Apparatus and method for hybrid photovoltaic device having multiple, stacked, heterogeneous, semiconductor junctions

A photovoltaic device and semiconductor technology, applied in semiconductor devices, photovoltaic power generation, energy conversion devices, etc., can solve the problem of batteries without substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

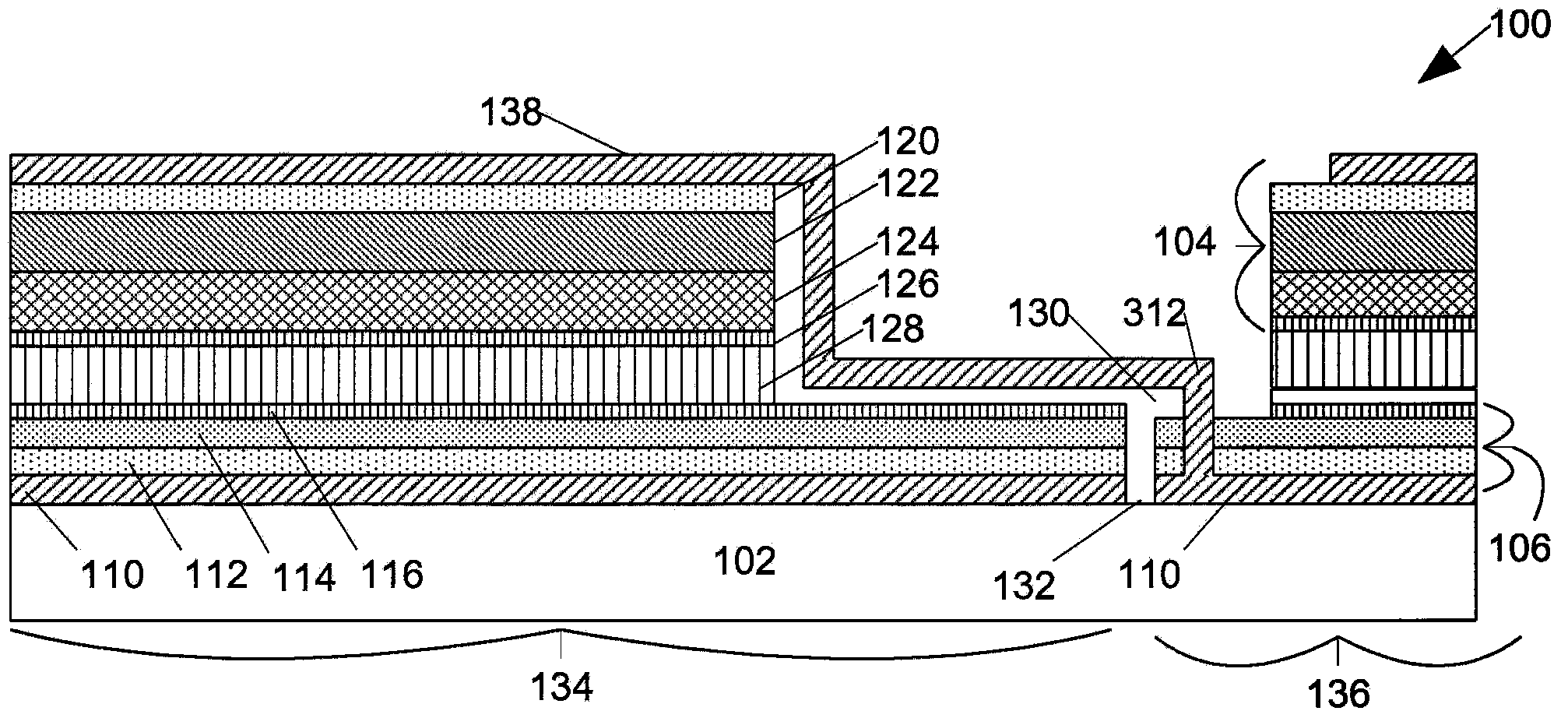

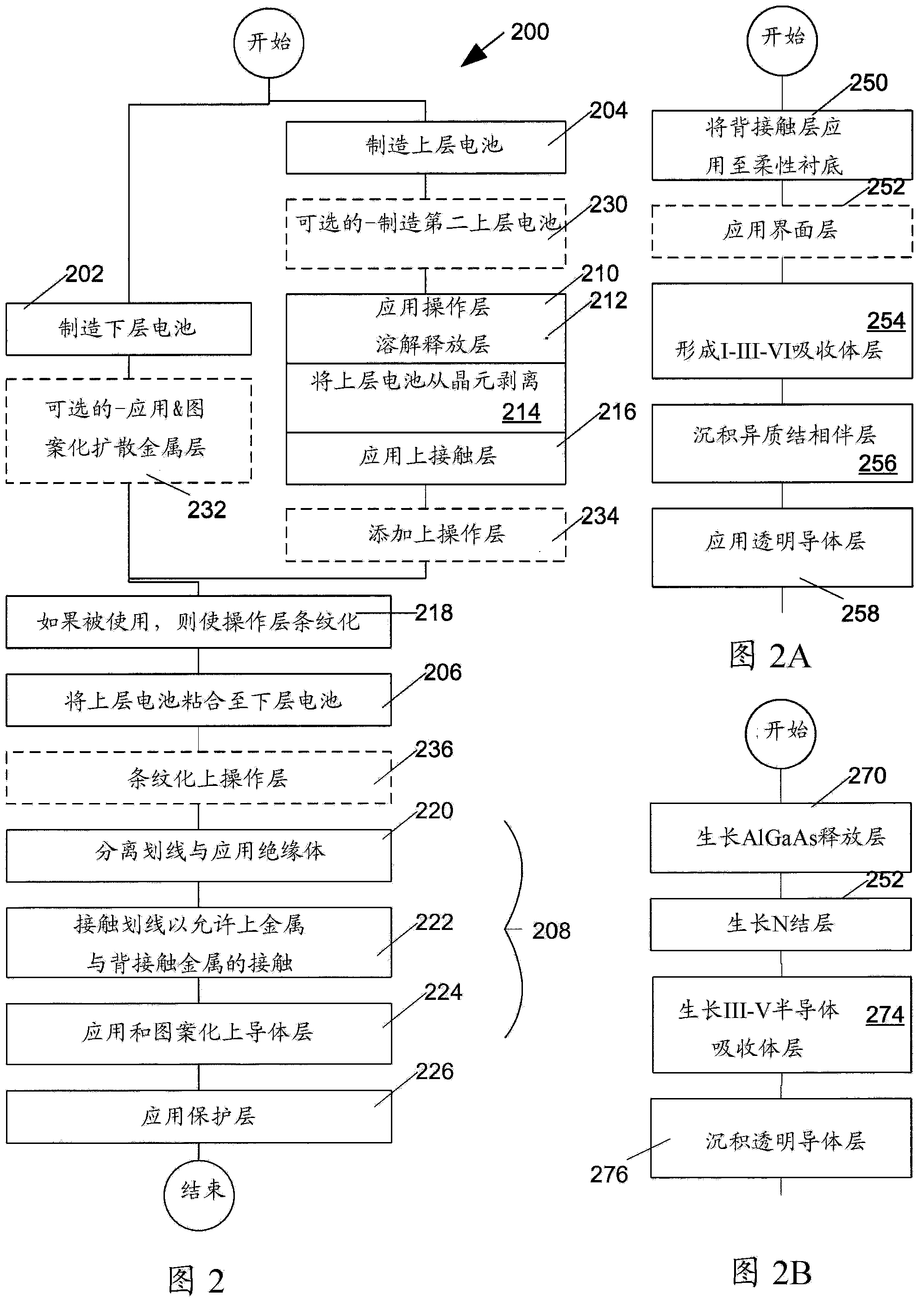

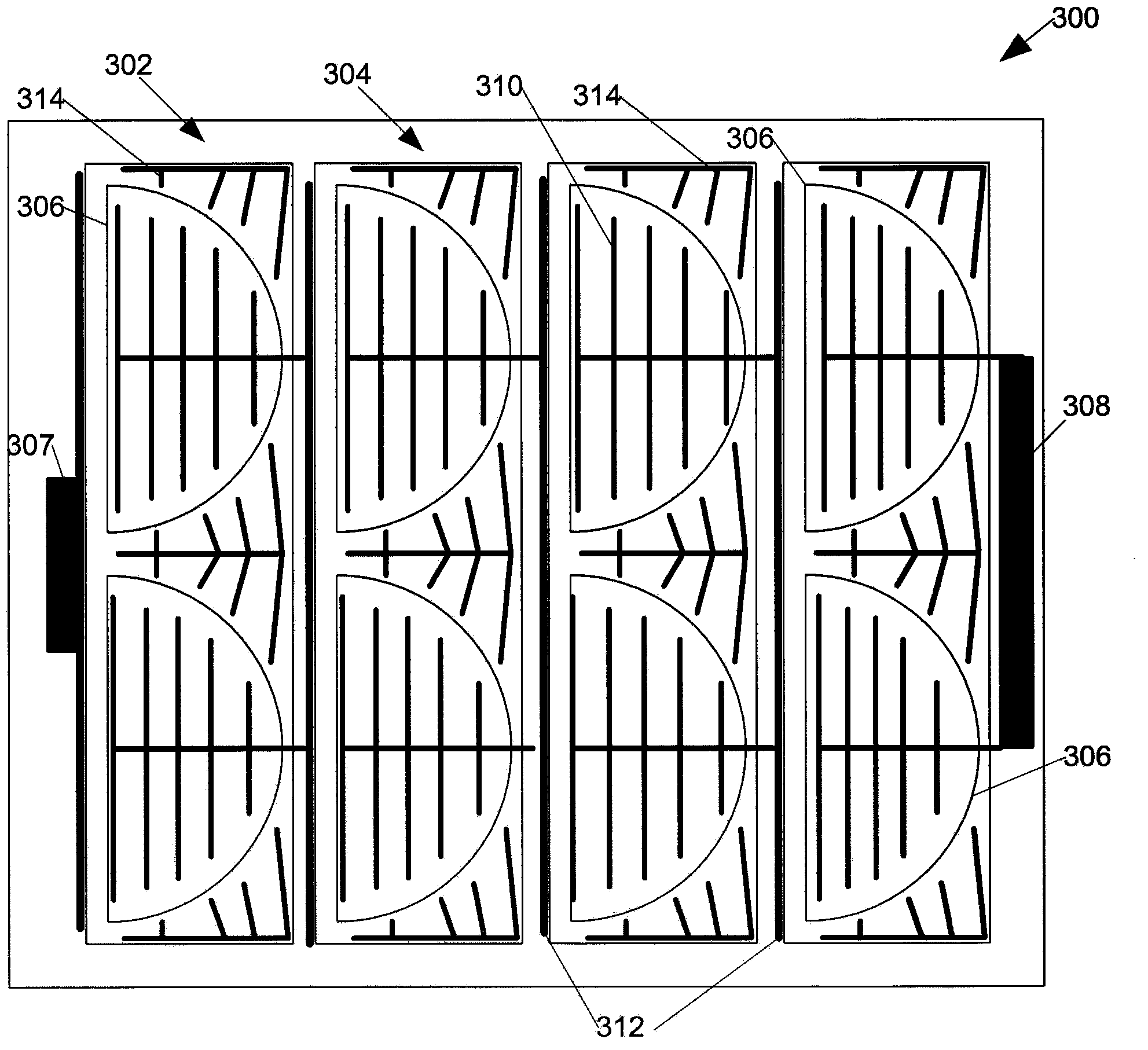

[0029] Certain III-V photovoltaic devices, such as those made of GaAs, AlGaAs, GaAsP, or InGaP, have a band gap such that the minimum energy available for photon absorption is significantly greater than in certain I-III-VI materials such as CIGS and The minimum energy available for photon absorption in similar materials). Therefore, a tandem multijunction photovoltaic device made of these materials and having a III-V junction above an I-III-VI junction will absorb high-energy photons in the III-V junction, assuming no losses in the interfacial and conductor layers and some lower energy photons passing through the III-V layer are absorbed in the I-III-VI lower layer junction.

[0030] One or more two high temperature processing steps to form and anneal the I-III-VI semiconductor alloy, and the high temperature processing step is performed in a gas including a large amount of selenium vapor. Similarly, GaAs and related compounds such as aluminum-gallium arsenide (AlGaAs) and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com