Method for inhibiting generation of grease in alkaline tower

A technology of alkali washing tower and butter, which is applied in chemical instruments and methods, purification/separation of hydrocarbons, hydrocarbons, etc., and can solve problems such as poor inhibition effect of butter, easy blockage of alkali washing tower, inconvenient operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

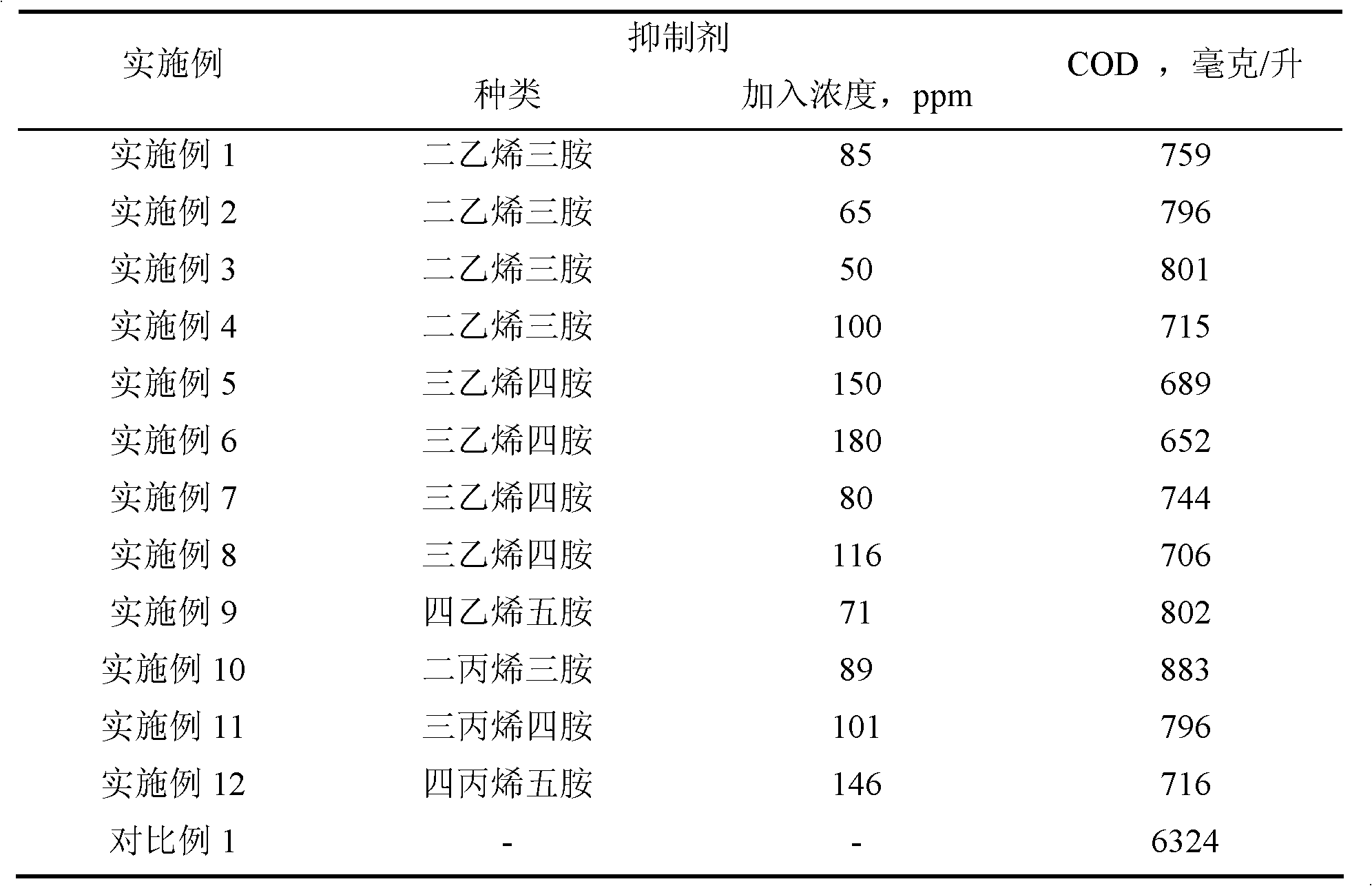

[0012] The inhibitor is applied to the caustic scrubber of the ETO unit, where the molar composition of the materials entering the caustic scrubber is: ethylene 49.1%, water 50.25%, acetaldehyde 0.05%, ether 0.01%, C 3 + W hydrocarbon 0.58%, CO 2 0.01%. The lye temperature of the caustic washing tower is 45℃, and the concentration of lye (NaOH) is 10%. The inhibitor diethylenetriamine is continuously injected into the lye circulation line using a piston pump, and the injection concentration is 85ppm. After 30 days of operation, there is no blockage. The tower phenomenon occurs. The test method of GB8978-1996 was used to test the COD value of lye in 759 mg / L. The results are shown in Table 1.

Embodiment 2~12

[0014] According to each step of [Example 1], only the added inhibitor and its concentration are different. The specific results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com