Manufacturing method of plastic building formwork

A technology of building templates and manufacturing methods, which is applied to the preparation of building components on site, building construction, construction, etc., can solve the problems of limited corner length, heavy weight, and difficult processing and molding, and achieve stable splicing and low weight. Lightening, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036]In order for those skilled in the art to further understand the features and technical contents of the present invention, please refer to the following detailed description and accompanying drawings of the present invention.

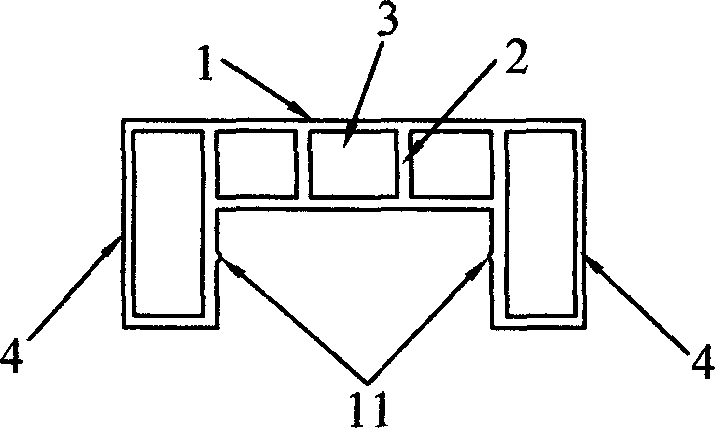

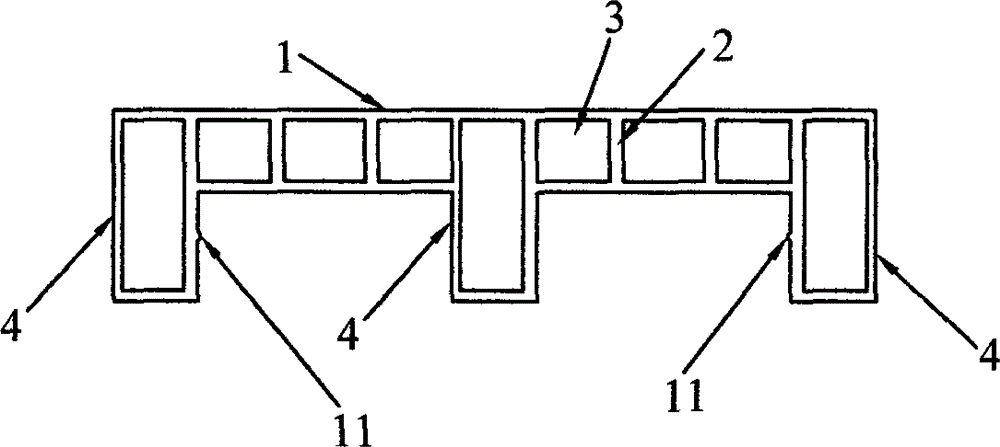

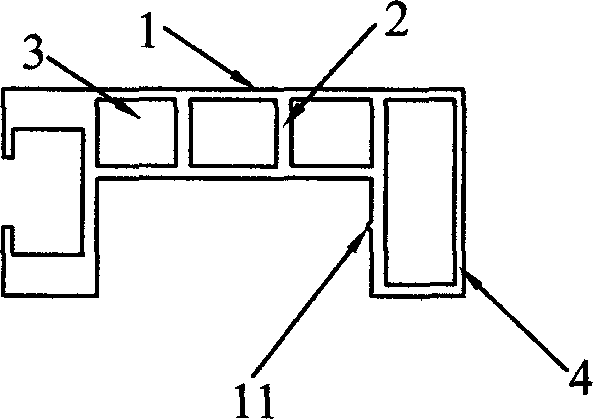

[0037] see Figure 1 to Figure 15 As shown, the present invention provides a plastic building template, which includes a flat rectangular plate 1, the rectangular plate is hollow and internally connected with a reinforcing rib 2, and the reinforcing rib separates the rectangular plate into a longitudinal section with The structure of at least two "mouth"-shaped cavities 3, the rectangular plate has at least one hollow leg 4 with a downwardly arranged longitudinal section in the shape of a "mouth", and the rectangular plate is connected with another rectangular plate. Assembled into a right-angled assembly assembly, the assembly assembly is detachably engaged with the rectangular plate, the assembly assembly has a clamping portion for adjacent recta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com