Polyethylene resin composition

A polyethylene resin and composition technology, applied in battery pack parts, electrical components, circuits, etc., can solve the problems of thermal shrinkage instability of microporous film thickness, and achieve excellent strength and fusing performance, film defects and film thickness. The effect of less unevenness and shorter time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0358] Hereinafter, the present embodiment will be described in more detail with reference to specific examples and comparative examples, but the present invention is not limited at all by the following examples and comparative examples.

[0359] [Measurement method and conditions]

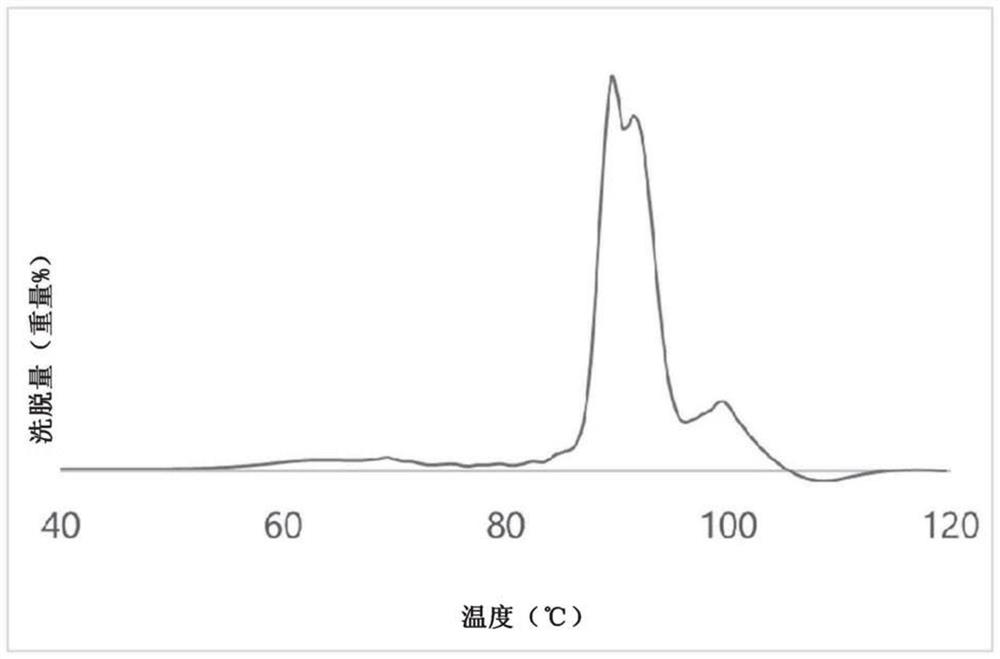

[0360] The physical properties of the polyethylene resin compositions of Examples and Comparative Examples were measured by the following methods.

[0361] (1) Molecular weight determination

[0362] The polyethylene resin composition and the extracted component obtained by (3) described later were used as a measurement sample, and 15 mL of o-dichlorobenzene was added to 20 mg of the measurement sample, and stirred at 150° C. for 1 hour, thereby preparing The sample solution was prepared and measured by gel permeation chromatography (GPC) under the following conditions.

[0363] From the measurement results, number average molecular weight (Mn), weight average molecular weight (Mw) and molecular...

manufacture example 1

[0464] (Production Example 1: Catalyst Synthesis Example 1: Preparation of Solid Catalyst Component [A])

[0465] (1) Synthesis of raw material (a-1)

[0466] 1 mol / L of Mg was charged into an 8 L stainless steel autoclave fully replaced with nitrogen 6 (C 4 h 9 ) 12 Al(C 2 h 5 ) 32000mL of hexane solution (equivalent to 2000mmol in terms of magnesium and aluminum), while stirring at 50°C, 146mL of 5.47mol / L hexane solution of n-butanol was added dropwise for 3 hours, and after the end, 300mL of hexane Alkane cleaning lines. Then, stirring was continued at 50°C for 2 hours. After completion of the reaction, it was cooled to normal temperature, and the obtained substance was used as a raw material (a-1). The raw material (a-1) was 0.704 mol / L in terms of magnesium concentration.

[0467] (2) Synthesis of raw material (a-2)

[0468] 1 mol / L of Mg was charged into an 8L stainless steel autoclave fully replaced with nitrogen 6 (C 4 h 9 ) 12 Al(C 2 h 5 ) 3 2000mL ...

manufacture example 2

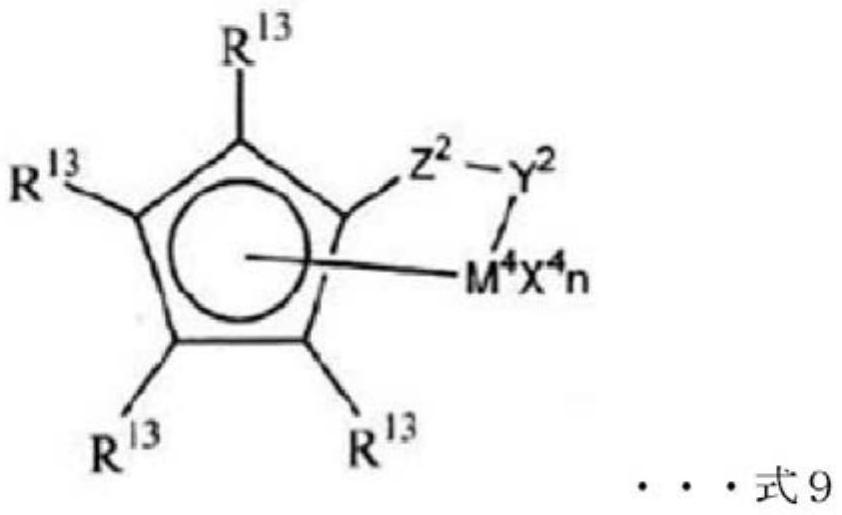

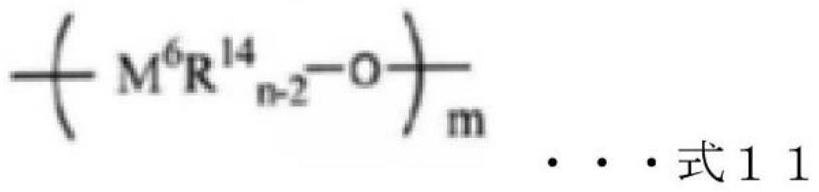

[0473] (Production Example 2: Catalyst Synthesis Example 2: Preparation of Supported Metallocene Catalyst Component [B])

[0474] (1) Synthesis of raw material [b-1]

[0475] The average particle size is 7μm, the specific surface area is 700m 2 / g and a particle inner pore volume of 1.9 mL / g were dehydrated by calcining at 500° C. for 5 hours in a nitrogen atmosphere.

[0476] Under a nitrogen atmosphere, 40 g of the dehydrated silica was dispersed in 800 mL of hexane in an autoclave with a capacity of 1.8 L to obtain a slurry.

[0477] While maintaining the resulting slurry at 20°C with stirring, 100 mL of a hexane solution of triethylaluminum (concentration: 1 mol / L) was added dropwise over 1 hour, followed by stirring at this temperature for 2 hours.

[0478] Then, unreacted triethylaluminum in the supernatant was removed by decantation of the obtained reaction mixture. In this manner, 800 mL of hexane slurry was obtained as the raw material [b-1] of the silica component...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average film thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com