Built-in truss used during installation of C-shaped plates and hoisting method for same

A hoisting method and truss technology, applied in the field of built-in trusses, can solve the problems of complex hoisting process of heavy components, large truss usage, and high technical requirements for truss erection, and achieve the effects of solving high-altitude construction problems, easy positioning, and reducing the frequency of shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

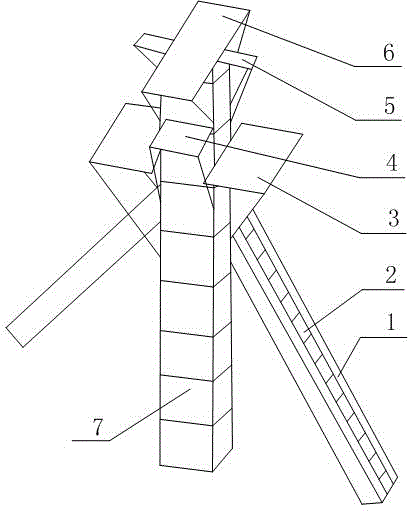

[0031] Such as figure 1 As shown, the built-in truss when the C-shaped plate is installed includes an intermediate truss 7 perpendicular to the ground. The two sides of the truss 7 are symmetrically provided with diagonal braces 1, one end of the diagonal brace 1 is fixed to the middle truss 7, and the other end is fixed to the ground; several layers of working platforms parallel to the ground are arranged on the middle truss 7, and each layer works The platform is arranged symmetrically on both sides of the middle truss 7 , and one end of the working platform is fixed to the middle truss 7 , and the other end is set outside the middle truss 7 , and the working platform is arranged above the diagonal brace 1 . For the convenience of description, the diagonal brace 1 is divided into left and right diagonal braces. Considering that the truss needs to bear the partial load of the C-shaped plate, and the overall height of the truss is 28.9m, in order to improve the overall stabili...

Embodiment 2

[0092] When hoisting the C-shaped plate, use step (a) to hoist all the C-shaped plates with one part of the four parts. The end face of each C-shaped plate is in contact with the second-layer working platform 5, and the side wall is in contact with the corresponding working platform at the same time. The working platform 6 of the first floor and the working platform 4 of the third floor are in contact. After the inside of the opening of the C-shaped plate is in contact with the working platform 3 of the fourth floor, the C-shaped plate is vertically lowered and snapped into the groove installed at the bottom of the built-in truss. Realize the installation and fixation of the C-shaped plate, and then use the bolts to penetrate and fix all the C-shaped plates in this part as a whole, and then lift and fix the C-shaped plate in turn according to the above actions for the remaining three parts. The C-shaped boards all adopt hoisting to fix the C-shaped boards of this part and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com