Heat-insulating and sound-proof interlayer-free cement wall with three layers poured and solidified at same time

A technology for thermal insulation and sound insulation, cement wallboard, applied in the direction of walls, buildings, building components, etc., can solve the problems of poor load-bearing, difficult construction and installation, and high manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

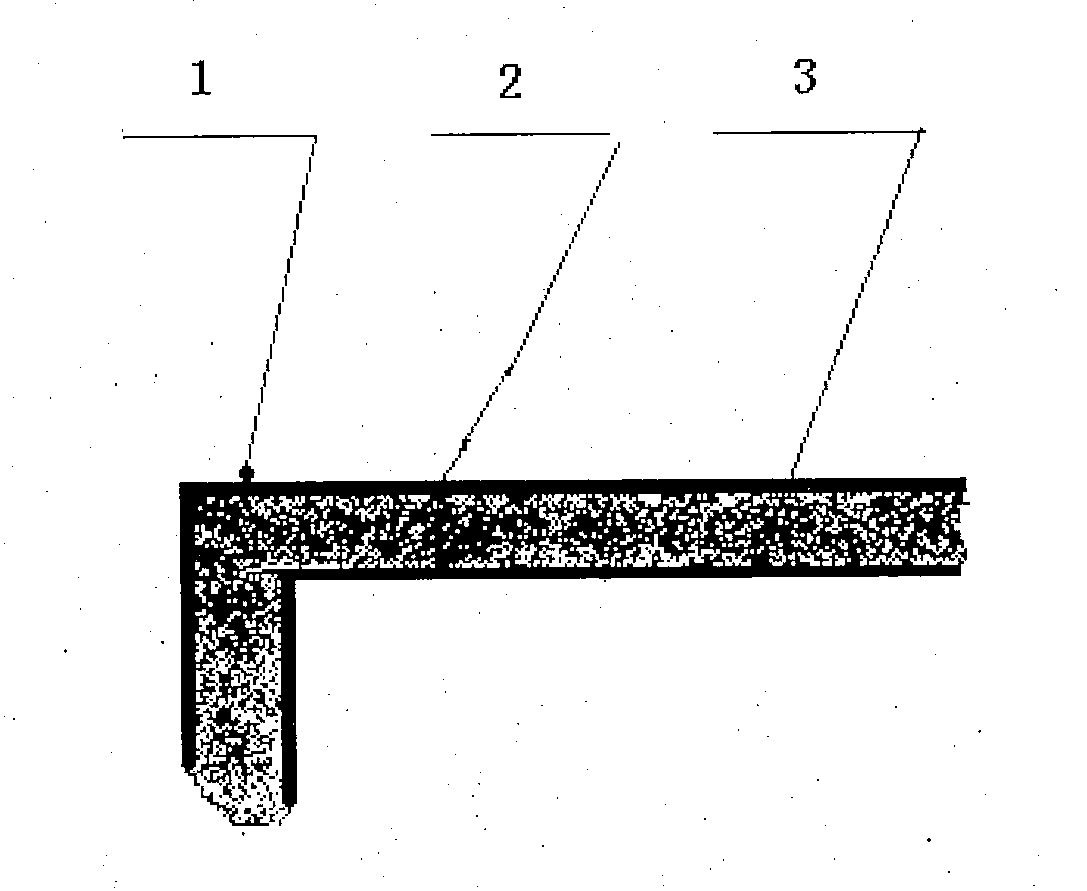

[0009] The present invention is composed of concrete layers 1, 3 and cement foam layer 2. The wall uses a special pouring device to achieve simultaneous pouring and solidification of three layers, to achieve a three-layer integrated wall without interlayers, and three times of pouring to achieve low cost, less operation labor, good thermal insulation and sound insulation of the product, and no interlayer phenomenon. Bear heavy features.

Embodiment 2

[0011] This embodiment is basically the same as Embodiment 1, and the arrangement of steel bars is added in the two concrete layers 1 and 3 of the wall.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com