Plug-in circuit breaker assembly

A circuit breaker assembly, circuit breaker technology, applied in the direction of electrical components, bus/line layout, substation/switch layout details, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

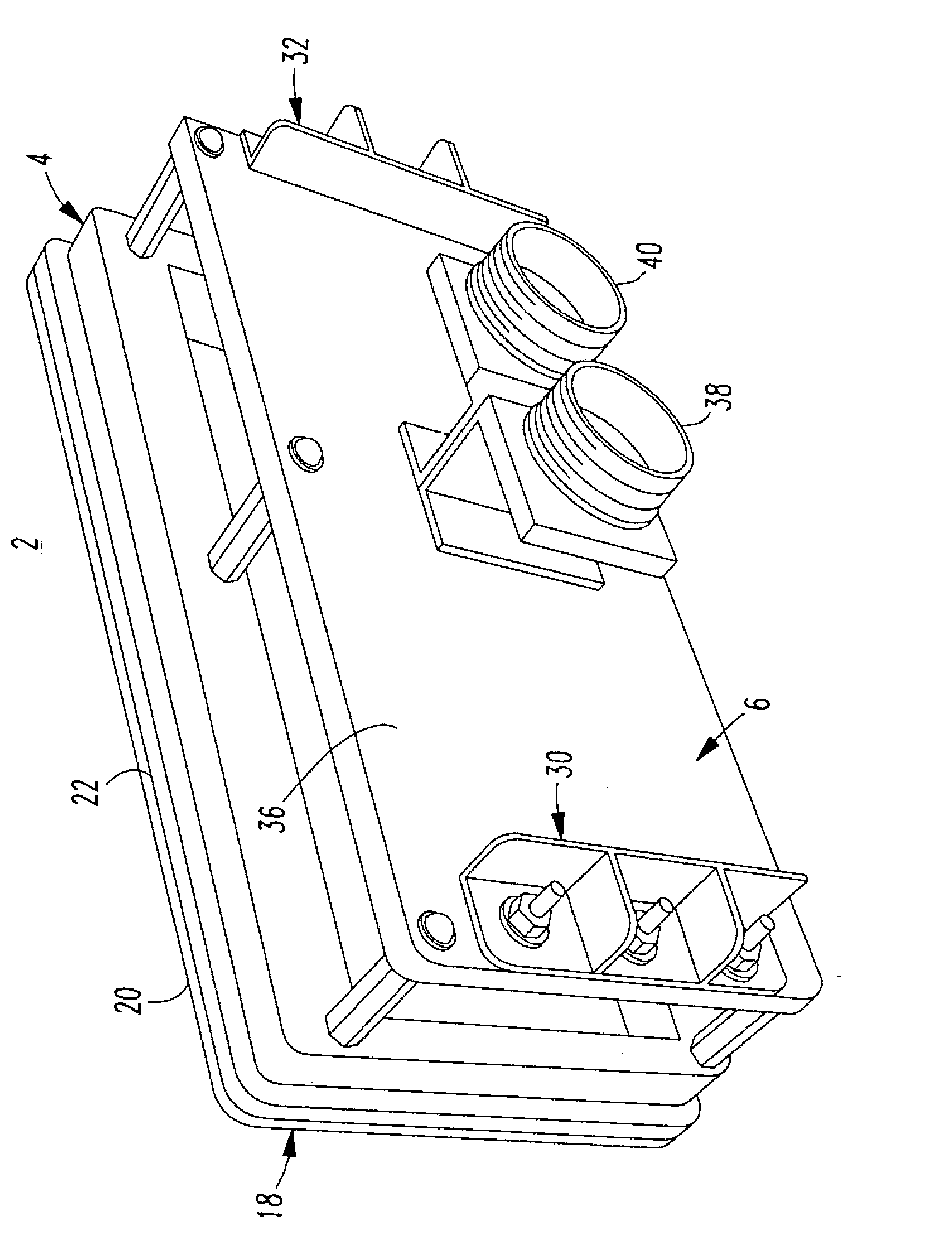

[0036] image 3 The rear of the plug-in circuit breaker panel 2 is shown comprising a first feeder 30 and a second feeder 32 for a three-phase system. Typically, for each feeder 30, 32, there may be a single three-pole AC breaker (not shown) and multiple single-pole AC breakers (not shown) for each of the three phases. For example, each feeder 30, 32 is a three-terminal junction box with three power terminals for the three phases of the corresponding feeder. The first surface 34 of the electrical bus structure 6 ( figure 2 ) close to the first plurality of plug-in parts 8 and the feeders 30 , 32 and their power terminals together with the plurality of load connectors 38 , 40 are coupled to the opposite second surface 36 . Thus, the load connectors 38 , 40 include load outputs (eg, loads) from corresponding circuit breakers 10 associated with the respective feeders 30 , 32 . In a similar manner, the power input (eg line) to the corresponding circuit breaker 10 is associated...

example 2

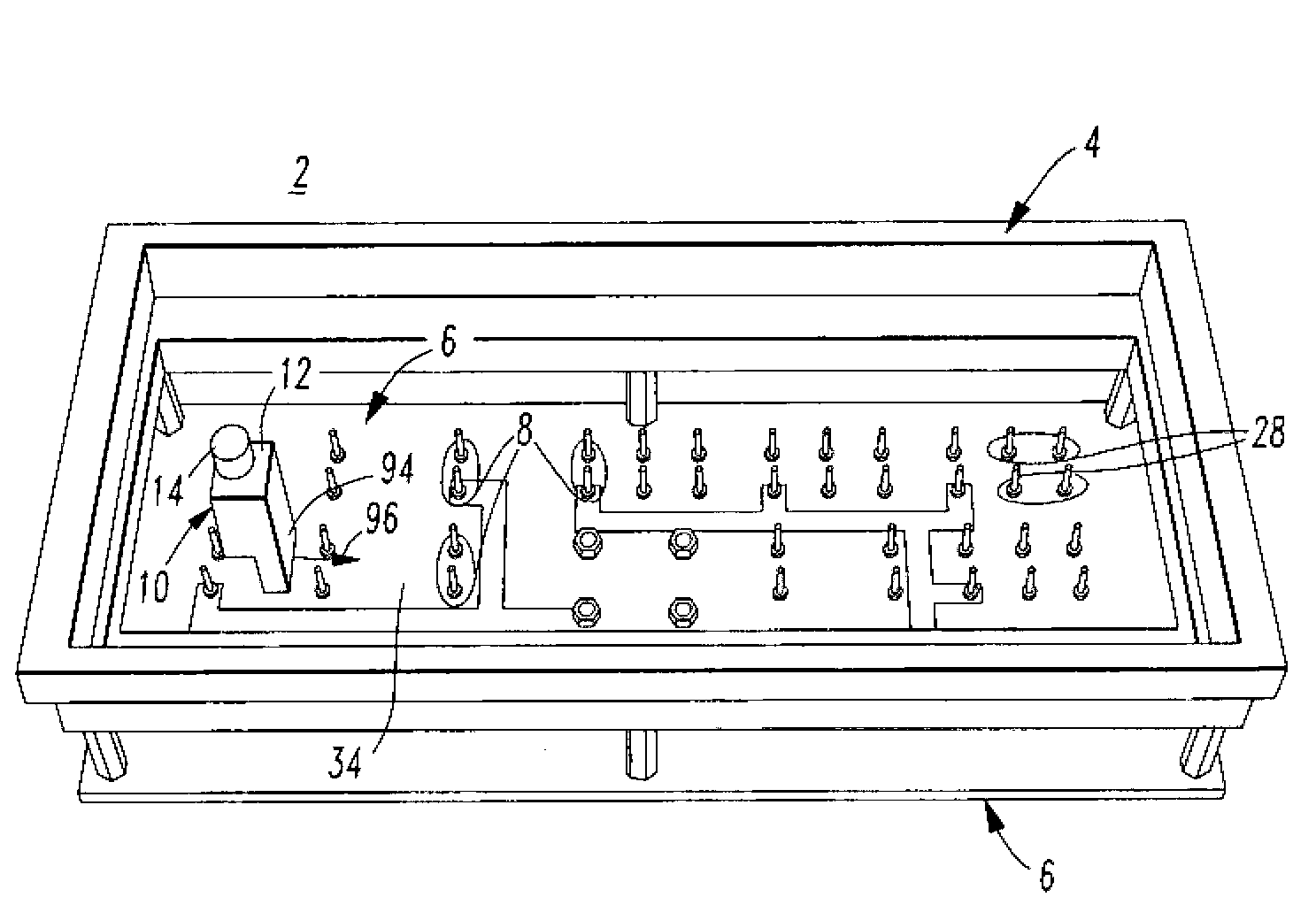

[0041] Figure 5 A circuit breaker 10 in a plug-in circuit breaker panel 2 is shown. Each of the plurality of first insertion parts 8 is a plurality of male terminals, and the second insertion part 16 is a plurality of female sockets. Alternatively, any suitable blade-to-fuse type or banana plug type connections may be used. The circuit breaker 10 can be easily swapped out using these plug-in parts 8 , 16 . The use of linear motion (eg, plug-in) circuit breaker pins and receptacles and faceplate 18 eliminates the threaded sleeves, nuts, washers, lock washers and terminal screws that would otherwise be employed with known aircraft circuit breakers. As a result, circuit breaker maintenance can be performed, for example and without limitation, in less than about 5 minutes, compared to hours with prior art methods. The breaker panel 2 remains fixed to the aircraft (not shown), thereby reducing moving parts and shortening the harness length for access. This also reduces point-t...

example 3

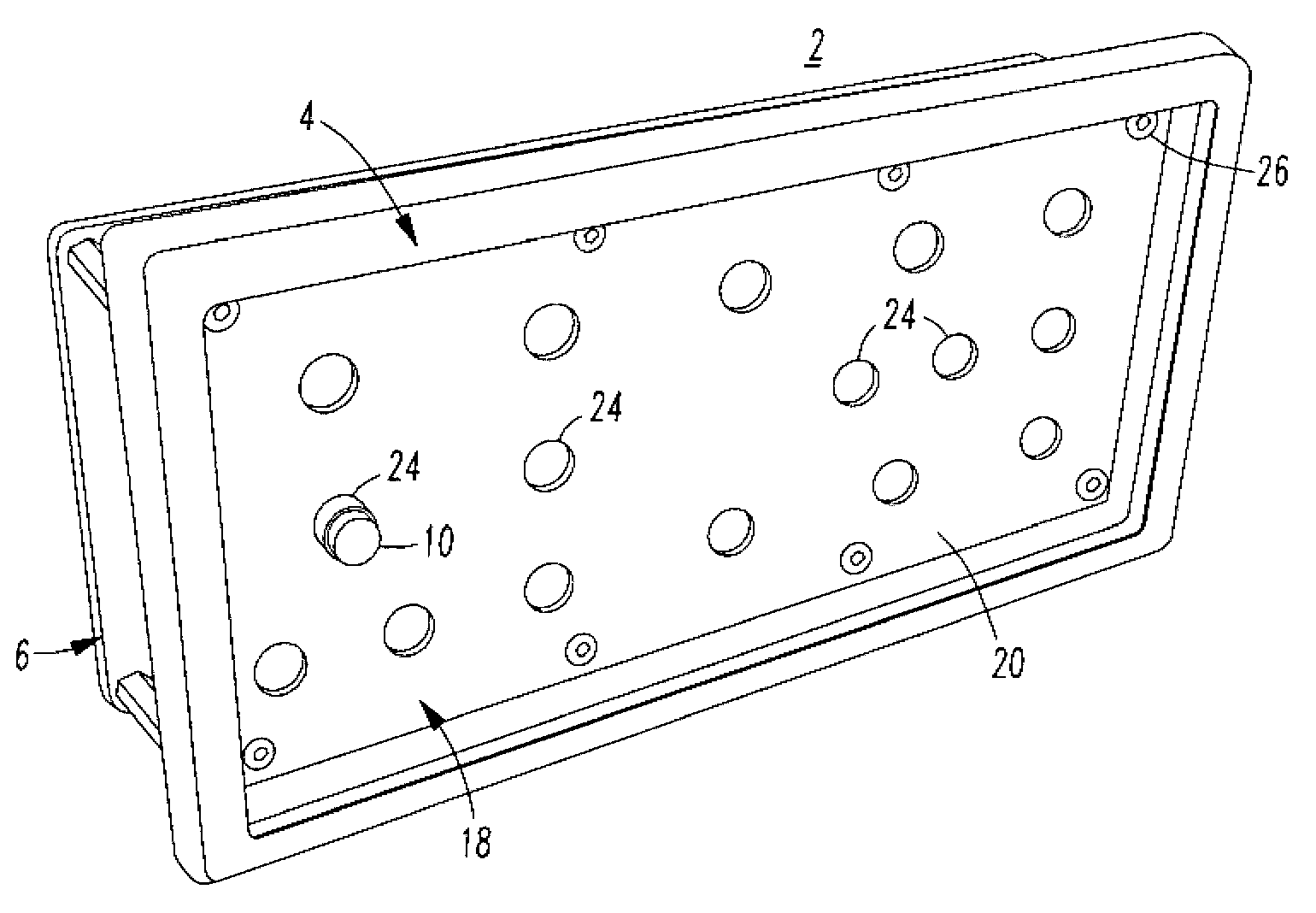

[0043] see Image 6 , another plug-in breaker panel 50 comprising a housing (not shown, but see figure 1 The housing 4) and the electrical bus structure 51, the electrical bus structure can be used with figure 1 The same or similar electrical bus structure. A first surface 52 of the panel 54 includes an illuminated legend 56 for a portion of a plurality of circuit breakers 58 . LED illuminated marking strip 60 may identify a corresponding circuit breaker (eg, 58 ) and a corresponding power circuit or load (not shown). The marking strip 60 can be configured to be easily removed and reconstituted in about 5 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com