Cu-CeO2 contact material and preparation method thereof

A contact material, cu-ceo2 technology, used in cable/conductor manufacturing, metal/alloy conductors, electrical components, etc., can solve the problems of low resistance to deformation, unstable arc, high cost, and achieve excellent resistance to arc ablation performance, the effect of reducing the degree of arc ablation, good arc stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

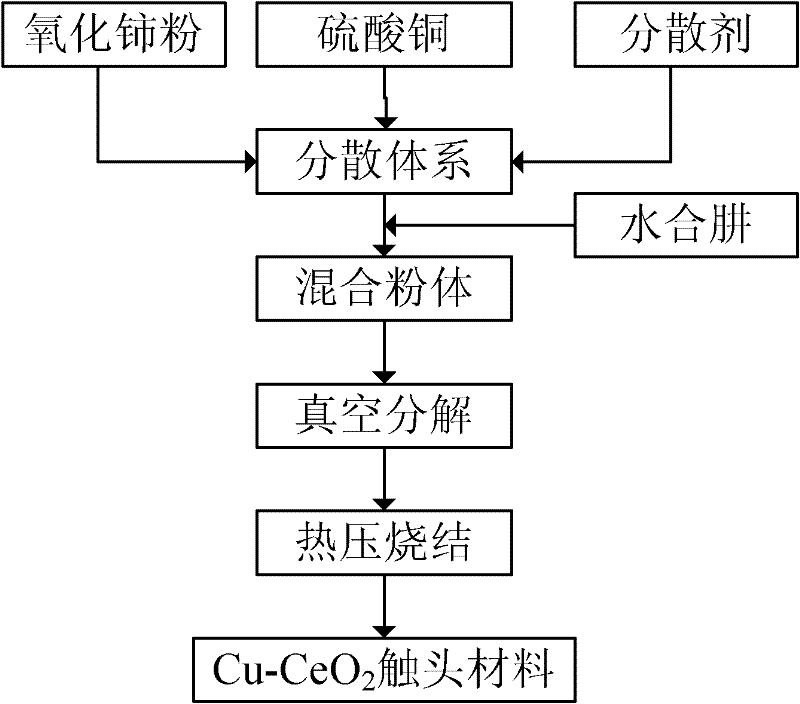

[0019] Such as figure 1 As shown, a Cu-CeO 2 A method of contacting a material comprising the steps of

[0020] The first step, weigh 50gCuSO 4 , dissolved in water to prepare CuSO with a mass concentration of 10% 4 aqueous solution;

[0021] The second step, weigh 0.2gCeO 2 , adding the CuSO prepared in the first step 4 In the solution, add 1% polyvinylpyrrolidone as a dispersant, stir until uniform to obtain a dispersion system;

[0022] In the third step, add 1.1 times of hydrazine hydrate to the obtained dispersion system, adjust the pH to 10 with sodium hydroxide, react at 70°C for 50 minutes, filter, and dry at 40°C for 3 hours to obtain a mixed powder;

[0023] The fourth step is to place the dried powder in the previous step in a vacuum furnace and keep the vacuum degree -3 Pa lasts for 2h;

[0024] The fifth step is to compact the mixed powder after passing through the vacuum furnace, and sinter at 850°C for 2 hours to obtain Cu-CeO 2 contact material.

Embodiment 2

[0026] Such as figure 1 As shown, a Cu-CeO 2 A method of contacting a material comprising the steps of

[0027] The first step, weigh 50gCuSO 4 , dissolved in water to prepare CuSO with a mass concentration of 5% 4 aqueous solution;

[0028] The second step, weigh 0.6gCeO 2 , adding the CuSO prepared in the first step 4 In the solution, add 1% polyvinylpyrrolidone as a dispersant, stir until uniform to obtain a dispersion system;

[0029] In the third step, add 1.1 times of hydrazine hydrate to the obtained dispersion system, adjust the pH to 11 with sodium hydroxide, react at 80°C for 30 minutes, filter, and dry at 50°C for 3 hours to obtain a mixed powder;

[0030] The fourth step is to place the dried powder in the previous step in a vacuum furnace and keep the vacuum degree -3 Pa lasts for 1h;

[0031] The fifth step is to compact the mixed powder after passing through the vacuum furnace, and sinter at 950°C for 2 hours to obtain Cu-CeO 2 contact material.

Embodiment 3

[0033] Such as figure 1 As shown, a Cu-CeO 2 A method of contacting a material comprising the steps of

[0034] The first step, weigh 50gCuSO 4 , dissolved in water to prepare CuSO with a mass concentration of 15% 4 aqueous solution;

[0035] The second step, weigh 1gCeO 2 , adding the CuSO prepared in the first step 4 In the solution, add 1% polyvinylpyrrolidone as a dispersant, stir until uniform to obtain a dispersion system;

[0036] In the third step, add 1.1 times of hydrazine hydrate to the obtained dispersion system, adjust the pH to 10.5 with sodium hydroxide, react at 75°C for 40 minutes, filter, and dry at 45°C for 3 hours to obtain a mixed powder;

[0037] The fourth step is to place the dried powder in the previous step in a vacuum furnace and keep the vacuum degree -3 Pa lasts for 1.5h;

[0038] The fifth step is to compact the mixed powder after passing through the vacuum furnace, and sinter at 900°C for 2 hours to obtain Cu-CeO 2 contact material.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com