Miniature surface-adhered type fuse

A surface mount and fuse technology, applied in emergency protection devices, electrical components, circuits, etc., can solve the problems of high cost and complicated procedures, and achieve the effect of simplifying the production process and improving the fusing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

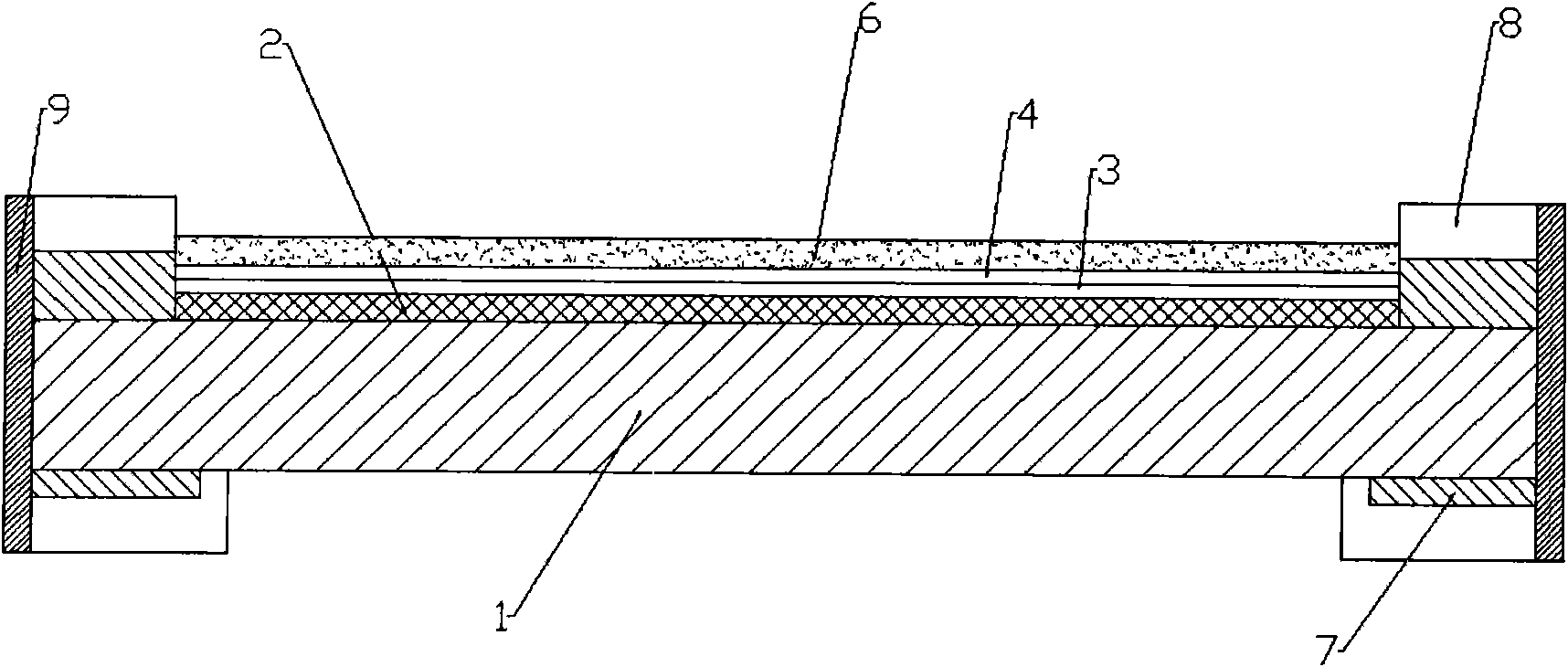

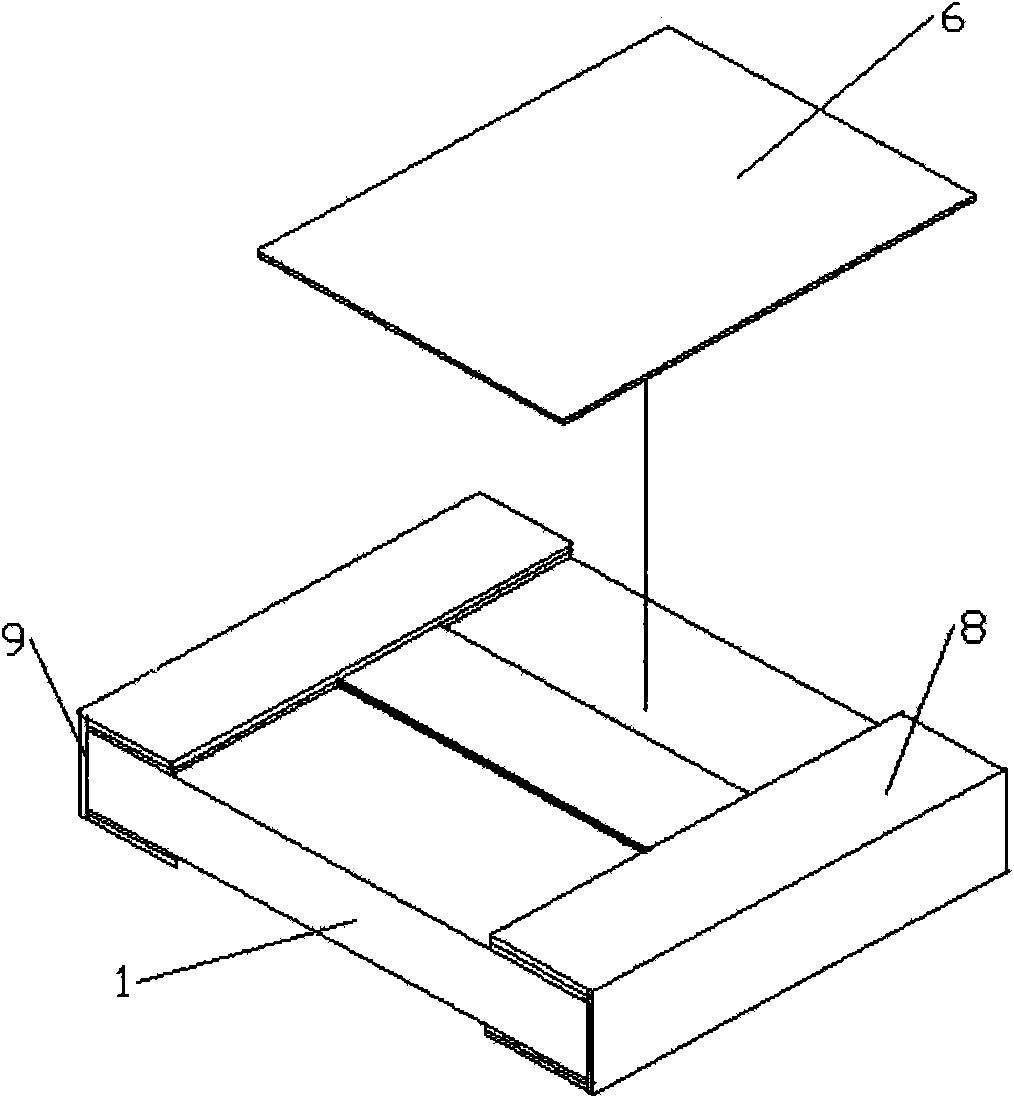

[0016] Such as figure 2 ,

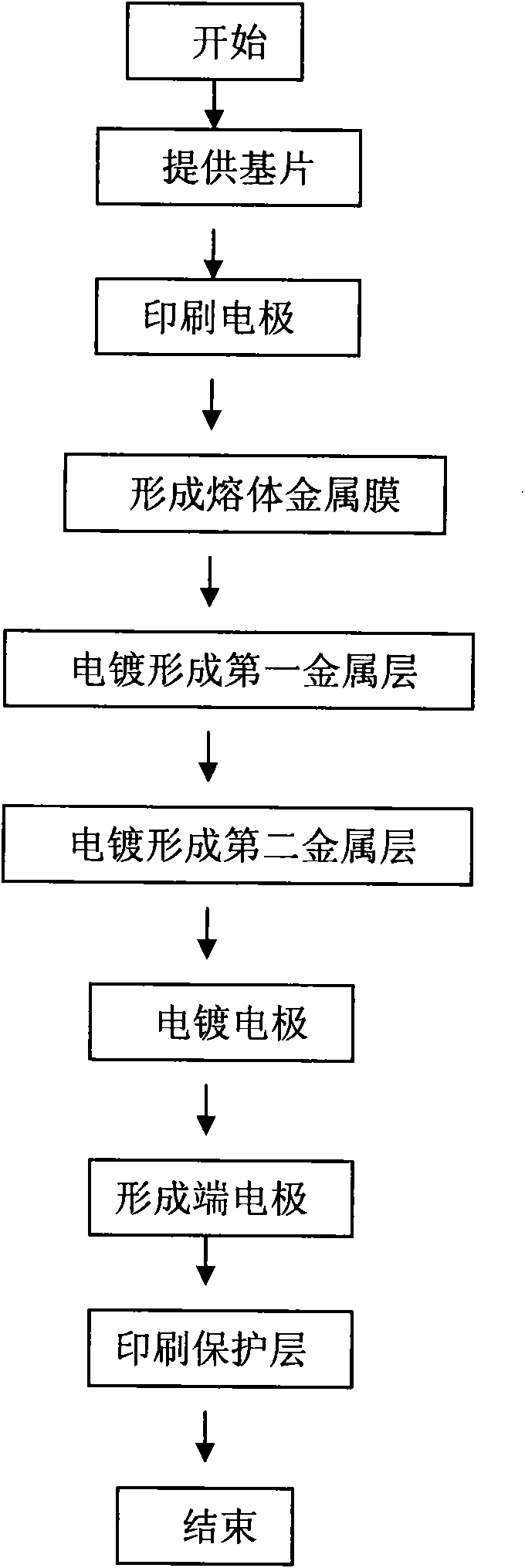

[0017] refer to figure 1 , figure 2 , the manufacturing method of the patent of the present invention comprises the following steps

[0018] Step 1: Provide an insulating substrate 1 made of Al 2 o 3 .

[0019] Step 2: screen-print a layer of thicker metal paste on the electrodes at both ends of the substrate 1, and the material is silver, copper or gold.

[0020] Step 3: According to the shape of the chip fuse melt, a layer of metal paste is printed on the substrate 1 by a screen printing method, and the material is silver, copper or gold. After high-temperature sintering, the melt metal film 2 and the electrode metal film 7 are formed, and the thickness of the melt metal film 2 is thinner than the electrode metal film 7; the sintering temperature is determined according to the composition of the slurry. The melt can be of any geometric shape.

[0021] Step 4: Coat the electrode part with a plating resist coating, and form a specific patt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com