Spring contact pin arrangement

A pin-in device and pin-in technology, which are applied to measurement devices, use mechanical devices to transmit sensing components, instruments, etc., can solve the problems of non-existence, no electrical switch path, and inability to explain whether the test object is defective, etc. Space saving, low flexibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

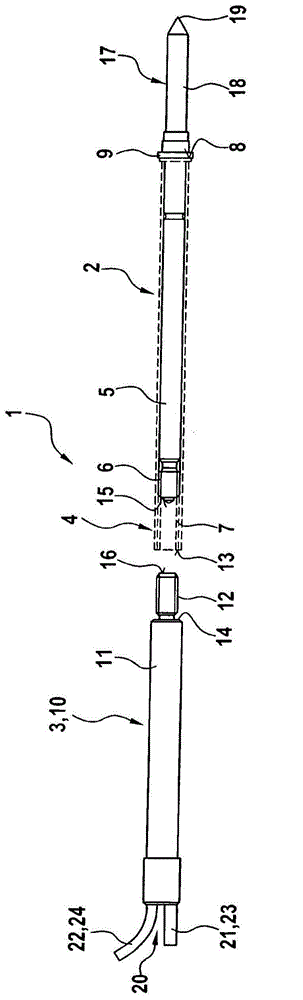

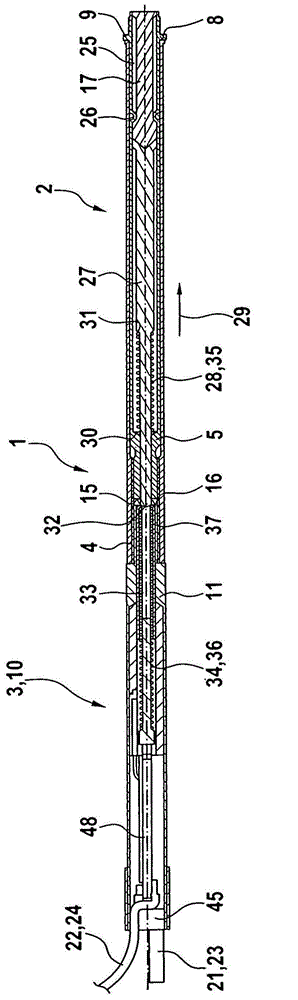

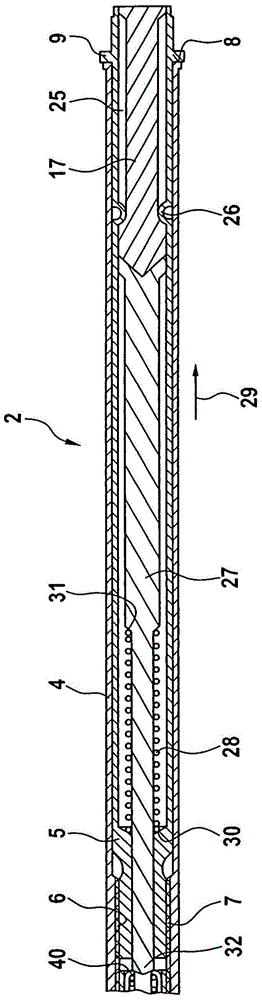

[0029] figure 1 Shown is a spring contact pin arrangement 1 with spring contact pins 2 , a position sensor 3 and a transparently shown coupling sleeve 4 . Most of the spring contact pins 2 are located inside the coupling sleeve 4 ; the position sensor 3 is in a state not connected to the coupling sleeve 4 , ie in the unmounted position. During operation, ie when testing an electrical test object (not shown) with the spring contact pin arrangement 1 , the spring contact pins 2 are held by the coupling sleeve 4 on a support of the test device. For this purpose, the pin housing 5 of the spring contact pin 2 has an external thread 6 which is screwed into an internal thread 7 of the coupling sleeve 4 . This screwing in takes place until the end face 8 of the coupling sleeve 4 touches the flange 9 of the pin housing 3 . Such as figure 1 As shown, the position sensor 3 is designed as a position sensor pin 10 and has a sensor housing 11 with an external thread 12 which can thus be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com