Bicycle Wire Sleeve Structure

A bicycle and wire technology, applied in the field of bicycle wire casing structure, can solve the problems of lack of toughness, reduced sensitivity, easy to cause danger, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

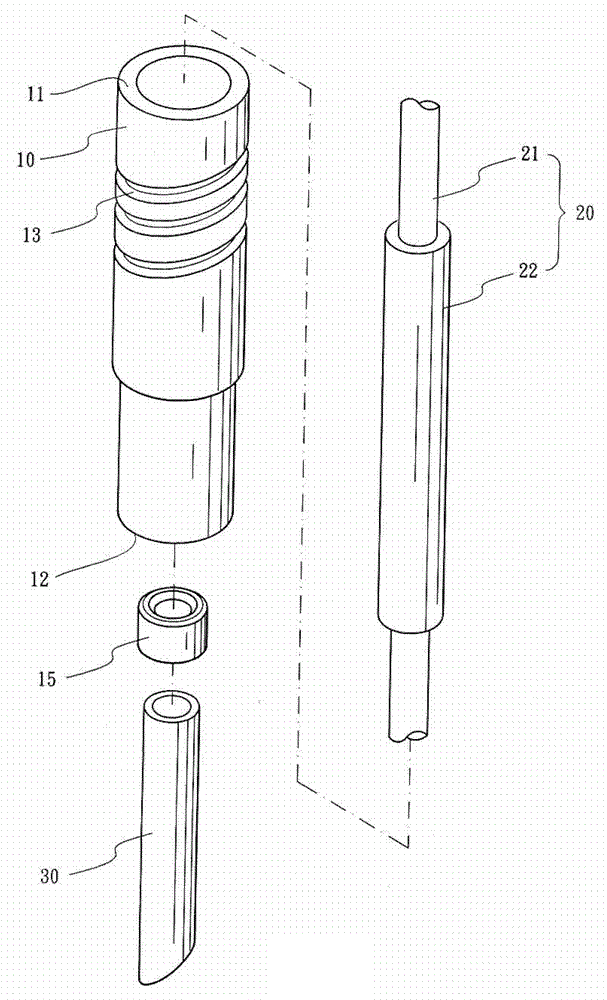

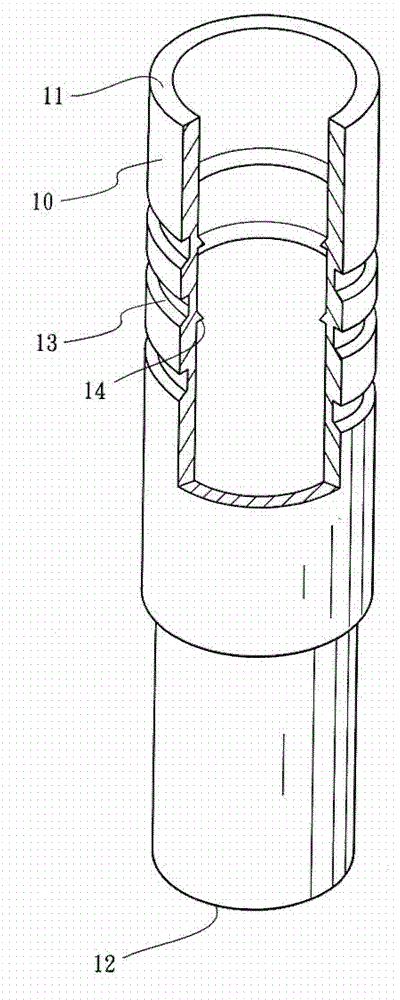

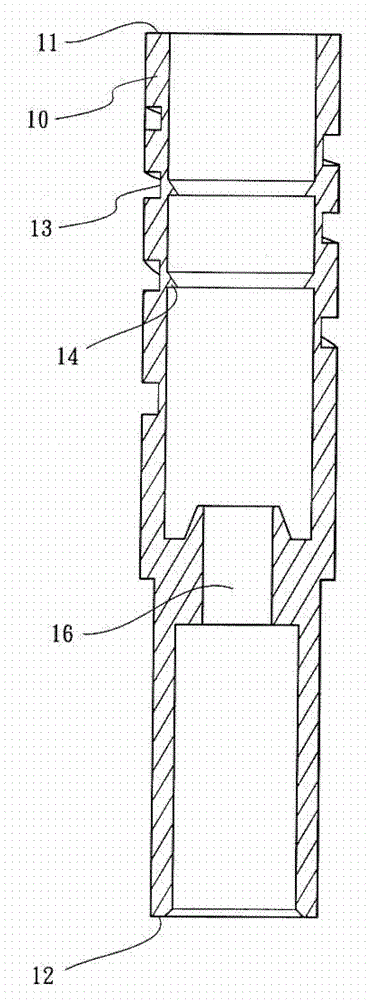

[0025] The present invention relates to a bicycle wire sleeve structure, please refer to Figure 1 to Figure 3 As shown, it includes an outer cover tube 10, a groove 13, and several protrusions 14. The outer cover tube 10 is made of plastic or metal, and the outer cover tube 10 defines two ends, which are respectively a first end 11 and a second end. 12, and several protrusions 14 are provided on the inner wall of the outer cover tube 10, the protrusions 14 are tapered and inclined towards the second end 12, so that the wire 20 can pass through the outer cover tube 10 from the first end 11 to the second end End 12 passes through, and presses wire 20 outer periphery with this projection 14, and braking control or file position conversion pulls wire 20 and makes wire 20 slide towards the first end 11 direction of outer cover tube 10, and the wire 20 that slides can be by bump 14 The top end of the top is pressed and limited in the outer cover tube 10, and the bump 14 fills the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com