Original pressure plate opening and closing device and office automation machine

A technology for an original pressing plate and an opening and closing device, which is applied in the directions of printing devices, wing openers, instruments, etc., to prevent original contamination, increase friction resistance, and prevent wear or strange noises.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

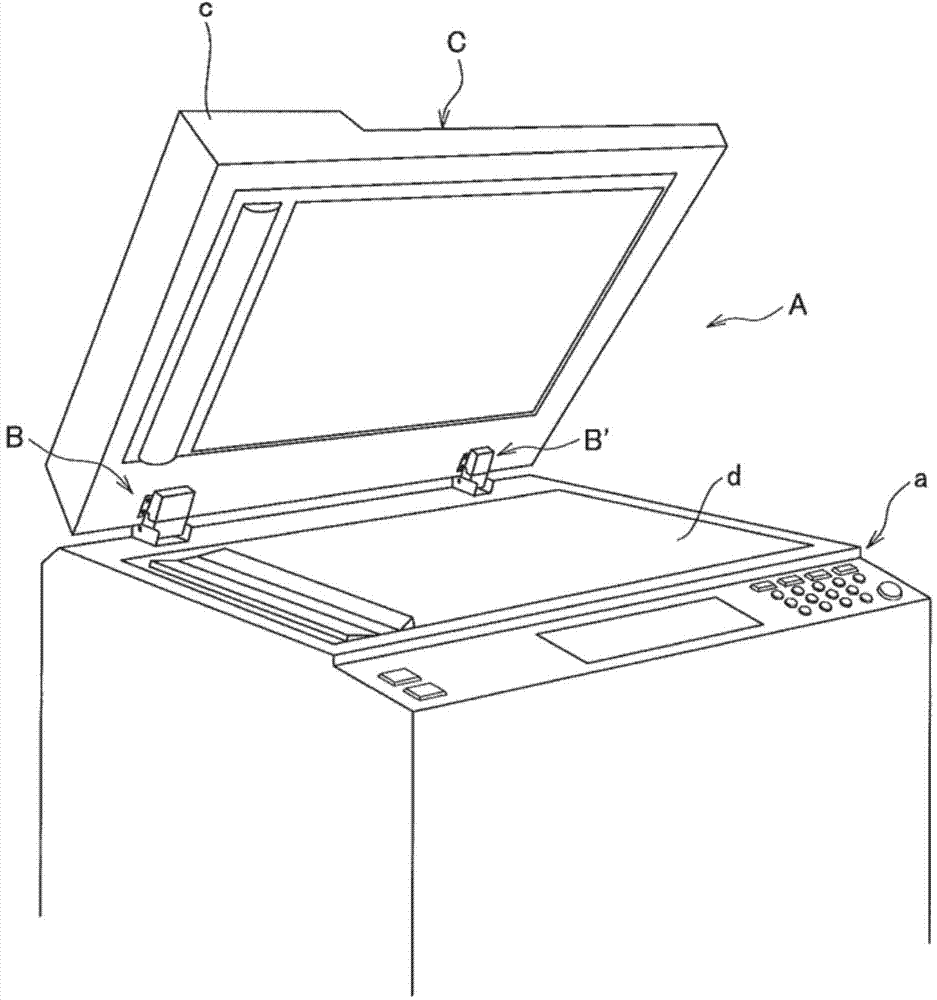

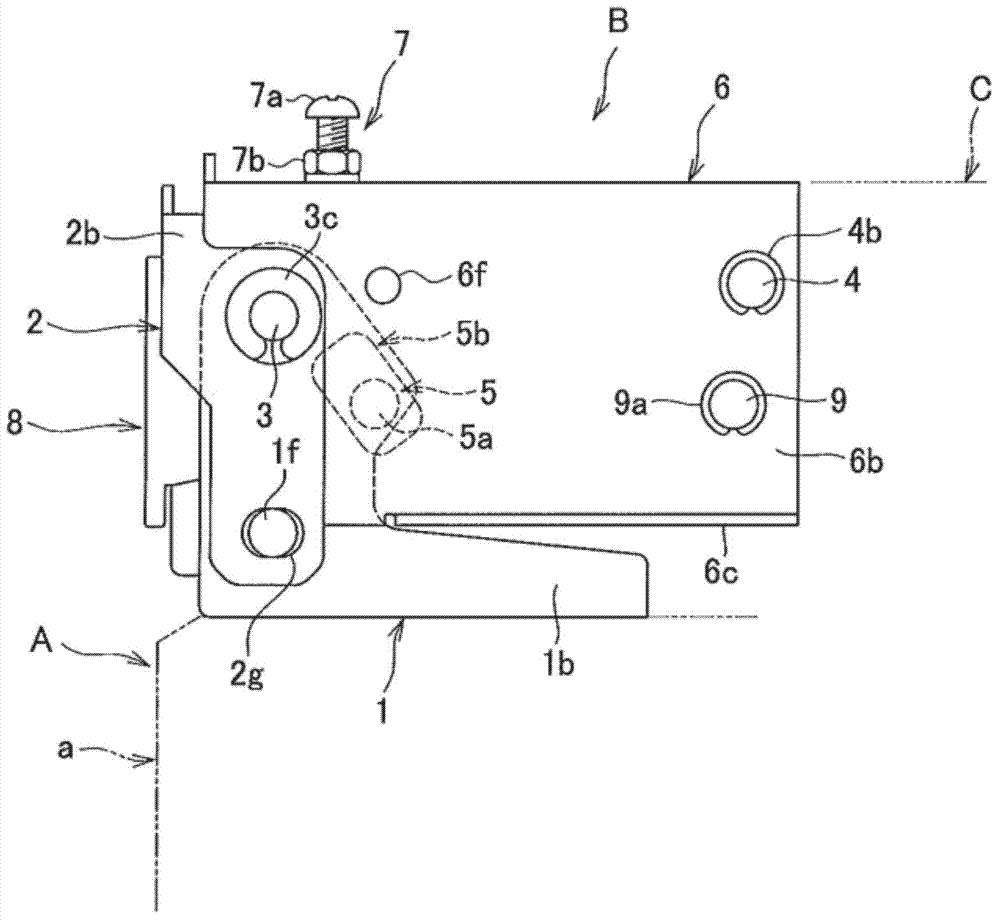

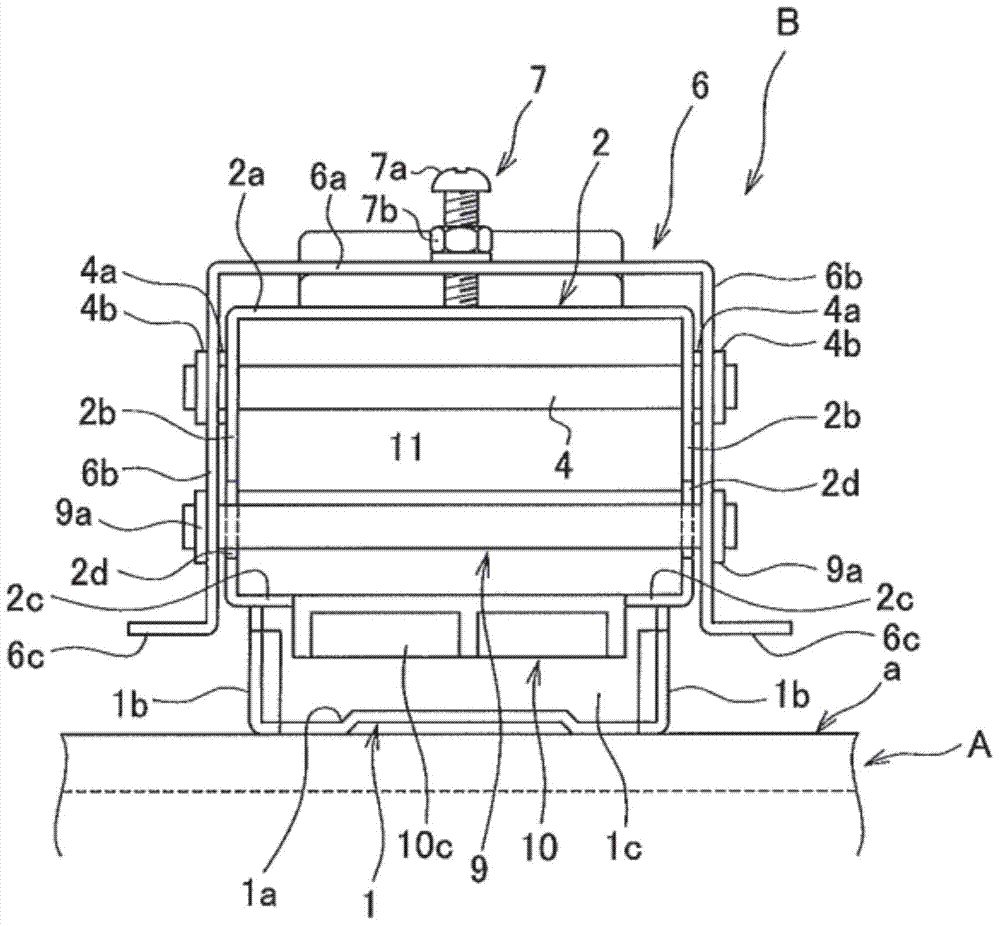

[0113] figure 1 It is a schematic diagram of the composite machine of the present invention. In the figure, a pair of document press plate opening and closing devices B, B' are passed through the top of the device body a of the compound machine A of the present invention, and a document press plate C with an automatic document feeder c is assembled in an openable and closable manner. Original press plate opening and closing devices B, B' The original pressing plate opening and closing device B on the left side of the figure is assembled with one side of the automatic document feeder c. Since the load is quite heavy during the opening and closing operation, Double compression springs are assembled, and the original pressing plate opening and closing device B' on the right side is only assembled with one set of compression springs (not shown in the figure) because of its light load. However, the composition of the important components of the present invention differs only in th...

Embodiment 2

[0131] Figure 8 to Figure 10It is a schematic diagram of another embodiment of the actuating element of the original pressing plate opening and closing device. It is worth mentioning that, although the components with the same reference numerals have slightly different shapes, since they are the same as the components of the document pressing plate opening and closing device B in Embodiment 1, their descriptions are omitted. The actuating element 15 of the original pressing plate opening and closing device D in Embodiment 2 is erected between the two side plates 6b, 6b of the lifting element 6 by a pivot, and an actuating pin 15a of a metal cylindrical rod and the actuating pin 15a go to The insertion hole 15c provided in the axial direction passes through, and is rotatably assembled with respect to the actuation pin 15a, and is constituted by a lift roller 15b made of synthetic resin. The lifting roller 15b has a roughly quadrangular shape in section, and abuts the flat sli...

Embodiment 3

[0135] Figure 11 to Figure 14 It is a schematic diagram of another embodiment of the pressure-receiving device of the document pressing plate opening and closing device of the present invention. The pressure member 20 of the document presser plate opening and closing device E in Embodiment 3 is provided with a cover portion 20f covering the exposed end of the cam slider 21 exposed from the support member 2 thereof. As for the composition of other elements, the composition of the actuating element 15 is the same as that of the document pressing plate opening and closing device D in the second embodiment, and other components are the same as those of the original pressing plate opening and closing device B in the first embodiment. Therefore, the descriptions of elements with the same reference numerals are omitted here. In addition, although not shown in the figure, a cover body covering the exposed end of the supporting element of the spring bearing element can also be provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com