Novel anti-collision column

A new type of anti-collision column technology, applied in the direction of floors, coverings/linings, buildings, etc., can solve the problems of easy local damage, high strength and rigidity requirements, etc., to achieve good protection, improve strength and rigidity, and reduce the possibility of sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

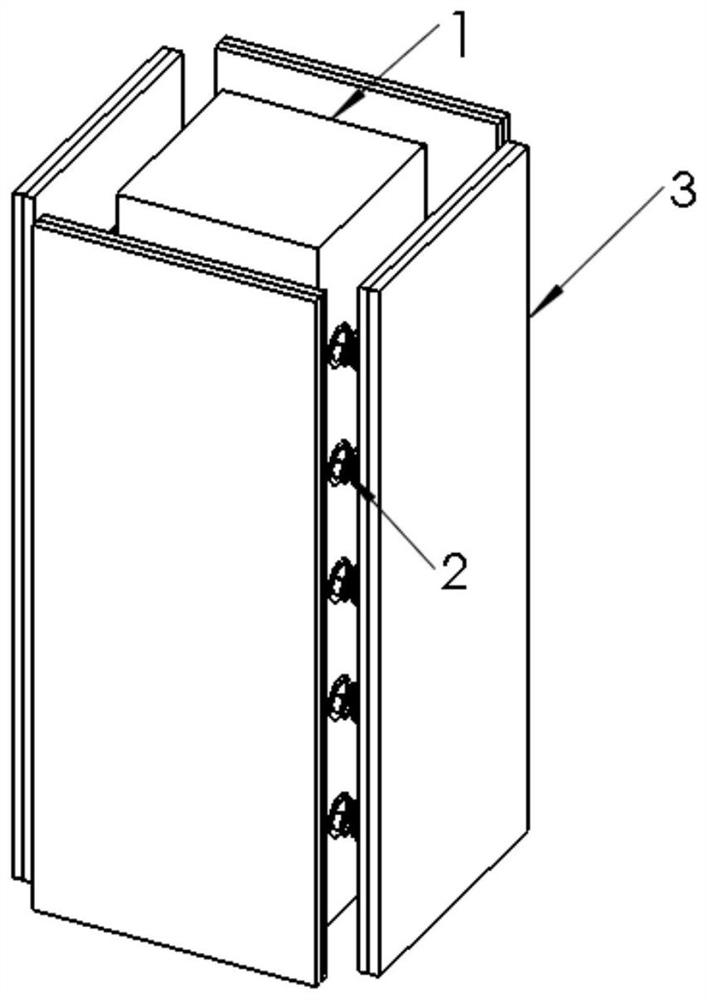

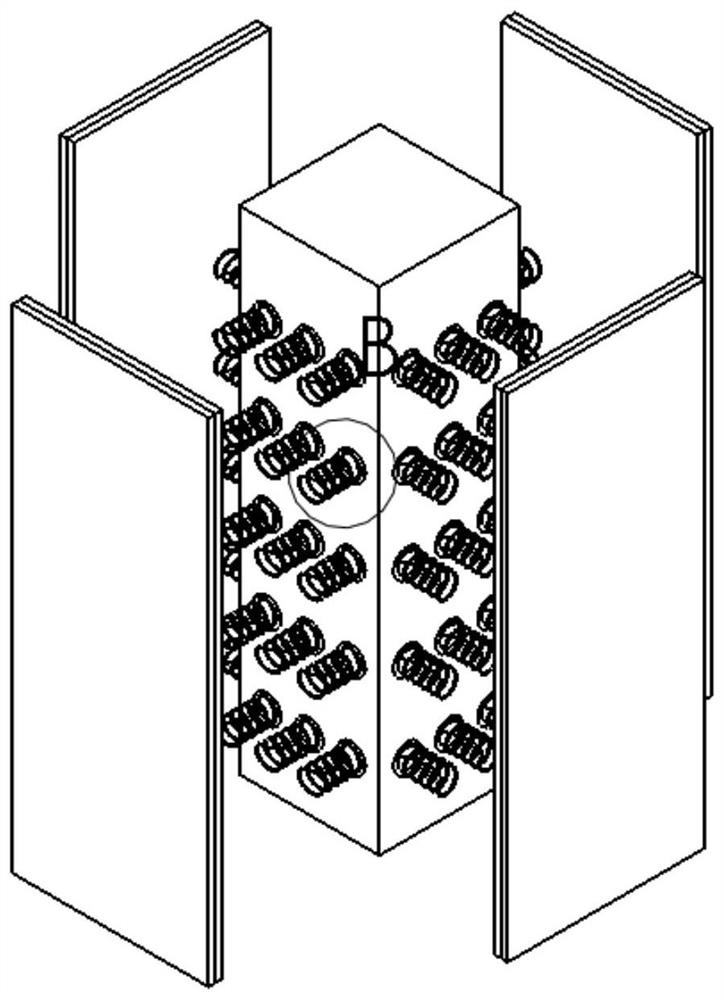

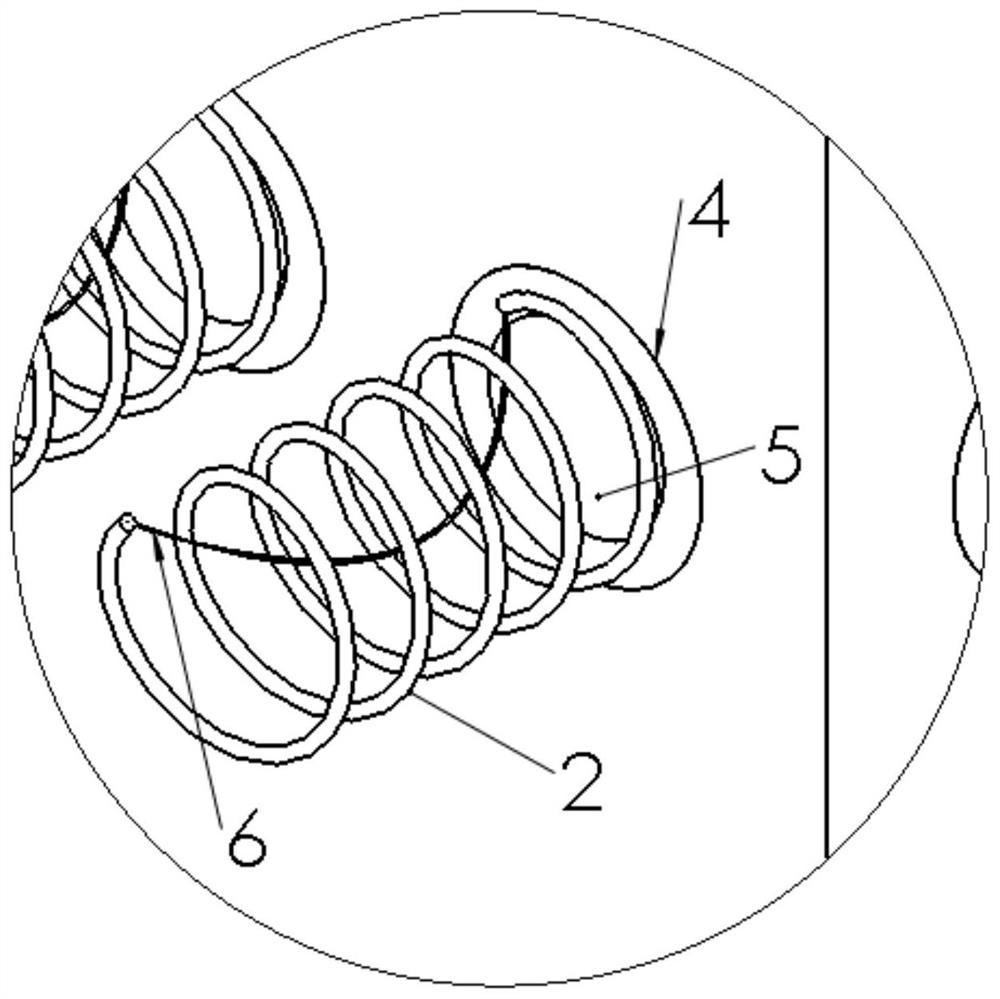

[0030] Example 1: Reference Figure 1 to Figure 5 , A new type of anti-collision pillar, including: a square column 1; also including: an anti-collision plate 3, the outer side of the anti-collision plate 3 is a rubber layer 301, the anti-collision plate 3 includes four, the anti-collision plate 3 and the square The side of the column 1 is matched; the compression spring 2, the anti-collision plate 3 is connected to the surrounding surface of the square column 1 through the compression spring 2, and the two ends of the compression spring 2 are respectively fixedly connected to the inner surface of the anti-collision plate 3 and the square column 1 In between, the compression springs 2 include more than three, and the compression springs 2 are evenly distributed on the inner surface of the anti-collision board 3.

[0031] Further, the inner surface of the anti-collision board 3 is a hard board 302.

[0032] Furthermore, it further includes: an annular embedded part 4 which is embed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com