Exhaust pre-filter device changed outside hot cell

A technology of pre-filter and hot chamber, which is applied in the direction of dispersed particle filtration, chemical instruments and methods, and separation of dispersed particles. The effect of sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

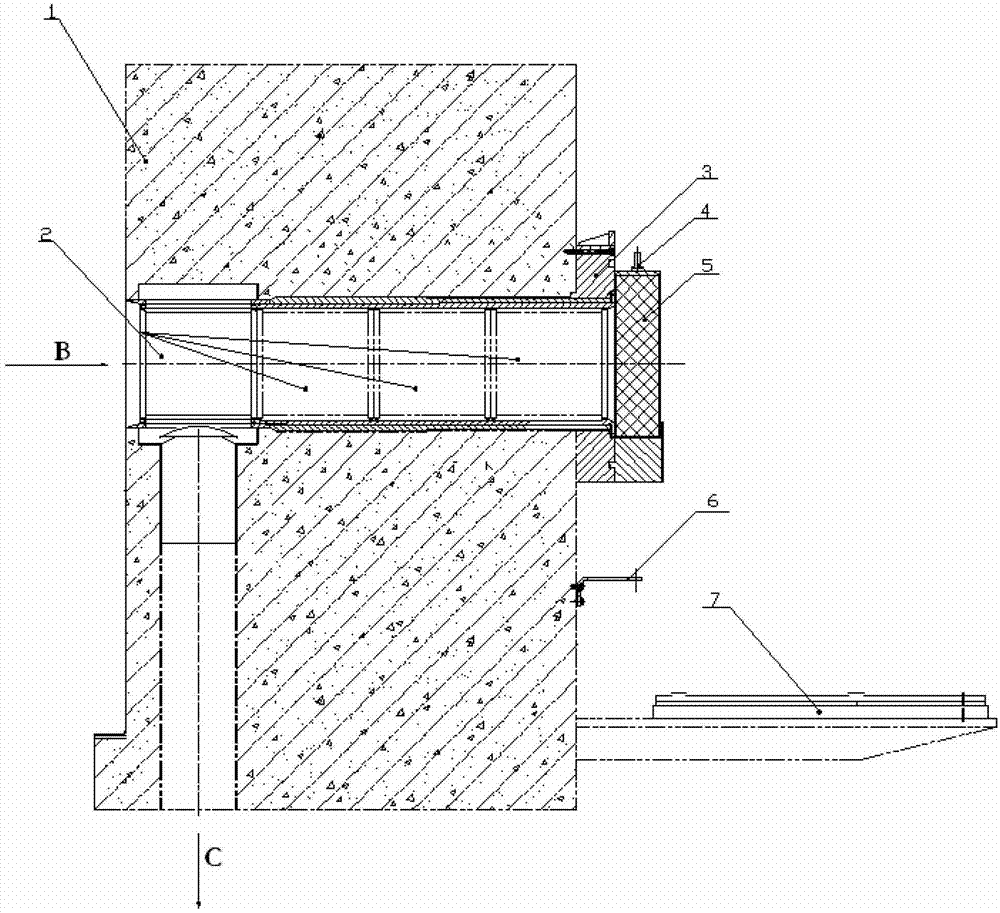

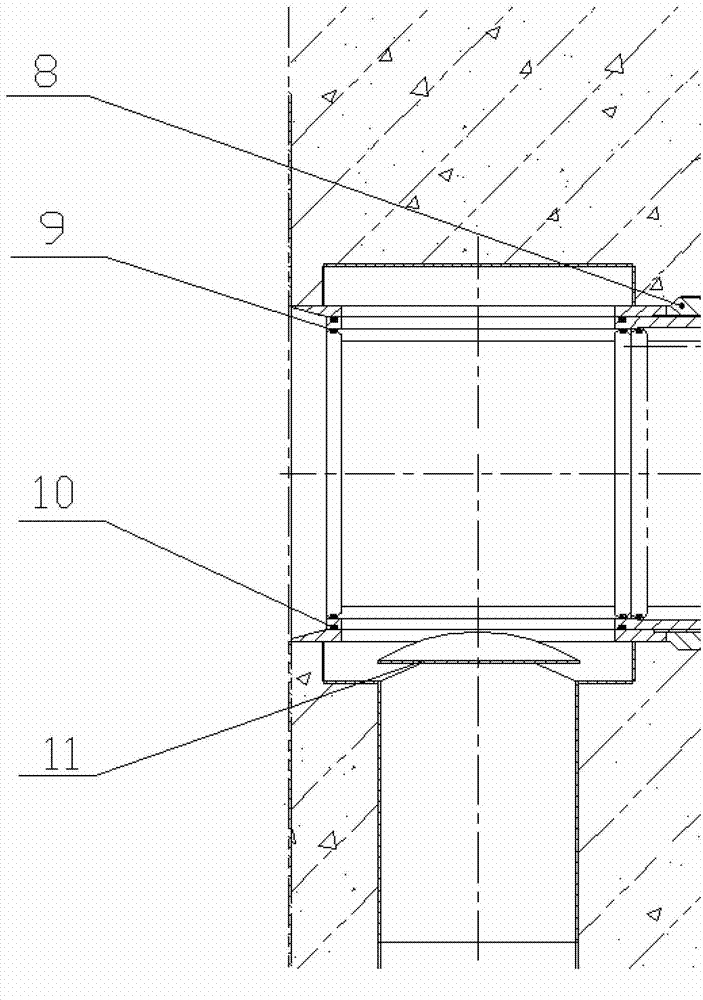

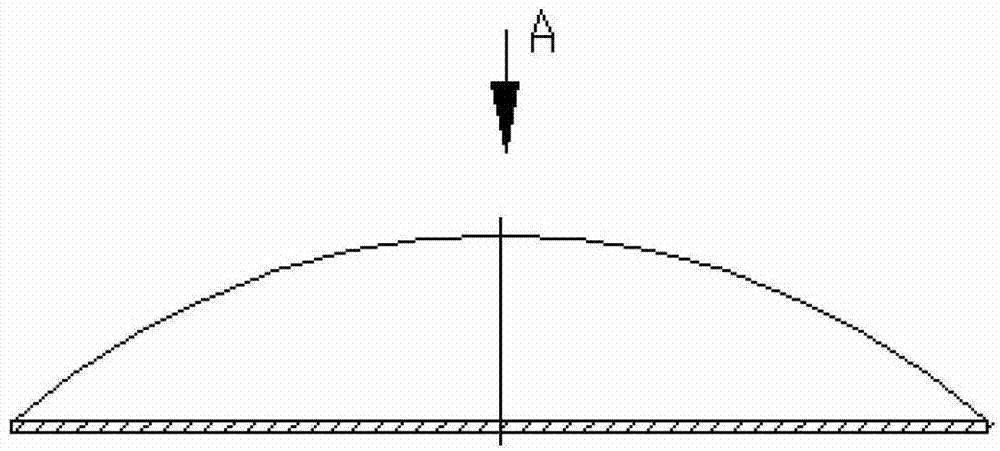

[0025] The exhaust air pre-filter device replaced outside the heat chamber of the present invention is mainly divided into pre-filters (such as figure 1 shown) and filter replacement trolley 19 (such as Figure 5 As shown) two parts: the pre-filter is set in the hot chamber concrete wall 1 channel, the outer casing 8 is arranged in the hot room concrete wall 1 channel, and several filter elements 2 of the pre-filter are arranged in the outer casing 8 in turn, among which One filter element is set on the top of the hot chamber exhaust channel and is in working condition, and the others are used as backup; one side of the outer casing 8 is provided with a protective gate 5 for sealing the hot chamber concrete wall 1 channel, and the top of the protective gate 5 is provided with a lifting ring 1 4; the filter element replacement trolley...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com