Temporary channel anti-skidding road surface for foundation pit excavation and construction method of temporary channel anti-skidding road surface

A temporary and foundation pit technology, applied to roads, roads, pavement details, etc., can solve problems such as tire slipping, rollover accidents, and non-recycling, and achieve the effects of avoiding tire slipping, increasing friction, and good anti-skid effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the present invention easier to understand, the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

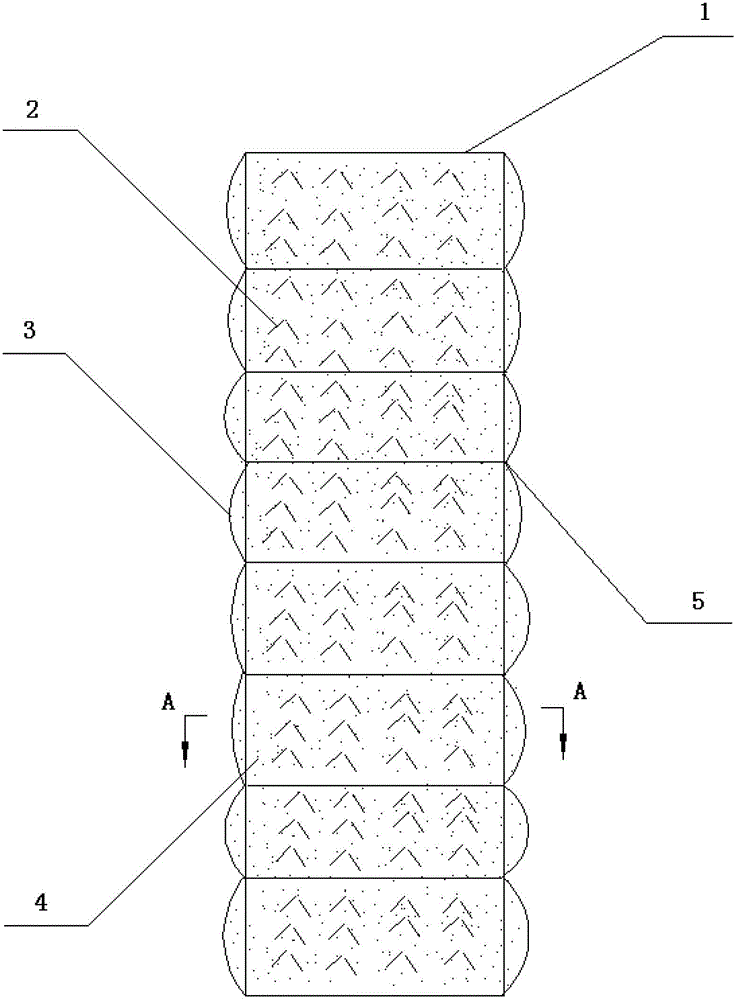

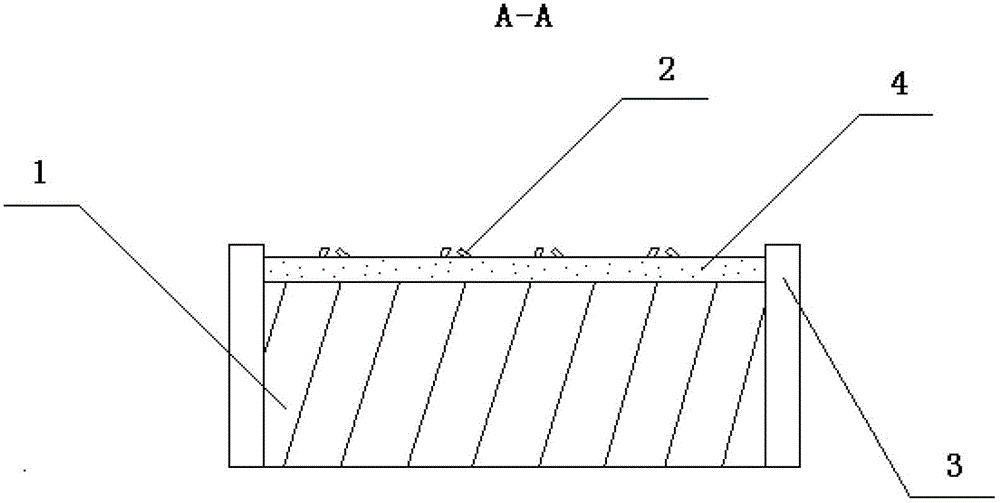

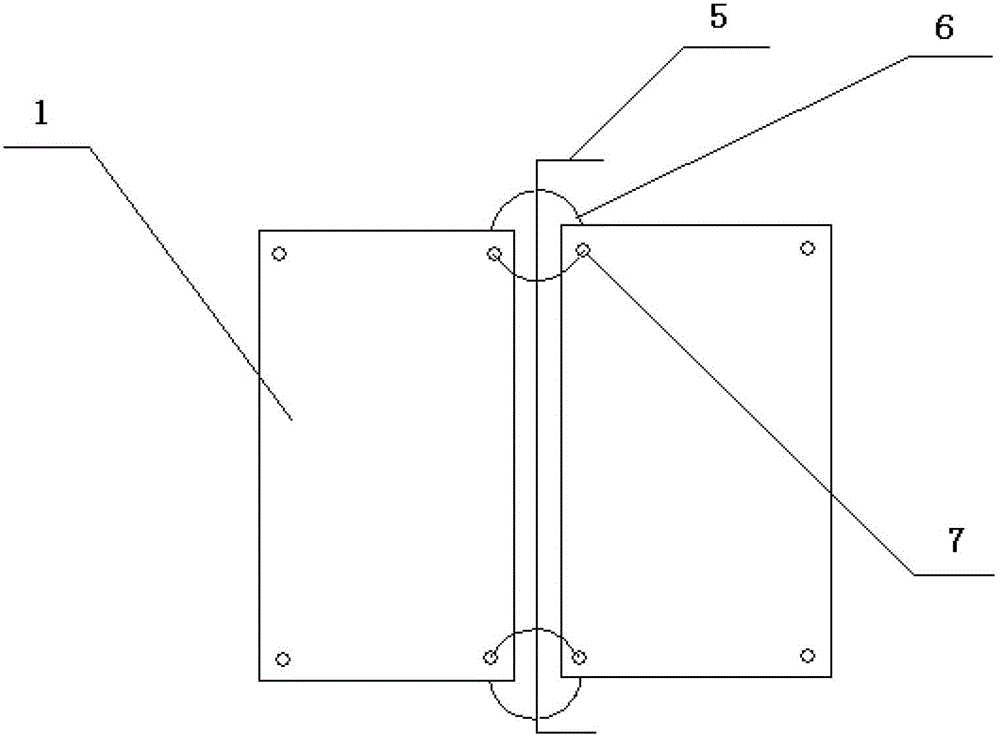

[0031] refer to figure 1 , figure 2 , image 3 The non-slip pavement for the temporary access of the present invention for foundation pit excavation consists of several interconnected non-slip pavement units; the non-slip pavement unit includes a rectangular steel plate 1, several eight-shaped steel blocks 2, and edge 3; the specification of the steel plate 1 is 4500×1000×20mm, and its four corners are respectively provided with perforations 7; several eight-shaped steel blocks 2 such as figure 1 As shown, they are arranged in rows and columns and welded on the steel plate 1; the two flanges 3 are respectively welded on both sides of the steel plate 1; The road surface is connected by the circular ring 6 passing through the perforation 7, and fixed by the bolts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com