A contact with the function of controlling the directional expansion movement of vacuum arc

A motion function, vacuum arc technology, applied in the direction of contacts, circuits, electrical switches, etc., can solve problems such as increasing production and processing costs, reducing the breaking current capability of switches, reducing the mechanical strength of the contact system, and the current-carrying density of contacts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

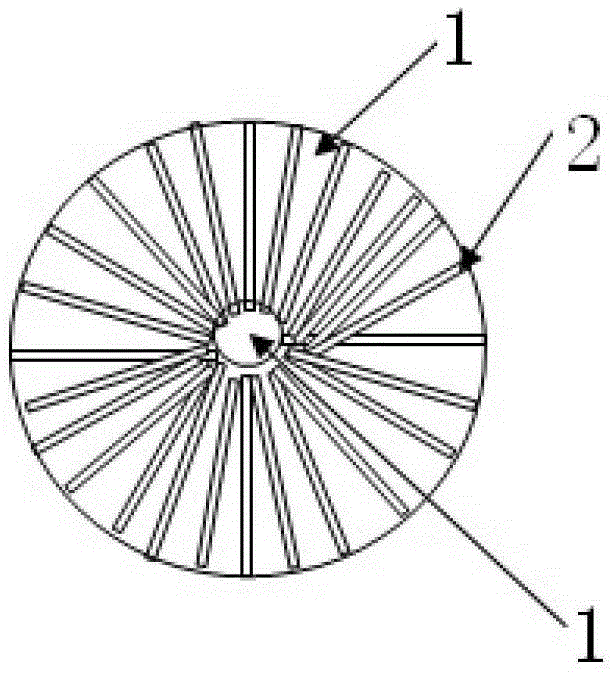

[0017] A contact with the function of controlling the directional expansion movement of the vacuum arc, the copper-based alloy material is a copper-chromium contact with a mass percentage of 47-52% chromium, and the second phase region contains 1-3% carbon, Carbon / CuCr contact area with 44-51% Cr, the second phase area is distributed radially from the center in the CuCr alloy matrix material, see figure 1 As shown, the number 1 indicates the contact material matrix, and the number 2 indicates the second phase region. The contact material matrix as a whole is fan-shaped, and the width of the nearly rectangular area of the second phase is 0.1-2 mm in cross section.

Embodiment 2

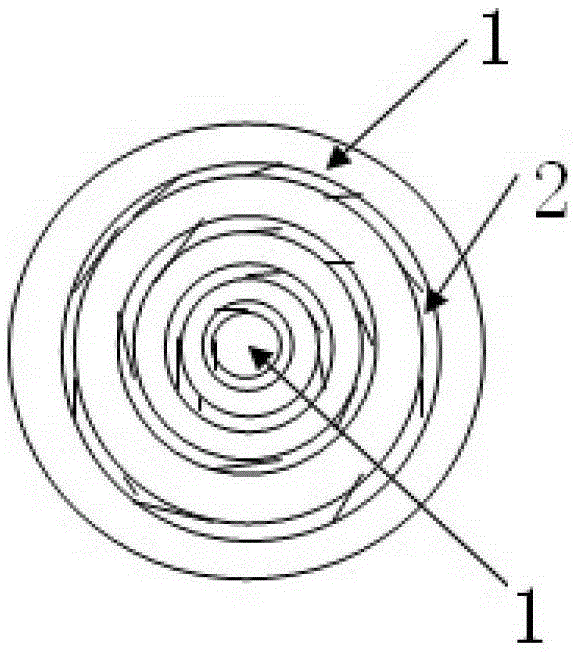

[0019] A contact with the function of controlling the directional expansion movement of the vacuum arc. The copper-based alloy material is a copper-chromium contact with a mass percentage of 22-28% chromium, and the second phase region is a carbon with a mass percentage of 1-3%. 19-27% chromium carbon / copper-chromium contact area, the second phase area is distributed in the copper-chromium alloy matrix material in a circular shape from the center, refer to figure 2 As shown, the number 1 indicates the contact material matrix, and the number 2 indicates the second phase region, and the width of the annular region of the second phase on the cross section is 0.1-2 mm.

Embodiment 3

[0021] A contact with the function of controlling the directional expansion movement of the vacuum arc. The copper-based alloy material is a copper-chromium contact with a mass percentage of 22-28% chromium, and the second phase region is a carbon with a mass percentage of 1-3%. 19-27% chromium carbon / copper-chromium contact area, the second phase area is helical from the center, and the width of the second phase helix on the contact cross section is 0.1-2mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com