Plate safe separation method and power charging structure

A separation method and plate technology, applied in the field of explosion processing, can solve problems such as machine crash and death, and achieve the effects of reducing the number of experiments, reducing local damage, and slowing the release of explosive energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

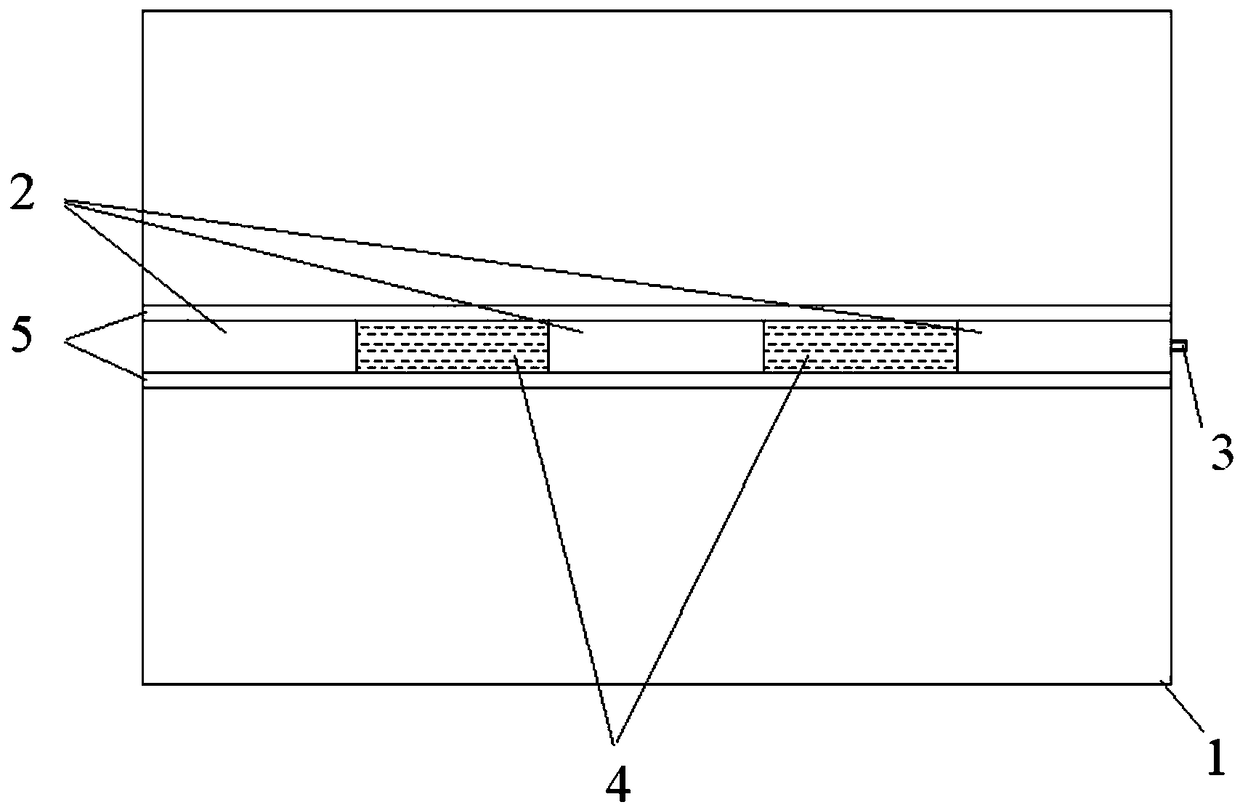

[0025] refer to figure 1 , the plate 1 is a titanium alloy plate with a length of 120 mm, a width of 66 mm, and a height of 12 mm.

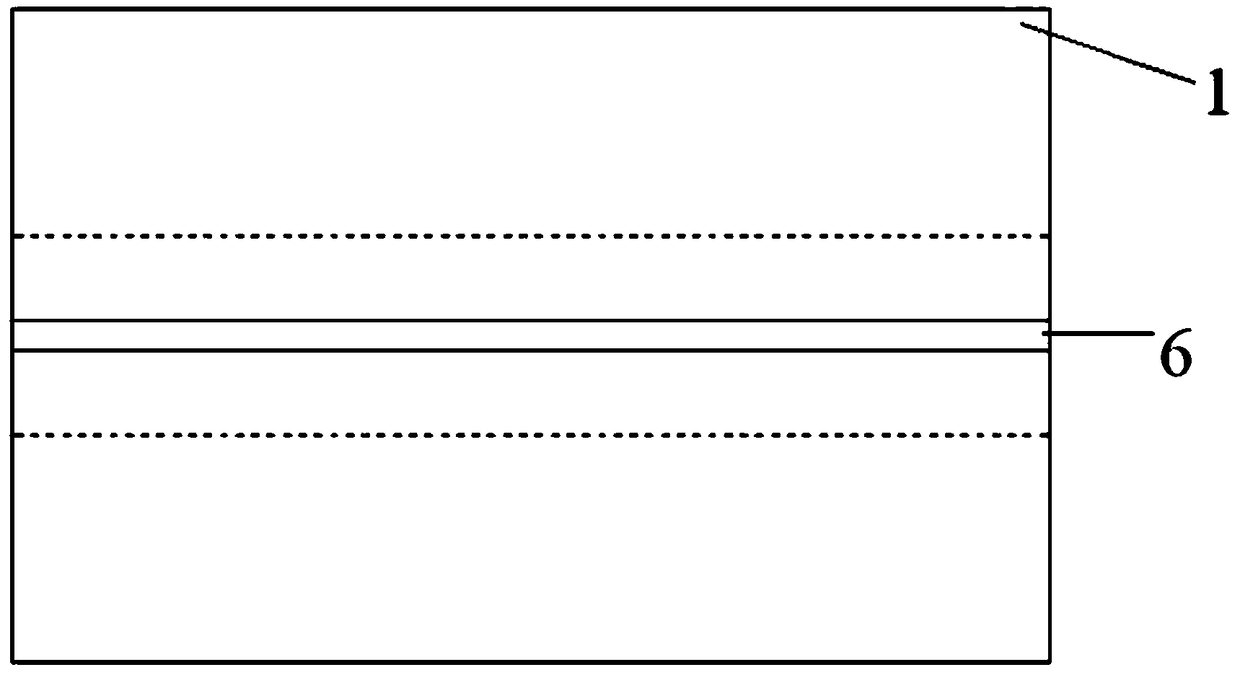

[0026] refer to figure 2 , The two sides of the central axis of the plate 1 are respectively marked with grooves 6 with a length of 120 mm, a width of 0.5 mm and a depth of 1 mm.

[0027] Drill a circular hole with a diameter of 8 mm and a length of 120 mm at the center of the plate 1, and the minimum wall thickness of the plate 1 is 2 mm at this time. The buffer layer 5 is a PVC pipe with a length of 120 mm and a thickness of 1.5 mm. The buffer layer 5 is put into the central circular hole of the plate 1 . Dynamite 2 is 25mm long. The spacer layer 4 has a length of 20mm, and the spacer layer 4 is a structure formed by covering the nonel with a plastic sleeve. The spacer layer 4 is placed between the explosives 2; the explosives 2 are detonated by the detonator 3.

[0028] According to the above-mentioned embodiment, the explosive 2 is deton...

Embodiment 2

[0031] When the length of the spacer layer 4 is 0, the charge structure in the hole of the plate 1 is a continuous charge structure, which is similar to the first embodiment and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com