Contact arrangement for establishing a spaced, electrically conducting connection between microstructured components

A contact device and micro-structuring technology, applied in the field of manufacturing such contact devices and component devices, can solve the problems of area loss and extra cost, and achieve the effect of small structure size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

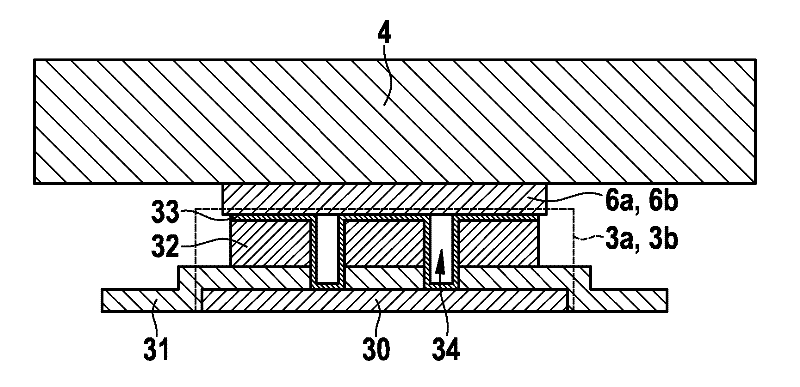

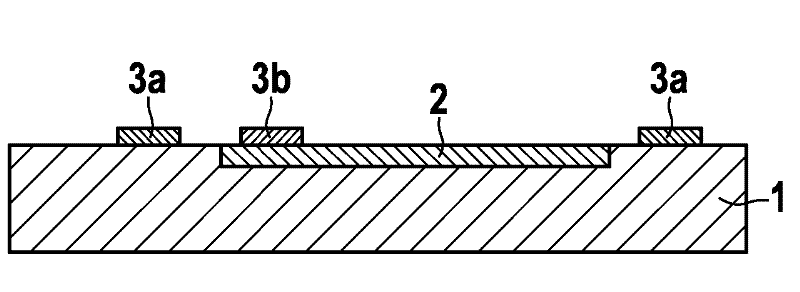

[0038] figure 1 A cap wafer 1 is shown, which comprises a microstructured first component 2 . Component 2 is shown schematically here and can be, for example, an application-specific integrated circuit (ASIC). The wafer 1 comprises a first contact device 3a and a second contact device 3b serving as a bonding frame. The first contacting device 3 a is mounted directly on the wafer, the second contacting device 3 b is mounted on the microstructured first component 2 .

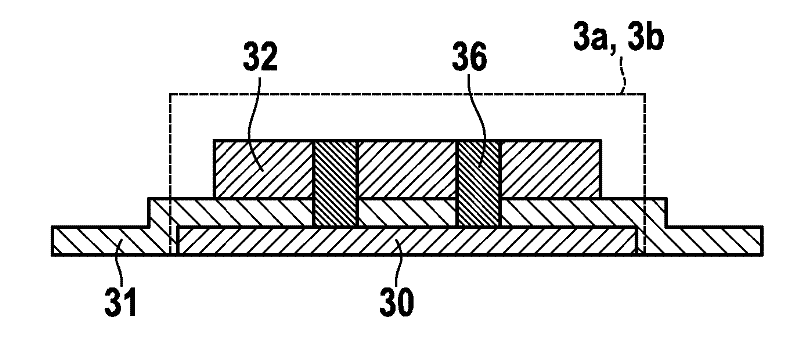

[0039] figure 2 A detailed view of the contacting devices 3a and 3b according to the invention is shown. In this case, the electrical connection contacts 30 are provided with a passivation layer 31 , wherein the material of the connection contacts 30 can be a metal such as aluminum or copper, which are used, for example, in ASICs as the uppermost wiring plane. Passivation layer 31 is typically a dielectric such as silicon dioxide or silicon nitride.

[0040] A dielectric spacer layer 32 is deposited on the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com