Automatic fusing system for side of fishing net

A fusing and automatic technology, applied in textiles and papermaking, cutting of textile materials, etc., can solve the problems of high labor intensity, affecting the service life of fishing nets, and easy to spread at the incision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

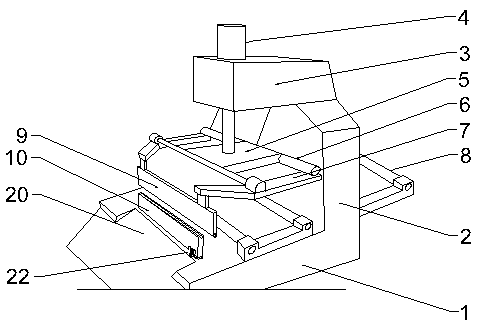

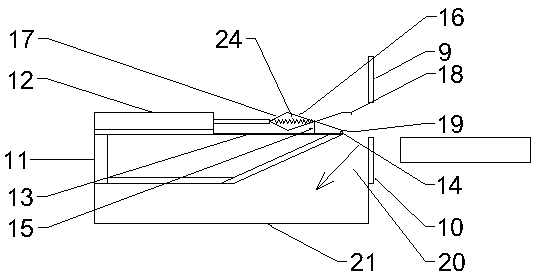

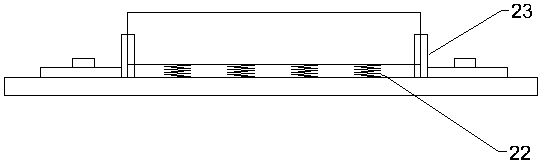

[0014] Below in conjunction with all accompanying drawings the present invention will be further described, and preferred embodiment of the present invention is: see appended figure 1 to attach image 3 , the automatic fusing system for fishing nets described in this embodiment includes a frame 1, one end of the frame 1 is provided with a conveyor belt 8, the other end of the frame 1 is provided with a bracket 2 on both sides, and the top of the bracket 2 is provided with a fixing plate 3, The lifting cylinder 4 is installed on the fixed plate 3, and the piston rod of the lifting cylinder 4 is connected with the fixed plate 5 downwards. Two parallel adjustment shafts 6 are installed on the fixed plate 5, and two cutter adjustment plates 7 are movable on the adjustment shaft 6. , a fuse blade 9 is installed at the bottom of the cutter adjustment plate 7, and a positioning knife seat 10 is provided on the frame 1 below the fuse blade 9, and the lower part of the fuse blade 9 shr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com