an expansion valve

一种膨胀阀、阀芯的技术,应用在机械设备、流体循环安排、制冷组件等方向,能够解决增加空调机能耗、增加制冷剂阻力、降低使用寿命等问题,达到减少频繁动作、提高使用寿命、提高寿命的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

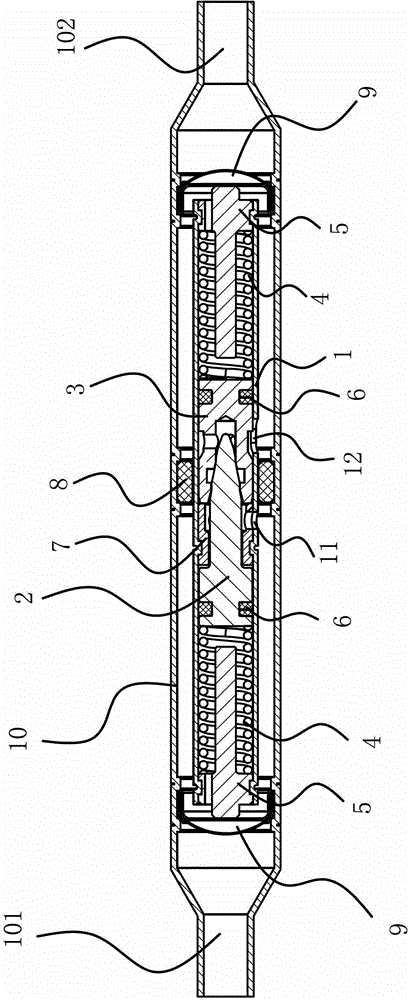

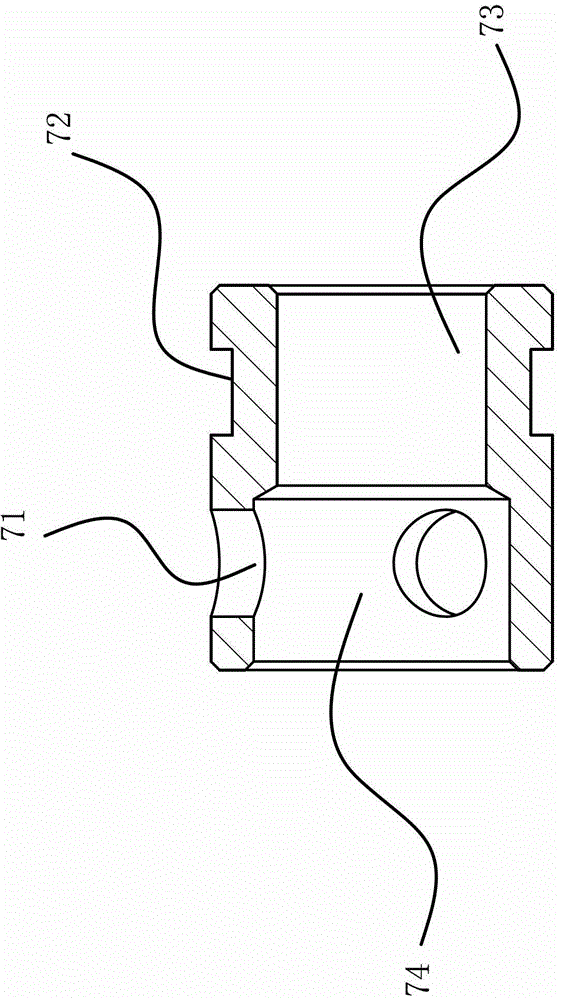

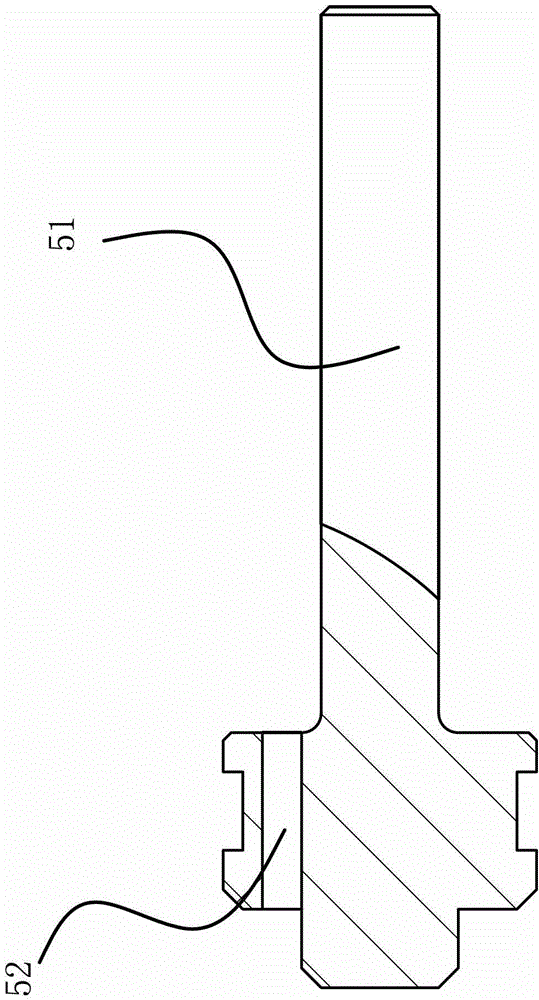

[0039] Such as figure 1 As shown, the expansion valve includes a casing 10 having an inlet port 101 and an outlet port 102. A straight cylindrical valve body 1 with an inner cavity is fixed inside the outer casing 10, and a valve body 1 is provided on the side wall to communicate with the inner cavity and the outer casing 10. The inlet 11 and the outlet 12, a spacer 8 is provided between the shell 10 and the valve body 1 to isolate the inlet 11 and the outlet 12, and the inner cavity is provided with a valve core one 2 and a valve core two 3 that can slide along the inner cavity, A retaining ring 7 is fixed in the middle of the inner cavity between the valve core one 2 and the valve core two 3, and the two ends of the inner cavity are respectively provided with spring assemblies that make the valve core one 2 and the valve core two 3 have a tendency to move toward the retaining ring 7, the valve A damping structure capable of buffering the first valve core 2 and the second val...

Embodiment 2

[0051] The structure and principle of embodiment two are basically similar to embodiment one, as Figure 6 As shown, the difference from Embodiment 1 lies in the addition of a small flow guide track structure. The structure of the small flow diversion track is that the valve core 2 3 is provided with a through hole 34 communicating with the outside of the valve body 1 and the hollow groove 33, and the through hole 34 is inlaid with a capillary. The flow rate of the through hole 34 can be changed by adding a capillary.

Embodiment 3

[0053] The structure and principle of embodiment three are basically similar to embodiment two, as Figure 7 As shown, the difference from the second embodiment lies in the structure of the small flow diversion track. The small flow diversion track structure is that the valve core one 2 is provided with a diversion groove 27 which can communicate with the hollow groove 33 and the front cylindrical hole 36 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com