and the socket 2 can also include a detachable first buckle and a second buckle, the first buckle and the second buckle One is set on the socket 2 and the other is set on the plug 1. The anti-loosening structure prevents the plug 1 from being loosened from the socket 21 through the fastening force between the first buckle and the second buckle. The fastening force between the first buckle position and the second buckle position is large, and the anti-loosening effect is good. At the same time, the plug-in fastening feels good, and it is convenient for the user to perceive whether the current plug 1 is inserted in place.

[0055] For other content not described in this embodiment, reference may be made to Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com