Collision sliding energy dissipation type bridge anti-seismic stop block structure with steel springs

An energy-consuming, steel spring technology, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as large impact force, beam body and concrete block damage, and insufficient horizontal shear force of reinforced concrete block

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below the present invention is further described:

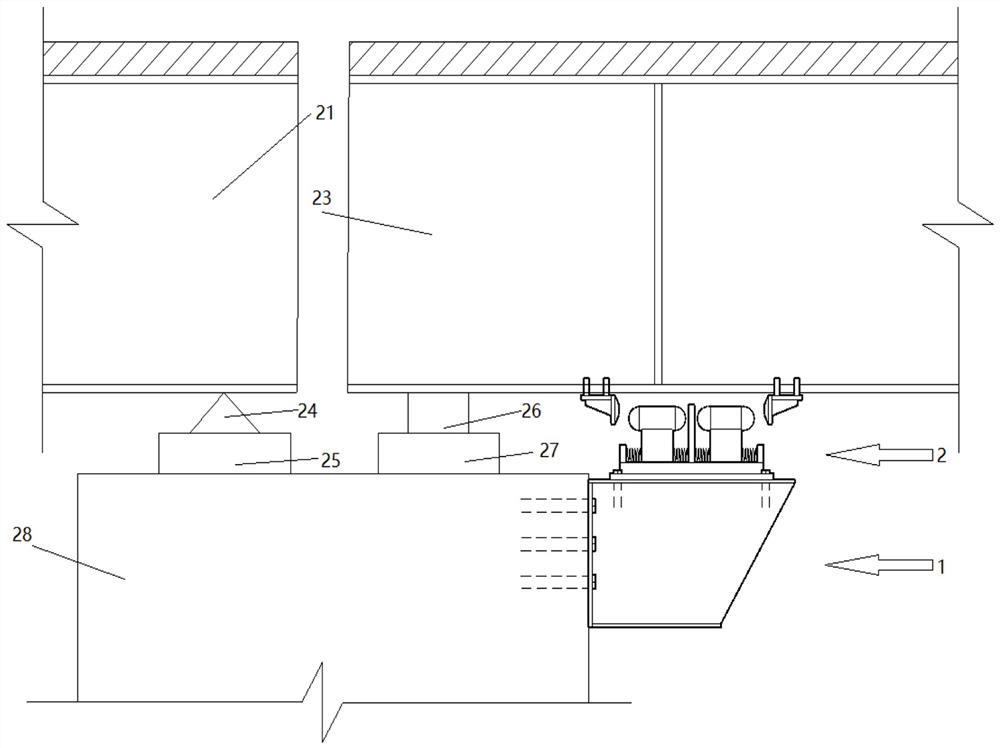

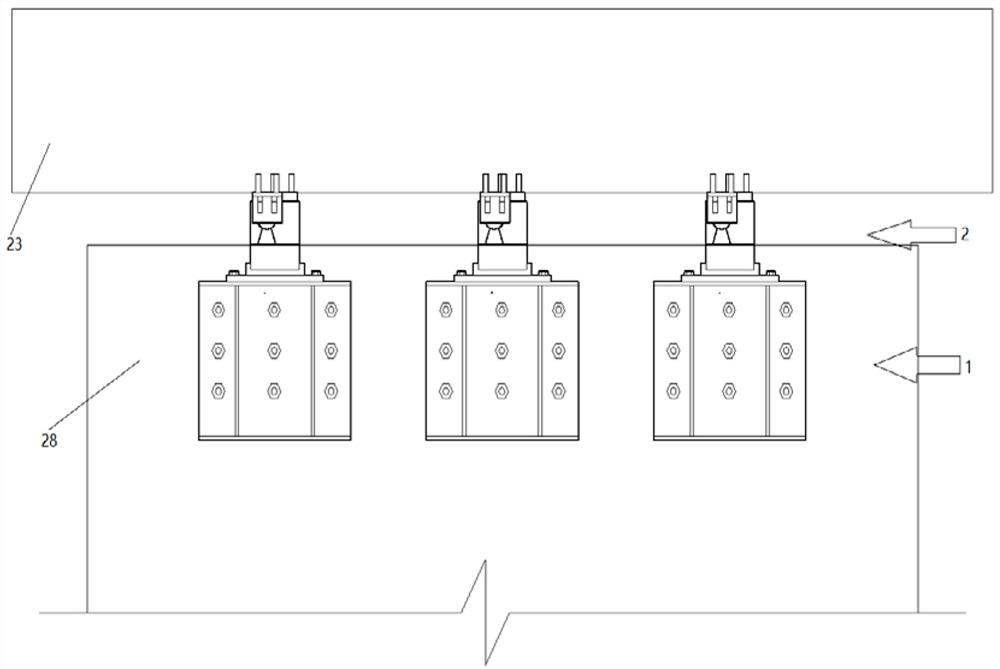

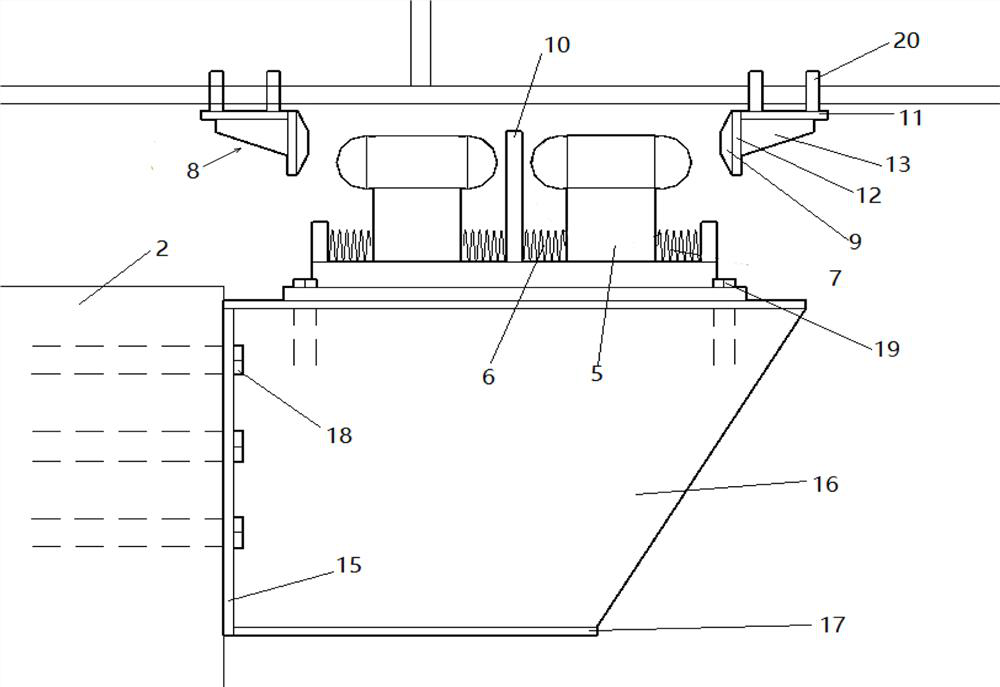

[0028] see Figure 1-7 .

[0029] The invention discloses an anti-seismic block structure of a collision-sliding energy-dissipating bridge with steel springs, comprising a steel corbel 1 and a block structure 2, the steel corbel 1 is fixed on a bridge pier 28 through steel corbel side plate bolts 18 Above the side wall; the block structure 2 includes a steel base plate 3, a sliding groove 4, a collision block 8, an energy dissipation type low yield point steel plate 10 and a double hemispherical slider 5, and the steel base plate 3 is fixed by bolts 19 On the top of the steel corbel 1, the sliding groove 4 is welded on the top surface of the steel bottom plate 3, and an energy-dissipating low-yield point steel plate 10 is fixed in the middle, and steel baffles are welded on the left and right sides, A chute for the sliding of the double hemispherical slider 5 is formed between the energy dissipation type low yield po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com