Arc-resistance piece structure and vacuum switch contact

A vacuum switch and arc-resistant technology, used in electrical switches, high-voltage/high-current switches, electrical components, etc., can solve the problems of small breaking capacity, large resistance, poor voltage withstand ability, and poor anti-welding ability, and achieve the cut-off value. Low, strong breaking ability, strong anti-welding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

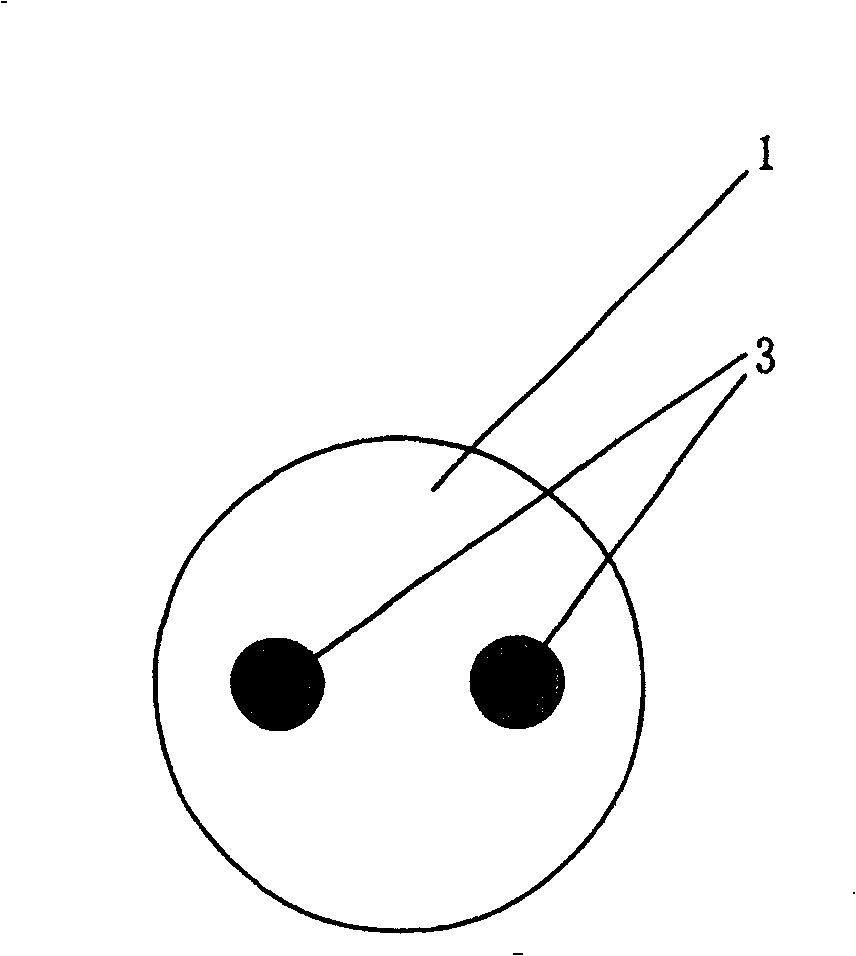

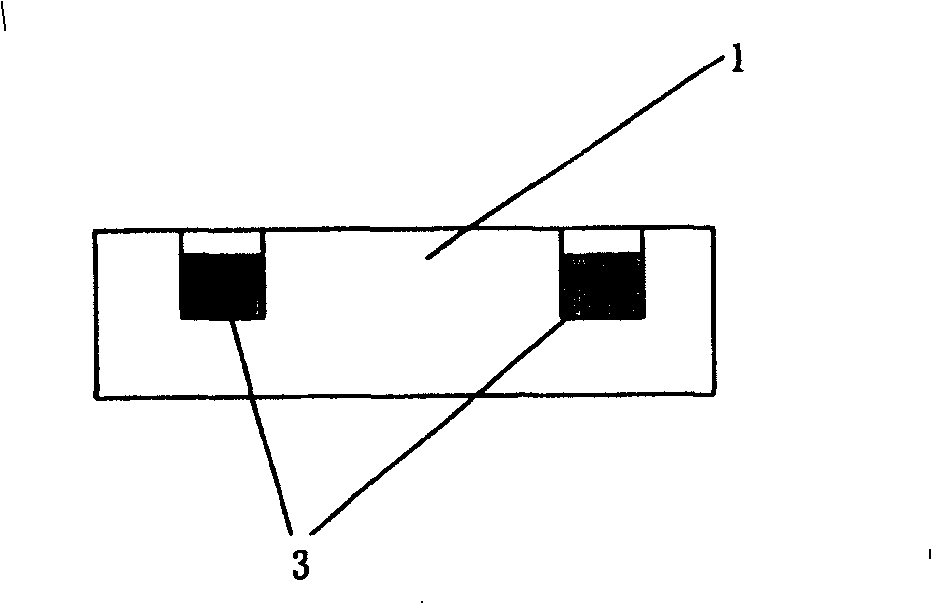

[0025] Such as figure 1 with figure 2 Shown is the plan view and cross-sectional view of Embodiment 1 of the arc-resistant member structure of the vacuum switch contact of the present invention. The arc-resistant part 1 is circular, with a thickness of 20 mm, made of copper-chromium alloy, and the weight percentage of chromium is 25% (CuCr25); Cu is -400 mesh, Cr is -400 mesh, and the upper surface of the arc-resistant part 1 is embedded with two A circular small cut-off value component 3 is made of AgWC alloy, the weight percentage of Ag is 70%, and the thickness is 5mm. The surface of the arc-resistant component 1 is higher than the surface of the small cut-off value component 3 .

[0026] When the contact of the vacuum switch is disconnected, the contact area of the contact gradually decreases until there is only one contact point between the contacts, and at the same time the contact resistance gradually increases, because the arc-resistant layer 1 is CuCr25, and its r...

Embodiment 2

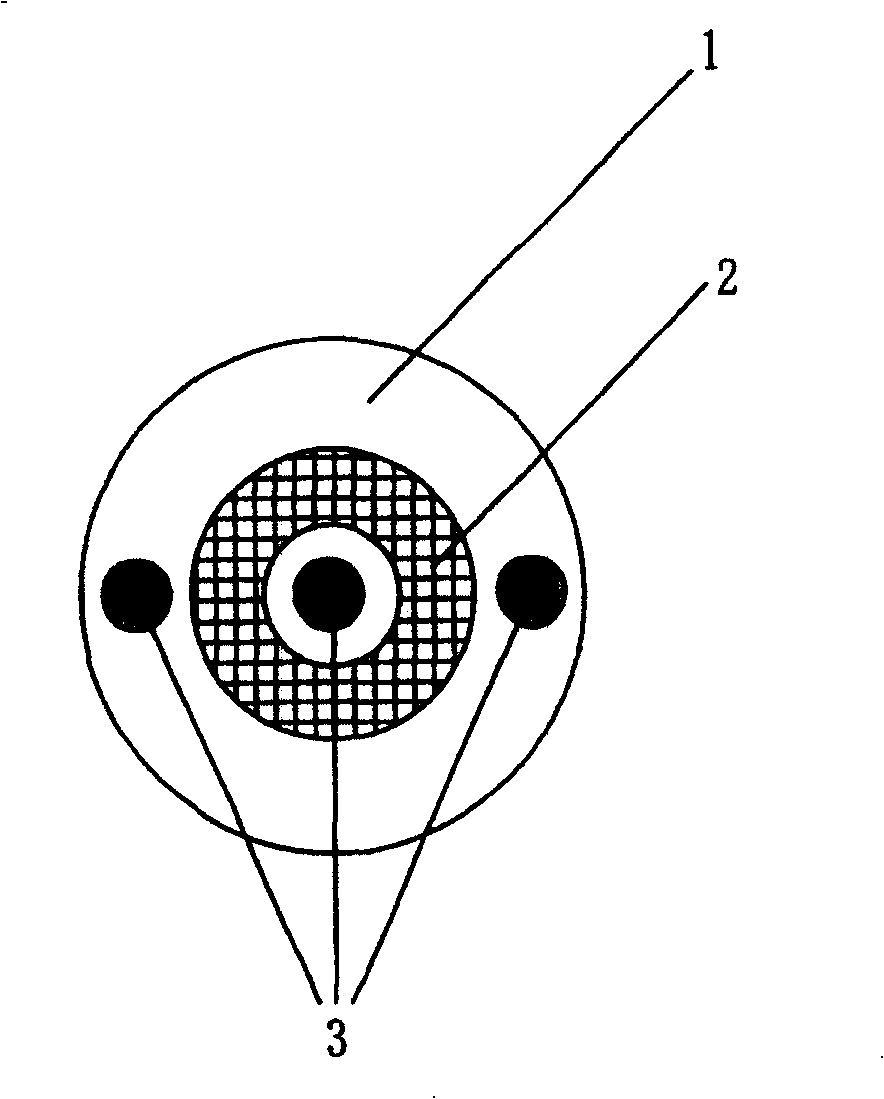

[0028] Such as image 3 with Figure 4 Shown is the top view and cross-sectional view of Embodiment 2 of the arc-resistant member structure of the vacuum switch contact of the present invention. The arc-resistant part 1 is circular, with a thickness of 15mm, made of copper-chromium alloy, and the weight percentage of chromium is 20% (CuCr20); Cu is -325 mesh, Cr is -325 mesh, and the upper surface of the arc-resistant part 1 is embedded with a ring The welding-resistant part 2 is 17mm in thickness, made of copper-chromium alloy, the weight percentage of chromium is 50% (CuCr50), the Cu is -325 mesh, and the Cr is -325 mesh. The surface of the welding-resistant part 2 is higher than the arc-resistant Surface of part 1. On the upper surface of the arc-resistant part 1, there are three circular parts 3 with small cut-off value embedded around the anti-fusion welding part 2. The material is AgWC alloy, the weight percentage of Ag is 2%, the thickness is 7mm, and it is flat with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com