Patents

Literature

38results about How to "Improve Fusion Performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

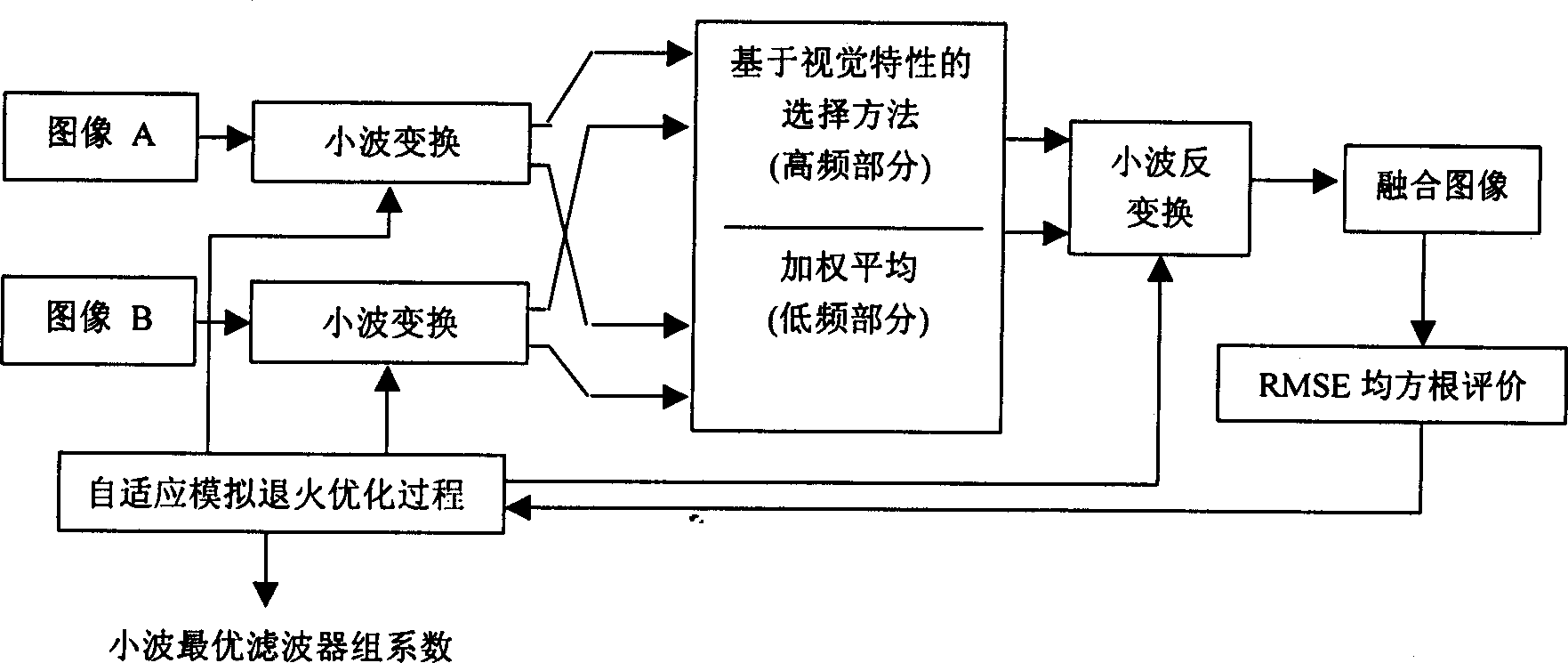

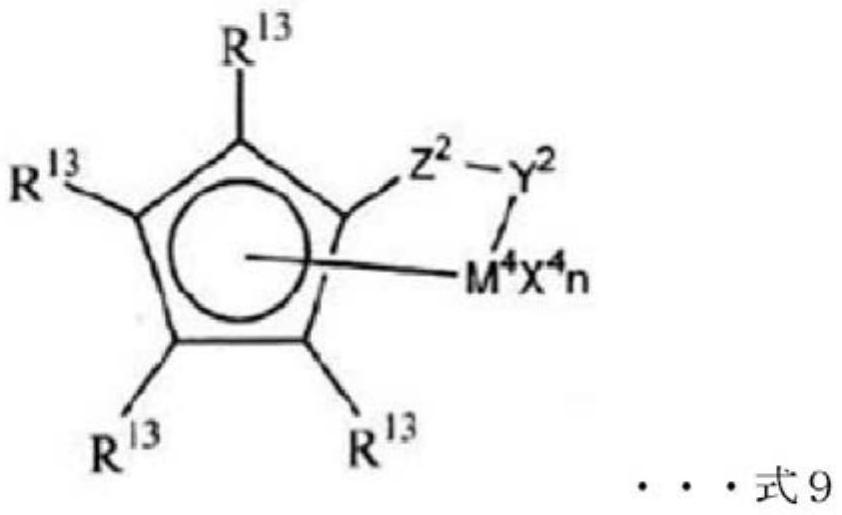

Multisensor image fusion method based on optimized small wave filter set

InactiveCN1794300AAvoid bad decisionsImprove Fusion PerformanceImage enhancementWeighted average methodWavelet filter

This invention relates to a merge method for multiple sensor images based on an optimum small wave filter set, which applies small waves to carry out multi-dimension dissolution to the being merged images to get a series of HF components and a lowest frequency component, then applies a character pick up method based on the visual property to the HF part for merging and applies the weighted average method to merge the low frequency part to get the merged image by small wave inverse transformation to the merged results, finally applies the smallest mean-root-square error to evaluate the merged images and carries out optimized search to small coefficient taking the pass-band energy and the non-pass band energy of the small filter coefficient so as to get the optimum design of the small filter set.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

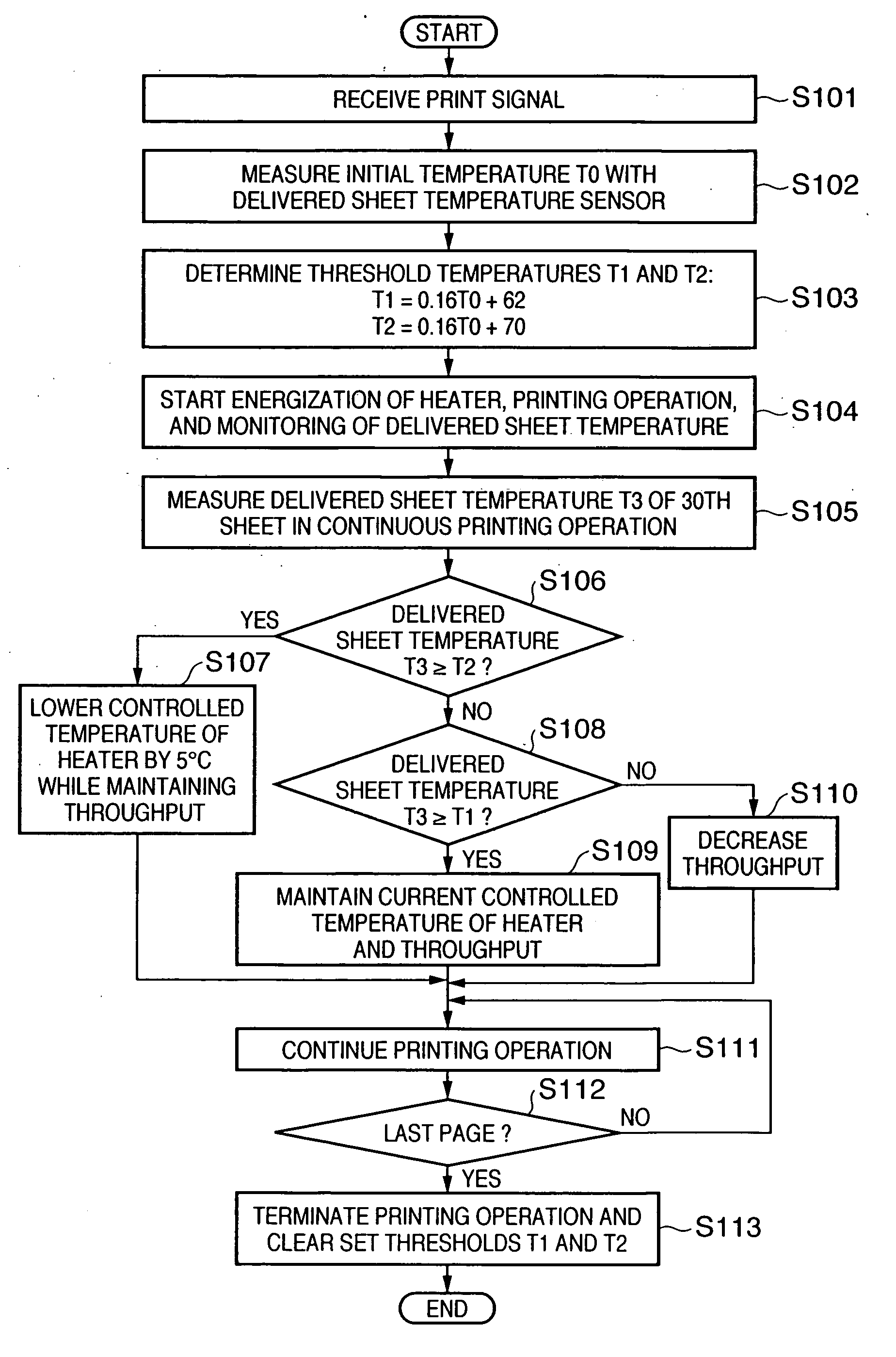

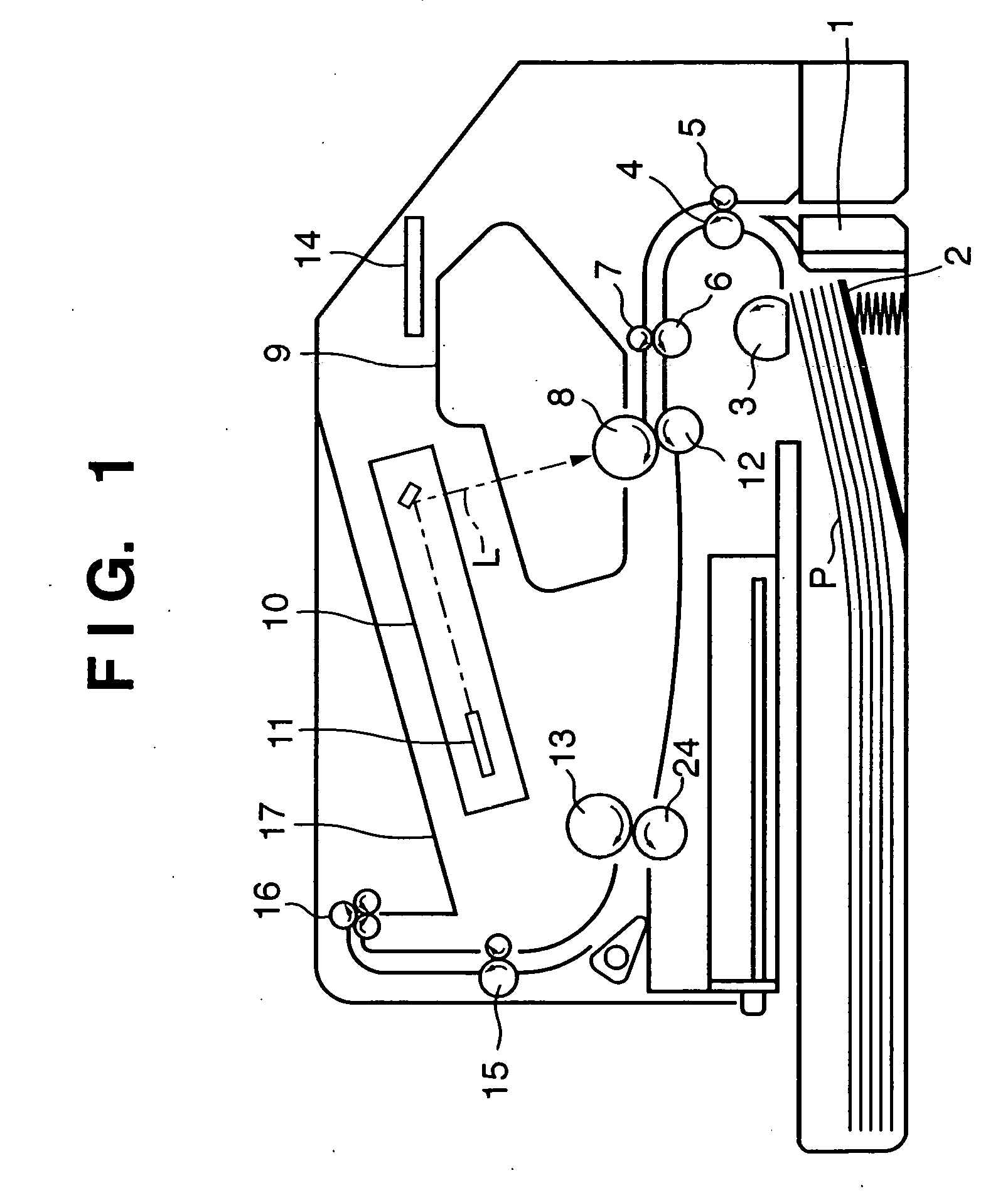

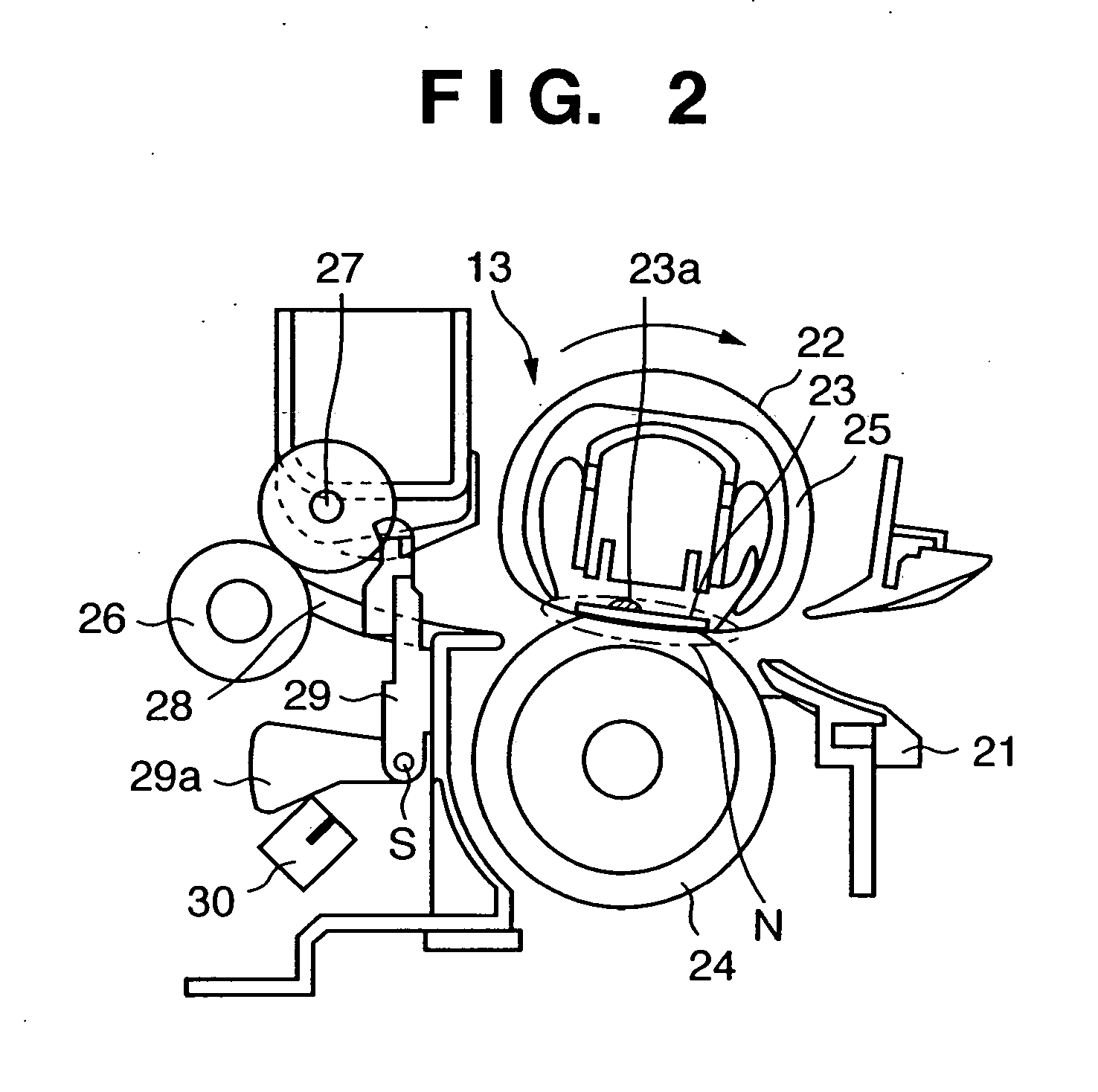

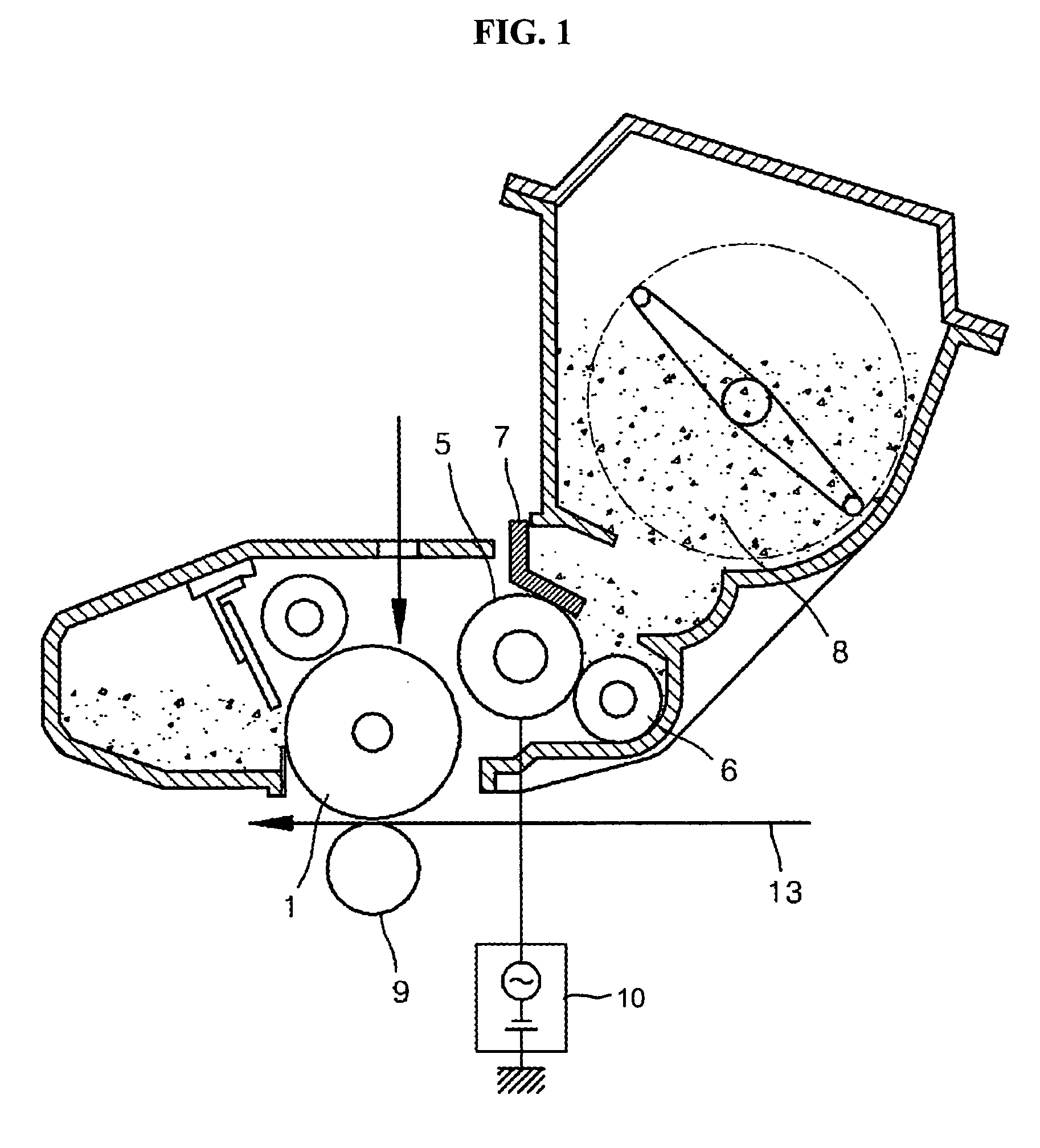

Image forming apparatus and its control method

InactiveUS20050191070A1Avoid deformationImprove Fusion PerformanceElectrographic process apparatusImage formationEngineering

Owner:CANON KK

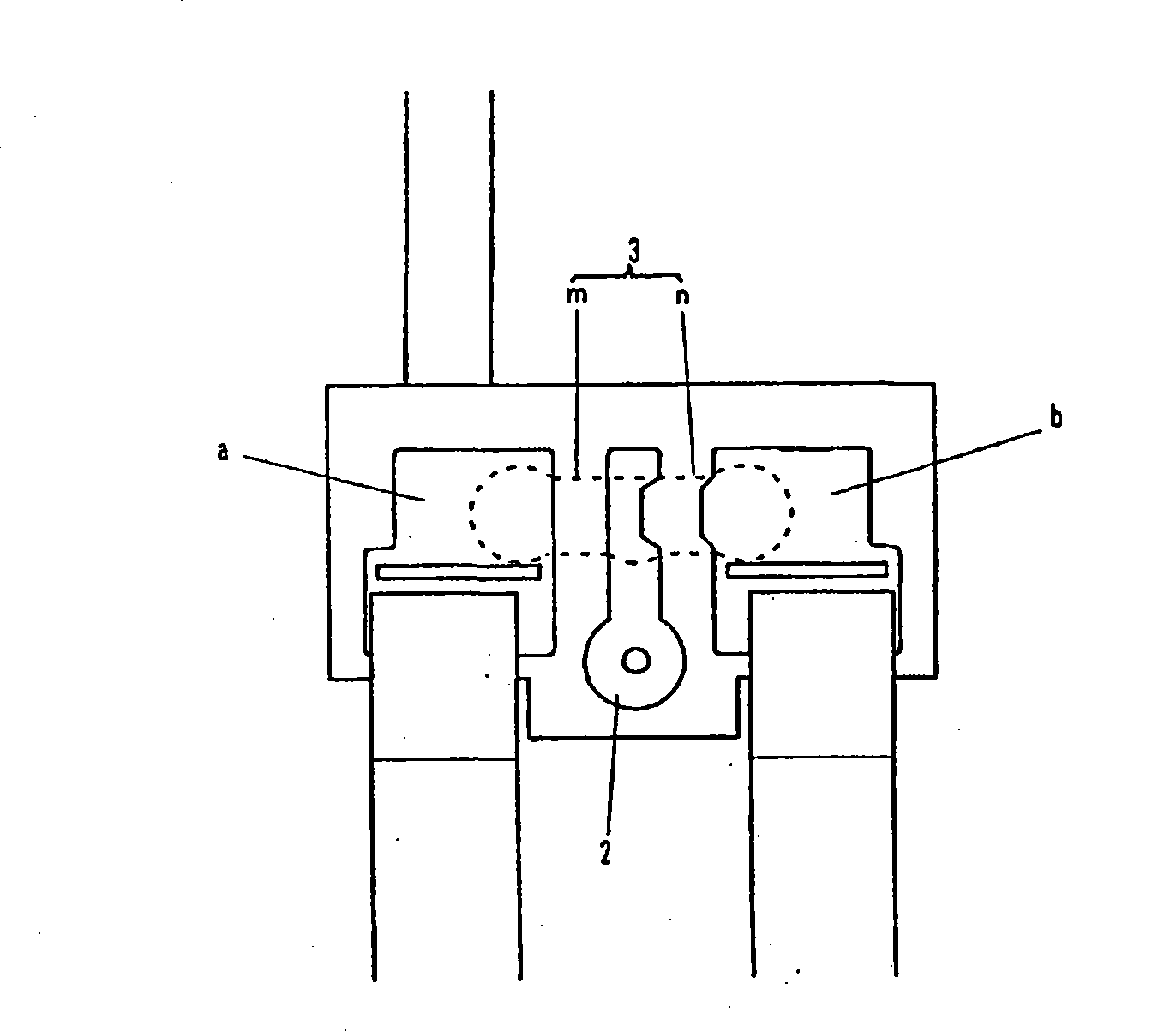

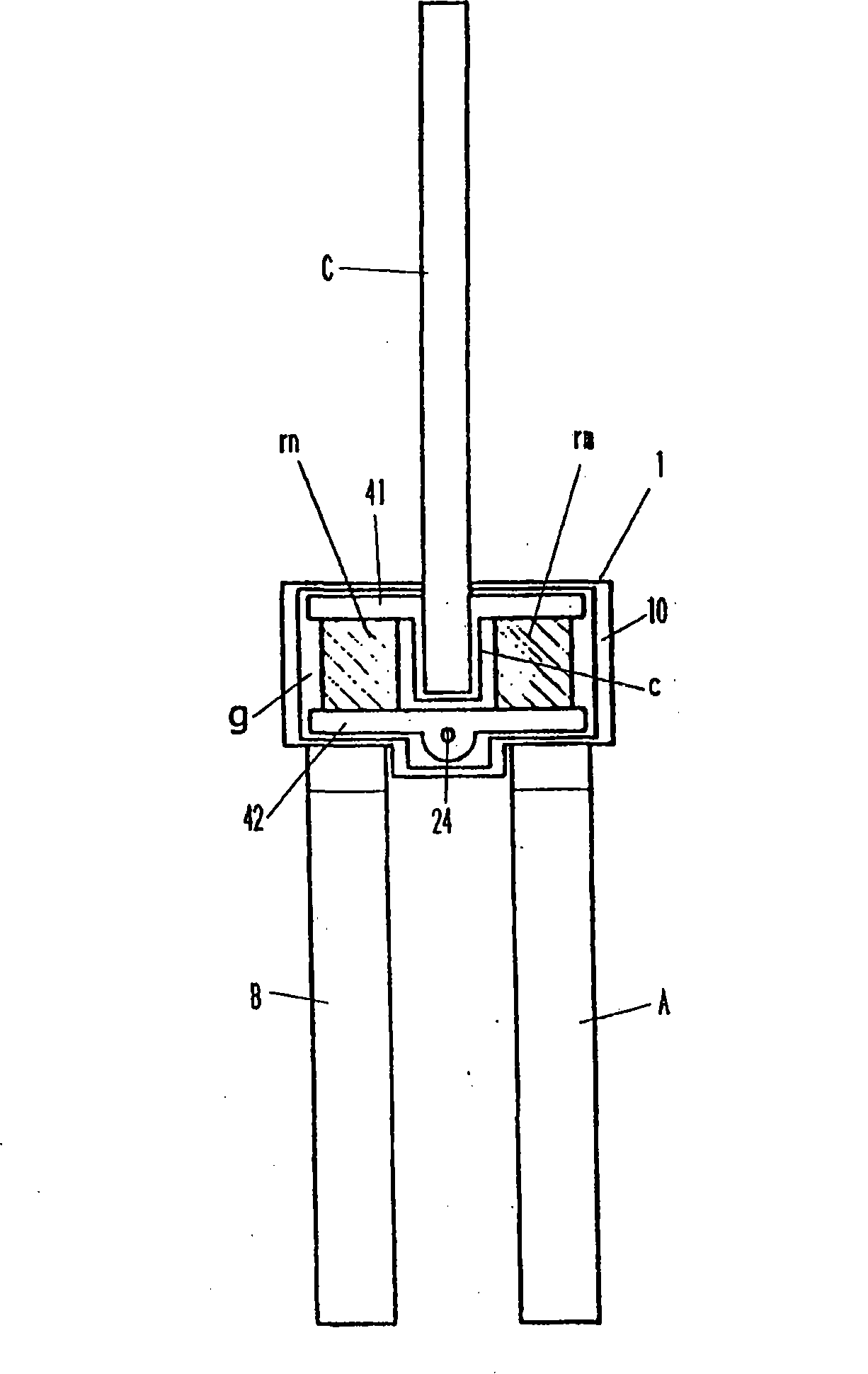

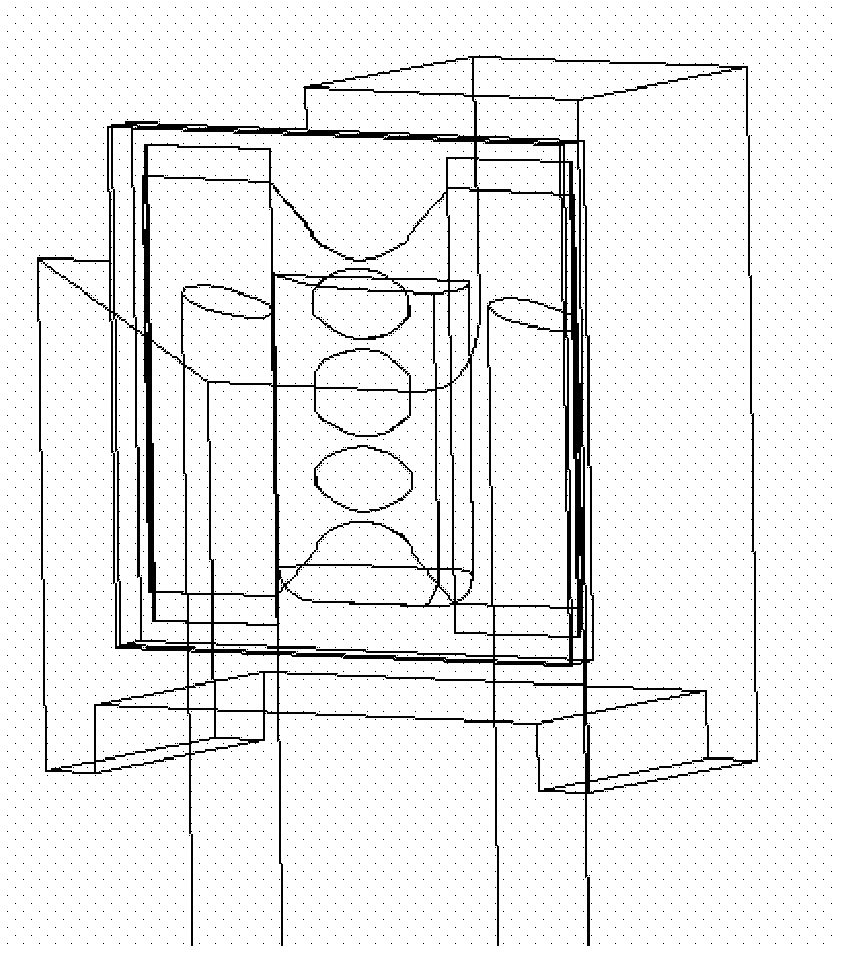

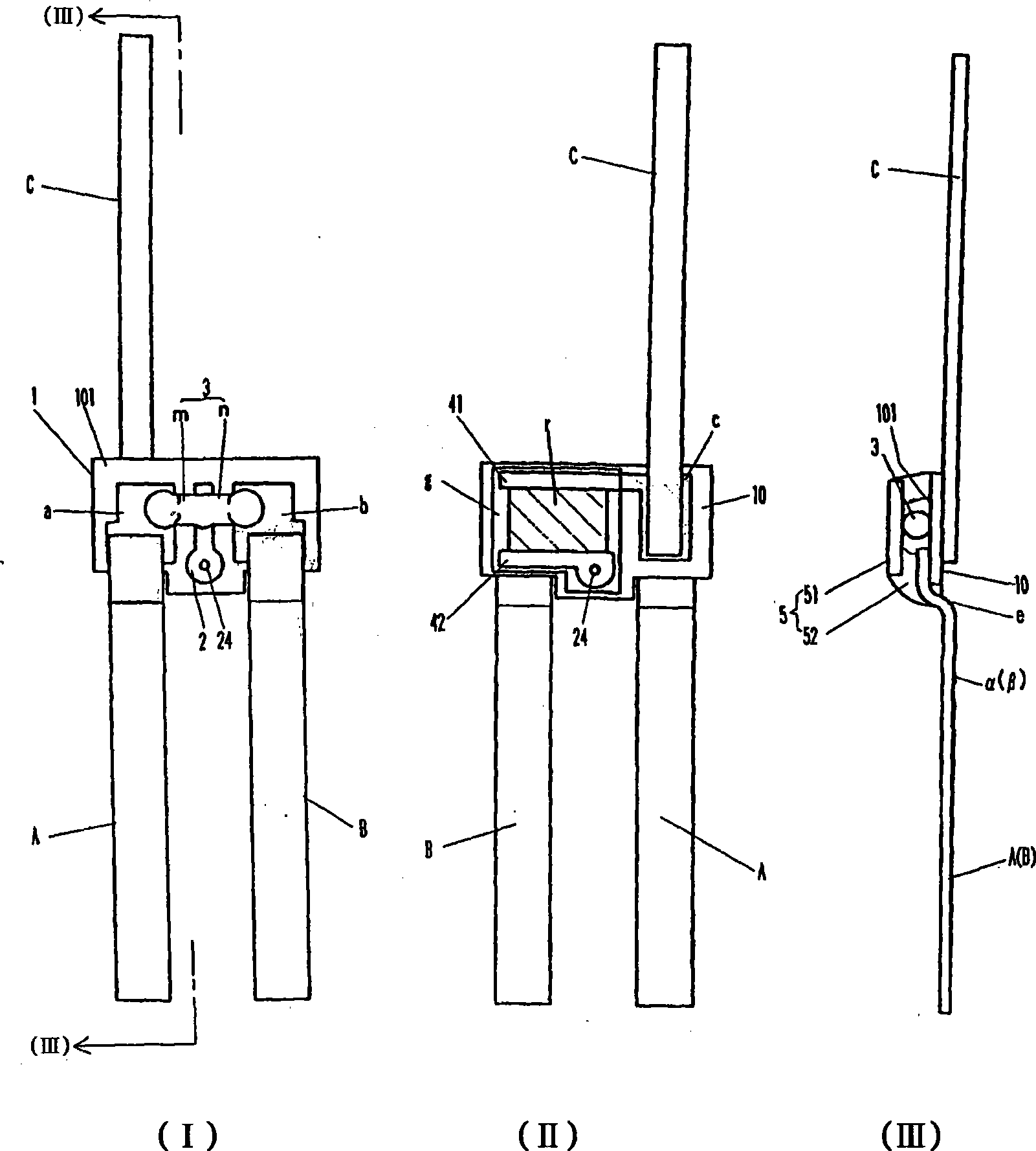

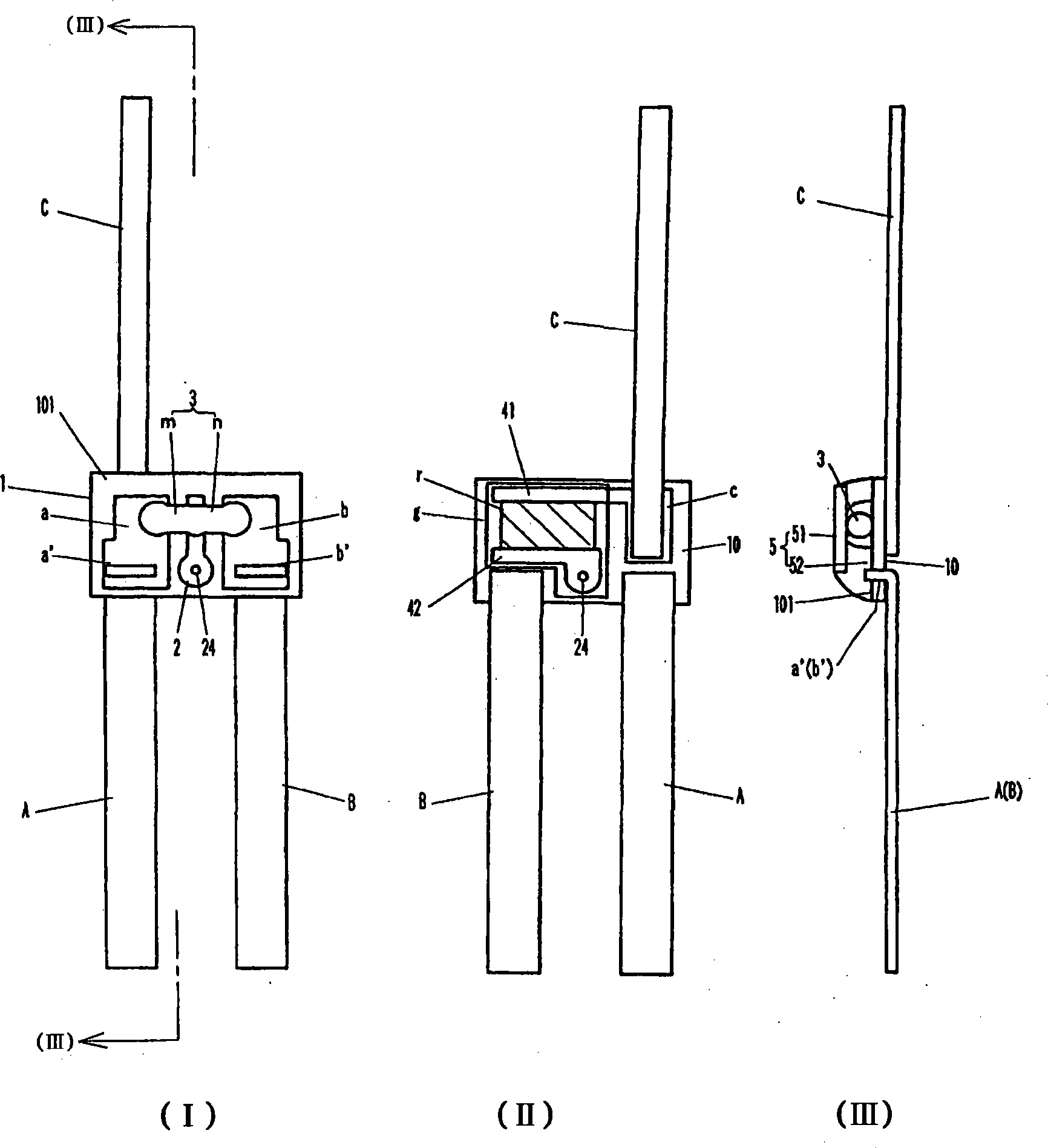

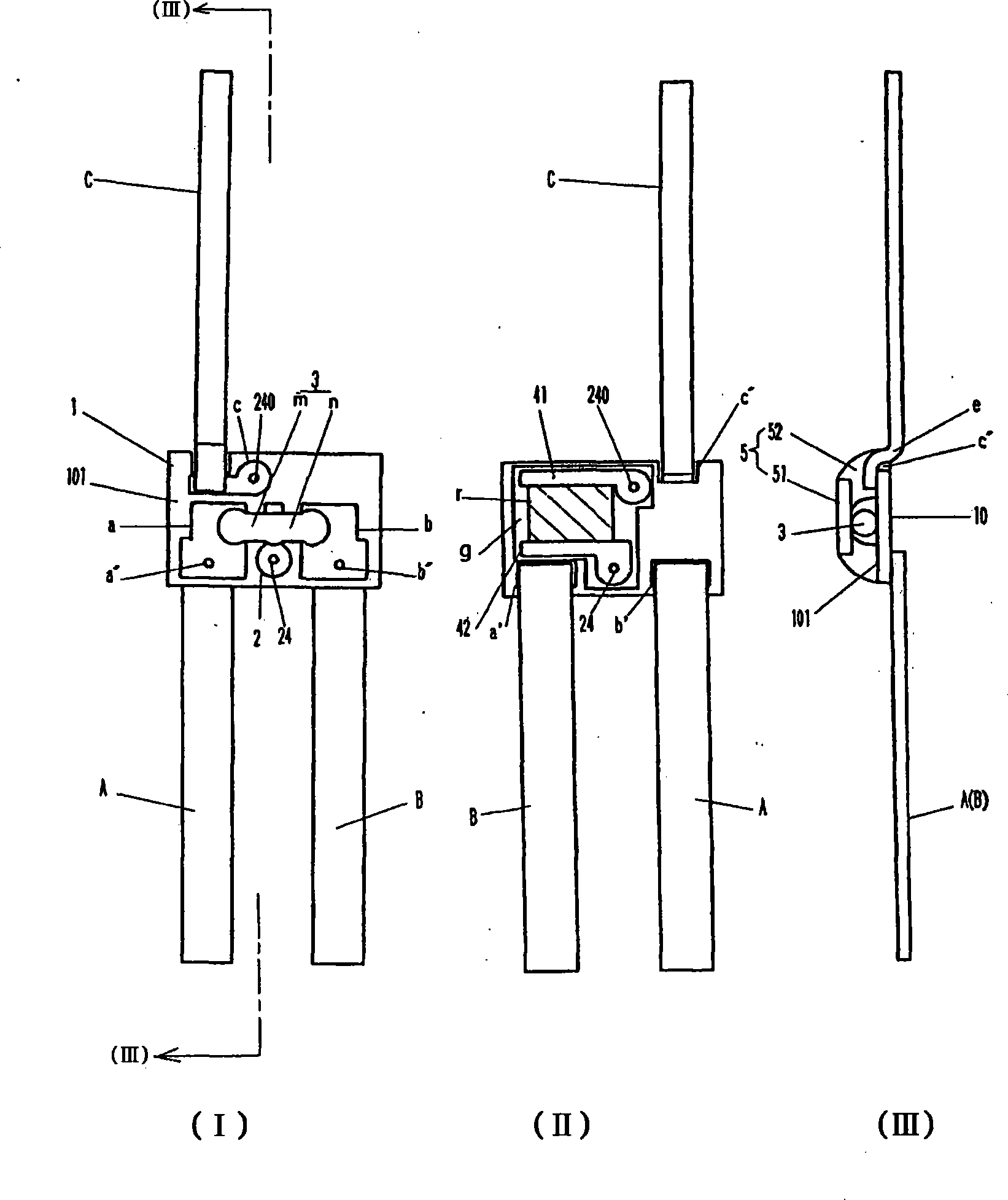

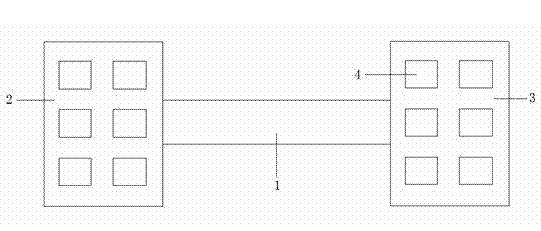

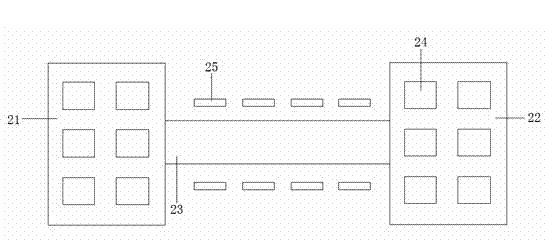

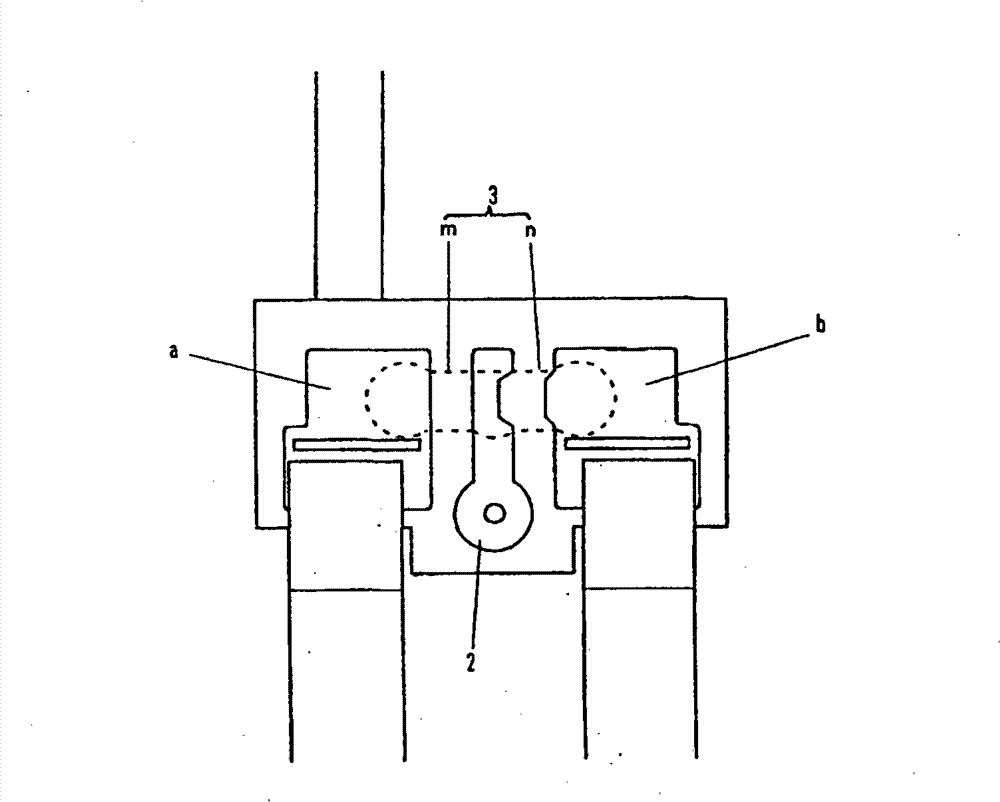

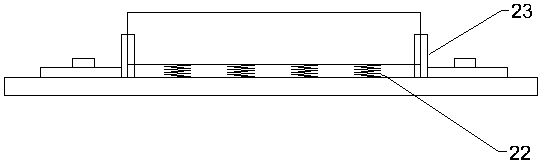

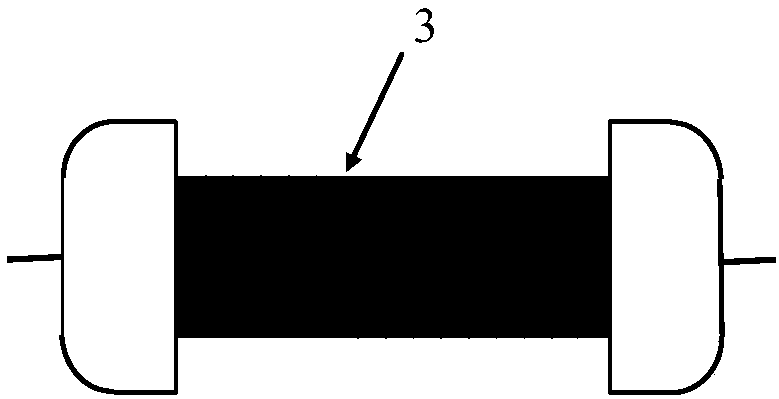

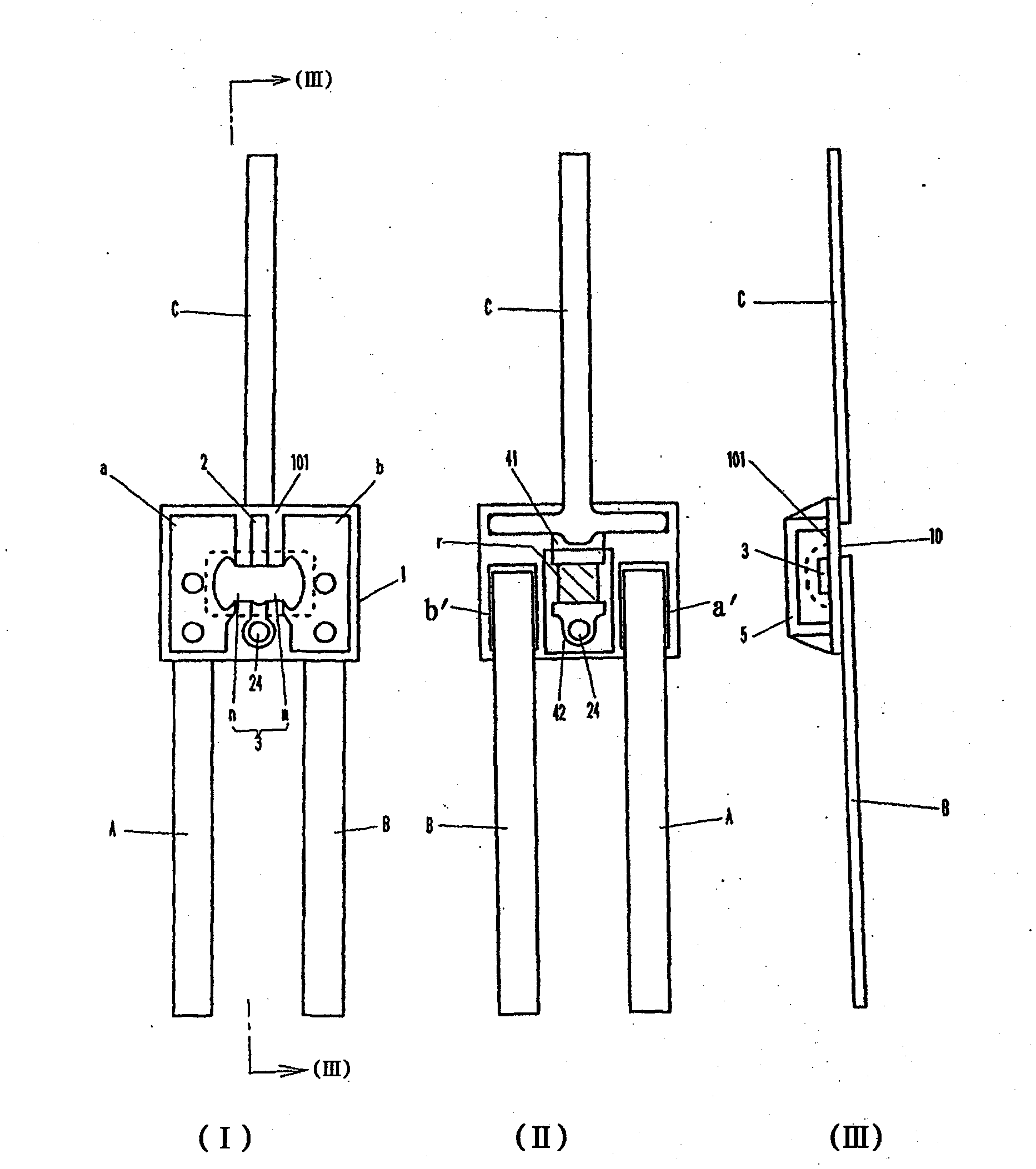

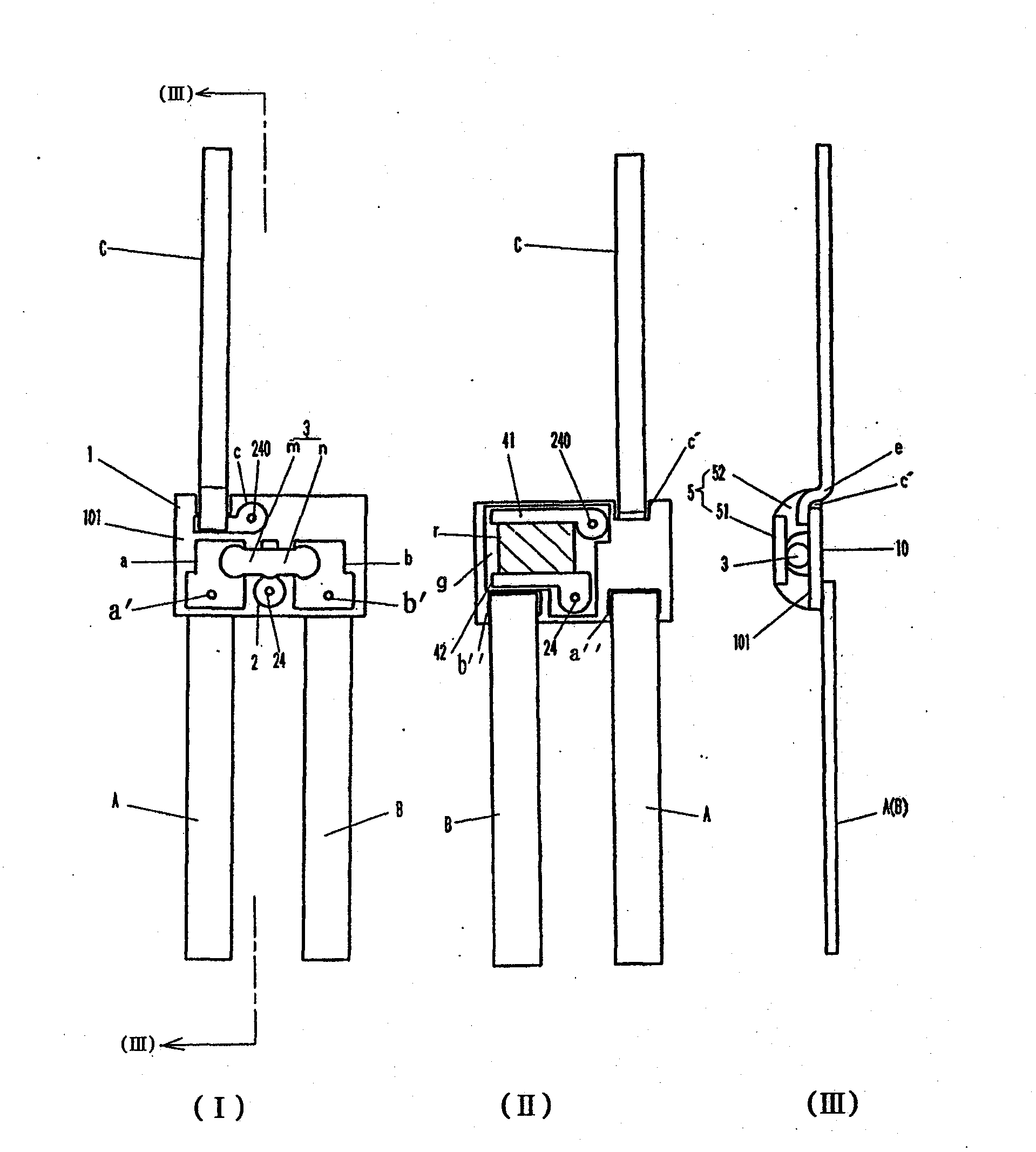

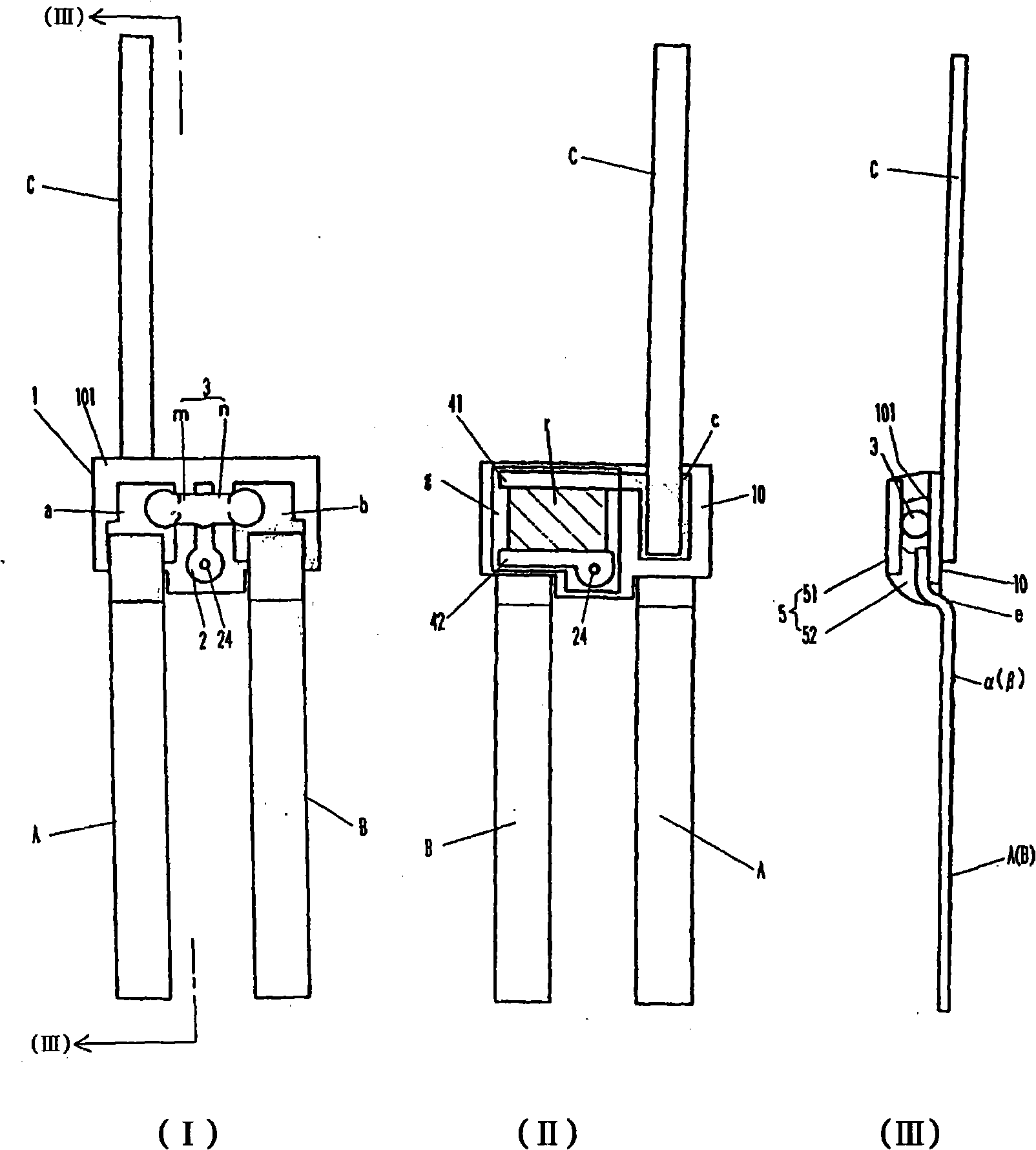

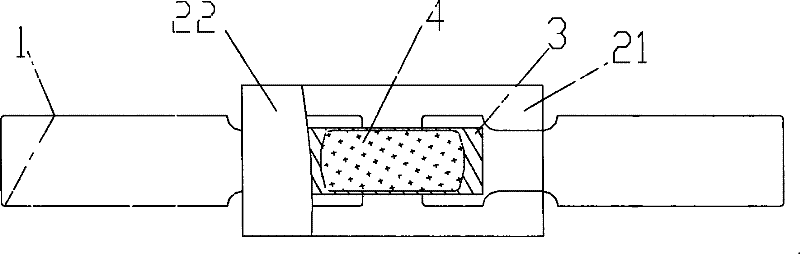

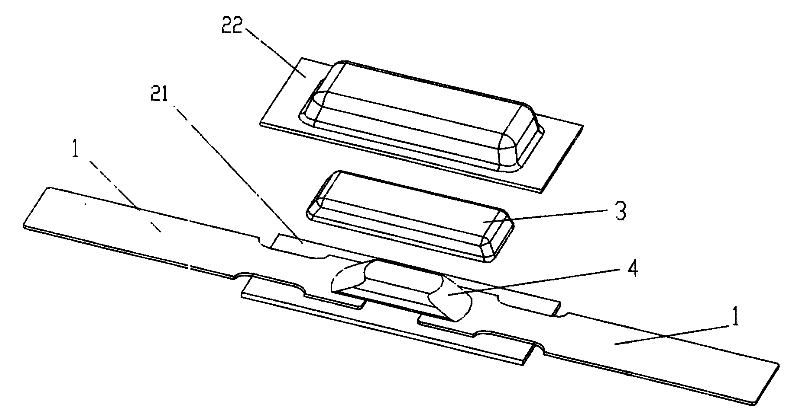

Substrate type temperature fuse with resistor and secondary battery protection circuit

InactiveCN101373680AEarly blownReduces the risk of blowoutsSecondary cellsHeating/cooling contact switchesSubstrate typeElectrical resistance and conductance

This invention provides a temperature fuse with resistor substrate and a secondary protection circuit, film electrodes on two sides and a middle film electrode are disposed on surface of the substrate, aforementioned electrodes are widely disposed, and the fuse element, fuse element part (m) between film electrode (a) and the middle film electrode, fuse element part (m) between film electrode (b) and the middle film electrode are also disposed thereon, film resistors leading the fuse elements to blow out via conduction heat are disposed on other surface of the substrate, so that each fuse element can blow out in optimization reliably and partly relative to another fuse element. Thus, distance between fuse element (m) and the film resistor (r) is different from distance of film resistor (r) of the fuse element part (m).

Owner:UCHIHASHI ESTEC

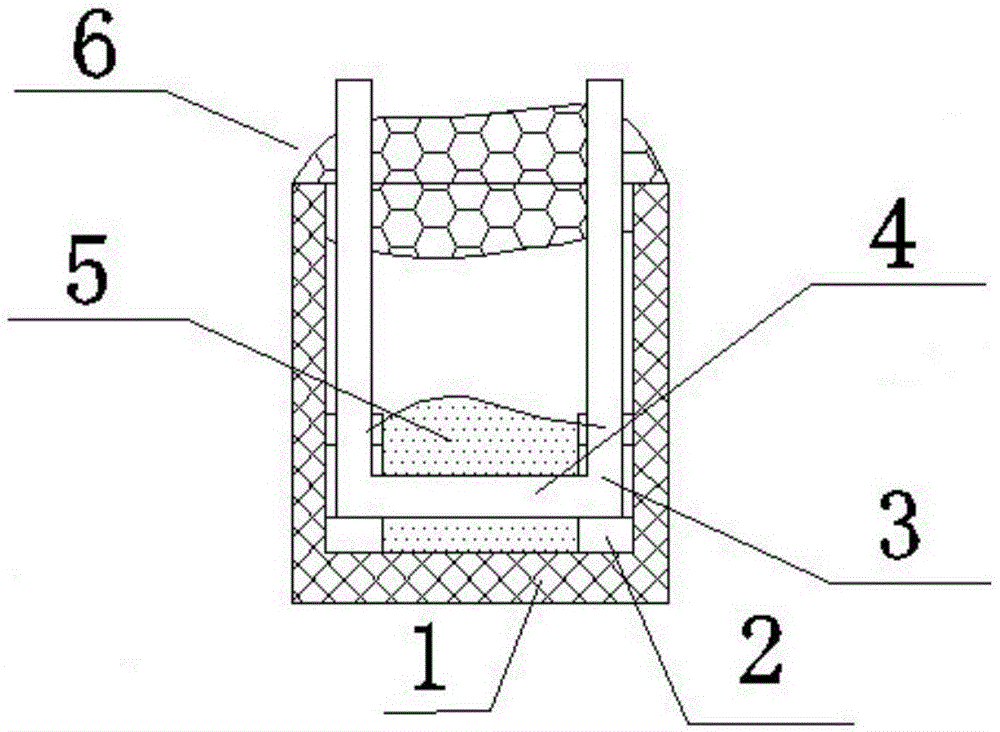

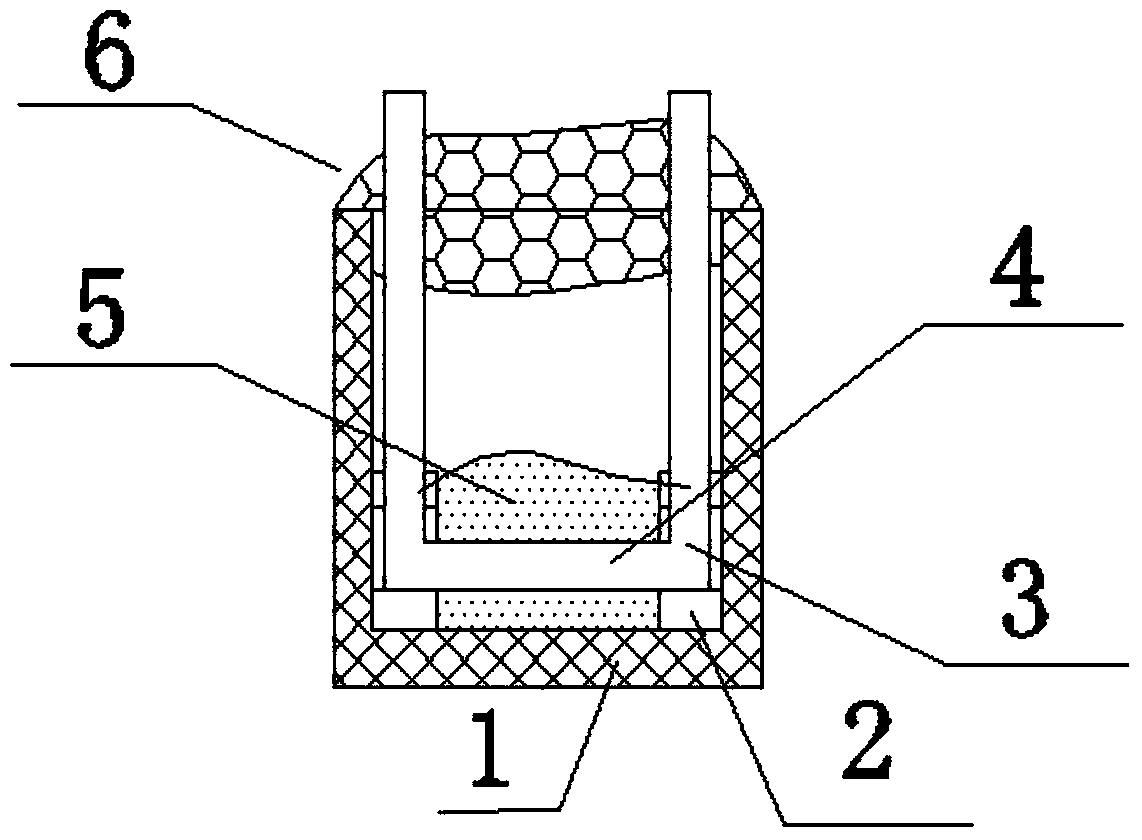

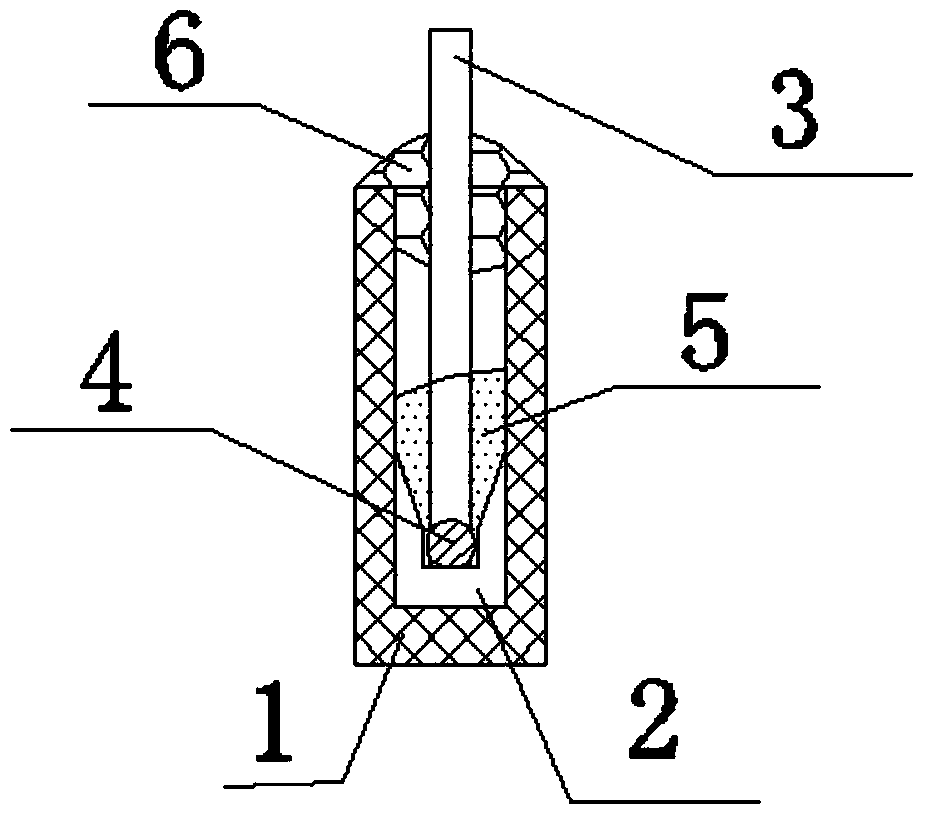

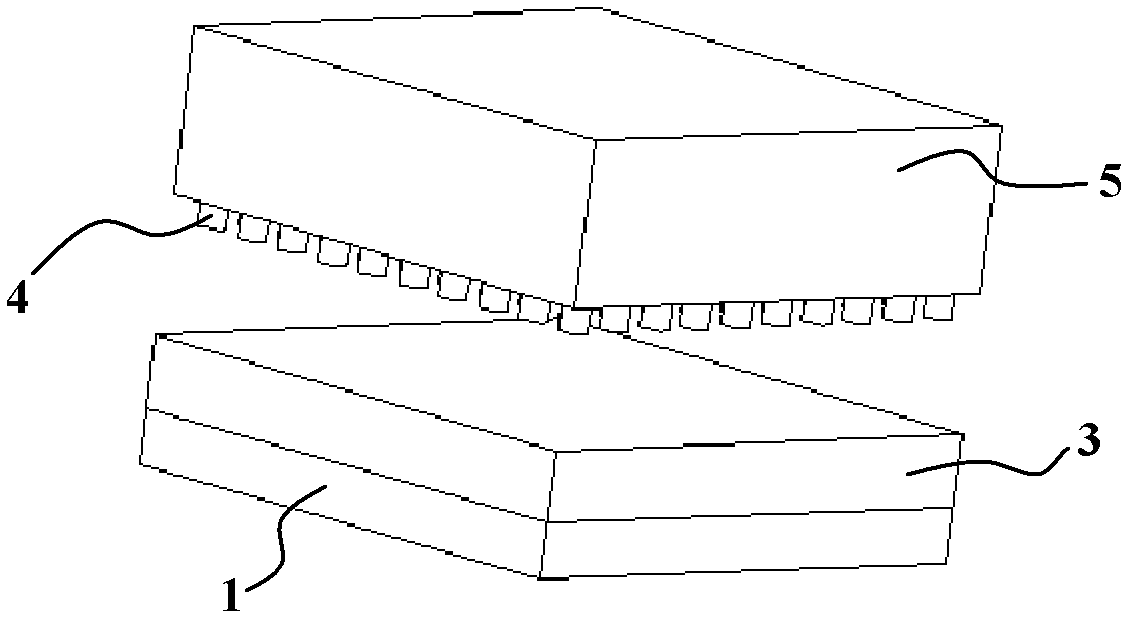

Alloy type thermal link with breaking current resistance

ActiveCN105428179AAvoid breakingImprove wettabilityEmergency protective devicesTemperature resistanceEngineering

The invention relates to an alloy type thermal link with breaking current resistance. The alloy type thermal link belongs to the technical field of manufacture of a fuse thermal link for electrical equipment. The alloy type thermal link comprises a housing, a lead wire, a thermal component, a cosolvent and an epoxy resin adhesive. Two sides of the bottom of the housing are respectively provided with a U-shaped positioning trough. Leads are inserted into the two U-shaped positioning troughs. One end of each of the two leads is welded with and is connected with the thermal component in an overlapping manner. Cosolvent is filled at the periphery of the thermal component. The height of a space between the thermal component and the bottom in the housing is 0.6mm-1.0mm. The other end of each of the two leads is exposed from the upper opening of the housing. The epoxy resin adhesive is filled at the periphery of the lead at the opening of the housing. The epoxy resin adhesive with a filler which has advantages of improving compactness, adjusting thermal expansion coefficient and improving high temperature resistance is added, thereby preventing corrosion of the thermal component by oxygen in the air. The self gravity function of the thermal component is used for improving breaking current resistance of the alloy type thermal link. The alloy type thermal link has advantages of high fusion performance, high product quality, simple structure, safe and convenient manufacture, and safe and convenient use.

Owner:洪湖市蓝光电子有限责任公司

Lubricant for producing non-copper plating solid core welding wire and preparation technology of welding wire

InactiveCN101362980ASimple production processIncrease polarityAdditivesBase-materialsCopper platingCarbon dioxide

The invention provides a lubricant which is used in the protection of the production of solid-core welding wires by using non-copper-plating carbon dioxide gas and a production technology of the welding wires. The lubricant is formed by mixing graphite and ferrous oxalate. The production technology of the welding wires comprises: steel wires with the diameter of Phi 5.5mm for welding are firstly drawn to the semi-finished welding wires with the diameter of Phi 1.865mm; the semi-finished welding wires with the diameter of Phi 1.865mm are drawn to the finished welding wires; the production technology is characterized in that: the lubricant which is formed by mixing the graphite and the ferrous oxalate is added in a mould box of the final two or three-channel mould during the drawing process into the finished welding wires; or the mixture of water-soluble dry wire drawing lubricant and triethanolamine stearate is added in the mould box of the former one or two-channel mould before adding the lubricant. When in welding of the non-copper-plating welding wires which are manufactured by the technology, the spatter is less and the metal coating performance is good. The rust-proof period of the welding wires which are packaged by thermoplastic thin films can reach more than three years.

Owner:张俐

Miniature surface-adhered type fuse

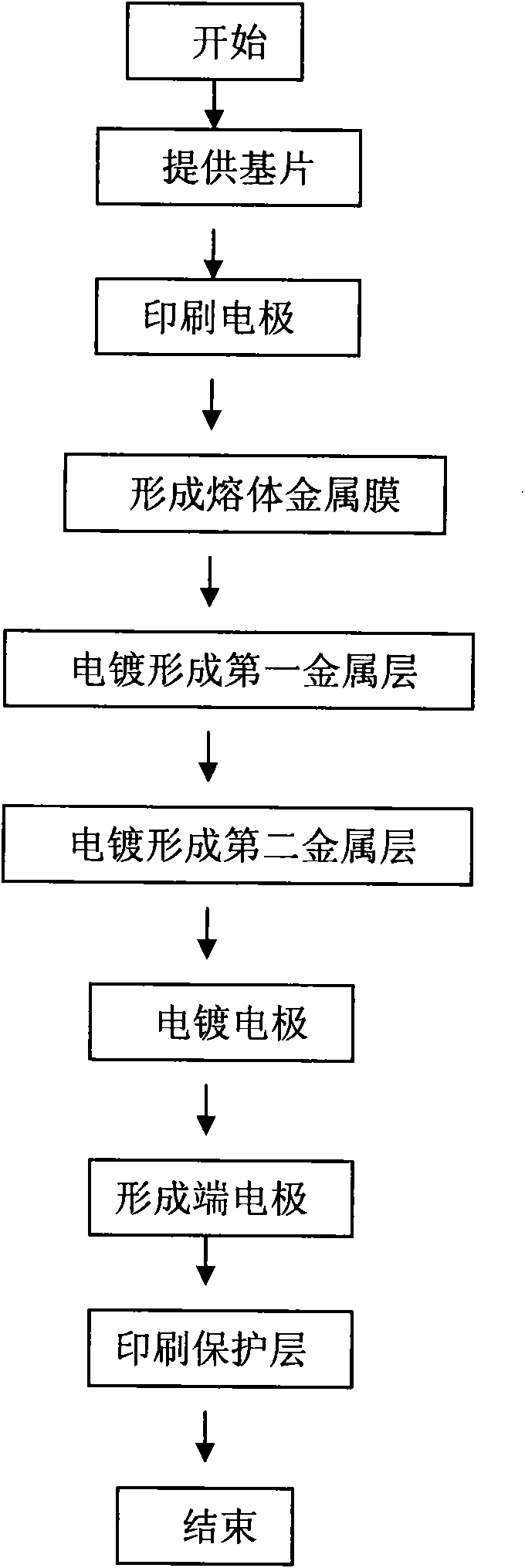

ActiveCN101593644ASimple production processEnhanced fusing performanceFuse device manufactureElectroplatingMetal

The invention relates to a miniature surface-adhered type fuse comprising an insulation base plate, an electrode part, a metal fusant part and a protection layer covered on the base plate and the fusant among the electrodes. The miniature surface-adhered type fuse is characterized in that the fusant is formed by a metal film, a first metal layer and a second metal layer together, and the three metal layers are respectively formed by a silk-screen printing method and an electroplating method. Because the final shape of the fusant of the fuse is determined before the fusant of the fuse is formed, re-shaping is not needed before one metal layer is formed every time, and the production technology is simplified.

Owner:NANJING SART SCI & TECH DEV

Miniature fuse

ActiveCN102623273ALow melting pointImprove Fusion PerformanceFuse device manufactureConductive pasteScreen printing

The invention discloses a miniature fuse, which consists of two wiring terminals, a substrate, a melt and an arc-extinguishing glass layer, wherein the melt is positioned on the surface of a ceramic sheet; the two wiring terminals are respectively electrically connected with the two ends of the melt; the arc-extinguishing glass layer, which covers the surface of the melt, is an arc-extinguishing glass sheet which consists of borosilicate lead glass; a plurality of micro-nano holes are formed on the surface of the arc-extinguishing glass sheet, which is contact with the melt; the melt is formed by electric conductive paste containing spherical or approximately-spherical metal particles through screen printing; the metal particles are 80 to 100 nm in diameter; hollow areas are arranged in the central areas in the metal particles; the micro-nano holes are 20 to 500 nm in diameter; the intervals between adjacent micro-nano holes are one to five times of the hole diameters of the micro-nano holes; and the hole depths of the micro-nano holes are one to 10 times of the hole diameters. The miniature fuse disclosed by the invention can effectively avoid the phenomenon of arc discharge and provides high insulation impedance.

Owner:SEMITEL ELECTRONICS

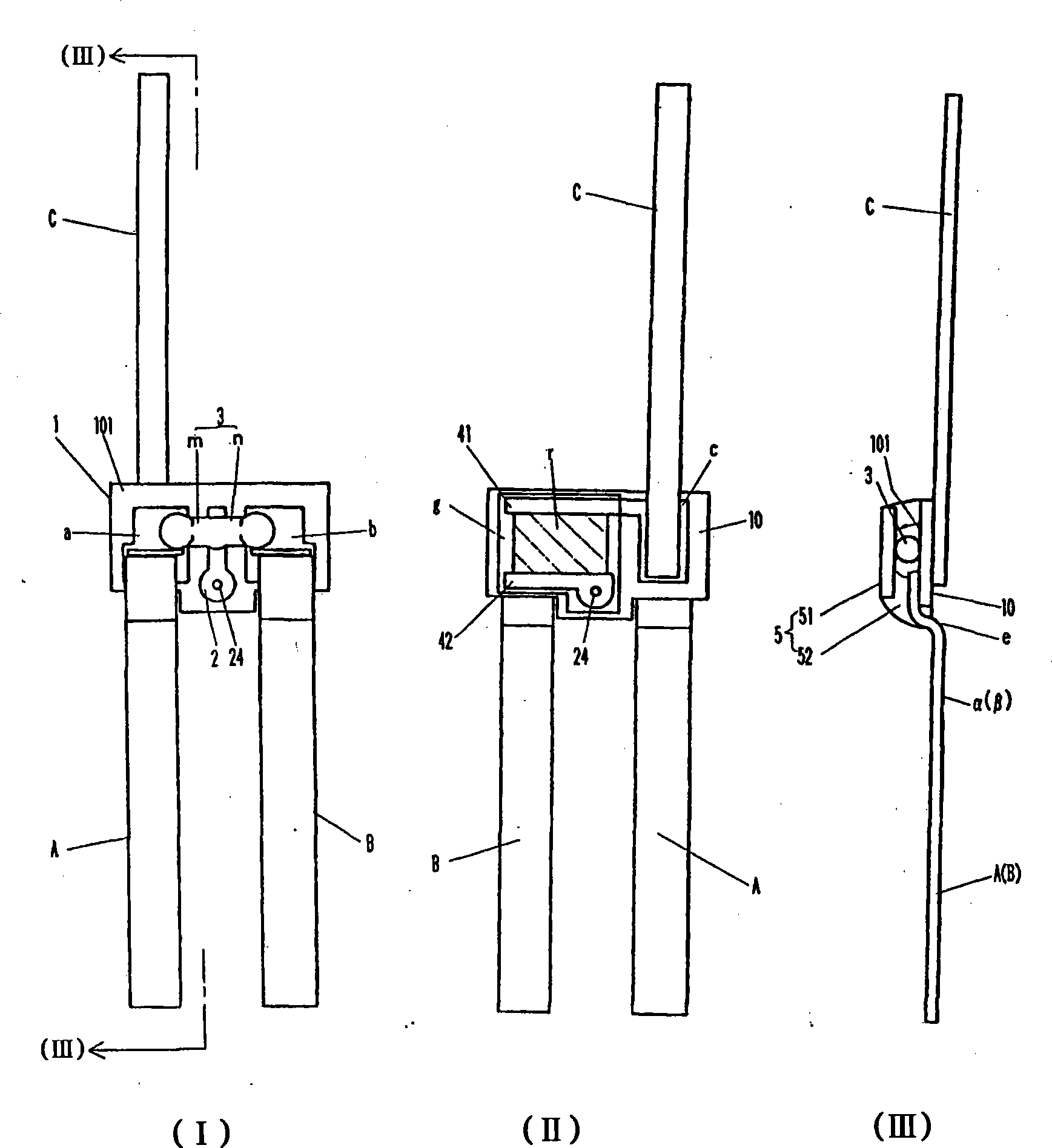

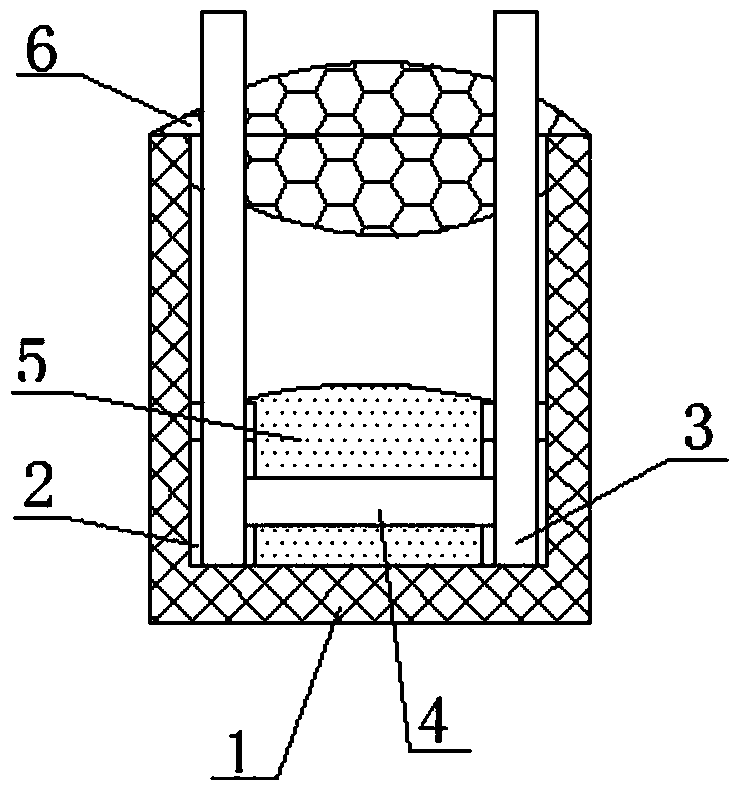

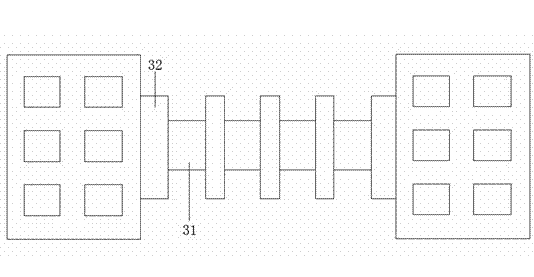

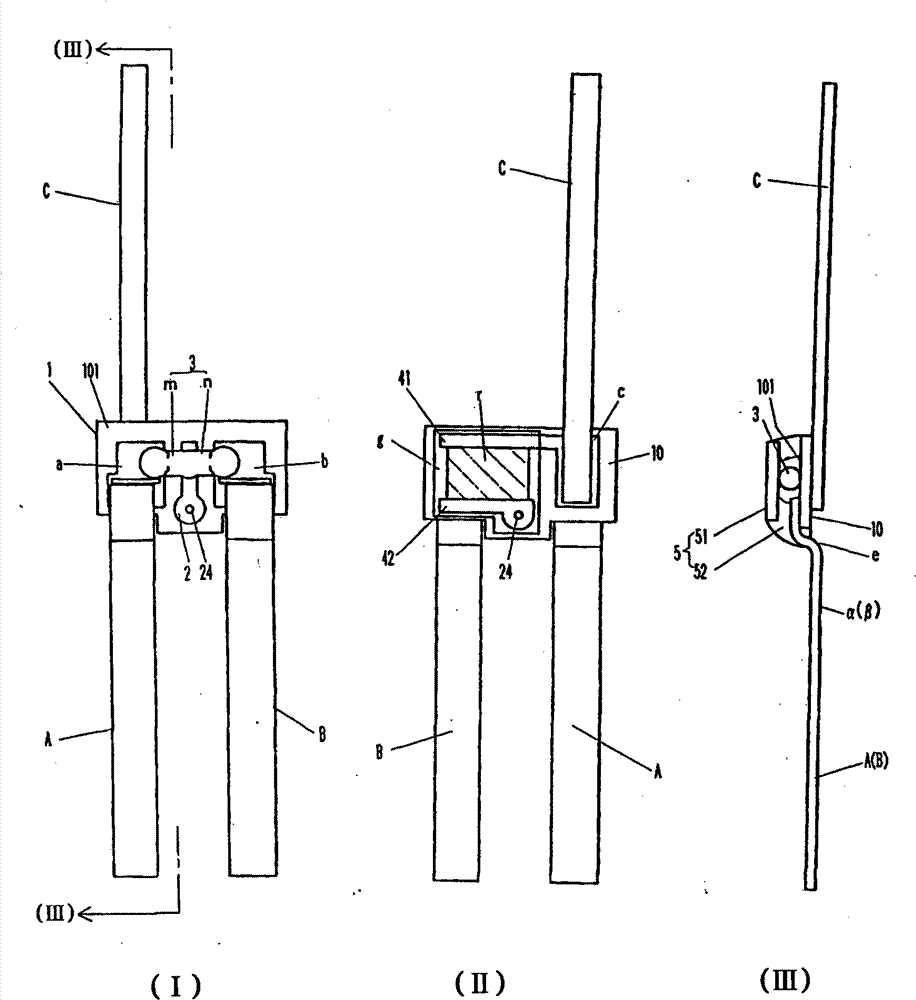

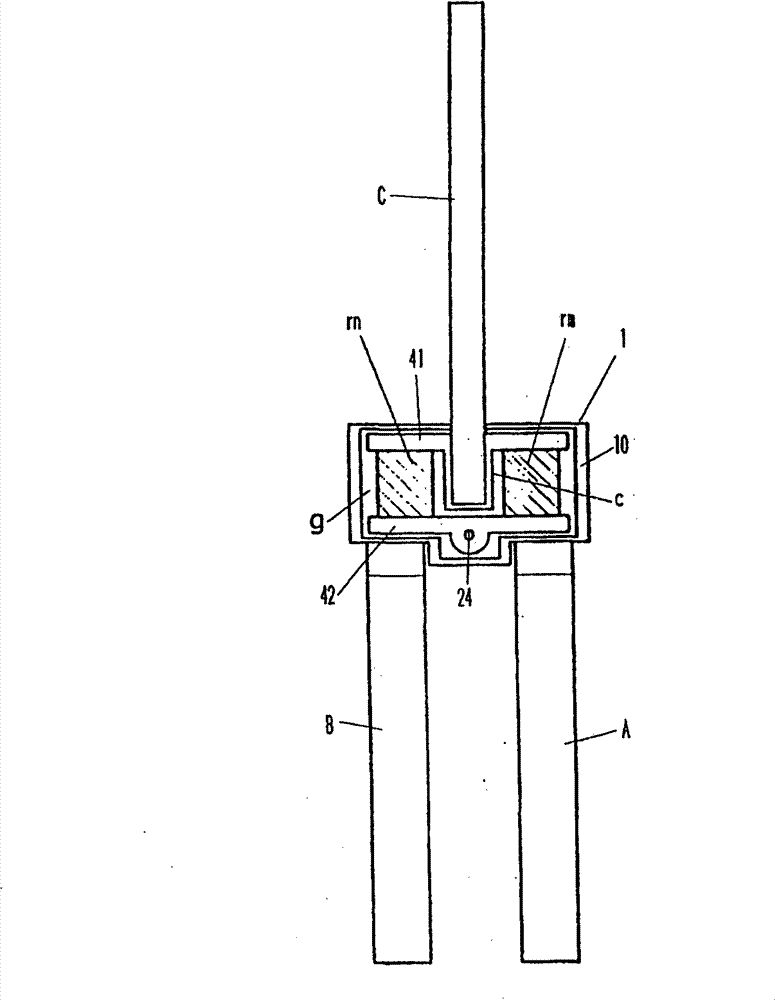

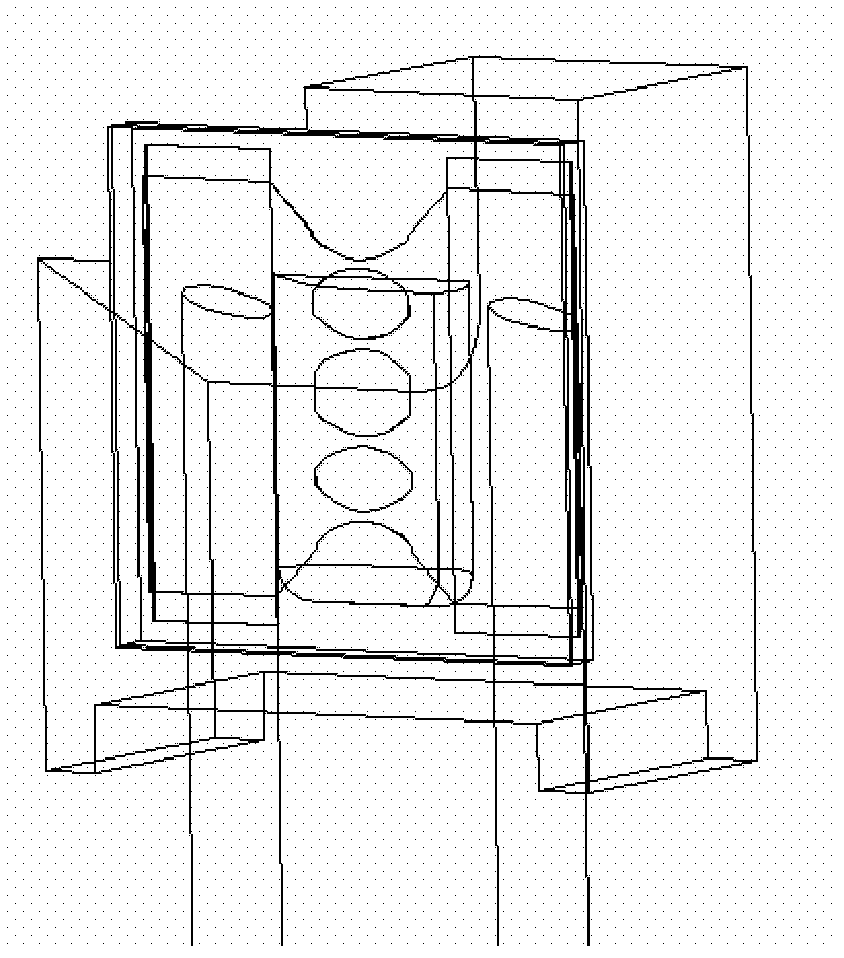

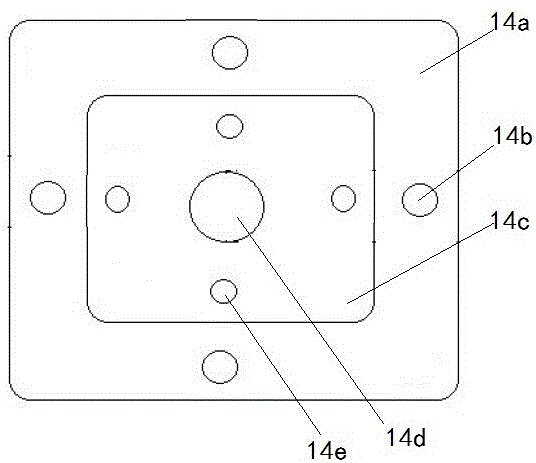

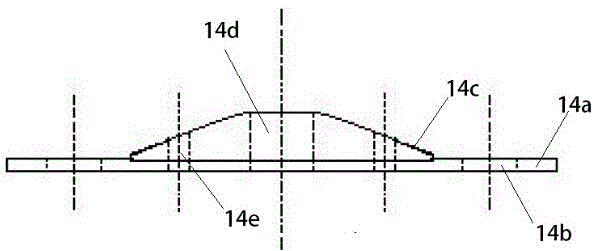

Temperature fuse with resistor and battery protection circuit

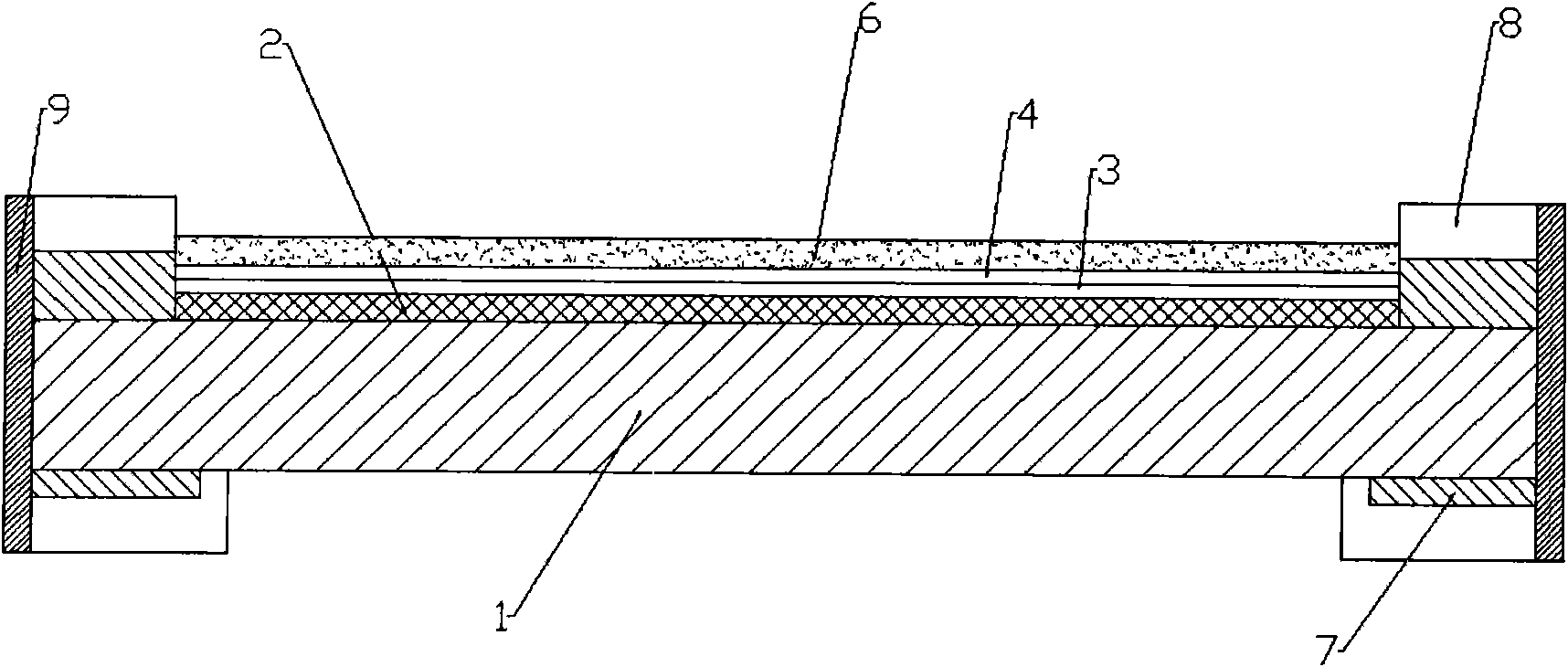

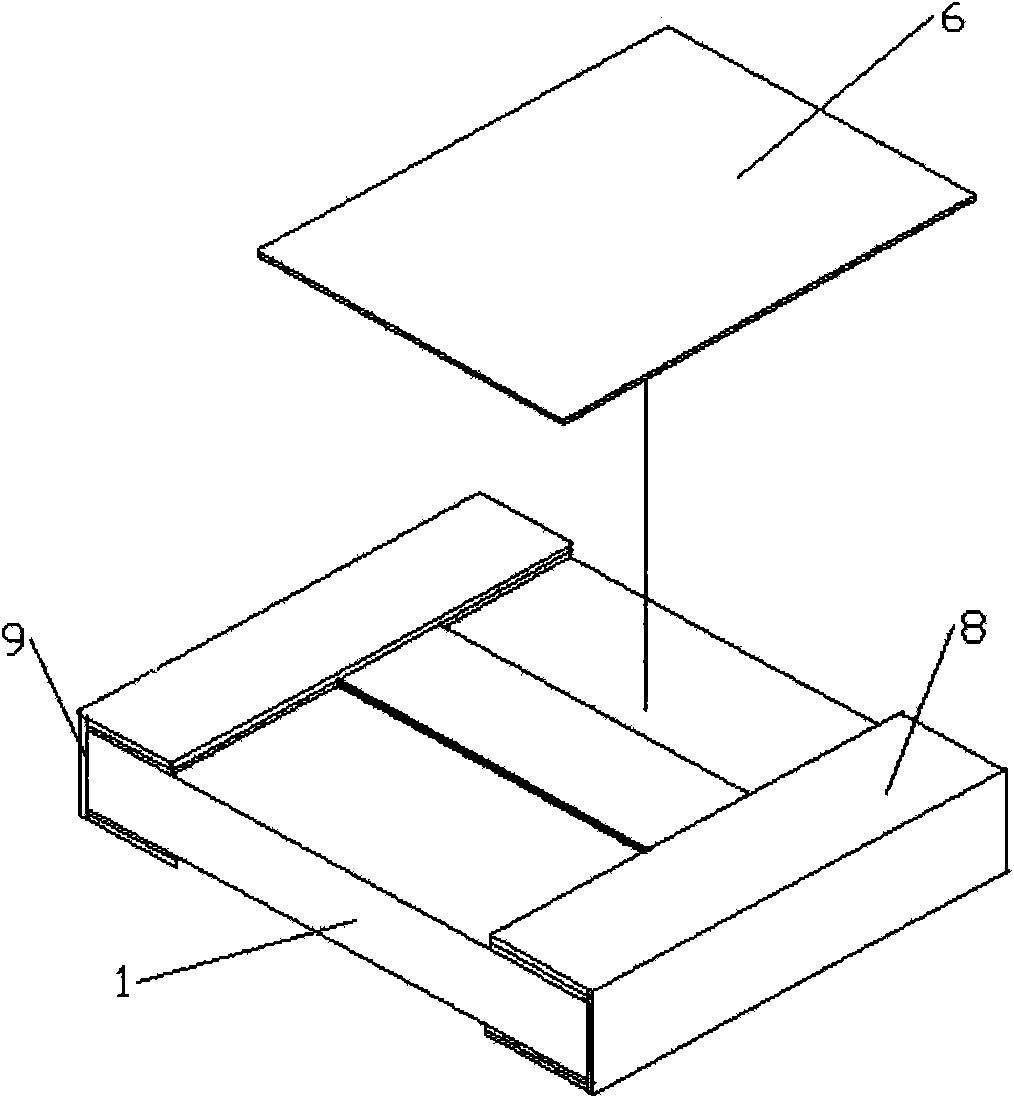

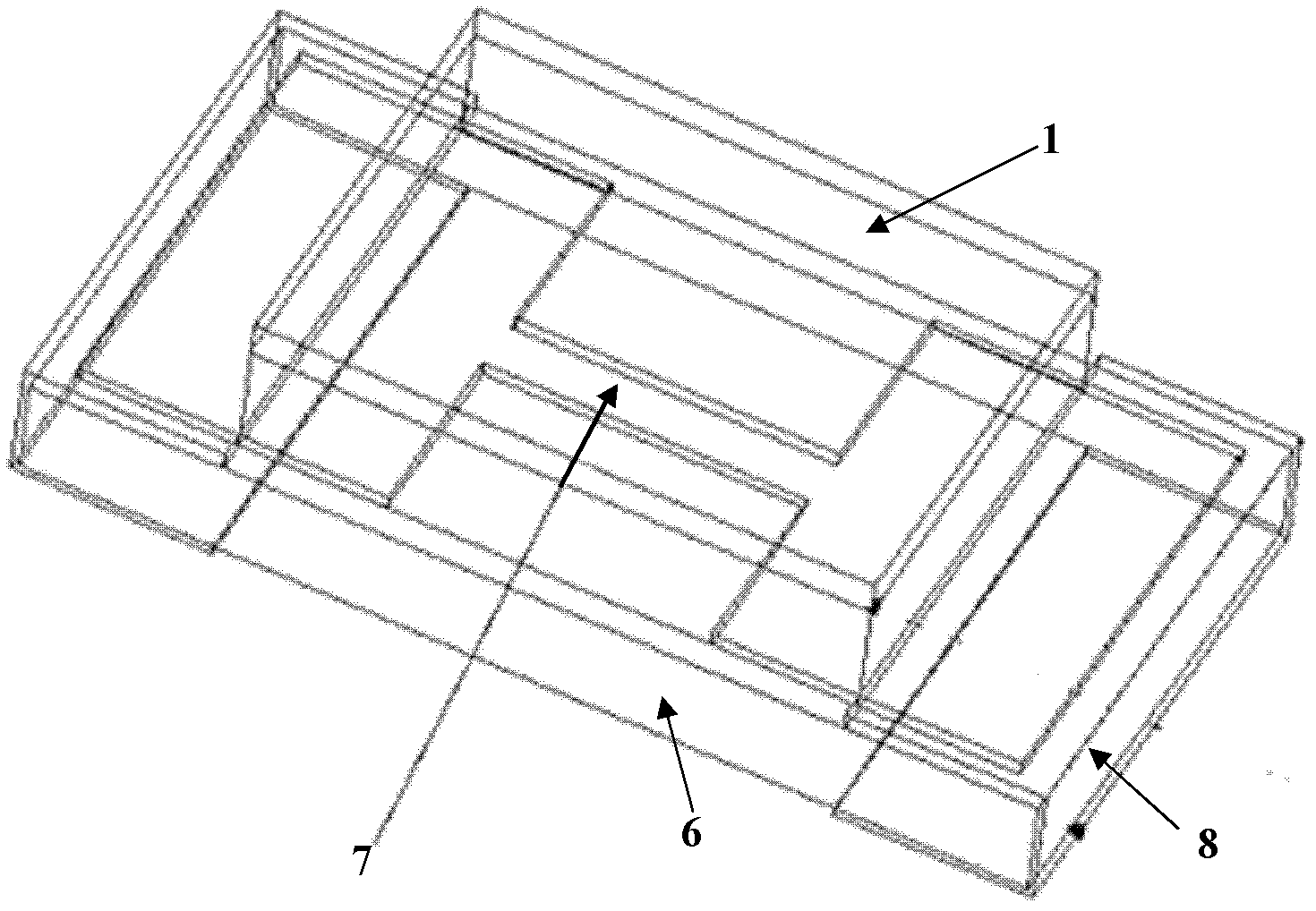

InactiveCN101373682AMake sure to form a spaceSmallness guaranteedPrinted circuit detailsSecondary cellsElectrical conductorBand shape

This invention provides a resistor temperature fuse and batter protection circuit board, aiming to realize minimization for main body with resistor temperature fuse and simplification of circuits for secondary battery protection circuit containing resistor temperature. Thus, fuse elements are thoroughly disposed on film electrodes of two sides and middle film electrode on surface of a substrate, on fore end for jointing ribbon leads of on each film electrode, on surface of the substrate is covered with insulation sealing, disposing film resistors by transversely crossing fore and rear electrodes on other surface of the substrate, one film electrode is electrically connected with the middle film electrode, fore end of the ribbon lead is jointed with side part of another film electrode via surface contact, step rising to other side of the substrate is formed on edge end position of ribbon lead close to the substrate, height difference between upper side of the step and other surface of the substrate equals to thickness of the ribbon lead.

Owner:UCHIHASHI ESTEC

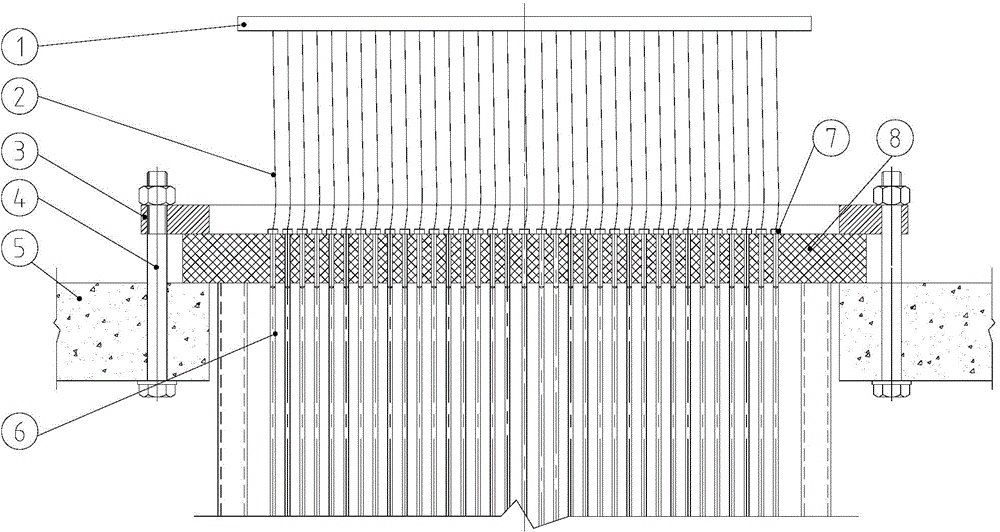

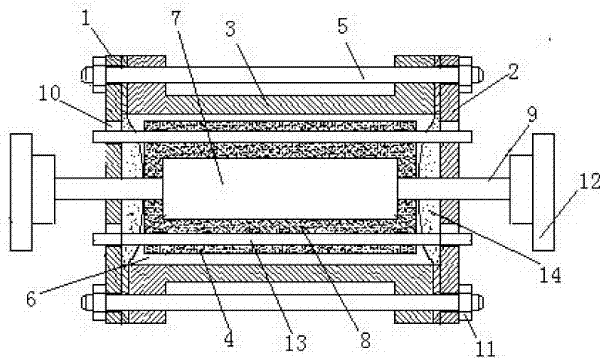

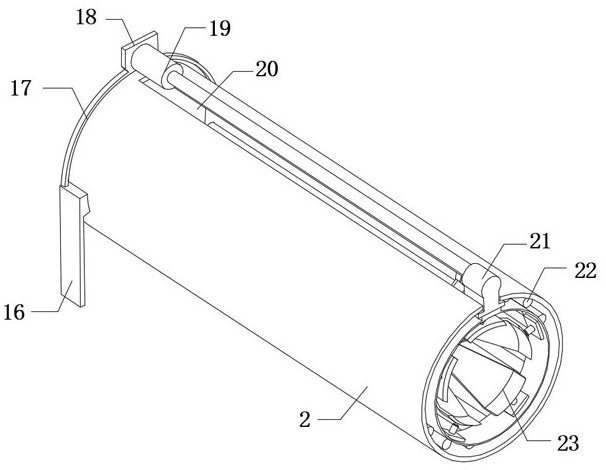

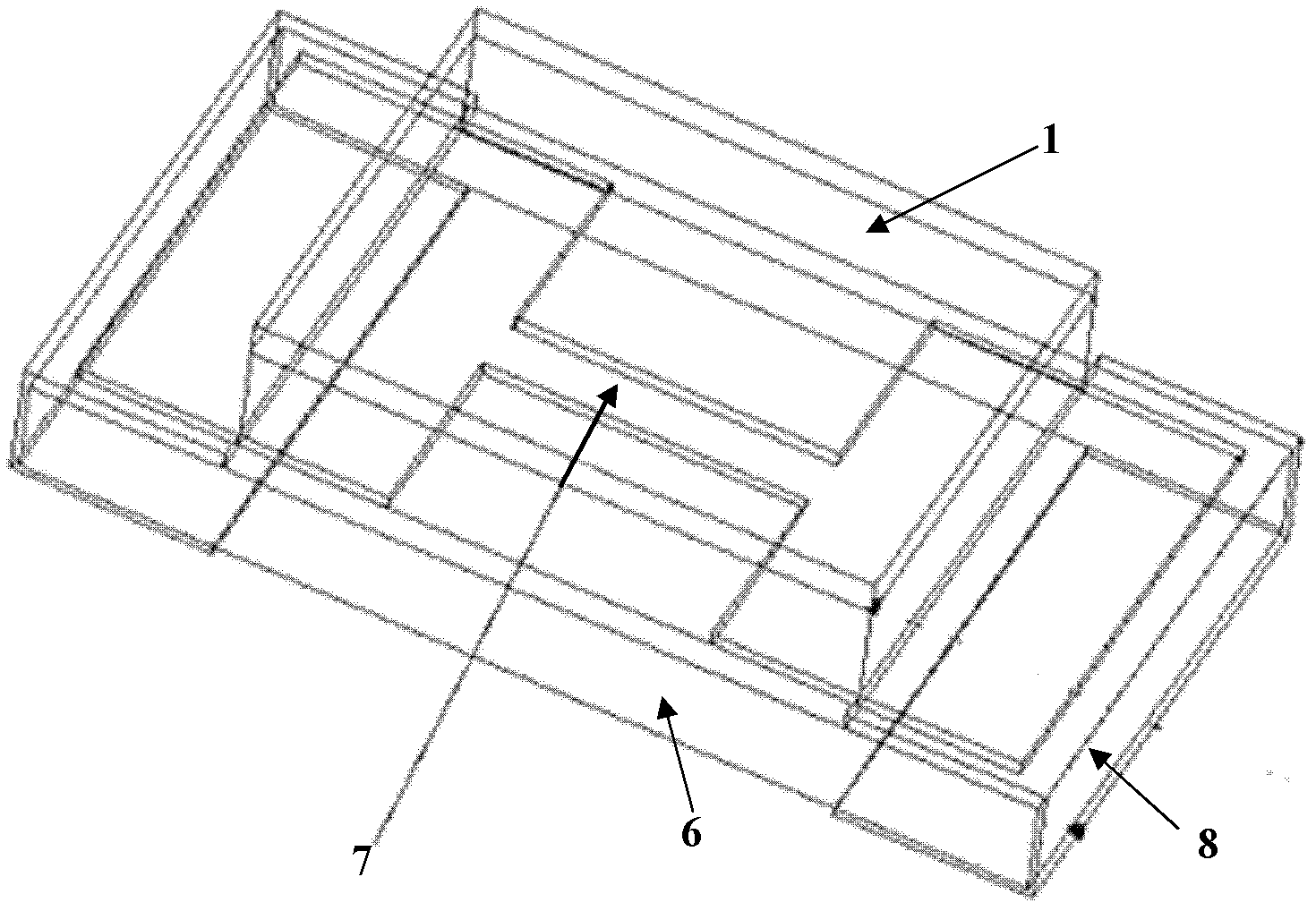

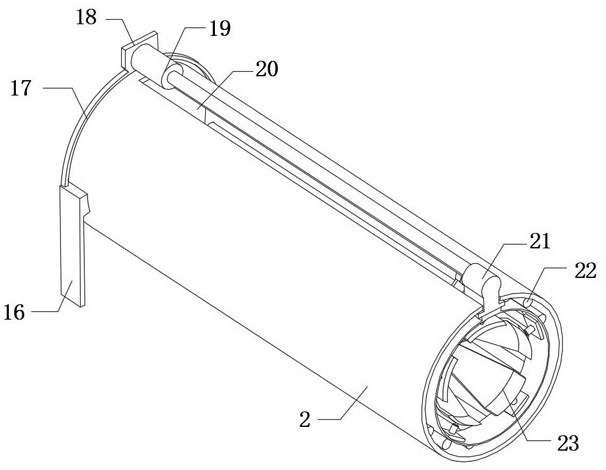

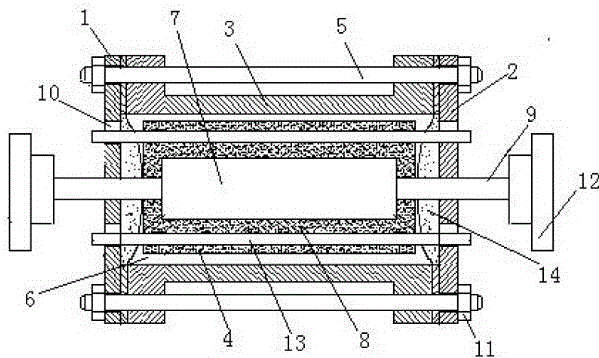

Device for utilizing electric heating tantalum expansion-prevention pin for sintering fluorine plastic pipe heat exchanger pipe plate

InactiveCN104890228AContain serious thermal expansion deformationContainment tightnessElectricityEngineering

The invention discloses a device for utilizing an electric heating tantalum expansion-prevention pin for sintering a fluorine plastic pipe heat exchanger pipe plate. The device comprises a circuit board device, cables, metal pressing plates, locking devices, movable chopping boards, fluorine plastic pipe bundles, electric heating tantalum pipes and the fluorine plastic pipe plate. The pair of metal pressing plates are connected with the pair of movable chopping boards below the metal pressing plates through the locking devices respectively, and the two ends of the fluorine plastic pipe plate are fixedly arranged between the metal pressing plates and the movable chopping boards; the fluorine plastic pipe plate is locked by the locking devices connected to the metal pressing plates and the movable chopping boards; the electric heating tantalum pipes are inserted into the fluorine plastic pipe bundles, and the fluorine plastic pipe bundles are inserted into fixed holes in the fluorine plastic pipe plate to be fixed; and each electric heating tantalum pipe comprises a cable, a tantalum cover, an expansion-prevention tantalum pipe, magnesium powder and an electric heating wire. The technical aims that tantalum pipe heat sintering and the expansion-prevention pin can be multiply utilized, a traditional PTFE heat exchanger pipe plate sintering complex technology process is simplified, and the sintering efficiency is improved are achieved.

Owner:北京北交富沃机电工程科技有限公司

An alloy type thermal fuse with breaking current resistance

ActiveCN105428179BAvoid breakingImprove wettabilityEmergency protective devicesEpoxyManufacturing technology

The invention relates to an alloy type thermal link with breaking current resistance. The alloy type thermal link belongs to the technical field of manufacture of a fuse thermal link for electrical equipment. The alloy type thermal link comprises a housing, a lead wire, a thermal component, a cosolvent and an epoxy resin adhesive. Two sides of the bottom of the housing are respectively provided with a U-shaped positioning trough. Leads are inserted into the two U-shaped positioning troughs. One end of each of the two leads is welded with and is connected with the thermal component in an overlapping manner. Cosolvent is filled at the periphery of the thermal component. The height of a space between the thermal component and the bottom in the housing is 0.6mm-1.0mm. The other end of each of the two leads is exposed from the upper opening of the housing. The epoxy resin adhesive is filled at the periphery of the lead at the opening of the housing. The epoxy resin adhesive with a filler which has advantages of improving compactness, adjusting thermal expansion coefficient and improving high temperature resistance is added, thereby preventing corrosion of the thermal component by oxygen in the air. The self gravity function of the thermal component is used for improving breaking current resistance of the alloy type thermal link. The alloy type thermal link has advantages of high fusion performance, high product quality, simple structure, safe and convenient manufacture, and safe and convenient use.

Owner:洪湖市蓝光电子有限责任公司

Electrophotographic developing agent

InactiveUS7998648B2Excellent fusing property and durabilityPrevent hot offset and wrap jammingDevelopersWaxAcid value

An electrophotographic developing agent is provided that includes a binder resin, a releasing agent, a colorant, and a charge control agent. By using a binder resin having a high acid value and a mixture of two waxes having different melting points as a releasing agent, a electrophotographic developing agent is obtained, which has excellent fusing property and durability and does not result in hot offset and wrap jamming.

Owner:HEWLETT PACKARD DEV CO LP

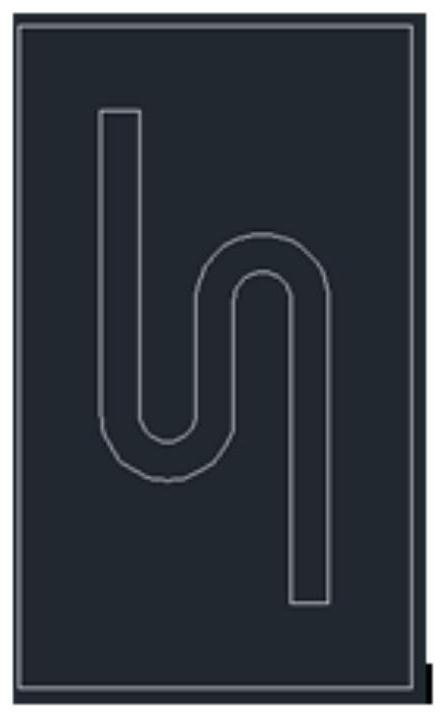

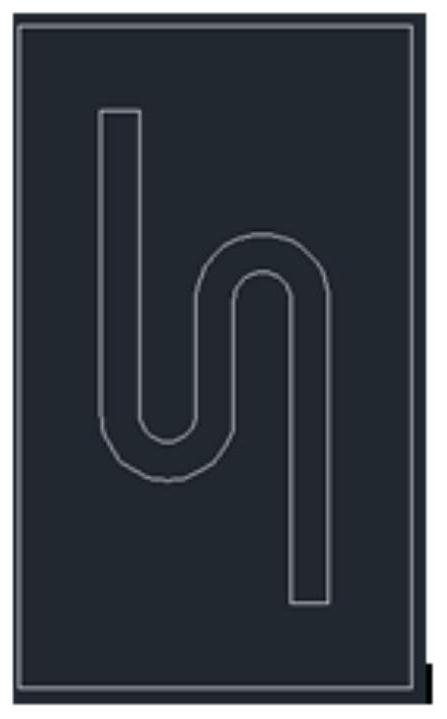

Surface-mounted fuse based on low-temperature co-fired ceramic technology and preparation method thereof

ActiveCN112266272AGood fusing performanceConcentration of fuse timeFuse device manufactureMetal/alloy conductorsCo-fired ceramicSi substrate

The invention discloses a surface-mounted fuse based on a low-temperature co-fired ceramic technology and a preparation method thereof. The preparation method comprises the following steps of sequentially preparing low-temperature co-fired ceramic powder, an organic carrier, low-temperature co-fired ceramic slurry, fuse electrode slurry, terminal electrode slurry, a positive electrode layer and aback electrode layer, then sequentially printing the low-temperature co-fired ceramic slurry, the fuse electrode slurry and the terminal electrode slurry on a ceramic substrate, and then co-firing each printing slurry layer to obtain a surface-mounted fuse semi-finished product, then, manufacturing a glass protection layer and identification characters on the surface-mounted fuse semi-finished product, and finally, acquiring a surface-mounted fuse finished product through a post-processing procedure. According to the preparation method, a low-temperature co-fired ceramic technology is utilized, so that the problems of diffusion and uneven surface during printing of the fuse electrode slurry are solved, and the pattern of the fuse is more complete, clearer and higher in controllability; thefusing process of the prepared surface-mounted fuse is rapid, and the phenomenon of arc discharge is avoided.

Owner:SEMITEL ELECTRONICS

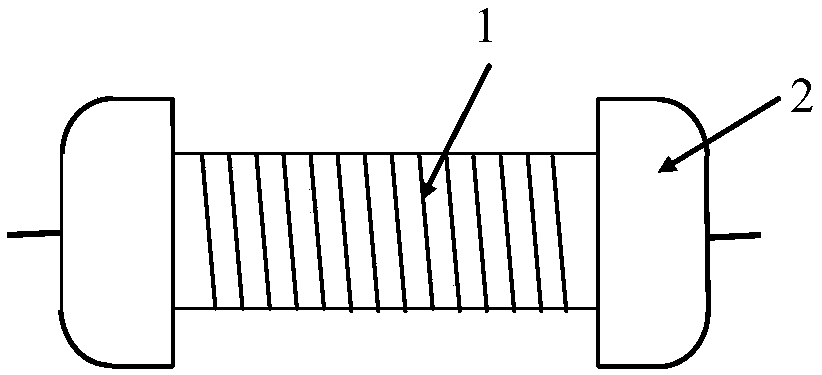

Fuse for electrical machine

InactiveCN104282512AEasy to disassembleImprove ventilation performanceEmergency protective devicesHeat sinkEngineering

The invention discloses a fuse for an electrical machine. The fuse comprises a left end cover, a right end cover, a shell and a fusion tube. The left end cover is mounted on the left side of the shell. The right end cover is mounted on the right side of the shell. A screw is arranged on the left end cover, the shell and the right end cover and penetrates through the left end cover, the shell and the right end cover in sequence. A cavity is formed among the left end cover, the shell and the right end cover. The fusion tube is mounted in the cavity. A fuse body is arranged in the fusion tube. The left end cover and the right end cover are both provided with binding posts. Each binding post is provided with ceramic insulation and cooling fins. The binding posts are both connected with the fusion tube. The left end cover and the right end cover are both provided with vent holes. Ceramic cooling sticks penetrating through the fusion tube are arranged in the vent holes. The left end cover, the shell and the right end cover are matched and fixed through the screw and a nut in sequence.

Owner:李亚林

Fire-prevention fuse used for electrical machinery and provided with ceramic insulating and radiating fins

InactiveCN105702539AEasy to disassembleImprove cooling effectEmergency protective devicesElectric machineEngineering

The invention discloses a fire-prevention fuse used for electrical machinery and provided with ceramic insulating and radiating fins. The fire-prevention fuse comprises a left end cover, a right end cover, a shell and a fuse tube, wherein the left end cover is mounted on the left side of the shell; the right end cover is mounted on the right side of the shell; a threaded rod is arranged on the left end cover, the shell and the right end cover, and the threaded rod penetrates through the left end cover, the shell and the right end cover in sequence; a hollow cavity is formed among the left end cover, the shell and the right end cover; the fuse tube is mounted in the hollow cavity; a melt is arranged in the fuse tube; a binding post is arranged on each of the left end cover and the right end cover separately; the binding posts are provided with ceramic insulating and radiating fins; the binding posts are both connected with the fuse tube; ventilating holes are formed in each of the left end cover and the right end cover; ceramic radiating rods penetrating through the fuse tube are arranged in the through holes; and the left end cover, the shell and the right end cover are matched with nuts and are fixed through the screw rod in sequence.

Owner:JINGJIANG SHUNHAI AUTOMOBILE TRADE CO LTD

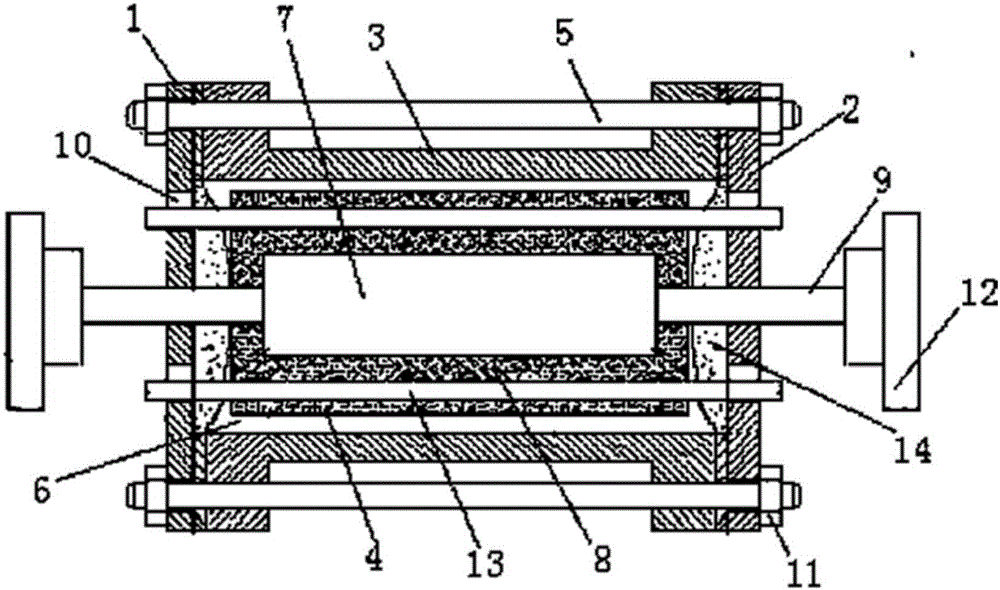

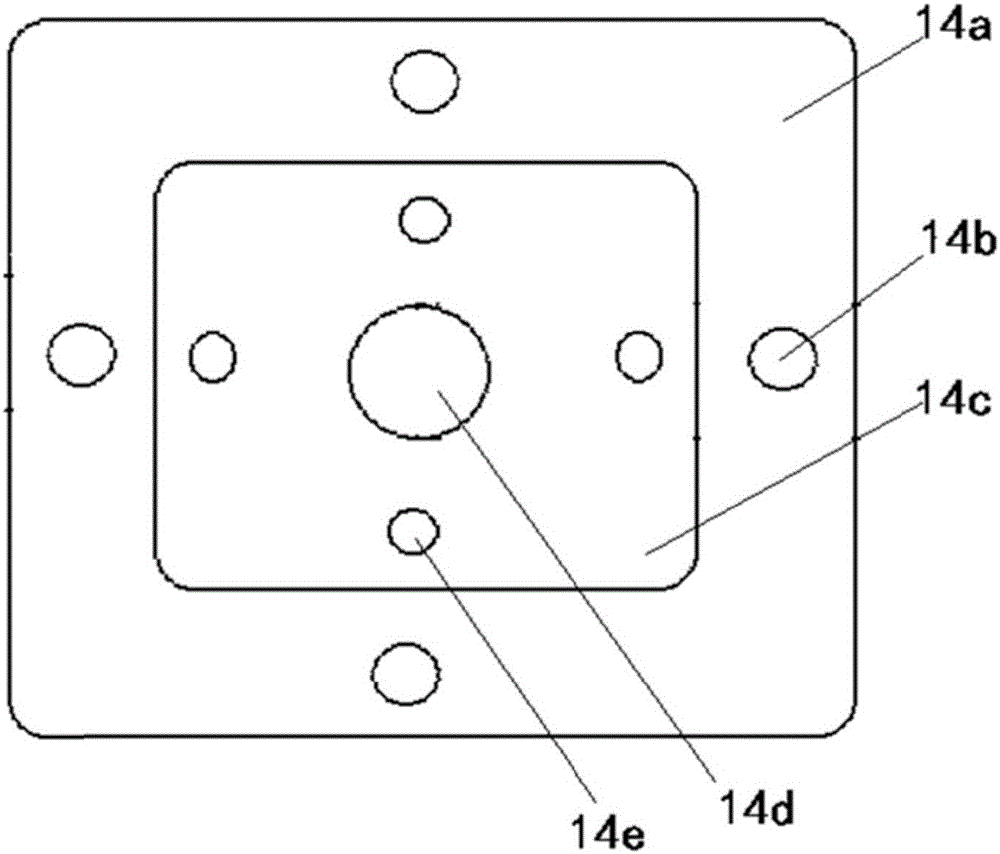

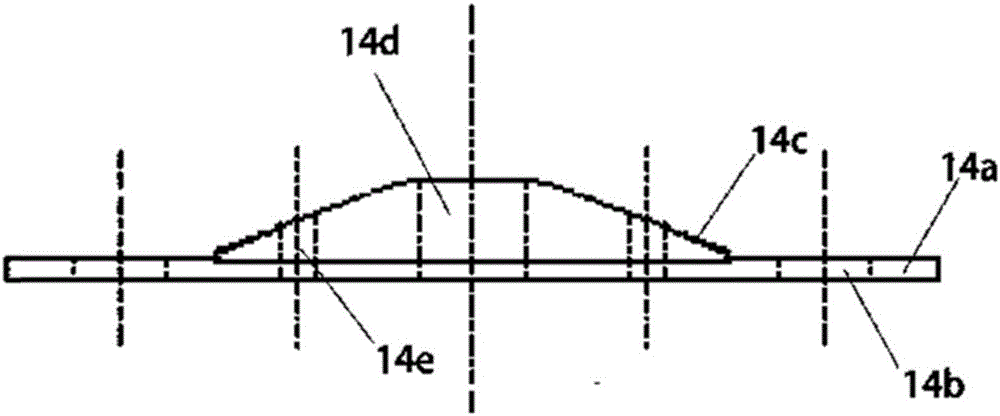

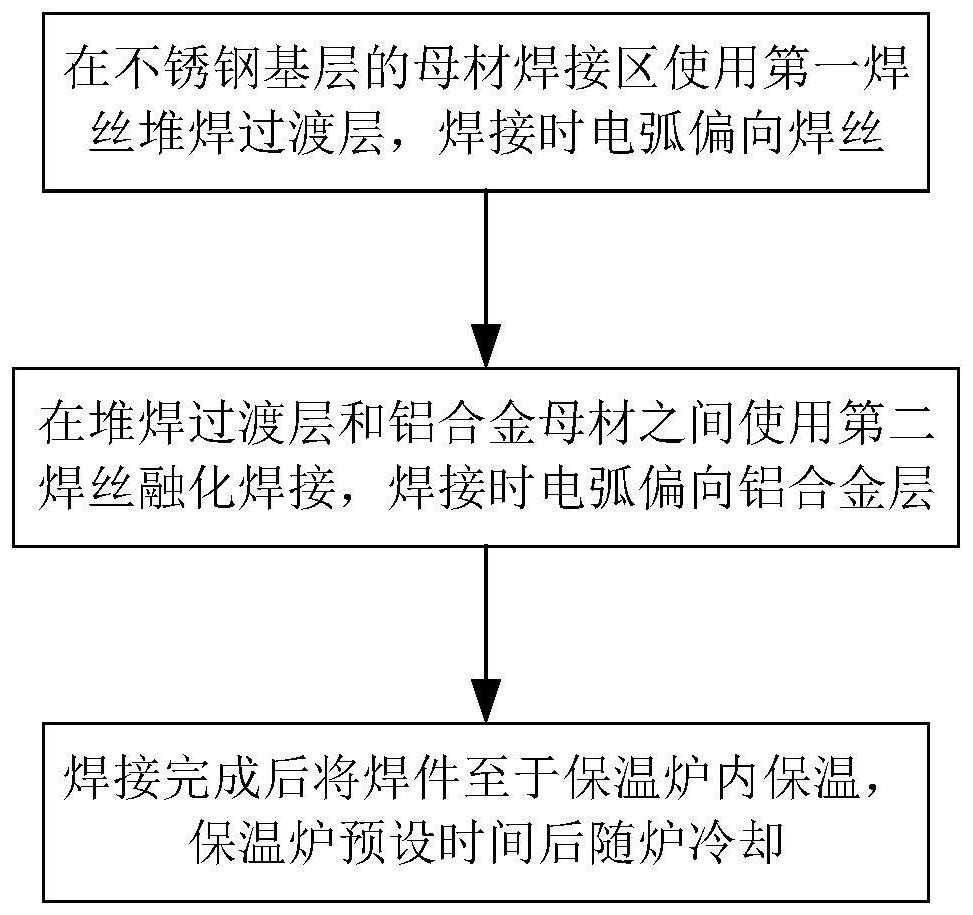

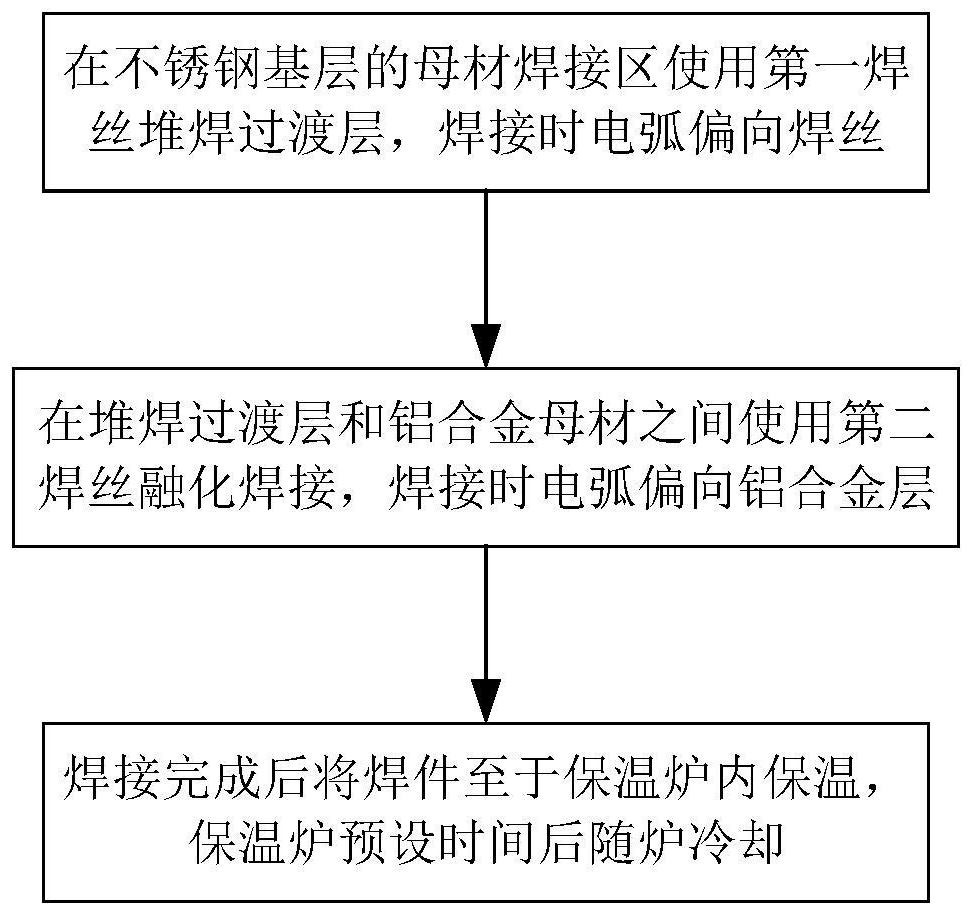

Welding process method of dissimilar metal part

ActiveCN112296492AImprove mechanical propertiesImprove Fusion PerformanceArc welding apparatusWelding/soldering/cutting articlesWeld seamFusion welding

The invention relates to the technical field of welding, in particular to a welding process method for dissimilar metal parts. The method is used for welding a stainless steel workpiece and an aluminum alloy workpiece or welding a low-carbon steel workpiece and the aluminum alloy workpiece and comprises the following steps that a transition layer is surfaced in a base metal welding area of a stainless steel base layer through a first welding wire, and electric arcs deflect to the welding wire during welding; a second welding wire is used for fusion welding between the surfacing transition layer and the aluminum alloy base metal, and electric arcs deflect to an aluminum alloy layer during welding; and after welding is completed, a weldment is placed in a heat preservation furnace for heat preservation, and furnace cooling is conducted after heat preservation is conducted for preset time. According to the welding process method for the dissimilar metal parts, due to the fact that the transition layer is welded to the base metal welding area of the stainless steel base layer in the welding process and then welded to the aluminum alloy base metal through the transition layer, the melting point of the transition layer and the melting point of the aluminum alloy parent metal can be kept within the same range, the welding seam components are uniform after welding, and the welding seamcannot be seriously deformed.

Owner:COMAC +1

Method for correcting electronically programmable fuse wire device

InactiveCN102867782AEnhanced electromigrationImprove Fusion PerformanceSemiconductor/solid-state device manufacturingComputational physicsMaterials science

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

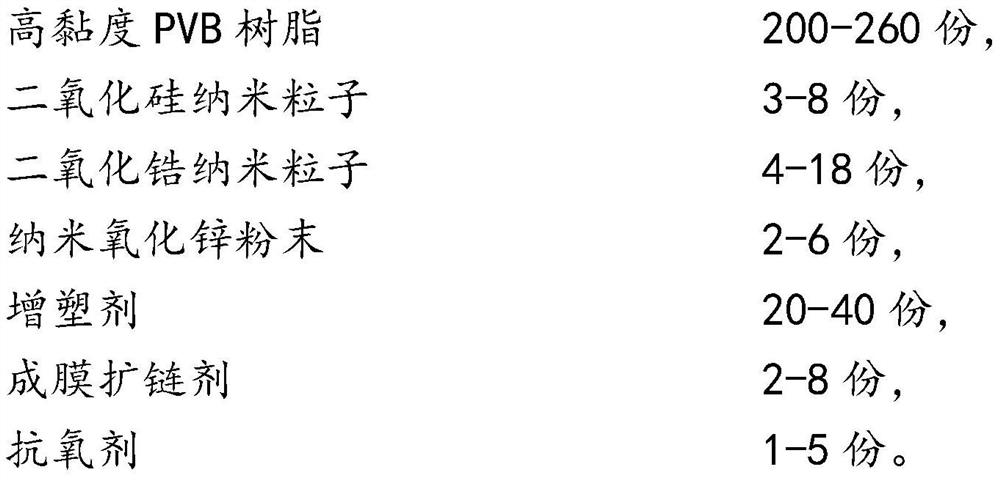

Nano heat-insulating PVB intermediate film for laminated glass and preparation method thereof

InactiveCN111944185AHigh hardnessImprove toughnessGlass/slag layered productsCoatingsSilica nanoparticlesPolymer science

The invention relates to a nanometer heat insulation PVB intermediate film for laminated glass and a preparation method thereof. The nanometer heat insulation PVB intermediate film comprises a modified PVB base film and a heat insulation coating at least compounded on the surface of one side of the modified PVB base film; wherein the modified PVB base film comprises the following raw materials inparts by mass: 200-260 parts of high-viscosity PVB resin, 3-8 parts of silicon dioxide nanoparticles, 4-18 parts of zirconium dioxide nanoparticles, 2-6 parts of nano zinc oxide powder, 20-40 parts ofa plasticizer, 2-8 parts of a film-forming chain extender and 1-5 parts of an antioxidant. The nanometer heat insulation PVB intermediate film prepared by the method has good heat insulation performance and sound insulation performance, the heat conductivity coefficient can be controlled below 0.8 W / (m*K), meanwhile, compared with a traditional PVB intermediate film, the hardness and toughness are improved, and the nanometer heat insulation PVB intermediate film has good light transmittance, good heat stability, excellent oxidation resistance and excellent yellowing resistance.

Owner:济源市舜峰纳米科技有限公司

Substrate type temperature fuse with resistor and secondary battery protection circuit

InactiveCN101373680BEarly blownReduces the risk of blowoutsSecondary cellsHeating/cooling contact switchesSubstrate typeElectrical battery

Owner:UCHIHASHI ESTEC

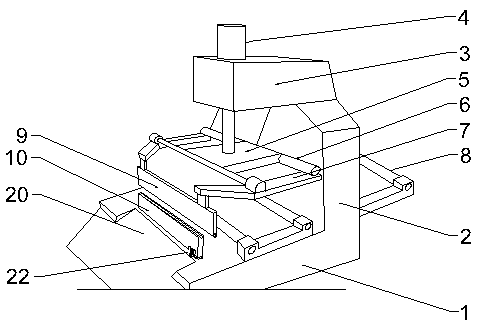

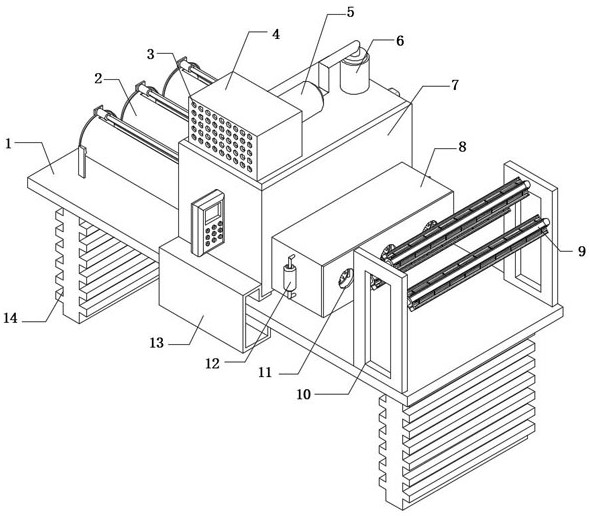

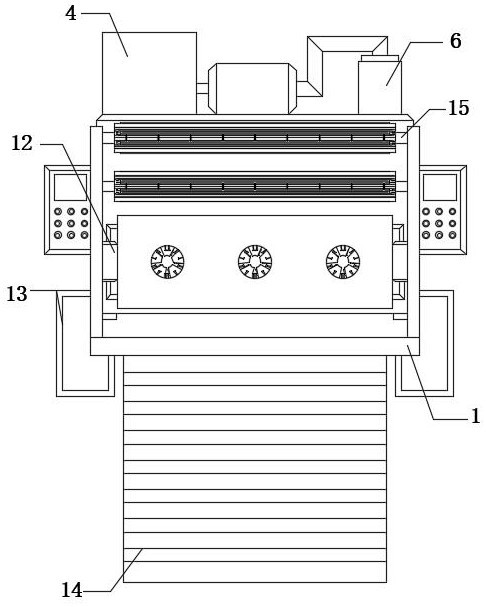

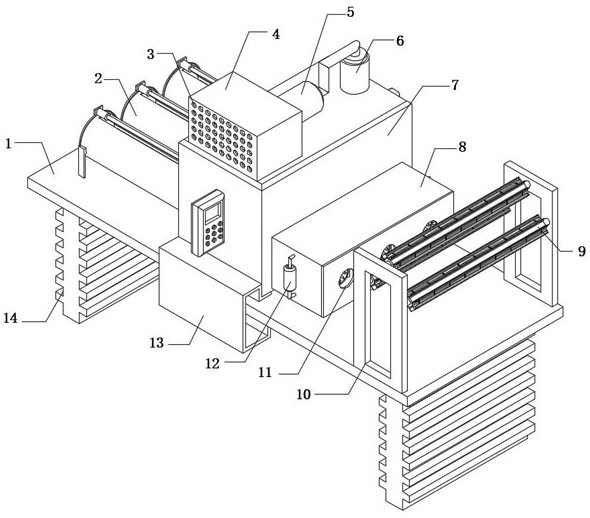

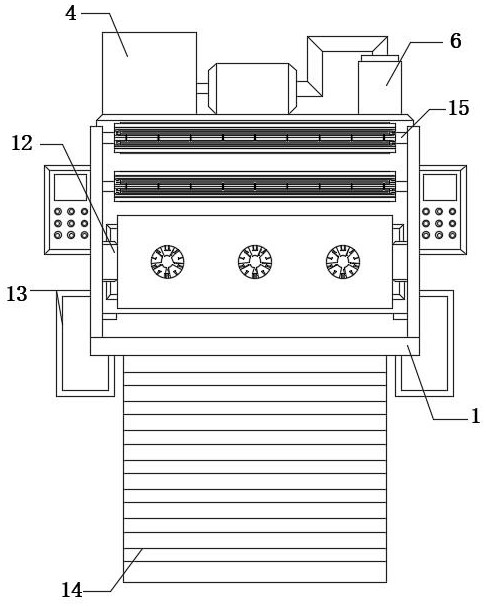

Automatic fusing system for side of fishing net

ActiveCN107675478AReasonable structureEasy to operateSevering textilesMarine engineeringStructural engineering

The invention provides an automatic fusing system for the side of a fishing net. The automatic fusing system comprises a rack, a conveyor belt is arranged at one end of the rack, supports are arrangedon the two sides of the other end of the rack, a fixed plate is arranged at the tops of the supports, a lifting air cylinder is installed on the fixed plate, a piston rod of the lifting air cylinderis downward and is connected with the fixing plate, two parallel adjusting shafts are installed on the fixed plate, two tool adjusting plates are movably installed on each adjusting shaft, a fusing blade is installed at the bottoms of the tool adjusting plates, a positioning tool apron is arranged on the part, below the fusing blade, of the rack, one side of the installed positioning tool apron isflush with the bearing face of the conveyor belt, and a net grasping assembly is arranged on the part, on the other side of the positioning tool apron, of the rack. By the adoption of the scheme, theautomatic fusing system is reasonable in structure, convenient to operate and good in fusing effect.

Owner:HUNAN XINHAI CO LTD

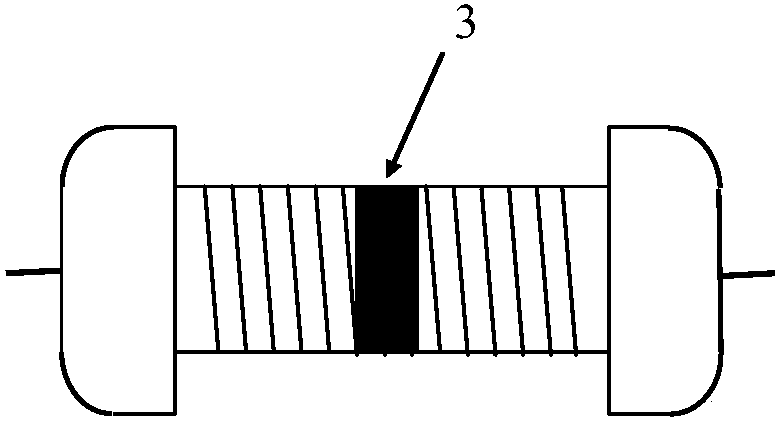

Preparation and coating method of a fuse for a wire-wound fuse resistor

InactiveCN106519882BImprove Fusion PerformanceSave raw materialsOther resistor networksCoil/loop resistive elementsBall millResistance wire

The invention discloses preparation and a coating method of a fusing agent for a wire-wound fusible resisto. The fusing agent comprises the raw materials in percentages by mass: 25-40% of phenolic resin, 5-15% of ethylene glycol monomethyl ether, 35-60% of tin powder, 2-10% of magnesium powder, 3-10% of sulfur powder and 2-10% of tributyl phosphate. The preparation method comprises the following steps: first, separately weighing the raw materials for later use; then pre-treating the sulfur powder, wherein the proportion of the pre-treatment is as follows: 12.5% of sulfur powder, 10% of anhydrous ethanol, 20% of ammonia water, 15% of deionized water and 42.5% of tetraethylorthosilicate; and then uniformly mixing the phenolic resin, the ethylene glycol monomethyl ether and the tributyl phosphate, adding the tin powder and the magnesium powder, adding a sulfur powder turbid liquid after being ball-milled, and mechanically mixing the mixture to obtain the fusing agent. The coating method comprises: finally, coating the fusing agent to 2-6 line widths in the middle position of a resistance wire on the resistor; and then drying and coating a heat-isolating layer and an insulating finishing coat. By virtue of the fusible resistor prepared by the invention, the resistance wire can be fused within 90s under a 1.14-time rated current, so that the technical requirements of a high performance charger on the fusible resistor are satisfied.

Owner:TIANJIN UNIV

A fuse machine for wire rope production and processing

ActiveCN113617978BImprove cooling and shaping effectCases that do not forkDispersed particle separationMetal working apparatusElectromagnetic heatingPhysics

The invention belongs to the technical field of steel wire rope processing, in particular to a fuse machine for production and processing of steel wire ropes, including a processing table and a fuse machine body, the top outer wall of the processing table is equidistantly connected with mounting plates, and each adjacent two The opposite outer wall of each mounting plate is fixedly connected with the same ring frame, the outer wall of the ring frame is fixedly connected with a cooling tube, and the outer wall of the cooling tube above is provided with a sliding groove. The present invention is provided with a preheating box, an electromagnetic heater, an arc-shaped limiting plate and a heat-conducting rod. At the position plate, the internal interference heat conduction frame inside the arc-shaped limit plate transfers heat to the steel wire rope, thereby pre-heating the steel wire rope to ensure that when the steel wire rope is cut inside the fuse machine, the steel wire rope is in an easy-to-cut state as a whole, and the safety of the fusing point is improved. Fuse effect.

Owner:江苏中英钢绳有限公司

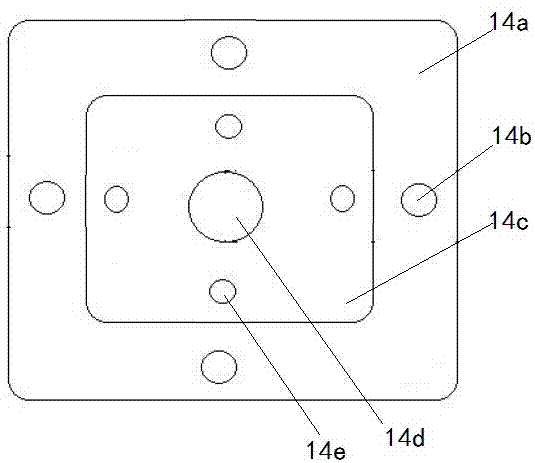

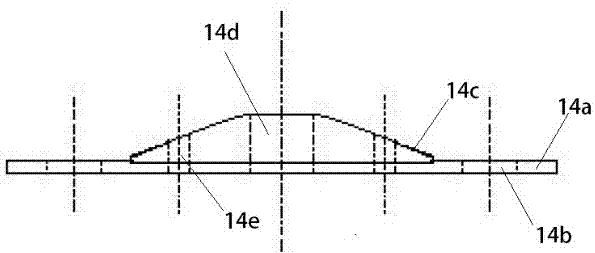

Temperature fuse with resistor and battery protection circuit

InactiveCN101373682BMake sure to form a spaceSmallness guaranteedPrinted circuit detailsSecondary cellsFilm resistanceBand shape

A resistance attach thermal fuse is provided to realize the miniaturization of a main body and the compaction of a circuit body for protecting a secondary battery, and to melt one fuse element part authentically than the other fuse element part. A resistance attach thermal fuse has both sided membrane electrode(a, b) and in-between membrane electrode(2) on one side(101) of a substrate(1). The fuse element(3) is installed through a membrane electrode. A strip-shaped lead conductor(A, B) is welded to the membrane electrode of both sides. The one side of the substrate is covered with an insulation sealing material(5). A front and end membrane electrodes(41,42) are installed on the other side(10). The film resistance (r) is installed through the front and end membrane electrodes. One of the front and end membrane electrodes electrically is wired to the in-between membrane electrode for the fuse element. The side part (c) of the membrane electrode on the other side of both side membrane electrodes is installed. The end part of the strip-shaped lead conductor(C) is welded to the side part. The step height (e) going up to the other side of the substrate is formed in the place adjacent to the edge of the substrate of the strip-shaped lead conductor (A, B).

Owner:UCHIHASHI ESTEC

Miniature fuse

ActiveCN102623273BLow melting pointImprove Fusion PerformanceFuse device manufactureMicro nanoConductive paste

The invention discloses a miniature fuse, which consists of two wiring terminals, a substrate, a melt and an arc-extinguishing glass layer, wherein the melt is positioned on the surface of a ceramic sheet; the two wiring terminals are respectively electrically connected with the two ends of the melt; the arc-extinguishing glass layer, which covers the surface of the melt, is an arc-extinguishing glass sheet which consists of borosilicate lead glass; a plurality of micro-nano holes are formed on the surface of the arc-extinguishing glass sheet, which is contact with the melt; the melt is formed by electric conductive paste containing spherical or approximately-spherical metal particles through screen printing; the metal particles are 80 to 100 nm in diameter; hollow areas are arranged in the central areas in the metal particles; the micro-nano holes are 20 to 500 nm in diameter; the intervals between adjacent micro-nano holes are one to five times of the hole diameters of the micro-nano holes; and the hole depths of the micro-nano holes are one to 10 times of the hole diameters. The miniature fuse disclosed by the invention can effectively avoid the phenomenon of arc discharge and provides high insulation impedance.

Owner:SEMITEL ELECTRONICS

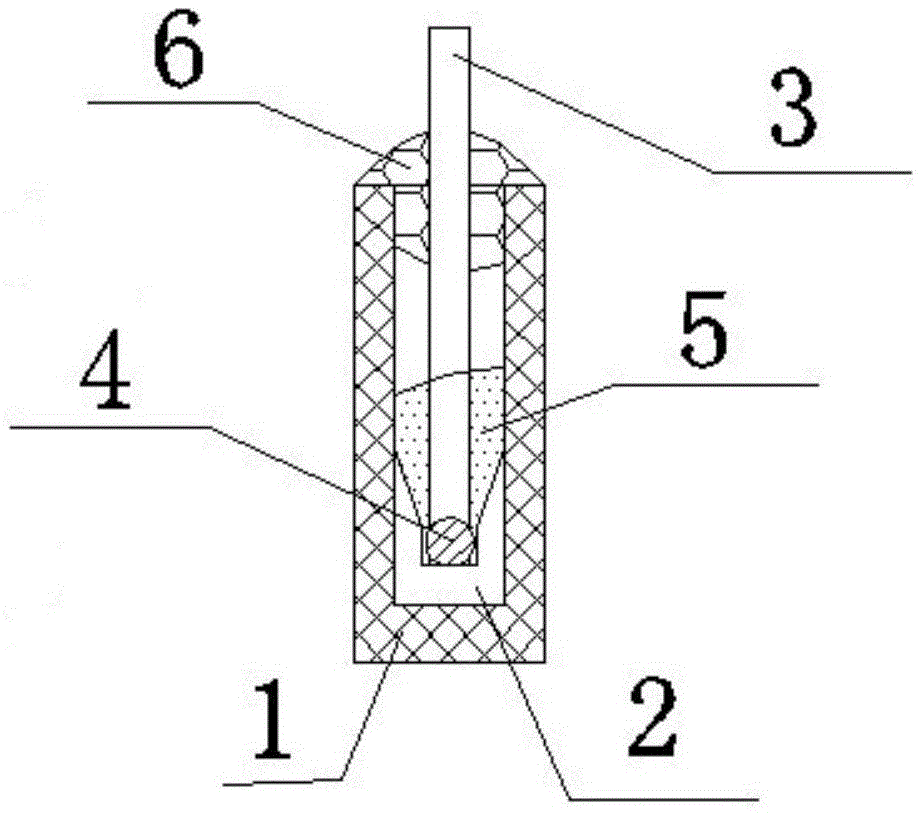

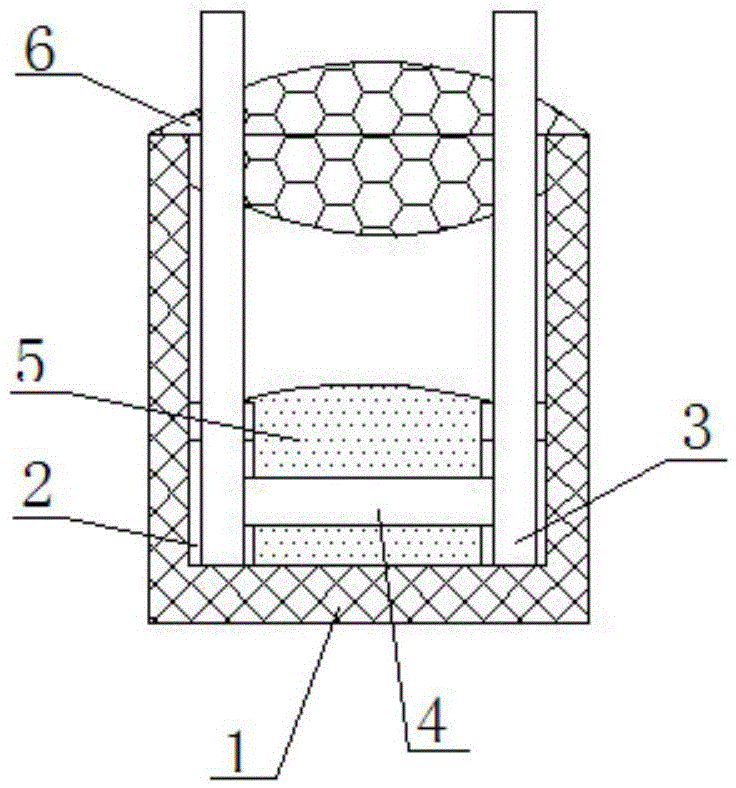

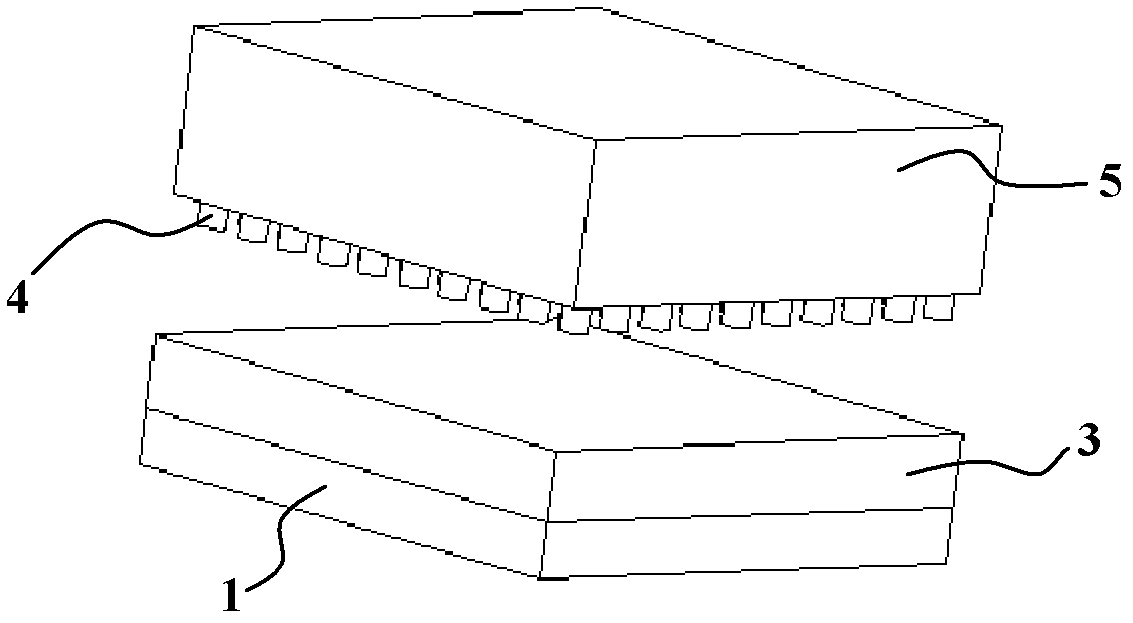

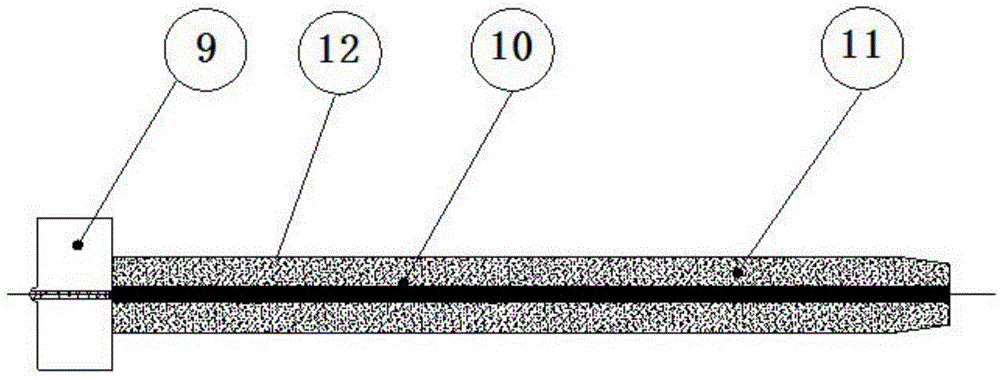

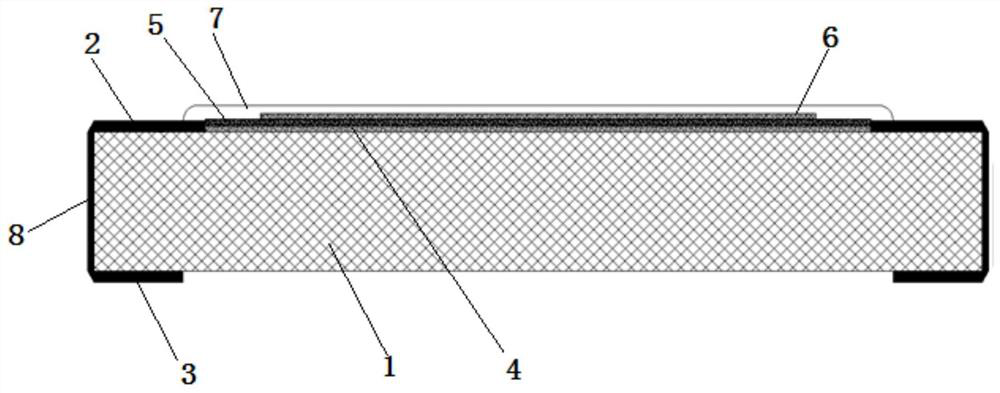

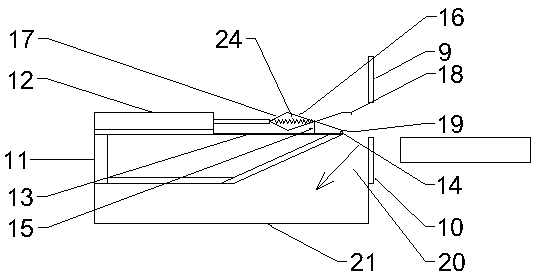

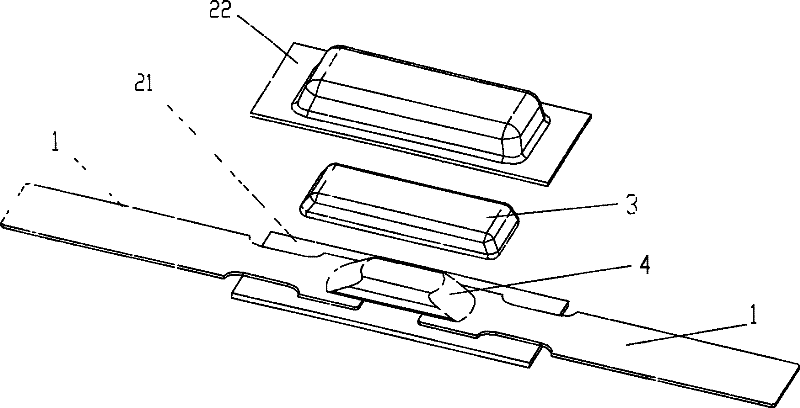

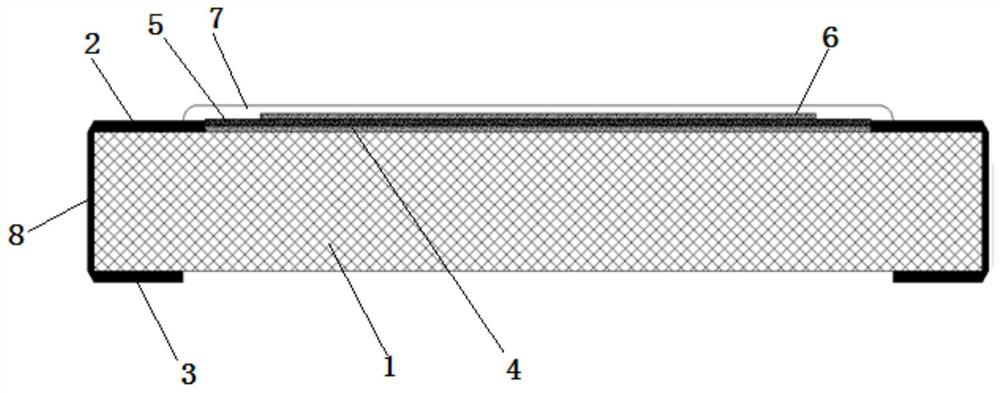

Fusing agent and temperature fuse containing the same

ActiveCN101197224BImprove Fusion PerformanceEffective draggingHeating/cooling contact switchesEmergency protective devicesAlcoholElectrical battery

The invention relates to a flux and a temperature fuse with the flux, wherein the flux is formed by mixing common rosin, stearic acid, liquid alcohol and minim small molecule acid in the following mixing ratio (weight percent): 50 percent to 70 percent rosin, 5 percent to 20 percent stearic acid, 10 percent to 40 percent liquid alcohol and 0.5 percent to 16 percent small molecule acid. The temperature fuse element comprises an electrode slice (1), an insulation bottom film (21) and insulation upper film (22), the flux (3) and a lower melting point alloy wire (4). Compared with the prior flux,the flux of the invention obviously improves the thermal-link performance and does not decompose during storage, and well maintain the activity of the flux. The thermal-link performance of the temperature fuse element used by lithium ion cell produced by the invention is obviously improved, thus forming better protection for lithium cell.

Owner:BYD CO LTD

Fusing machine for steel wire rope production and processing

ActiveCN113617978AImprove cooling and shaping effectAvoid contact deformationDispersed particle separationMetal working apparatusPhysicsEngineering

The invention belongs to the technical field of steel wire rope processing, and particularly relates to a fusing machine for steel wire rope production and processing. The fusing machine for steel wire rope production and processing comprises a processing table and a fusing machine body; mounting plates are fixedly connected to the outer wall of the top of the processing table at equal intervals; one annular frame is fixedly connected to the outer walls of the opposite sides of every two adjacent mounting plates; a cooling cylinder is fixedly connected to the outer wall of the annular frame; and a sliding groove is formed in the outer wall, located at the upper part, of the cooling cylinder. According to the fusing machine for steel wire rope production and processing, through the arrangement of a preheating box, an electromagnetic heater, an arc-shaped limiting plate and a heat conduction rod, before entering the fusing machine, the steel wire rope firstly penetrates through thep reheating box; the electromagnetic heater is started; the heat conduction rod transmits heat to the arc-shaped limiting plate; an inner abutting heat conduction frame in the arc-shaped limiting plate transmits the heat to the steel wire rope to perform preliminary preheating treatment on the steel wire rope; and therefore, it is guaranteed that the whole steel wire rope is in an easily-cut-off state when the steel wire rope is cut off in the fusing machine, and the fusing effect of a fusing point is improved.

Owner:江苏中英钢绳有限公司

Surface mount fuse based on low temperature co-fired ceramic technology and preparation method thereof

ActiveCN112266272BImprove Fusion PerformanceNo arc phenomenonFuse device manufactureMetal/alloy conductorsSurface mountingSlurry

The invention discloses a surface mount fuse based on low-temperature co-fired ceramic technology and a preparation method thereof; the preparation method comprises the following steps: sequentially preparing low-temperature co-fired ceramic powder, an organic carrier, low-temperature co-fired ceramic slurry, and a fuse electrode paste, terminal electrode paste, positive electrode layer, and back electrode layer, and then print low temperature co-fired ceramic paste, fuse electrode paste, and terminal electrode paste on the ceramic substrate in sequence, and then co-fire each printing paste layer. Burn to obtain the semi-finished surface mount fuse; then, make a glass protective layer and identification characters on the semi-finished surface mount fuse, and finally obtain the finished surface mount fuse through post-processing; the preparation method uses low-temperature co-fired ceramic technology to solve It solves the problem of diffusion and surface unevenness during printing of the fuse electrode paste, and makes the graph of the fuse more complete, clear and controllable; the fusing process of the prepared surface mount fuse is rapid, and there will be no phenomenon of arcing .

Owner:SEMITEL ELECTRONICS

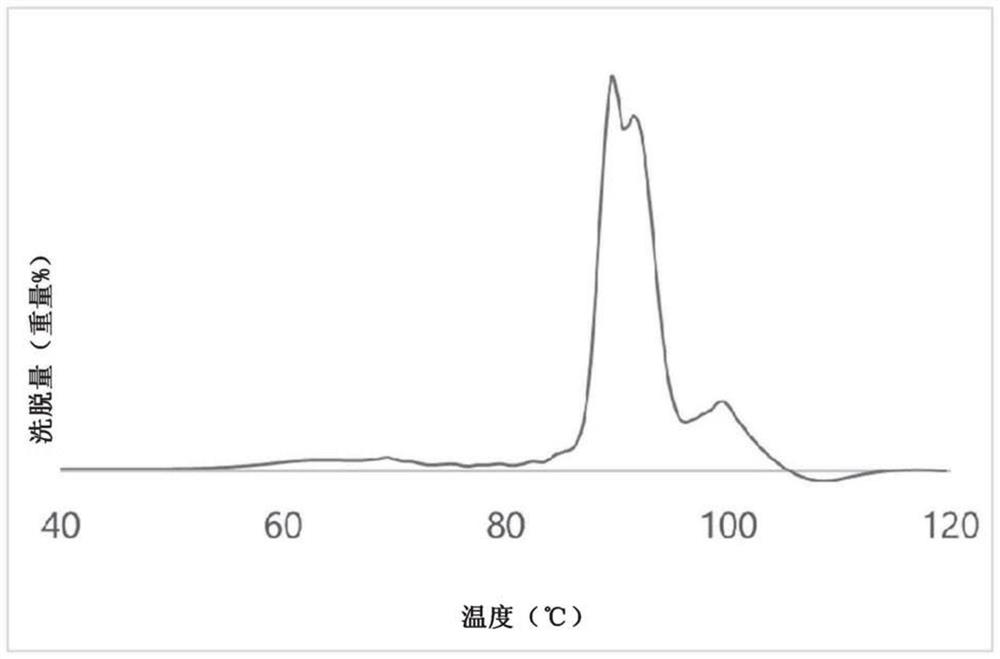

Polyethylene resin composition

PendingCN113045694AExcellent strength and fusing performanceShorten the timeCell component detailsPolymer chemistryAnalytical chemistry

The present invention obtains a polyethylene resin composition which, when processed into a separator for a battery, has excellent strength and fusing performance, can shorten the time from the beginning of fusing to the end of fusing, and has little film defects and film thickness unevenness. The polyethylene resin composition has Mw of 100,000 or more to 1000,000 or less and Mw / Mn of 2 or more to 18 or less. For a solution where an extracted component is obtained by carrying out temperature-rise dissociation fractionation on the polyethylene resin composition in accordance with prescribed conditions 'temperature-rise dissociation fractionation conditions for polyethylene resin compositions' and orthodichlorobenzene is used as a solvent, when cross-fractionation chromatography is performed in accordance with prescribed conditions 'CFC measurement condition for extraction component', the cumulative elution amount at 40 DEG C or more and less than 90 DEG C is 10 mass% or more and less than 70 mass% of the total elution amount, and the cumulative elution amount at 90 DEG C or more and 95 DEG C or less is 10 mass% or more of the total elution amount. And the temperature at which the maximum elution amount is reached is 88 or more or 100 DEG C or less.

Owner:ASAHI KASEI KOGYO KK

A welding process method for dissimilar metal parts

ActiveCN112296492BImprove mechanical propertiesImprove Fusion PerformanceArc welding apparatusWelding/soldering/cutting articlesCarbon steelWelding process

Owner:COMAC +1

A kind of temperature fuse resistor with accurate fuse for half short circuit

ActiveCN113053603BEvenly distributedFusing speed is fastCoil/loop resistive elementsMetal/alloy conductorsElectrical resistance and conductanceInsulation layer

The invention discloses a half-short-circuit and precise melting temperature insurance resistor, which belongs to the field of electrical components and relates to the technology of temperature insurance resistors. By changing the winding structure of the existing resistors, the alloy wires are evenly arranged when the ordinary resistors are wound. , this product uses the central winding process, and the alloy wire of the resistor is intensively wound at 30% of the center of the rod surface, so as to achieve the effect of localized heat generation of the resistor during operation and the effect of accelerating its fusing speed; by changing the current There is a coating layer structure, the coating layer is three layers, and the inner layer is a fuse layer. The fuse coating material containing low melting point metals (sinum, antimony) is used to greatly accelerate the fuse performance of the resistor. The second layer is the barrier temperature suppression layer, which uses a unique formula of temperature barrier material. This material plays a role of heat preservation, so that the temperature of the resistance alloy wire is isolated in the heat preservation layer when the resistance alloy wire is fused. The temperature of the resistance surface layer is lower than 400 ° C. The third layer Make the outer layer for common silicone resin material.

Owner:安徽省昌盛电子有限公司

Fuses for Electrical Machinery

InactiveCN104282512BEasy to disassembleImprove cooling effectEmergency protective devicesElectric machineryEngineering

The invention discloses a fuse for an electrical machine. The fuse comprises a left end cover, a right end cover, a shell and a fusion tube. The left end cover is mounted on the left side of the shell. The right end cover is mounted on the right side of the shell. A screw is arranged on the left end cover, the shell and the right end cover and penetrates through the left end cover, the shell and the right end cover in sequence. A cavity is formed among the left end cover, the shell and the right end cover. The fusion tube is mounted in the cavity. A fuse body is arranged in the fusion tube. The left end cover and the right end cover are both provided with binding posts. Each binding post is provided with ceramic insulation and cooling fins. The binding posts are both connected with the fusion tube. The left end cover and the right end cover are both provided with vent holes. Ceramic cooling sticks penetrating through the fusion tube are arranged in the vent holes. The left end cover, the shell and the right end cover are matched and fixed through the screw and a nut in sequence.

Owner:李亚林

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com